A Guide to Custom DTF Transfers

Share

Think of custom DTF transfers as the modern answer to garment decoration—almost like a high-tech, permanent sticker for your clothes. The technology prints your vibrant, full-colour design onto a special film. This film is then coated with a powdered adhesive and heat-pressed directly onto fabric, creating a seamless, durable print that feels like part of the garment itself.

The Modern Solution for Custom Apparel

Direct-to-Film (DTF) technology has quickly become a favourite in the UK’s custom apparel scene, offering a seriously powerful alternative to older printing methods. Its main draw? Incredible versatility. Unlike other techniques that are notoriously picky about materials, custom DTF transfers can be applied to almost anything.

This flexibility has been a game-changer for everyone from small businesses to large-scale print shops, allowing them to create stunning designs without the complex setup traditionally required. The process is refreshingly straightforward, efficient, and delivers professional-looking results every single time.

Fabric Freedom and Colour Brilliance

One of the standout features of DTF is its ability to work flawlessly across a massive range of fabrics. We’re talking about:

- Natural Fibres: 100% cotton, linen, and canvas.

- Synthetic Materials: Polyester, nylon, and even fleece.

- Blended Fabrics: Popular cotton/polyester mixes and tri-blends.

- Speciality Items: It can even handle tricky surfaces like treated leather or denim.

This adaptability opens up a whole world of creative possibilities. You can brand everything from team uniforms and corporate workwear to fashion-forward streetwear and personalised gifts, all using the same reliable method. What’s more, DTF truly excels at producing brilliant, opaque prints on dark garments—something that often poses a challenge for other technologies.

DTF printing essentially removes the creative barriers imposed by fabric type. It allows your design to be the focus, ensuring it looks just as vibrant on a black polyester jacket as it does on a white cotton t-shirt.

A Growing Force in the UK Print Industry

The rise of DTF isn’t just a passing trend; it’s a significant shift in the market, driven by the massive demand for personalised products. The global DTF market was valued at an impressive USD 2.72 billion in 2024 and is set to grow substantially. The UK, with its robust textile sector, is a key player in this expansion as more and more businesses adopt DTF for its cost-effectiveness and on-demand capabilities. You can read the full research about the DTF printing market growth from Grand View Research.

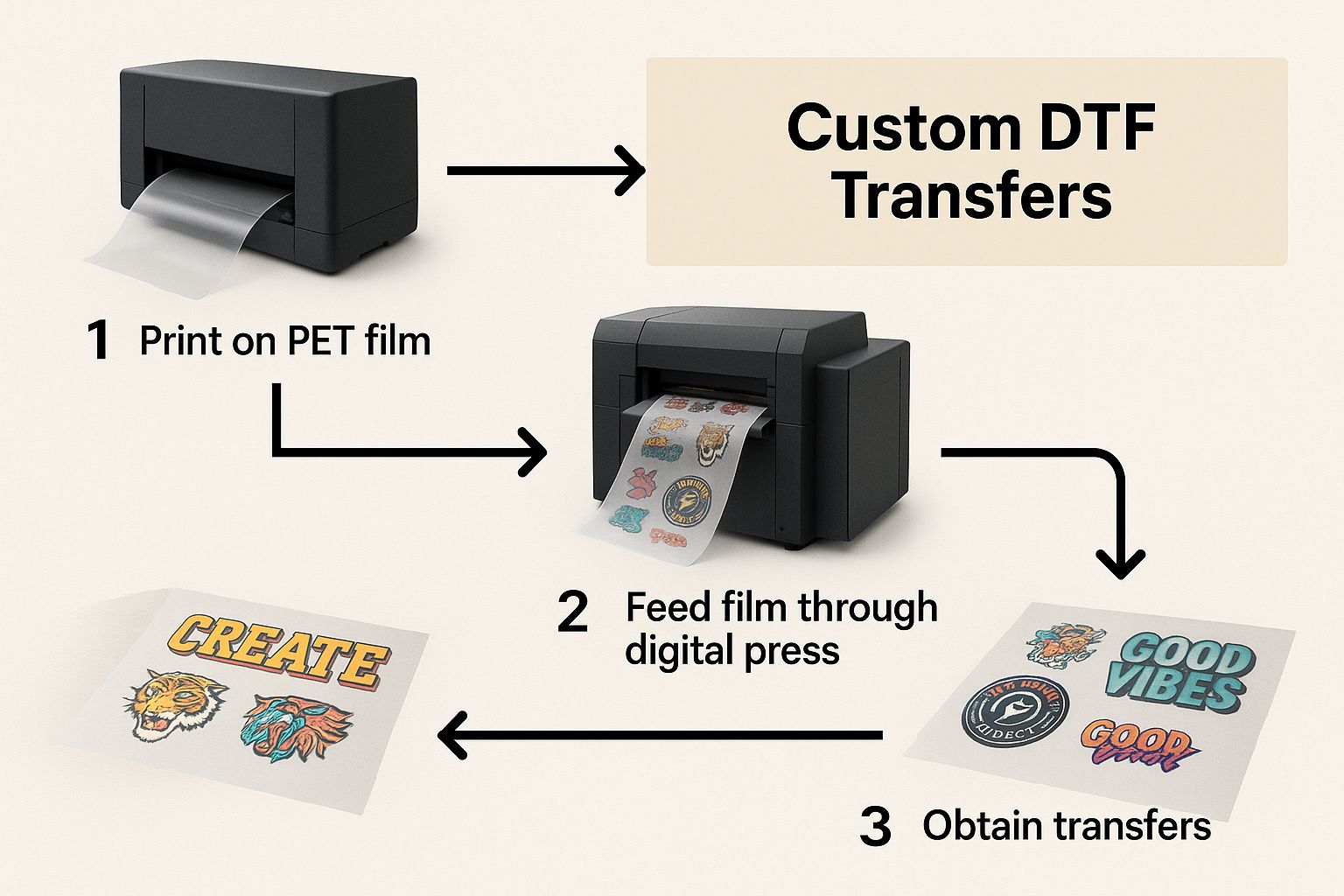

The visual below shows the first step in creating these versatile transfers, where a digital press feeds the special PET film.

This image captures the beginning of a process that brilliantly combines digital precision with practical application, making high-quality customisation accessible to everyone.

The DTF Transfer Creation Process Step-by-Step

Ever wondered how a digital design becomes a vibrant, wearable piece of art? It might seem like magic, but the journey of a custom DTF transfer is a surprisingly logical and finely-tuned process. Each step builds on the last, all working together to create a durable, professional finish.

Let's pull back the curtain and walk through exactly how your idea travels from a file on a screen to a finished print, ready to wear. Seeing how it all works is the best way to understand why DTF is so reliable and produces such incredible results time after time.

Stage One: Artwork Preparation

It all starts with your design. To get a flawless print, the artwork needs to be spot-on from the beginning. Honestly, this first step is probably the most critical for getting that crisp, clean look you’re after.

The main thing we need is a high-resolution digital file. We always recommend a PNG file with a transparent background, set to a resolution of 300 DPI (dots per inch). This setup is crucial—it means we only print your design, not an ugly background box, and it keeps every edge sharp and clear, with no pixelation in sight.

Stage Two: Printing onto PET Film

Once your artwork is good to go, it’s sent over to a specialised DTF printer. This isn’t your average office machine; it’s built for one specific, very clever job. Instead of printing on paper or fabric, it prints your design onto a special carrier material called PET (polyethylene terephthalate) film.

The magic here happens in two layers:

- The Colour Layer: First, the printer lays down all the colours of your design using Cyan, Magenta, Yellow, and Black inks. The image is printed in reverse, like a mirror image of the final product.

- The White Underbase: Right after the colour goes down, a layer of brilliant white ink is printed directly over it. This white base is the secret weapon. It acts like a primer, making sure your colours pop with full opacity, even on dark or brightly coloured fabrics.

This two-layer approach is why DTF transfers look so stunningly vibrant on any garment, no matter the colour.

Stage Three: The Adhesive Powder Application

With the design freshly printed and the ink still wet, it’s time for the ingredient that makes it all stick. The film moves through a station where it’s coated in a fine, sugar-like adhesive powder made of thermoplastic polyurethane (TPU).

This clever powder only clings to the wet ink of the design, and any excess is simply shaken off. It’s a bit like dusting a cake with icing sugar—it only sticks where you want it. This ensures that only the printed areas become sticky, keeping the rest of the film clean.

This adhesive powder is the key bonding agent. When it gets hot, it melts and transforms into a powerful, flexible glue that locks your design permanently into the fabric's fibres.

Next, the powdered film is passed through a curing oven. The heat melts the powder into a smooth, even adhesive layer that covers the back of your design. At this point, the transfer is fully prepped and ready for the main event.

Stage Four: Heat Press Application

The final step is bringing it all together: applying the cured transfer to your garment with a heat press. This stage is all about precision—the right combination of heat, time, and pressure creates that perfect, long-lasting bond. Much like the printing itself, applying DTF transfers requires specific settings; for similar processes, you can find guides on heat press settings for sublimation.

First, the garment is pre-pressed for a few seconds. This gets rid of any moisture or wrinkles and creates a perfectly flat surface. The DTF transfer is then carefully placed on the fabric. The heat press is brought down, applying a specific temperature (usually between 150-165°C) and firm pressure for about 10-15 seconds.

Once the time is up, the film is peeled away, leaving just your beautiful design permanently bonded to the material. Depending on the film, this might be a "hot peel" (done immediately) or a "cold peel" (after it’s cooled down). And just like that, you’ve created amazing custom apparel! To see how this stacks up against other methods, have a look at our breakdown of different approaches to t-shirt printing personalised for your needs.

How DTF Transfers Stack Up Against Other Methods

Choosing the right way to print your designs can feel like a minefield, with every method claiming it's the best. To cut through the noise, it helps to see how custom DTF transfers actually perform against the big names in garment decoration. It’s not about finding one superior method, but about figuring out which one is the perfect match for your specific project.

Let's do a real-world, head-to-head comparison between DTF and its main rivals: Direct-to-Garment (DTG), screen printing, and heat transfer vinyl (HTV). This isn't just about technical specs; it’s about what those differences mean for your creative ideas, your budget, and the final look and feel of your apparel.

DTF vs Direct to Garment (DTG)

At first glance, DTF and DTG look like two peas in a pod. Both are digital, making them brilliant for detailed, full-colour designs. The key difference is how they get the ink onto the shirt. Think of DTG as an inkjet printer for fabric—it prints straight onto the t-shirt. DTF, on the other hand, prints onto a special film first, which is then heat-pressed onto the garment.

That tiny difference in process leads to some major advantages for DTF, especially when it comes to what you can print on. DTG is notoriously picky, working best on 100% cotton and needing a messy pre-treatment spray, especially for dark-coloured clothing. DTF completely bypasses this headache. It sticks beautifully to cotton, polyester, nylon, fleece, and all sorts of blends, with absolutely no pre-treatment required.

DTF gives you a level of fabric freedom that DTG just can't touch. You can use the exact same vibrant, detailed transfer across a whole product line—from cotton tees to polyester tracksuits—keeping your brand's look consistent.

Financially, DTF is also a much more approachable option for UK businesses just starting out. A quick look at the startup costs makes it clear. A decent DTG setup can set you back anywhere from £13,500 to £36,500. In contrast, you can get started with a DTF system for between £4,500 and £19,500. When you add in much faster production times—just a few seconds per transfer compared to several minutes for a single DTG print—DTF becomes a seriously attractive choice for small to medium-sized brands.

DTF vs Screen Printing

Screen printing is the old-school heavyweight of the industry. It's famous for its durability and being incredibly cheap on massive print runs. The process involves pushing ink through a mesh screen, one colour at a time. And that's where its limitations start to show.

Screen printing is a nightmare for small orders or designs with lots of colours. Every single colour needs its own screen, which means high setup costs and long lead times before you even print the first shirt. Custom DTF transfers are fully digital, so there are zero colour limits and zero setup fees. This makes them perfect for one-off samples, small batches, or web-store orders.

When it comes to fine detail, DTF is the clear winner. It can handle photographic prints, subtle colour gradients, and tiny lines with razor-sharp clarity. Screen printing can produce great results, but it often struggles with the complex shading and intricate details that DTF handles without breaking a sweat. If your work involves complex graphics, our guide comparing DTF vs Screen Printing for modern apparel is worth a read.

Durability is always a hot topic. A well-made screen print is tough, no doubt, but it can feel thick and plasticky on the shirt. It’s also prone to cracking over time, especially on stretchy fabrics. DTF prints have a much softer feel and fantastic stretchability, bonding with the fabric in a way that often outlasts the garment itself without cracking or fading.

DTF vs Heat Transfer Vinyl (HTV)

Heat Transfer Vinyl, or HTV, is a popular choice for hobbyists and simple jobs, like putting names and numbers on sports kits. It involves cutting your design out of a sheet of coloured vinyl and pressing it onto the garment.

But HTV quickly becomes a slog for anything complex or multi-coloured. Each colour has to be cut out and layered by hand—a fiddly process called 'weeding'—which takes ages and really limits how intricate your design can be. With DTF, you print the entire full-colour design in one go, making it vastly more efficient for anything beyond basic shapes and text.

DTF vs DTG vs Screen Printing at a Glance

To make things a bit clearer, here’s a quick table breaking down how these methods compare on the factors that matter most.

| Feature | Custom DTF Transfers | DTG Printing | Screen Printing |

|---|---|---|---|

| Best For | Full-colour, complex designs on any fabric; all order sizes. | Detailed designs on 100% cotton; small to medium runs. | Simple designs (1-4 colours); very large bulk orders. |

| Fabric Versatility | Excellent (Cotton, poly, blends, nylon, etc.) | Limited (Best on 100% cotton). | Good (Works on most, but inks may vary). |

| Colour & Detail | Unlimited colours, photo-quality detail. | Unlimited colours, great detail. | Limited by screen count, struggles with gradients. |

| Feel on Garment | Soft, flexible, and lightweight. | Very soft, as ink soaks into fibres. | Can be thick and heavy, especially with many colours. |

| Setup Cost | None for print jobs. | None for print jobs. | High per-colour setup cost. |

Ultimately, DTF neatly fills a gap in the market. It gives you the incredible, full-colour detail of DTG, but with the freedom to print on almost any fabric, and an efficiency for complex art that vinyl just can't compete with. It’s the best of all worlds for many modern creators.

The Big Wins: Why Choose Custom DTF Transfers?

When you’re looking at different ways to get a design onto a garment, you quickly realise that the small details matter. With custom DTF transfers, the advantages aren’t just small tweaks—they're a genuine leap forward in quality, efficiency, and pure creative freedom. It's a combination of benefits that makes DTF an incredibly powerful tool for businesses and creators all across the UK.

From the massive range of fabrics it works with to the stunning detail and colour, DTF neatly solves many of the headaches found in older printing methods. It takes the best bits of modern digital printing and pairs them with a dead-simple application process. Let’s get into the specifics of what makes this technology such a standout choice.

Works on Just About Anything: Unmatched Fabric Versatility

One of the biggest selling points for DTF is its incredible ability to stick to almost any fabric you can think of. Forget the limitations of other methods like DTG, which really only likes 100% cotton. DTF transfers couldn't care less; they adhere beautifully to a huge variety of materials, no special pre-treatment needed.

This means you can slap the exact same, high-quality design across a whole range of products and keep your branding perfectly consistent. This includes:

- Natural Fibres: Cotton, denim, canvas—the classics.

- Synthetic Materials: Polyester, fleece, and even nylon.

- Blended Fabrics: All those popular cotton/poly mixes.

- Even the Awkward Stuff: Treated leather or waterproof jackets that other methods won't touch.

This kind of freedom lets you expand your product line without needing a different printing setup for every single material. It simplifies everything and opens up a world of new creative possibilities.

Jaw-Dropping Detail and Colour

Custom DTF transfers are superstars when it comes to reproducing complex, full-colour designs with photographic accuracy. The printer lays down your entire design—gradients, tiny details, and all—onto the film in one go. A white ink underbase is automatically applied, acting like a primer to make sure your colours are bright and bold, even on the darkest of fabrics.

This is a game-changer for anyone with intricate logos, fine lines, or designs that use a whole rainbow of colours. With screen printing, you’d need a separate screen for every single colour, making those jobs complicated and expensive. With DTF, there are no colour limitations. Your creativity is the only thing setting the boundaries.

DTF technology basically takes your digital design, captures it perfectly, and moves it flawlessly onto fabric. The final print is a true mirror of your original art, complete with sharp edges and brilliant, punchy colours.

This makes it perfect for everything from detailed company logos to massive, illustrative graphics. You get professional, retail-quality results every single time, bringing your vision to life without any compromises.

Tough as Nails, But Soft to Touch

A print is only as good as its ability to last. Custom DTF transfers are famous for their durability. The special adhesive creates a powerful bond with the fabric's fibres, resulting in a print that stands up incredibly well to washing and everyday wear.

These transfers are built to survive 50+ washes without cracking, peeling, or fading—often outlasting the t-shirt itself. What's more, the finished print feels surprisingly soft and flexible. It moves and stretches with the fabric, so you don't get that stiff, cracking effect you sometimes see with thick screen prints or vinyl. To get the most out of every print run, check out our guide on DTF transfer sheets and how to best arrange your designs.

A Smarter, Faster Way to Work

Beyond just the quality of the print, DTF offers some serious advantages for your workflow, making it a brilliant choice for on-demand businesses. The whole process is quick—you can apply a transfer to a garment in as little as 10-15 seconds.

But the real secret weapon is the 'print now, press later' model. You can order a big batch of your transfers and simply store them until an order comes in. No more guessing sizes and colours and ending up with boxes of unsold, pre-printed stock. This lets you respond instantly to new trends without a massive upfront investment. It’s the kind of flexibility that’s perfect for small businesses, event organisers, and online shops.

When to Use Custom DTF Transfers

Knowing the theory is one thing, but seeing how custom DTF transfers actually perform out in the wild is where they really start to make sense. This isn't just a technical marvel; it's a seriously practical tool for a huge range of creative and business projects. Figuring out where DTF shines will help you see if it’s the right move for what you’ve got planned.

So, let's switch from the 'what' to the 'when' and look at some real-world situations where DTF isn't just an option—it's the best choice you can make.

For Small Businesses and Merch Creators

If you’re running a small business, working as an independent artist, or selling your creations on Etsy, custom DTF transfers are a total game-changer. They completely sidestep the hefty setup costs and big minimum orders you’d face with something like screen printing. This means you can create a small batch of branded t-shirts, tote bags, or hoodies without taking a massive financial gamble.

That kind of flexibility is perfect for testing out new designs or dropping a limited-edition product. Being able to produce gorgeous, full-colour prints on demand lets you jump on trends fast, keeping your stock lean and your brand looking fresh.

For Sports Teams and Corporate Events

Sports teams and companies often need sharp, durable gear with complex, multi-coloured logos. DTF is built for this. The transfers are incredibly tough, standing up to the abuse of a match and countless washes without cracking or fading.

Plus, because DTF works so well on polyester and other performance fabrics, it’s the go-to for modern sportswear. You can get crisp, professional-looking logos on everything from football kits to company polo shirts, making sure your team or brand looks completely on point.

The real beauty of DTF is its versatility. You can press the exact same logo onto a whole mix of items—cotton tees for event staff, polyester jackets for the team—and maintain perfect brand consistency across the board.

For Fashion Startups and Print-on-Demand Brands

For anyone launching a fashion line or a print-on-demand (POD) brand, DTF is a powerful partner. The tech allows for incredibly detailed, photo-quality designs with no limit on colours, giving you total creative freedom. You can bring complex graphics to life that would be a nightmare—or just flat-out too expensive—with other methods.

The numbers make sense, too. If you’re starting a custom t-shirt business in the UK, using DTF transfers means you can be profitable with very little money down. With an average gross profit of around £15.50 per shirt, selling just 100 shirts a month could net you about £1,550 in profit. It’s a low-risk way for new brands to get in the game. You can dig into these numbers a bit more by learning about the profitability of a DTF t-shirt business.

More Creative Use Cases

The potential doesn't stop there. DTF is brilliant for all sorts of projects:

- Personalised Gifts: Create truly one-of-a-kind presents for birthdays, anniversaries, or Christmas.

- Small-Batch Event Gear: Perfect for making custom shirts for stag and hen dos, family reunions, or charity runs.

- Workwear and Uniforms: Easily add durable logos to hi-vis jackets, aprons, or trade uniforms.

At the end of the day, if your project needs detailed, colourful designs on different types of fabric—especially for small to medium-sized runs—custom DTF transfers are an incredible choice. Take a look at Psyque’s collection of direct-to-film transfers to see what’s possible.

How to Order and Apply Your DTF Transfers

So, you’ve seen what custom DTF transfers can do, and now it's time for the fun part: bringing your designs to life. Getting your artwork from a digital file onto a finished garment is a surprisingly simple process. This guide will walk you through ordering from Psyque and applying your transfers for that perfect, professional look.

Your journey begins with your artwork. Get your design ready as a high-resolution PNG file—300 DPI is the sweet spot—with a transparent background. This is crucial because it ensures every detail comes out crisp and clean, and you only print the design itself, not an ugly background box.

Next, you’ll upload your file on our order page. This is also your chance to be really smart about your setup by creating a gang sheet. Think of it as a way to tile multiple designs, logos, or even neck tags onto a single transfer sheet. Arranging your art like this is a game-changer for cutting down waste and reducing your cost per print. It’s perfect if you’re knocking out multiple orders at once.

The Application Process: A Step-by-Step Guide

Once your custom DTF transfers arrive, the final step is getting them onto the fabric with a heat press. This is where the magic happens, creating a permanent bond between the print and the material. The key to a durable, long-lasting finish is consistent heat and even pressure.

Follow these simple steps for a flawless application every single time:

-

Pre-Press the Garment: Set your heat press to the right temperature (usually between 150-165°C). Pop the garment on the press and give it a quick press for 5-7 seconds. This gets rid of any moisture and wrinkles, giving you a perfectly flat surface to work with.

-

Position Your Transfer: Carefully lay the DTF transfer onto the garment, design-side down. If you're worried about it shifting, a little heat-resistant tape can hold it securely in place.

-

The Main Press: Cover the transfer with a Teflon sheet or a sheet of parchment paper. This protects both the print and your heat press platen. Press down with firm pressure for 10-15 seconds. The heat and pressure work together to activate the adhesive, fusing the ink right into the fabric’s fibres.

-

Peel and Reveal: Let the transfer cool down completely. This is called a "cold peel," and it's a vital step. Once it's cool to the touch, gently peel the film away starting from a corner, using a steady, even motion. Your vibrant design is now a permanent part of the garment.

-

Final Press (Optional but Recommended): For an extra-durable, matte finish that feels softer to the touch, place the parchment paper back over the design and press again for just 5-7 seconds.

Getting your settings just right is what separates a good print from a great one. For more detailed advice, check out our comprehensive heat press temperature guide to nail the perfect application on different types of fabric.

Troubleshooting Tip: If you ever find your transfer is applying unevenly, it's almost always a pressure issue. Double-check that your heat press is calibrated correctly and giving even pressure across the entire surface. A quick pre-press also solves most common hiccups before they start.

Got Questions About Custom DTF Transfers? We've Got Answers

Stepping into a new printing method always brings up a few questions. To help you get started with total confidence, we’ve put together the answers to the queries we hear most often about custom DTF transfers.

How Long Do DTF Transfers Last on Clothing?

Properly applied, high-quality DTF transfers are built to last. They’re professionally rated to endure 50-100 washes, which, let's be honest, often means they’ll outlive the garment itself. Thanks to their incredible stretchiness, you don't have to worry about the cracking and fading that plagues other print methods. The colours stay bold and bright, wash after wash.

Can I Just Use a Home Iron to Apply a DTF Transfer?

While it might seem tempting, we really advise against using a home iron. A heat press is the proper tool for the job because it delivers two things an iron can't: consistent temperature and even pressure. This combination is crucial for getting the adhesive to properly bond with the fabric for a permanent finish. Using an iron is a recipe for patchy application, peeling edges, and a design that won't last.

Think of it this way: a heat press properly bakes the design right into the fabric’s fibres. An iron just sort of toasts the surface. For a professional, long-lasting result, a heat press isn't just recommended—it's essential.

What Kind of Fabrics Can I Use DTF Transfers On?

This is where DTF really shines. The versatility is a massive part of its appeal, letting you print on a huge range of materials without any special pre-treatments. You can confidently press these transfers onto just about anything, including:

- Cotton and all sorts of poly/cotton blends

- 100% polyester and other performance wear

- Cosy fabrics like nylon, fleece, and even denim

- Tricky surfaces like treated leather

This makes DTF the perfect all-in-one solution if you're looking to create a consistent brand look across lots of different types of clothing and accessories.

Ready to see what DTF can do for your designs? Psyque offers premium, ready-to-press custom DTF transfers that make creating professional-quality gear incredibly simple. Check out our services and start your project today at Psyque.co.uk.