UK Custom T Shirt Printing Near Me Guide

Share

So, you’re searching for “custom t shirt printing near me.” You want the convenience of a local printer, but you're not willing to sacrifice quality. The secret is knowing what you're actually looking for before you start.

If you’re planning a big event and need 50+ identical shirts, screen printing is almost always your most cost-effective bet. But if you’ve got a complex, multi-coloured design or just want a single, one-of-a-kind tee, then digital printing (often called DTG) is where it's at.

Understanding Your Local Printing Options

Before you dive into Google, let’s get clear on what your project actually needs. Are you kitting out a corporate team, organising a stag do, or just bringing a personal design to life? The right printer for one job is often the wrong choice for another.

The custom tee game in the UK is booming, especially with digital methods making it faster and easier to get incredible detail. While online design tools have made a huge splash, don't discount the local shops. Traditional offline printers still command a massive 51% revenue share, mostly because they’re the go-to for bulk orders from schools, sports clubs, and businesses. You can get a deeper dive into these trends from recent custom T-shirt printing market analysis.

Nail Down These Details First

Before you pick up the phone or send an email, get your own specs sorted. Thinking this through first will save you a ton of time.

- Quantity: How many shirts are you getting? One? A dozen? A hundred? This is the biggest factor that will steer you toward the right printing method.

- Design Complexity: Is it a simple, one-colour logo or a full-blown photographic print with loads of gradients? The more complex the design, the more likely you’ll need digital printing.

- T-shirt Material: What's the shirt made of? A 100% cotton tee takes ink differently than a polyester blend. Your printer will need to know this.

- Turnaround Time: When do you need them? Be honest. Many local printers can pull off a miracle and offer same-day service, but it’ll cost you.

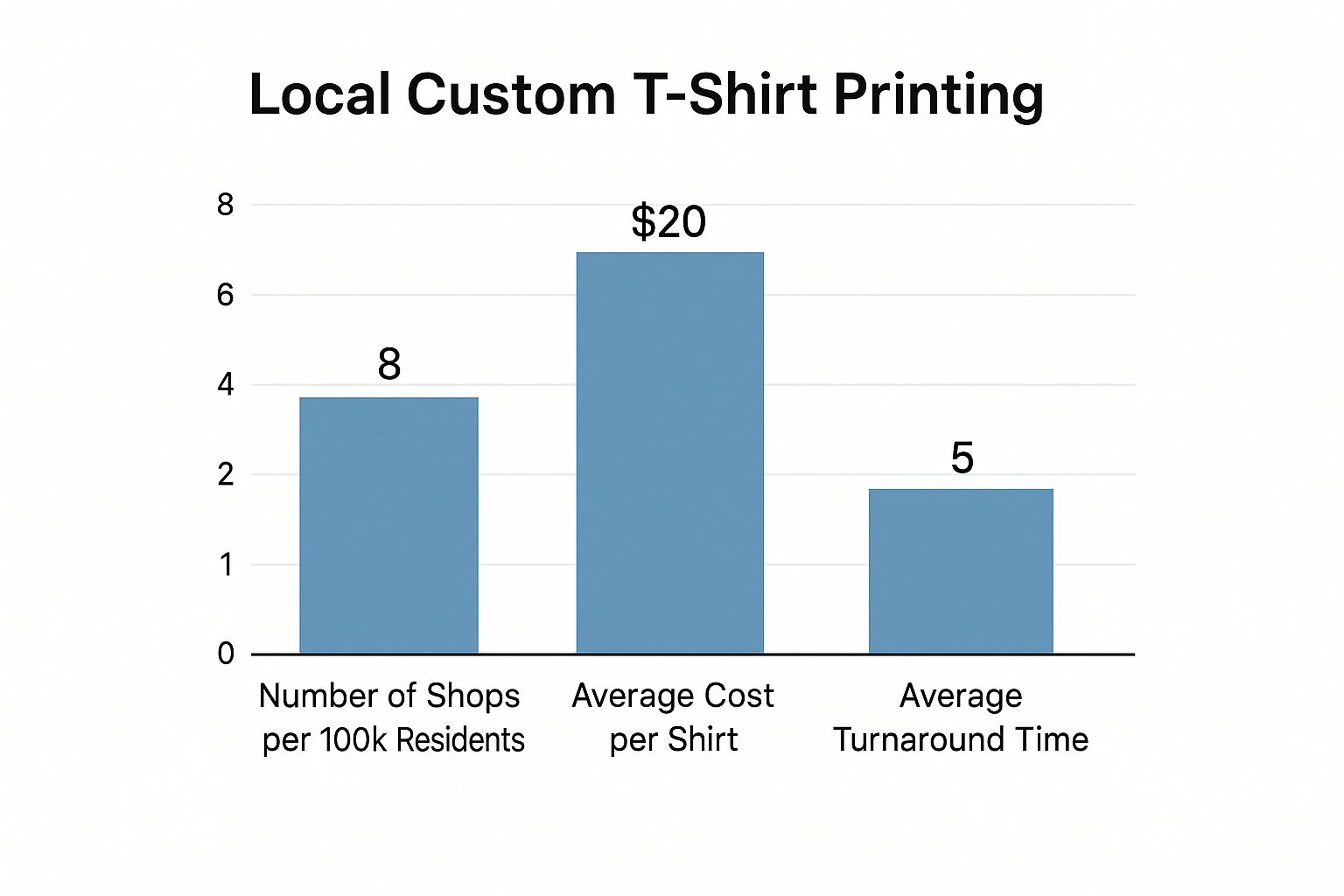

This chart breaks down some of the key things to keep in mind when looking for a local printer.

It really just comes down to balancing what you need against what's realistic in terms of cost and speed.

The "best" printer is a myth. The right printer is the one whose services perfectly match your quantity, design, and deadline. Get those three things clear in your head, and your search becomes ten times easier.

Choosing Your Printing Method at a Glance

Navigating the different printing techniques can feel a bit technical, but it’s actually pretty straightforward. Most local printers will specialise in one or two of these. Here’s a quick rundown to help you understand the lingo.

| Printing Method | Best For | Typical Cost | Minimum Order |

|---|---|---|---|

| Screen Printing | Simple designs (1-4 colours) in large batches (25+). | Low per shirt on big orders, but high setup cost. | Usually 20-25 shirts. |

| DTG (Direct-to-Garment) | Full-colour photos, complex graphics, and single orders. | Moderate per shirt, with no setup fee. | None. Perfect for one-offs. |

| Heat Transfer Vinyl (HTV) | Bold text, numbers, and simple logos (e.g., sports kits). | Varies by design complexity. | None, but can be slow for many shirts. |

| Embroidery | Professional logos on thicker garments like polos or hoodies. | Higher than printing, priced by stitch count. | Often 5-10 items. |

Ultimately, knowing whether you need 50 screen-printed tees for your band or just one highly detailed DTG shirt for a birthday gift is the key. Once you know what you need, you'll know who to call.

Finding and Shortlisting Local Printers

Starting your hunt with a "custom t shirt printing near me" Google search is the obvious first move, but the real gems are usually buried a little deeper. To build a solid shortlist, you need to cast a wider net before zeroing in. The goal is to find three to five local businesses that look promising.

Don't just stick to the main search results. Flip over to Google Maps and get a visual layout of printers in your area. Get specific with your search terms, like "DTG printing Manchester" or "screen printer for bands London." This approach often uncovers specialists who might not rank on page one for generic searches but are legends in their niche.

Expanding Your Search Tactics

Search engines are only part of the puzzle. Some of the best recommendations come from word-of-mouth, and the modern version of that lives in online communities.

- Local Business Directories: Sites like Yell or your local Chamber of Commerce are goldmines for established printers who might not have a slick social media game but have been doing great work for years.

- Community Facebook Groups: Jump into your town's "small business recommendations" group. Ask for genuine feedback on custom apparel printers—you'll get honest, unfiltered reviews from real people who've actually spent money with them.

- Niche Forums: Need shirts for a band, a gaming event, or another specific scene? Find the UK-based forums for that interest. The members there will have direct experience and won't hold back.

The process of tracking down and vetting a good local printer shares a lot of DNA with finding any skilled professional. In fact, many of the same strategies for finding a development partner apply just as well here.

Think of a printer's online presence as their digital shopfront. A strong portfolio, clear photos of their recent work, and visible, positive customer reviews are all massive green flags. It shows they're proud of their work and that they're a professional, reliable operation.

Once you've got a list, see how your local options measure up by checking out our deep-dive guide on the best https://psyque.co.uk/blogs/news/custom-t-shirt-printers.

How to Vet Your Shortlisted Printers

Alright, you've got a solid shortlist from your "custom t shirt printing near me" search. Now for the most important part: vetting. This is where you separate the pros from the pretenders. Looking at their website portfolio is one thing, but you need to dig deeper.

Your first contact with a printer says everything. Whether you call or email, pay close attention. Are they quick to respond? Do they sound like they actually care about your project? A great printer acts more like a partner, offering real advice to make your final tee even better than you imagined. A slow, generic reply is a major red flag.

Key Questions to Ask

Before you even think about placing an order, you need some straight answers. Their replies will tell you all you need to know about their capabilities, professionalism, and whether they're the right fit for your specific job.

- Can you provide a physical sample? This is non-negotiable. You have to see and feel their work in person. It’s the only way to judge the print quality, the accuracy of the colours, and the feel of the garment itself.

- What's your real turnaround time? Get a firm timeline for an order of your size and complexity. If they give you a vague "sometime next week," walk away.

- What are your exact file requirements? Get the specifics. Ask about file formats (AI, PNG, etc.), resolution (300 DPI is the industry standard), and colour mode. Nailing this from the start avoids frustrating production delays.

- Can I see your work in person? If they have a physical shop, ask to pop in. Seeing their equipment up close and checking the quality of other jobs they're running is a huge confidence booster.

This hands-on approach is crucial, especially now. The custom T-shirt game is blowing up globally, set to rocket from USD 4.67 billion in 2025 to a massive USD 11.37 billion by 2035. New printing tech and a hunger for unique gear are fuelling this fire.

A good printer will talk you through the tech. They’ll explain why screen printing is your best bet for a big run of simple logos, or why DTG is the only way to nail the insane detail in your artwork. Their expertise should be your guide.

Finally, do your own homework. Getting your head around the different methods for printing on t-shirts in the UK will arm you with the right knowledge to question their recommendations and make a choice you won't regret.

Preparing Your Design File for Flawless Printing

Even the most advanced printer on the planet can't salvage a badly prepped design file. Seriously. Getting your artwork print-ready is the single most important thing you can do to make sure your custom t-shirt looks professional, not like a blurry, amateur mess.

Nailing this also speeds up your order and helps you dodge those frustrating delays or extra setup fees that printers tack on for fixing your files.

First thing you need to get your head around is the difference between vector and raster images. Think of it this way: a raster image (like a JPEG or PNG) is made of tiny squares called pixels. When you try to make it bigger, it just stretches those squares out, leaving you with a blocky, pixelated disaster. This is probably the number one reason for disappointing prints.

A vector file (formats like AI, EPS, or SVG), on the other hand, is built with mathematical paths. You can scale it up to the size of a lorry without it losing a shred of quality. This makes vector the gold standard for most printing methods, especially screen printing.

Key Technical Specs

To avoid that painful back-and-forth email chain with your printer, get these technical details right from the start. They are the foundation of a quality print.

- Resolution: Always, always aim for 300 DPI (dots per inch) at the final size you want it printed. Anything lower will almost certainly look soft or blurry on the actual fabric.

- Colour Mode: Your screen shows colours in RGB (Red, Green, Blue). Printers don't. They use CMYK (Cyan, Magenta, Yellow, Black). You need to convert your files to CMYK to get a much more accurate idea of how the colours will actually look when printed.

- File Format: Just ask your printer what they prefer. It saves a lot of guesswork. Generally, a vector format like AI or EPS is king. If you absolutely have to use a raster image, a high-resolution PNG with a transparent background is your next best bet.

Here’s a pro tip from years of experience: simplify your design just a little for fabric. Those super-fine lines or tiny, intricate bits of text that look great on screen can easily get lost or bleed into the cotton. Bolder shapes and clearer text always translate better from your monitor to a shirt.

Getting into the technical side of things can feel a bit daunting, but it’s absolutely worth the effort. For a complete walkthrough of the whole shebang, check out this in-depth guide to custom t-shirt printing which breaks it all down.

Get the file right, and you guarantee the final product actually matches the vision in your head.

Placing Your Order and Nailing the Details

Alright, you’ve found your printer and your design file is ready to rock. Now for the final push: placing the order and locking in every last detail. This part is all about communication – getting it right means avoiding some seriously expensive mistakes down the line.

When you send that order, be ridiculously specific. Don't just ask for "10 medium blue shirts." Spell it out: give them the exact garment model number, the precise Pantone colour code, and a full breakdown of sizes and quantities. Crystal clear instructions stop the printer from guessing on your behalf.

Don't Skip the Digital Proof

Before a single drop of ink touches fabric, you need to demand a digital mock-up, or what the pros call a "proof." This is your sneak peek of how the design will look on the actual shirt, showing you everything from placement and scale to the colours. Whatever you do, never skip this step.

A digital proof is your last line of defence against disaster. Check it like your life depends on it—typos, weird colours, off-centre graphics. Once you approve a proof with a mistake, that mistake is officially yours, not the printer's.

Seriously, stare at that proof. Does the design look lost on an XXL shirt? Is the text perfectly centred? This is your final chance to tweak things before the presses start rolling.

Reading the Fine Print: Quotes and Timelines

Once you've given the proof the green light, you’ll get a final quote and a production timeline. Go through it line by line and hunt for any sneaky hidden costs. Keep an eye out for:

- Setup Charges: Pretty standard for screen printing, this covers the cost of making the screens.

- Artwork Fees: Some shops will charge you if they need to clean up or tweak your design file.

- Delivery Costs: Make sure this is included if you aren't picking the order up yourself.

The demand for custom gear in the UK is blowing up, partly thanks to government sports initiatives driving the need for team kits and event merch. Market reports are even predicting a massive 11.5% CAGR for the UK’s custom printing scene between 2025 and 2030. That means a healthy, competitive market for you. You can dive deeper into the numbers in this custom T-shirt printing market report.

Finally, get a firm completion date. Knowing the exact timeline helps you plan everything else, especially if you're up against a tight deadline. And if you're in a proper jam, it's worth seeing what's possible with next day delivery on custom t-shirts.

Got Questions About Local T-Shirt Printing?

Diving into custom apparel for the first time can throw up a few questions, especially when you're hunting for a solid local printer. Getting straight answers upfront saves you a headache later and makes sure the final product is exactly what you had in your head. Here are the no-nonsense answers to the questions we hear all the time.

How Much Does a Custom T-Shirt Cost in the UK?

This is always the first question, and the honest answer is: it depends. The price of a custom tee isn't fixed; it's a moving target based on a few key things.

For a single, one-off t-shirt using digital printing (like DTG or DTF), you’re typically looking at somewhere between £15 and £25. This is perfect for a unique gift, a prototype, or a personal design with tons of detail.

But if you're ordering in bulk for a band, event, or your business, screen printing is where you save big. For an order of 50+ shirts, the price per item drops hard, often landing in the £5 to £10 range. The final cost will always come down to the quality of the blank shirt, how many colours are in your design, and the total number you order. Always get a detailed quote that breaks everything down, including any setup fees and VAT.

Screen Printing vs DTG: What’s the Difference?

Knowing the two main printing methods helps you pick the right tool for the job. They both have their strengths.

-

Screen Printing: This is the old-school, tried-and-true method. It uses a stencil (a screen) to push ink onto the fabric, one colour at a time. The results are incredibly durable and it gets cheaper per shirt the more you print. It's the go-to for band merch, staff uniforms, and big corporate orders with simpler, bold graphics (think one-to-four colours).

-

Direct-to-Garment (DTG): Think of this as a massive, specialised inkjet printer that sprays ink directly onto the cotton. It can reproduce millions of colours, making it the undisputed champ for complex, photographic designs and smooth gradients. DTG is perfect for small orders or even single prints because there are zero setup costs per colour.

The easiest way to decide comes down to quantity and complexity. Got a simple logo for 100 shirts? Screen printing is your winner. Got a detailed, full-colour photo for just one tee? DTG is the only sensible choice.

Can I Supply My Own T-Shirts for Printing?

It’s a common ask, but the answer is usually no. While you might find a smaller independent printer who’s flexible, most established shops will insist on supplying the garments themselves.

And for good reason. Printers have spent ages testing their inks and machines on specific brands and fabric blends (like 100% ringspun cotton vs. a 50/50 poly-cotton). Using their own stock means they can guarantee the quality and durability of the print. If a customer brings in a random shirt, the printer has no idea how the ink will cure or if it will survive the first wash. It's always best to ask first before you go out and buy your own stock. While you're at it, you can even find some killer design inspiration, like these cheap Viking t-shirts that still look great.

What’s the Standard Turnaround Time?

Timelines can vary quite a bit, so patience is a virtue. A printer's current workload, the size of your order, and the print method all factor in.

For a small DTG order (1-10 items), a turnaround of 3-5 business days is pretty standard. For a bigger screen printing job, you should probably plan for 7-14 business days from the moment you sign off on the final design proof. If you have a hard deadline for an event, make that crystal clear right from the start.

At Psyque, we specialise in high-quality DTF printing to bring your most vibrant and detailed designs to life. Our expertise ensures your custom apparel is exactly as you imagined, with fast dispatch and dedicated customer support. Start creating your perfect custom t-shirt by visiting us at https://psyque.co.uk.