Printing on T Shirts UK A Complete Guide

Share

Getting a T-shirt printed in the UK should be simple. Yet, it's become a maze of acronyms like DTF, DTG, and screen printing, leaving you wondering what's best for your brand, event, or just that one-off design you've been dreaming up.

This guide is here to cut through the noise. We'll walk you through everything you actually need to know—from the core printing methods to figuring out costs, quality, and finding the right UK-based printer for the job.

Your Complete Guide to T-Shirt Printing UK

Welcome to your go-to resource for custom apparel in the United Kingdom. Whether you're a small business owner looking to create merch, an event organiser needing promotional gear, or just want a single unique tee, we’re here to demystify the entire process. A custom T-shirt is so much more than just clothing; it’s a walking billboard, a team uniform, and a personal statement all rolled into one.

And it’s a market that’s absolutely booming. The UK’s custom T-shirt printing scene pulled in around USD 200.1 million in 2023 alone. Projections show it’s set to more than double, hitting an estimated USD 419.6 million by 2030. That explosion tells you one thing: people want high-quality, personalised gear more than ever.

What This Guide Covers

Our mission is to arm you with the right knowledge so you can make smart decisions. We'll break down the three main printing technologies used today, explaining them in simple, practical terms.

By the time you're done here, you’ll understand:

- The core printing methods and which one is the right tool for your specific project.

- How costs are calculated based on how many you order, how complex your design is, and the printing technique used.

- What to expect for turnaround times from printers here in the UK.

- Insider tips for getting the best quality and making sure your design looks incredible and actually lasts.

Once your printing game is sorted, you can focus on the next step. Putting some effective social media sales strategies into practice can seriously boost revenue from your new custom apparel.

First things first, though. To give you a bird's-eye view, the table below offers a quick comparison of the main printing methods we’re about to dive into.

Think of this guide as your trusted partner in crime, helping you get from a rough idea to a professionally printed T-shirt with total confidence. We’re here to make the whole thing straightforward and successful.

Decoding the Main UK Printing Methods

Choosing how to get your design onto a t-shirt is a bit like picking the right tool for a job. You wouldn't paint a whole house with a tiny paintbrush, and you wouldn't use a massive roller for a miniature portrait. Each technique—Screen Printing, Direct-to-Garment (DTG), and Direct-to-Film (DTF)—has its own turf, its own process, and its own ideal outcome.

Getting your head around these core differences is the first step toward getting a final product you'll actually love. So, let’s break down the big three and ditch the jargon to see how they really work and which one is perfect for your project.

Screen Printing: The Stencil Powerhouse

Think of screen printing as a seriously refined stencilling process. A mesh screen is prepped with a stencil of your design, and then ink gets pushed through the open bits directly onto the t-shirt. Simple. But here's the catch: every single colour in your design needs its own separate screen, which is why the initial setup can be slow and pricey.

This method is the undisputed champ for big batch orders—we’re talking merchandise for a band, staff uniforms, or promo t-shirts for a massive event. Once those screens are made, printing becomes incredibly fast and efficient, meaning the cost per shirt plummets as the quantity goes up.

It’s no surprise that screen printing is the dominant force in the wider UK custom printing market, capturing a massive 54.13% of the market share. It just proves its value for anyone needing affordability and durability on a large scale.

- Best For: Big orders (think 25+ items) with simple, bold designs that don't have a million different colours.

- Fabric Compatibility: A real workhorse. It’s excellent on cotton, polyester, and all sorts of blends.

- Pros: Super cost-effective for bulk orders, prints are extremely durable, and the colours come out vibrant and punchy.

- Cons: A total waste of money for small runs or one-offs because of those high setup costs. It also struggles with photographic images or super-complex, multi-coloured designs.

Direct to Garment (DTG): The Fabric Inkjet Printer

Direct-to-Garment, or DTG, works pretty much like the inkjet printer in your home office, but it's built for fabric. The t-shirt is loaded into the machine, and the printer's head sprays water-based inks straight onto the garment, where they soak right into the fibres. No screens, minimal setup. This makes it the go-to for highly detailed or photorealistic designs.

Got a complex image with countless colours, smooth gradients, and tiny details? DTG is your answer. It's perfect for printing just one t-shirt or a small batch because the cost per item stays the same whether you order one or twenty.

Key Insight: The real magic of DTG is its knack for detail. It perfectly captures the nuance of a photograph or intricate artwork without the colour limits you get with screen printing. The final print also has a very soft feel, since the ink becomes part of the fabric itself.

The main drawback? DTG is a bit of a fabric snob. It performs best on 100% cotton garments because the water-based inks are designed to bond with natural fibres. While you can print on some cotton blends, you might find the colours aren't as vibrant and the print won't last as long on fabrics with a high polyester count.

Direct to Film (DTF): The Modern Hybrid

Direct-to-Film (DTF) is the innovative newcomer that cherry-picks the best bits from other methods. The process is straightforward: your design is printed onto a special film, a powdered adhesive is applied to the back, and then the whole thing is heat-pressed onto the t-shirt. Instead of soaking in, the ink sits on top of the fabric as a tough, flexible layer.

You can think of DTF as creating a high-quality, modern-day iron-on transfer that feels way better and lasts much, much longer. This technique gives you the same full-colour, detailed printing as DTG, but without being picky about fabrics. DTF sticks beautifully to cotton, polyester, nylon, and even tricky materials like leather.

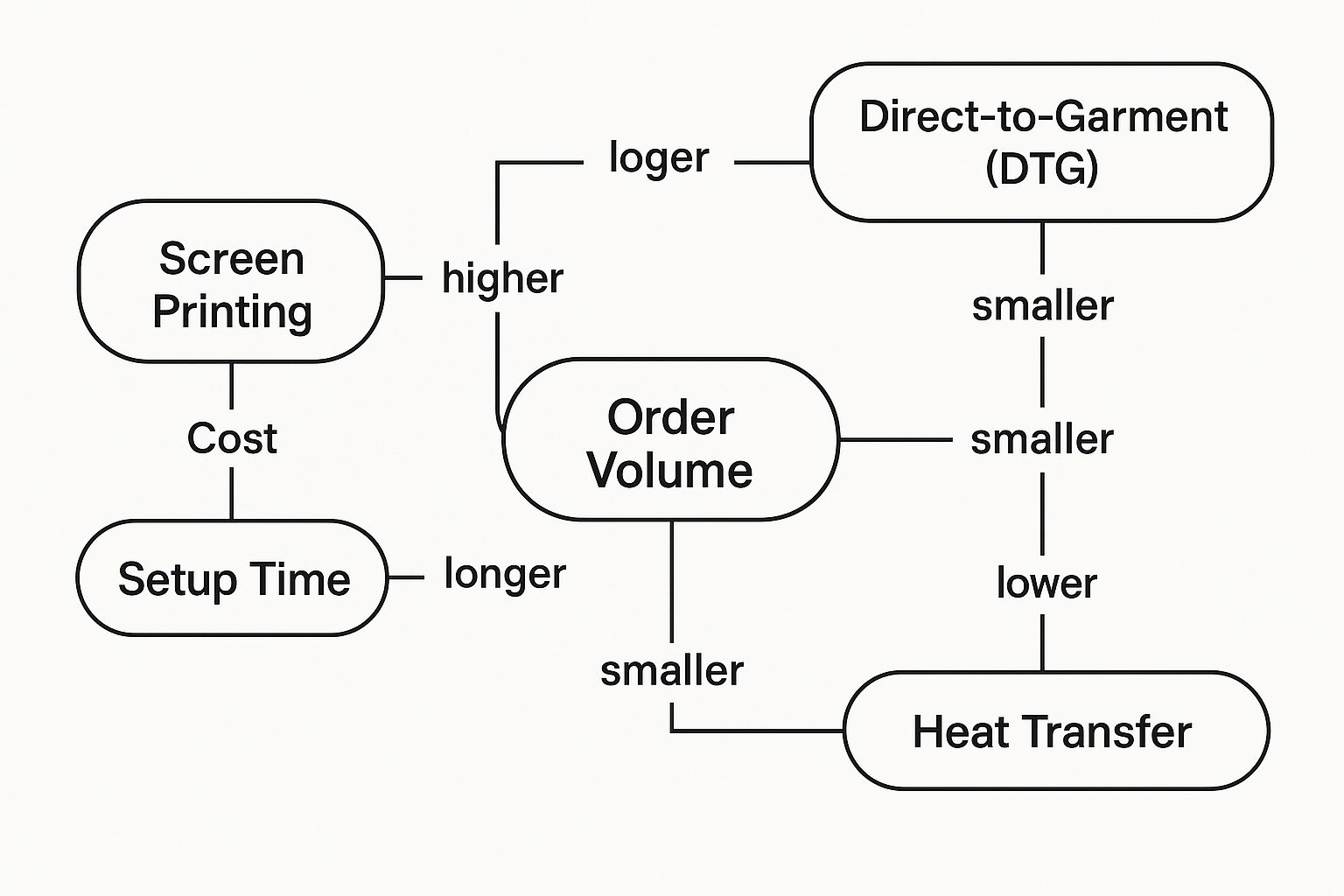

This graphic helps map out where each method shines when it comes to cost and order size.

As you can see, screen printing is the king of high-volume, low-cost production. Meanwhile, digital methods like DTG and DTF give you the freedom to handle smaller, more detailed orders without breaking the bank.

- Best For: Small to medium-sized orders, full-colour designs, and printing on pretty much any fabric you can throw at it.

- Fabric Compatibility: Insanely versatile. It works on cotton, polyester, blends, spandex, and more, in any colour.

- Pros: Incredible colour vibrancy and detail, works on almost any fabric, and the prints are durable and stretchy.

- Cons: The print has a slightly more noticeable feel on the shirt compared to the super-soft finish of DTG.

Each method has its strengths, and your final choice usually boils down to your design, your order quantity, and your fabric. For a head-to-head comparison, check out our guide on DTF vs screen printing for graphic tees. And if you really want to get into the weeds, this guide on DTF vs DTG Printing: A Guide to Custom Apparel is a great deep dive.

Costs, Timelines, and How Many Shirts You Actually Need

Alright, let's talk money and time. Getting your head around the cost and delivery schedule is just as crucial as nailing the design. The final bill and when your box of tees arrives will boil down to three things: the print method you choose, the size of your order, and how complex your artwork is. Getting this balance right is the secret to getting a great deal when printing on T-shirts in the UK.

Every print method has a totally different cost structure, which is why one isn't just "cheaper" than another. It's about picking the right tool for the job.

This is the bit that trips people up—the constant tug-of-war between price, speed, and volume. Master this, and you'll get exactly what you want without breaking the bank.

How the Costs Break Down

Screen printing is a game of scale. The biggest cost is all upfront in the setup. For every single colour in your design, a unique screen has to be made. That means a simple one-colour graphic needs one screen, but a design with five colours needs five separate screens. That setup fee adds up fast.

This is why ordering just a few screen-printed tees will make your wallet cry. But once those screens are made? The cost to print each extra shirt is tiny. This is why screen printing gets ridiculously cheap per shirt on big orders. It's the undisputed king for band merch, event staff uniforms, or any time you need 25 or more identical shirts.

DTG and DTF, on the other hand, are much more straightforward. Think of them like your desktop printer—there are no screens to make and almost zero setup costs. The price is pretty much based on the ink used and the time it takes the machine to print your one-off garment.

This makes them the perfect choice for:

- One-off custom prints for a birthday gift or your own wardrobe.

- Small batches for a new brand testing the waters with a fresh design.

- Designs with loads of colours and detail, which would cost a fortune in screen setup fees.

What to Expect for UK Turnaround Times

How long it takes to get your tees in hand is tied directly to the print method and your order size. A UK printer’s schedule is all about the setup time versus the actual printing speed.

For instance, getting a big screen printing job ready can take hours, but once the machine is rolling, it can churn out shirts incredibly quickly. In contrast, a single DTG print might be done and dusted in just a few minutes.

Key Takeaway: Don't get fixated on just the cost per shirt; look at the total project cost. A £15 DTG shirt for a one-off is a bargain. But paying £15 per shirt for a 100-piece screen print order? You're being taken for a ride.

A standard turnaround for most custom printing on t shirts uk jobs is somewhere between 5 to 10 working days. This isn't set in stone, though. A massive, complex screen printing order will naturally take longer because of the prep work involved. Plus, you have to consider the print shop's current queue. It’s always smart to order well ahead of any hard deadline.

A Practical Cost and Time Comparison

To really see how this works in the real world, let’s map it out. The table below gives you a rough idea of costs and delivery times for different order sizes. These are ballpark figures for the UK market, and every printer is different, but it’s a solid starting point for your budget.

Estimated Cost and Turnaround by Order Size

Here’s a comparative look at how cost-per-shirt and production time stack up between screen printing, DTG, and DTF for typical UK order volumes.

| Order Quantity | Screen Printing (Est. Cost/Shirt) | DTG (Est. Cost/Shirt) | DTF (Est. Cost/Shirt) | Typical UK Turnaround |

|---|---|---|---|---|

| 1-5 Shirts | Not Cost-Effective | £15 - £25 | £14 - £22 | 3-7 Working Days |

| 25 Shirts | £7 - £12 | £12 - £18 | £10 - £16 | 5-10 Working Days |

| 100+ Shirts | £4 - £8 | £10 - £15 | £8 - £13 | 7-14 Working Days |

As you can see, if you just need one shirt, DTG or DTF is the only way to go. But the second you hit that 25-shirt mark, screen printing storms ahead as the most budget-friendly option, with the price per shirt dropping dramatically. Understanding this from the start is how you plan your project without getting hit with any nasty surprises.

Right, let's get into the nitty-gritty. A killer design is one thing, but getting it onto a T-shirt so it looks sharp and actually lasts is a whole different battle. The final quality of your tee comes down to a three-way partnership: your artwork, the shirt you pick, and the print method itself. Nail these three, and you've got a piece of kit that looks pro and won't die in the wash.

https://www.youtube.com/embed/mHyJNlXDVvo

We're not just talking about how it looks fresh out of the box. We're talking about how it looks and feels after ten spins in the machine. That’s what separates memorable merch from a one-wear wonder. When it comes to printing on T shirts UK, durability is king.

Feel and Vibrancy: What's the Difference?

Every print method leaves its own signature on the fabric. We call this the "hand feel"—it's literally how the print feels under your fingertips, and it makes a huge difference to how people rate the quality.

Screen printing, for example, lays down a thick, solid layer of plastisol ink that sits right on top of the fabric. This gives it a slightly raised, almost rubbery feel that’s incredibly tough. It's why the colours are so punchy and opaque, especially on dark tees.

DTG, on the other hand, is the total opposite. It feels like almost nothing at all because the water-based inks soak right into the cotton fibres. You get a super-soft, breathable finish, but sometimes the colours can look a little less intense than a screen print, particularly on coloured garments. DTF printing slots neatly in the middle, giving you a smooth, flexible transfer that sits on the fabric with brilliant colour vibrancy and a modern feel.

Prep Your Artwork Like a Pro

Your printer is only as good as the file you send them. Chuck them a low-res, pixelated image, and you’re guaranteed to get a blurry, amateur-looking print back. If you want sharp, clean results, you have to get your artwork right from the start.

Pay attention to these three things:

- File Type: Vector files (AI, EPS, SVG) are the absolute gold standard. They're built with maths, not pixels, so you can scale them up to the size of a bus without losing a shred of quality. If you have to use a pixel-based image, make it a PNG with a transparent background.

- Resolution: For any pixel-based file, 300 DPI (dots per inch) at the final print size is the bare minimum. Anything less is going to look blocky and just plain bad.

- Colour Mode: Your monitor shows colours in RGB (Red, Green, Blue). Printers use CMYK (Cyan, Magenta, Yellow, Key/Black). Always design in or convert your files to CMYK. This ensures the colours you see on screen are as close as possible to what comes out on the shirt.

Seriously, sending your printer a high-resolution, print-ready file is the single most important thing you can do to guarantee a top-quality result. It kills the guesswork and makes sure your design looks exactly how you pictured it.

Why the T-Shirt Itself Is Half the Battle

Think of the T-shirt as the canvas. You wouldn't paint a masterpiece on a flimsy piece of paper, right? The fabric composition and weight make a massive difference to the final look, feel, and lifespan of your print.

For instance, DTG printing absolutely loves 100% ringspun cotton. The natural fibres are perfect for soaking up the water-based inks, giving you a vibrant print that feels incredibly soft. Try printing DTG on a 50/50 poly-cotton blend, and you’ll often get a faded, "vintage" vibe because the ink just doesn't bond properly with the synthetic polyester.

Screen printing and DTF are way more forgiving and work well on cotton, polyester, and blends. But the garment's weight, measured in GSM (Grams per Square Metre), also matters. A heavier shirt, around 180-200 GSM, feels more premium and gives a solid surface for printing. A cheap, lightweight tee around 140 GSM might not last as long and could compromise the print's durability.

Ultimately, getting a personalised T-shirt printed is a team effort between your design, the fabric, and the ink. Don't neglect the canvas.

Finding the Right UK T-Shirt Printing Service

Alright, you know the methods, you’ve got a handle on the costs, and you know what separates a killer print from a forgettable one. Now for the final mission: finding the perfect UK-based partner to bring your designs to life.

Choosing a service for printing on t shirts uk isn’t just about hunting down the cheapest quote. It’s about finding a reliable printer who actually gets your vision and can deliver a product you’re proud to put your name on.

The UK is packed with options, from massive online print factories to small, independent shops down the road. They all offer a different vibe and experience, so knowing what to look for is everything.

What to Look For on a Printer's Website

A printer’s website is their digital shopfront. It should give you confidence right away. Before you even think about firing off an email, do a quick quality check for a few tell-tale signs of a professional and reliable setup.

A strong portfolio is non-negotiable. Look for crisp, high-quality photos of their actual work. Do they show off different styles and printing techniques? This is your first clue about their skills and the quality you can expect.

Next, look for transparent pricing. Even if you need a custom quote, a good printer will have clear guidelines on how they figure out costs, including any setup fees or discounts for bigger orders. Hidden fees are a massive red flag. Finally, hunt for real customer reviews on their site, Google, or Trustpilot to see what actual clients are saying.

Key Questions to Ask Any Potential Printer

Once you’ve got a shortlist, it’s time to ask some direct questions. How they answer will tell you a ton about their process and how they treat their customers. Don't be afraid to dig a little—it can save you a world of pain later.

Kick things off with these essentials:

- Can I see or order a sample? A good printer will be happy to sort you out with a sample, even if it costs a few quid. Holding the real thing is the only way to truly judge the print quality and the feel of the garment.

- What’s your proofing process? Ask if they send a digital mock-up (a "proof") for you to approve before the main print run starts. This step is critical for catching mistakes before it’s too late.

- What's your policy on reprints or errors? If something goes wrong—a misprint, the wrong colours—how do they fix it? A decent company will have a clear plan for making things right.

- What are your exact artwork requirements? Get the specifics on file types, resolutions, and colour modes they need. Giving them the right files is half the battle.

Don't underestimate the power of clear communication. A printer who replies quickly, is genuinely helpful, and is transparent from the get-go is probably a solid partner. Slow, vague replies are often a sign of chaos to come.

Think about the demand for custom team gear. It's a huge driver in the UK market. Government-backed sports schemes, like the Rugby Football Union's 'Impact 25' program supported by over £12 million, are all about getting more people involved. That means more teams needing kits and merch. Finding a printer who can handle that kind of specific demand is crucial. You can learn more about the growth drivers in the custom t-shirt market if you want to go deeper.

Local Print Shops vs. Large Online Platforms

Your final choice might boil down to a big-name online service versus a local, independent print shop. The huge platforms often have competitive prices and slick ordering systems, which is great for simple, straightforward jobs.

But a local UK business can offer a much more personal touch. You can often talk directly to the person who’ll be printing your shirts, hash out the details, and build a proper relationship. Plus, supporting local means you’re investing back into your own community. Exploring the services offered by different custom t-shirt printers will help you find the perfect match for your project.

Right then, you’ve got the basics down on printing methods, costs, and quality. But there are always a few nagging questions that pop up right before you’re ready to hit ‘go’ on an order.

Let’s clear the air and tackle the most common queries we get about printing on T-shirts UK. This is the stuff that helps you go from confused to confident.

What’s the Cheapest Way to Print T-Shirts in the UK?

There’s no single "cheapest" way—it all comes down to how many tees you’re ordering. Think of it as a trade-off between the initial setup cost and the price you pay for each individual shirt.

For bigger batches, say 25 T-shirts or more, screen printing is almost always your best bet for your wallet. Sure, the setup is a bit pricier because a custom screen has to be made for every colour in your design. But once that’s done, pumping out more shirts is incredibly cheap, and the price per tee plummets as you add more.

On the flip side, if you just need one or a tiny handful (fewer than 10), then Direct-to-Garment (DTG) or Direct-to-Film (DTF) is the way to go. These are digital methods with basically zero setup fees, making them perfect for testing a design, grabbing a one-off gift, or making samples without a huge cash investment.

How Long Will My Printed T-Shirt Actually Last?

The lifespan of your print is a team effort between the printing tech and how you treat the garment. Any professionally made print should hold up to plenty of washes, but some methods are just naturally tougher than others.

A high-quality screen print is the undisputed king of durability. That thick layer of plastisol ink creates an incredible bond with the fabric. Honestly, it will probably outlive the T-shirt itself and can last for years without cracking or fading.

DTG prints, where the ink soaks right into the cotton fibres, also hold up really well if you look after them. The golden rules? Always wash inside out on a cool cycle (30°C) and never, ever put it in the tumble dryer. DTF transfers are also seriously resilient and flexible, which means they resist cracking even as the shirt stretches.

Can I Print on Any Type of T-Shirt?

This is a massive one. The short answer is no, you can’t just use any print method on any old tee. The fabric is the canvas, and each technique has its favourite material to work with. Get this wrong, and you’re in for a bad time.

Here’s the simple breakdown:

- DTG Printing: This method is a die-hard fan of 100% cotton. Its water-based inks are designed to fuse with natural fibres, giving you that soft-hand feel and punchy colour. Try it on polyester, and you’ll end up with a faded, weak-looking print that won’t last.

- Screen Printing: This one’s way more versatile. Screen printing works a treat on cotton, polyester, and all sorts of poly-cotton blends. The inks are tough enough to stick to pretty much anything you throw at them.

- DTF Printing: This is the most adaptable of the bunch. DTF transfers stick beautifully to almost any fabric you can think of—cotton, polyester, nylon, and even tricky materials that other methods can’t handle.

Matching your fabric to your print method isn't just a suggestion; it's essential for getting a print that looks incredible and is built to last.

Ready to bring your unique designs to life with vibrant, durable prints? At Psyque - DTF Print & Press, we specialise in high-quality DTF printing perfect for any fabric. Explore our collections or get in touch for your custom project at https://psyque.co.uk.