Direct Printing to Garment A Practical Guide

Share

Picture your office printer. Now, imagine swapping out the paper for a t-shirt and hitting 'print'. That's the core idea behind direct-to-garment printing. It’s a game-changing method that uses specialised inkjet tech to shoot water-based inks directly onto fabric, making it possible—and affordable—to print single, super-detailed designs.

Understanding the Magic Behind DTG Printing

Often just called DTG, this process works a lot like the printer on your desk, but it’s built for textiles. You lay a garment—a hoodie, a tote bag, whatever you've got—onto a flatbed called a platen. The printer then passes over the fabric, jetting microscopic droplets of ink that soak right into the fibres.

It's a completely digital workflow. You send a file straight from a computer to the printer, which then perfectly reproduces your design with a full spectrum of colours. This completely sidesteps the messy, time-consuming screen setup needed for traditional methods like screen printing. It’s the perfect weapon for creating photorealistic images, complex details, and smooth colour gradients that used to be a nightmare to get right on clothing.

For a quick overview, here's everything you need to know about DTG in a nutshell.

DTG Printing at a Glance

| Aspect | Description |

|---|---|

| Technology | Specialised inkjet printer that applies water-based inks directly onto fabric. |

| Best For | Full-colour photos, detailed graphics, gradients, and small to medium-sized orders. |

| Fabrics | Works best on 100% cotton but can also be used on high-cotton blends. |

| Feel | The ink soaks into the fibres, resulting in a soft, breathable print. |

| Key Advantage | No minimum order quantity, making it ideal for one-off prints and testing designs. |

This table shows why DTG has become such a go-to for so many creators and businesses needing flexibility and high-quality results without the commitment of a large print run.

How It Shook Up the Custom Apparel World

Before DTG came along, getting a single custom t-shirt made was a pain. It was either wildly expensive or simply not possible. Old-school methods needed a separate setup for every single colour, which made small batches a total waste of money. DTG smashed those barriers.

Here’s how it changed the game:

- No Minimum Orders: You can print just one item without getting hit with huge setup fees. This is a lifesaver for testing new designs, making personalised gifts, or launching a clothing line without buying hundreds of shirts upfront.

- Unlimited Colour Palette: Screen printing adds costs for every new colour. With DTG, you can reproduce millions of shades in one go, at no extra charge. This gives you total creative freedom for complex, vibrant artwork.

- Soft-Hand Feel: Because the water-based ink is absorbed by the fabric instead of sitting on top of it, the finished print feels soft and breathable. It literally becomes part of the garment.

At its core, direct-to-garment printing is about access. It gives creators the power to bring an idea to life by tearing down the financial and technical walls that used to stand in the way.

The Basic Workflow

The whole operation isn't just about the printer. A proper DTG setup also needs a pre-treatment machine to prep the garment and a heat press to cure the ink afterwards. That final step is crucial—the heat press permanently bonds the ink to the fabric fibres, making sure your design is tough enough to survive the wash.

This trio of prep, printing, and curing is what delivers a professional-grade product that’s ready to wear straight off the press.

From File to Fabric: How a DTG Print is Made

Ever wondered how a digital design jumps from your computer screen onto a t-shirt? It’s a slick, multi-step workflow that blends digital precision with good old-fashioned textile chemistry. Forget the messy, manual setups of older methods; this is a streamlined journey from pixel to product.

Let's walk a single t-shirt through the entire process, from the moment the file is opened to the final, ready-to-wear garment. It all boils down to three key phases: getting the design right, prepping the fabric, and then the main event—printing and curing.

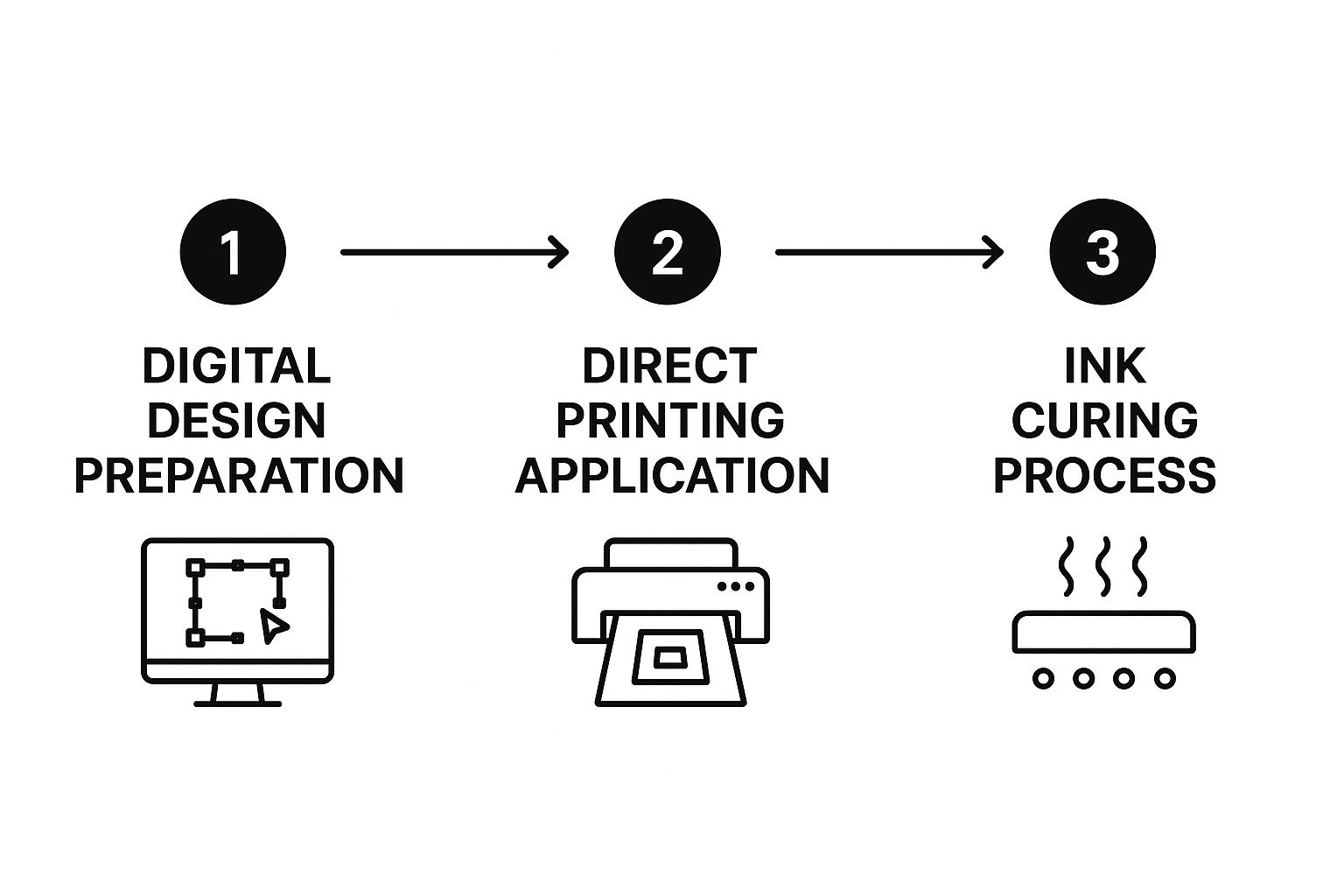

This is the clean, linear flow of the whole operation.

As you can see, each step builds on the last. Screw up one, and the final print will pay the price.

Step 1: Artwork Preparation

It all starts with your design file. The quality of this single file determines the quality of the final print. No pressure, right? The gold standard for DTG is a high-resolution PNG file, set at 300 DPI (dots per inch). This ensures your graphic is sharp and clean, not a pixelated mess when it’s printed.

Why a PNG? Two words: transparent background. This format lets your design float on the shirt without an ugly white or coloured box around it. The printer only lays down ink where your graphic is, leaving the garment’s own colour to do the rest.

It’s a classic case of garbage in, garbage out. A low-res, poorly prepped file will always produce a blurry, disappointing print. Even the most advanced DTG printer can’t fix a bad source file.

Step 2: Garment Pre-Treatment

Before a single drop of ink hits the fabric, the shirt itself needs to be prepped. We do this with a pre-treatment solution—a clear, water-based liquid that’s sprayed evenly over the print area. After a quick trip to the heat press to dry, it's ready to go. This step is absolutely non-negotiable, especially for dark-coloured clothing.

Think of it like using a primer before you paint a wall. This invisible layer stops the water-based DTG inks from just soaking into the fabric and looking dull. Instead, the ink sits right on top, creating the vibrant colours and sharp details you’re after.

On dark garments, the pre-treatment is even more critical. It acts as the perfect bonding agent for the white underbase ink, making sure your colours pop instead of looking faded and washed out.

Step 3: Printing and Curing

With the shirt pre-treated and locked onto the printer's platen, the magic happens. The digital file is zapped over to the DTG printer, which acts a lot like a massive, high-spec inkjet printer. Its print heads glide across the fabric, jetting microscopic droplets of specialised textile ink with incredible precision.

If we're printing on a dark garment, the machine first lays down a solid layer of white ink. This is called the underbase, and it creates an opaque canvas so the colours on top look bright and true to the original design. After that, the CMYK (cyan, magenta, yellow, and black) inks are applied over the top to bring the full-colour graphic to life.

The final, and arguably most important, stage is curing. The freshly printed shirt is moved to a commercial heat press, which clamps down with consistent heat and pressure. We’re typically talking around 160°C for 90 seconds. This process permanently bonds the ink to the fabric fibres, making the design durable enough to survive the washing machine.

This technology has become a massive area of focus in the UK, with industry giants like Epson and Brother constantly pushing for faster print speeds and more sustainable inks. It's this progress that allows everyone from small businesses on Etsy to larger operations on Shopify to offer lightning-fast, on-demand printing that keeps up with trends. To get a better sense of where things are headed, you can learn more about the evolving DTG market in the UK and its shift towards super-responsive supply chains.

Choosing the Right Fabrics for DTG Printing

The garment you choose is the canvas for your art, and not all canvases are created equal when it comes to direct-to-garment printing. The fabric you pick has a huge impact on how vibrant your print looks, how it feels, and how long it lasts. Nail this, and you're halfway to a professional-looking product.

Think of DTG's water-based inks like watercolours. If you splash them on a thick, absorbent paper, the colours sink in and look rich. Try painting on a glossy piece of plastic, and the water just beads up and wipes right off. Fabric works in a surprisingly similar way.

The Gold Standard: Natural Fibres

For DTG, natural fibres are king, and 100% ringspun cotton sits on the throne. Its absorbent fibres are the perfect match for water-based DTG inks. They basically act like a sponge, soaking up the ink and letting it bond directly with the material.

This is exactly why DTG prints on good cotton feel so soft and breathable. The design becomes part of the shirt, not just a stiff layer sitting on top. While any cotton will do in a pinch, ringspun cotton is a level up. Its smoother, tighter knit gives you a superior surface for razor-sharp details and colours that pop.

Other killer natural fibre options include:

- Combed and Ringspun Cotton: An even softer, more durable version of the classic.

- Bamboo: Known for its silky feel and moisture-wicking properties, it takes DTG ink beautifully.

- Hemp: A durable, eco-friendly option that gives prints a slightly more rustic, textured vibe.

Navigating Cotton Blends

So, what about poly-cotton blends or those popular tri-blends? You can still print on them, but the results will be different. A standard 50/50 cotton/polyester blend, for example, will give you a more faded, 'vintage' look.

This happens because the ink can only bond with the cotton. The polyester fibres essentially repel the water-based ink, meaning only half the material is getting properly dyed. While this can be a cool look for certain designs, it's important to know what you're getting into. The print won’t be as bold or solid as one on 100% cotton.

The rule is simple: the higher the cotton content, the brighter your DTG print will be. As you add synthetic fibres like polyester, the print will naturally look more muted and Heathered.

Fabrics to Avoid for DTG Printing

Knowing what works is crucial, but knowing what doesn't work can save you a ton of headaches and money. Some materials are completely incompatible with the DTG process and will give you a disappointing print that vanishes in the wash.

The number one enemy is 100% polyester. Its synthetic, non-absorbent fibres give the water-based inks nothing to grab onto. The ink will just sit on the surface, look blotchy, and fail to cure. Most of it will wash away after the first rinse.

Other fabrics to steer clear of include:

- Nylon

- Rayon (unless it's in a blend with a very high cotton percentage)

- Any fabric with a waterproof or moisture-wicking coating

For anyone getting into apparel decoration, understanding fabric is fundamental. To see how different materials are handled across various methods, you can learn more about the versatile options for custom t-shirt printing and find the perfect match for your project. Choosing the right garment isn't just a suggestion; it's a non-negotiable for a print that lasts.

Weighing the Pros and Cons of DTG

So, you're thinking about printing a t-shirt. Simple, right? Not so fast. The method you choose is a huge deal, and direct printing to garment (DTG) comes with its own set of killer strengths and noticeable weaknesses. Getting your head around this balance is the key to figuring out if it’s the right weapon for your project.

DTG isn’t a magic bullet for every single job, but when it’s the right fit, the results are undeniable. Let’s cut through the noise and look at both sides of the coin.

The Upsides of Direct to Garment Printing

One of the biggest wins for DTG is the insane level of detail and colour it can handle. Think of it like a high-end inkjet printer, but for fabric. It can reproduce millions of colours, smooth gradients, and subtle photographic tones with pinpoint accuracy. This throws the door wide open for complex, artistic designs that would be a nightmare—or just flat-out impossible—with other methods.

But the good stuff doesn't stop there:

- No Minimum Order: This is probably the biggest game-changer. You can print a single, one-off tee just as easily as you can print fifty. This completely removes the financial risk of ordering in bulk, making it perfect for testing new designs, creating personalised gifts, or launching a clothing brand without a mountain of upfront investment.

- Soft-Hand Feel: Nobody wants to wear a thick, plastic-feeling print. With DTG, the water-based inks soak directly into the garment’s fibres instead of sitting on top like a heavy layer. The result? A print that’s soft, breathable, and feels like it’s part of the shirt itself. It’s a massive plus for comfort and a premium feel.

- A More Eco-Friendly Fight: In a world drowning in waste, DTG is a more sustainable choice. It uses non-toxic, water-based inks and creates way less waste than old-school methods. Plus, the print-on-demand model it fuels is a direct attack on overproduction, one of the biggest problems in the fashion industry.

At its core, the power of DTG is its flexibility. It smashes the old barriers of high setup costs and minimum orders, putting the power to create custom apparel into anyone's hands.

The Downsides of Direct to Garment Printing

Of course, no tech is perfect, and DTG has some real limitations you need to know about. The most obvious one is its speed when it comes to big orders. It’s brilliant for small batches, but the time it takes to print each garment one by one makes it pretty inefficient for runs of hundreds or thousands of the same design.

The cost structure is also a different beast. The per-shirt price is great for small runs, but it doesn't drop off a cliff as the quantity goes up, unlike screen printing. For massive orders, the old-school methods often win on pure economies of scale. If you're weighing up options for bulk apparel, this deep dive into DTF vs screen printing for graphic tees breaks down exactly how those costs stack up.

Key Limitations to Keep in Mind

Beyond speed and cost, there are a couple of other things to be aware of before you dive in.

Fabric Compatibility

DTG is a bit of a diva when it comes to fabrics. It performs best on natural fibres, with 100% cotton being its happy place. The water-based inks are made to bond with these materials. You can get away with high-cotton blends, but performance on 100% synthetic fabrics like polyester is just plain bad. You'll end up with a faded, blotchy mess that won't last.

Colour Matching Precision

While DTG can produce a huge spectrum of colours, nailing an exact Pantone match can sometimes be tricky. The final look of the ink can be subtly affected by the colour and texture of the t-shirt itself, which is something to think about if you're a brand with super strict colour rules.

To make it even clearer, here’s a head-to-head breakdown.

DTG Printing Pros Versus Cons

This table cuts straight to the chase, comparing the main advantages and disadvantages of using direct printing to garment technology.

| Advantages of DTG | Disadvantages of DTG |

|---|---|

| Unlimited colour palette and photorealistic detail. | Slower production speed for large bulk orders. |

| No minimum order quantity, perfect for one-offs. | Higher per-item cost for very large quantities. |

| Soft, breathable feel as ink bonds with fabric. | Limited to cotton and high-cotton blend fabrics. |

| More sustainable with less water and waste. | Exact Pantone colour matching can be challenging. |

Ultimately, whether you should use direct printing to garment comes down to what you’re trying to do. For intricate, full-colour designs on small-to-medium orders, its edge in quality, flexibility, and sustainability is tough to beat. But if you’re cranking out a simple, high-volume job on different types of fabric, you might find other methods are a better fit for the fight.

The Rise of On-Demand Apparel in the UK Market

The tech behind direct printing to garment is impressive, sure, but its real power is in the business models it’s kicked down the door for. This isn't just about printing a t-shirt; it's the engine driving a massive shift in the UK’s entire apparel industry. It’s fuelling the explosive growth of e-commerce, print-on-demand (POD) services, and a culture that craves one-of-a-kind gear.

This whole shift couldn’t have come at a better time. Shoppers, especially younger ones, are tired of mass-produced fashion. They want stuff that screams them – whether that’s a t-shirt with a super-niche pop culture reference or merchandise from their favourite indie YouTuber. DTG makes meeting that demand not just possible, but ridiculously profitable.

And this isn't just a hunch; the numbers are telling the same story. The UK's direct to garment printing market was valued at around USD 130.8 million and is on track to hit USD 274 million by 2030. That's a growth rate of about 13.6% a year. This boom is tied directly to the thirst for custom gear from online stores and personalised fashion brands. If you want to dig deeper, you can explore more data on this market expansion and see why this tech is such a big deal for modern businesses.

A New Era for Entrepreneurs

Honestly, the biggest impact of DTG is how it’s completely democratised the fashion world. Not long ago, launching a clothing line meant sinking a ton of cash upfront. You had to guess which designs would sell, order hundreds of units in different sizes, and pray you weren't left with a garage full of unsold stock. That kind of financial risk was a massive wall for small creators.

Direct printing to garment flips that whole script. By teaming up with a print-on-demand provider, anyone can launch an entire clothing brand with zero inventory.

- No Upfront Costs: A product only gets printed after a customer has already paid for it. No more bulk buying.

- Unlimited Creativity: You can upload hundreds of designs to your online shop and see what sticks with your audience, all without spending a penny.

- Minimal Risk: If a design bombs? No big deal. Just take it down. There's no dead stock and no wasted money.

This zero-inventory model means anyone with a solid idea—artists, influencers, musicians, small businesses—can jump into the apparel game on a totally level playing field.

Redefining the Supply Chain

This technology also completely rewires the old-school retail supply chain. Forget the long, slow slog of manufacturing overseas, shipping containers, and warehousing. The on-demand model is fast, lean, and local.

The rise of print-on-demand, powered by direct printing to garment, represents a fundamental move from a "make then sell" model to a "sell then make" model. This change drastically reduces waste and increases agility.

And that agility is a massive advantage. Brands can now react to trends in real-time, dropping topical or meme-inspired designs within hours of them going viral. It transforms clothing from a static product into a dynamic, living medium for cultural expression. All of this is made possible by the sheer efficiency and flexibility of DTG technology.

Why DTG Is a More Sustainable Choice

Let's be honest, in a world where everyone's looking at the label, how your gear gets made matters. A lot. It's not just about killer designs and soft cotton anymore; customers want to know you're not wrecking the planet to print a t-shirt. This is where direct-to-garment printing doesn't just compete—it wins.

Its eco-friendly edge isn't some minor footnote; it’s baked right into the technology. DTG tackles waste and pollution from multiple angles, starting with the very ink that brings your designs to life.

Water Conservation and Reduced Pollution

Traditional textile printing is a notoriously dirty business. Seriously. It’s responsible for a staggering 17–20% of all industrial water pollution globally. Think about that. Old-school methods guzzle insane amounts of water for dyeing fabrics and washing out screens, spewing chemical-heavy gunk into our waterways. If you want to go down that rabbit hole, you can explore the full impact of textile manufacturing on water resources and see just how bad it gets.

Direct-to-garment printing flips the script entirely. It’s pretty much a waterless process.

- Water-Based Inks: DTG printers use non-toxic, water-based pigment inks. These are way kinder to the environment than the plastisol or solvent-based inks you'll find in most screen printing setups, meaning fewer harmful chemicals are involved.

- No Screen Washouts: Since the whole process is digital, there are no screens. No screens means no need for the massive water-intensive cleaning process and none of the chemical solvents used to strip off old ink.

This massive drop in water use and chemical waste makes DTG a much cleaner, smarter choice for making apparel. It’s perfectly in sync with the growing demand from both customers and regulators for greener manufacturing.

The Power of Printing on Demand

Okay, here’s the biggest environmental game-changer: DTG completely obliterates overproduction. The old fashion model is built on a "make-it-all-and-hope-it-sells" gamble. This leads to mountains of unsold clothes getting dumped in landfills. It’s a disaster.

Direct-to-garment printing enables a much more intelligent approach.

By running a "print-what-sells" model, DTG directly attacks the overproduction crisis. A t-shirt is only printed after a customer has actually ordered it. This cuts inventory waste down to almost nothing.

This on-demand system means no more guessing games with stock. No more warehouses packed with last season’s designs that nobody wants. Every single item is produced with a purpose and an owner, which is a huge move towards a more responsible way of doing things.

For any modern, eco-aware brand, this isn't just a nice little feature—it’s a core part of their identity. This is what makes direct-to-garment printing the responsible choice for the future of conscious apparel.

Common Questions About DTG Printing

Jumping into the world of custom tees can feel like navigating a minefield of jargon. When it comes to direct-to-garment printing, a few key questions always seem to pop up. Getting straight answers is the only way to figure out if it’s the right move for your project.

Let's cut through the noise. This section tackles the big questions about durability, cost, and what you can actually print on.

How Durable Are DTG Prints Compared to Screen Prints?

This is the big one. The short answer? Modern DTG prints are tough as nails. When you care for them properly, they’ll often last as long as the t-shirt itself.

It’s all down to the science. The water-based inks actually soak into the fabric fibres instead of just sitting on top like a plastic sticker. This means you don’t get that cracking and peeling you see on older, thicker prints. For the best results, wash your DTG gear inside out on a cool cycle and skip the tumble dryer. While a solid screen print is also built to last, a well-made DTG print gives you similar longevity with a much softer, more breathable feel.

Is DTG Printing Expensive for a Single T-Shirt?

Nope. In fact, for a one-off t-shirt or a small batch, DTG is the most wallet-friendly method out there. Why? Because it has basically zero setup costs.

Screen printing demands a separate, costly screen for every single colour in your design. That process takes time and money. With DTG, the printer just fires up and prints all the colours at once, straight from a digital file. This makes it a no-brainer for testing out a design, creating a personalised gift, or sampling a product without having to order hundreds. Just remember, once you get into huge bulk orders of the same design, screen printing usually wins on price per shirt.

DTG's real superpower is making small-batch printing affordable. It demolishes the financial barrier, opening up custom apparel for individuals and small brands who don't need a warehouse full of stock.

Can You Print on Dark Garments with DTG?

Yes, and this is where DTG technology really shines. Printing on dark apparel isn't just possible; it's one of its most impressive tricks. The secret is a layer of white ink called an underbase.

Before your design is printed, the machine lays down a solid foundation of white ink that acts like a primer on the dark fabric. The colour inks are then printed right on top of this bright white layer. This guarantees your design pops with vibrant, true-to-life colours instead of getting swallowed by the dark material. It’s this underbase that makes stunning, full-colour graphics on a black or navy blue tee possible. If you're weighing up your options, seeing what different custom t-shirt printers can do is a great next step.

At Psyque, we specialise in dragging your most chaotic designs into reality with our advanced DTF printing. Check out our collections and start your own custom apparel raid today at https://psyque.co.uk.