A Practical Guide to DTF Transfer Sheets

Share

DTF transfer sheets are basically specialised films that let you press high-quality, full-colour designs onto pretty much any fabric. The best way to think of them is like a high-tech temporary tattoo for your clothes, but the result is a permanent, vibrant, and surprisingly flexible print that feels great.

What Are DTF Transfer Sheets Anyway?

Imagine you want to create a custom t-shirt with a really detailed, multi-coloured design. In the past, you’d be looking at a complicated screen printing setup, or you’d end up with a print that felt stiff and plasticky, like a cheap iron-on. This is exactly where DTF transfer sheets come in and change everything. They act as the perfect carrier for your digital designs, holding the ink and adhesive in a neat little package until you’re ready to press it.

This technology has quickly become a massive deal in the custom apparel world. To give you an idea, the Direct to Film printing market in Europe and the UK is part of a global industry valued at around USD 2.72 billion in 2024. That massive number just shows how many creators and businesses are now relying on DTF for its incredible quality and efficiency. (You can dig into those numbers over on Grandview Research if you're curious).

The Three Core Components

To really get your head around how these sheets work, you need to know about the three key players that team up to create the final print. Each one has a specific job, and they all have to work together perfectly to get a flawless result.

- PET Film: This isn't just any old bit of plastic. It's a specially coated Polyethylene Terephthalate (PET) film made to hold the ink precisely without letting it bleed. The matte side is designed to grip the ink, while a special coating on the film ensures the design releases cleanly onto your fabric when you apply heat.

- DTF Ink: These are specialised water-based pigment inks, created to be super vibrant, flexible, and tough. The process uses a full spectrum of colours—Cyan, Magenta, Yellow, and Black—plus a crucial white ink base layer. It’s this white layer that makes your designs pop, even on the darkest of fabrics.

- Adhesive Powder: This fine, white powder is the unsung hero of the whole operation. After the design is printed onto the film, it gets a dusting of this thermoplastic polyurethane (TPU) powder. When you heat it, it melts and acts like a powerful glue, bonding the ink securely into the fabric's fibres for good.

In short, the film is the canvas, the ink is the paint, and the adhesive powder is the super-strong glue that makes your art permanent. If one part is missing, the whole transfer just won’t work.

This simple but brilliant trio is what makes DTF so versatile. It’s the reason you can get incredibly detailed, soft graphics that can stretch with the fabric and survive dozens of washes without cracking or fading. If you want to learn more about bringing your own ideas to life, you can explore our guide on getting started with DTF prints. This foundation is what allows you to press stunning designs onto cotton, polyester, leather, and so much more.

How a Design Jumps from Film to Fabric

The real magic begins when your digital design is ready to leave the screen and find its new home on fabric. This is where a simple dtf transfer sheet becomes a durable, wearable piece of art, all thanks to a few carefully coordinated steps. It’s a bit like baking a cake – get the ingredients and the timing right, and the result is perfect.

This journey from pixel to print isn't just clever; it's also incredibly popular. Here in the UK, the boom in personalised fashion has seen local creators turn to DTF for its amazing quality on small-batch and on-demand jobs. Globally, the market for transfer paper products, including these films, is on a serious growth trajectory, projected to climb from USD 3.3 billion in 2025 to USD 5.7 billion by 2035.

The First Step: Printing Your Vision

It all starts with a specialised DTF printer. This isn't your standard office machine; it’s built to handle the unique PET film and the specific pigment inks that make this whole process work. The printing itself is a clever two-part sequence.

First, the printer lays down all the colours of your design (Cyan, Magenta, Yellow, and Black) onto the matte side of the film. Then, in a second pass, it prints a perfectly aligned layer of brilliant white ink directly on top. This white layer is absolutely crucial. It acts as a solid base, making sure your design's colours are bright and bold, no matter what colour garment you're printing on.

Without that white underbase, your colours would look washed out and thin on dark fabrics. It's the foundation that makes the entire design pop.

Applying the Magic Powder

With the ink still wet on the dtf transfer sheet, it's time for the next stage: the adhesive powder. This fine, white powder is a thermoplastic polyurethane (TPU), which is just a fancy way of saying it’s the 'glue' that will permanently lock your design onto the fabric.

The sheet gets a generous coating of this powder, but it only sticks to the wet ink. The blank areas of the film stay clean. Any extra powder is then shaken off, which is key to ensuring you only get the adhesive where the design is. This little step is what prevents a stiff, plasticky box from forming around your finished print.

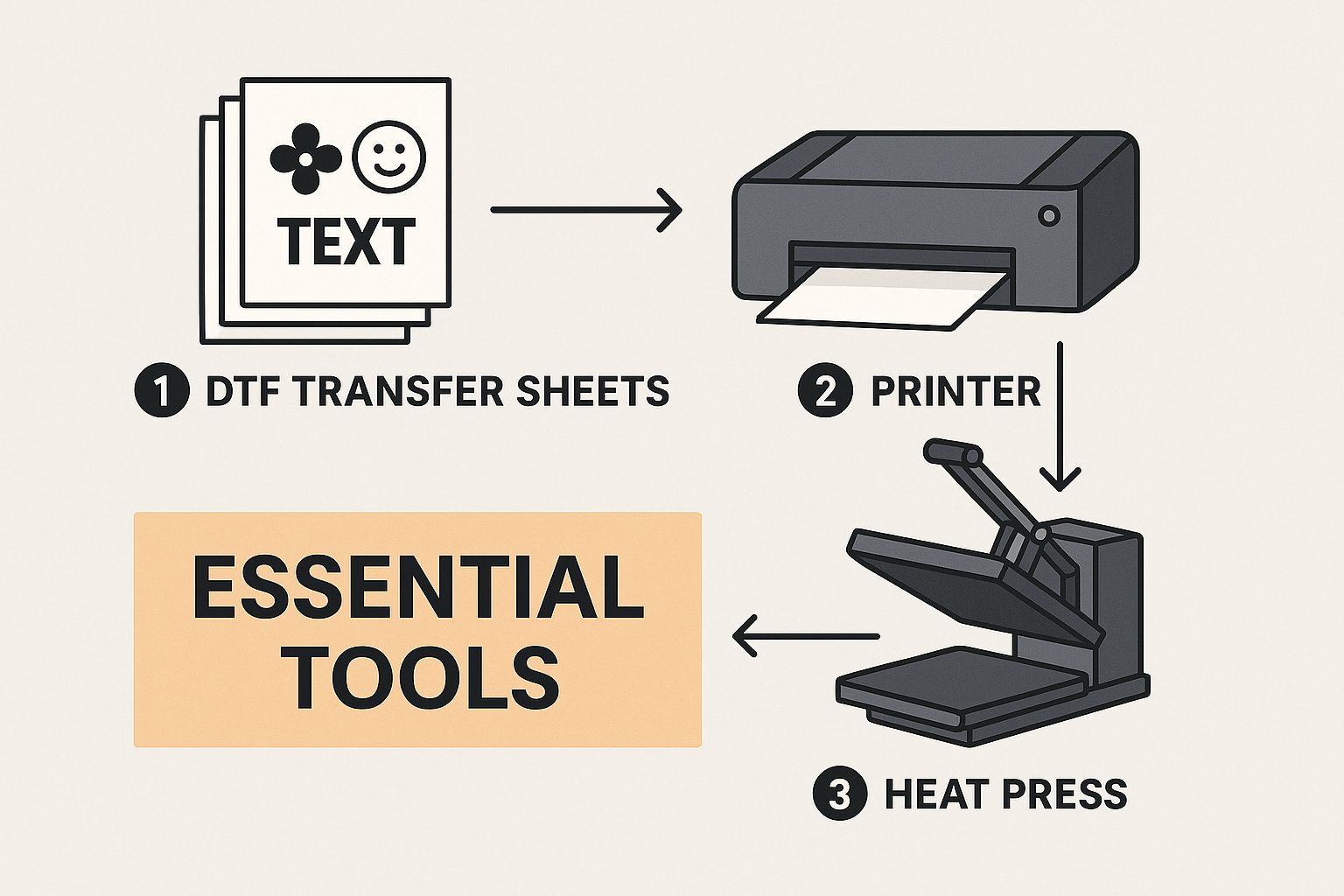

The infographic below shows the essential tools that bring this all together.

As you can see, each piece of equipment has a specific job, from the initial print right through to the final press that creates the finished garment.

Curing and Preparing for the Press

The powdered film isn’t quite ready for the fabric yet. First, it needs to be cured. This involves heating the sheet, usually by passing it through a small curing oven or by hovering a heat press just over the surface. The heat melts the powder just enough to transform it into a smooth, slightly rubbery layer that seals in the ink.

This 'baking' step merges the separate layers of ink and powder into a single, stable transfer that’s ready to go. Once it's cured, the design is no longer fragile. You can store it for months or head straight to the heat press. For a deeper dive into this workflow, check out our guide to understanding DTF printing.

The Final Transfer: Heat Pressing

Now for the most satisfying part: the heat press. This is where your design makes the final jump from the film to the fabric.

- Positioning: The cured dtf transfer sheet is placed exactly where you want the design on the garment.

- Pressing: A heat press applies a controlled combination of heat (usually around 150-165°C) and firm, even pressure for about 10-15 seconds.

- Bonding: The heat reactivates the cured adhesive, causing it to melt deep into the fabric's fibres and taking the ink layer with it for the ride.

- Peeling: Once the timer goes off, the PET film is peeled away, leaving just the vibrant, soft design permanently bonded to the material.

The final result is a flawless graphic that feels like it’s part of the fabric itself, ready to handle stretching, washing, and whatever else you can throw at it.

Real-World Benefits of Using DTF Transfers

So, why are so many creators and businesses getting excited about DTF? It's not just about the technical specs. It's about how it solves real, everyday printing problems. From mind-boggling versatility to being surprisingly light on the wallet, DTF transfer sheets are a perfect fit for modern apparel customisation.

These benefits come together to create a printing method that’s both powerful and incredibly approachable. It's putting professional-grade tools into the hands of small brands and solo creators, letting them produce quality that was once reserved for huge industrial operations.

Unmatched Versatility Across Materials

One of the biggest wins for DTF is its incredible ability to work with a massive range of materials. Forget being picky about fabrics. Unlike other methods that have a very specific diet, DTF is happy to work with almost anything you throw at it.

We're talking way beyond the classic cotton t-shirt. DTF transfers stick beautifully to polyester, poly-cotton blends, nylon, and even tricky surfaces like treated leather. This blows the doors wide open for creativity.

- For Small Businesses: A local gym can brand their cotton tees, polyester performance tops, and nylon gym bags all using the exact same set of transfers. No fuss.

- For Fashion Brands: Designers can get experimental, printing detailed graphics onto denim jackets, canvas totes, or even wooden accessories, keeping their branding consistent across an entire collection.

- For DIY Creators: You can personalise anything from a leather notebook to a pair of canvas trainers, all with the same DTF transfer sheets.

This flexibility means you don't need a different setup for every type of product, which saves a ton of time and money. It streamlines your whole process and lets you say "yes" to more varied and interesting projects.

Stunning Vibrancy and Detail

When it comes to pure visual punch, this is where DTF truly shines. The process delivers photorealistic detail and a spectrum of colour that other methods just can't touch, especially on dark fabrics.

The secret weapon? A crucial layer of white ink is printed first as an underbase. Think of it like a coat of primer on a dark wall—it gives the colours a bright, opaque foundation to sit on. This stops the garment's colour from muddying your design, so every shade pops exactly as you intended.

The end result is a print that feels like it’s part of the fabric, not like a heavy plastic sticker sitting on top. It’s soft, lightweight, and doesn’t ruin the natural feel of the garment.

This means you can confidently print complex photos, designs with soft gradients, or logos with tiny, crisp text, and know the final product will look sharp and professional. The vibrancy and detail are second to none.

Impressive Durability and Feel

A beautiful print is worthless if it doesn't last. DTF transfers are engineered to be tough, standing up to wash after wash and plenty of stretching without cracking, peeling, or fading. The ink doesn't just sit on the surface; it chemically bonds with the fabric fibres.

This resilience makes DTF a fantastic choice for all sorts of gear:

- Workwear: Tradespeople can count on their branded hi-vis vests and hoodies to handle daily abuse and frequent washing.

- Children’s Clothing: Parents can relax knowing the cute designs on their kids' clothes won't flake off after a few tumbles in the machine.

- Fashion Items: Your custom creations will keep that "just-printed" freshness for much longer, preserving the quality and value of your work.

Cost-Effective for Small to Medium Runs

In the past, getting full-colour custom garments meant dealing with massive setup costs, especially with screen printing. This often made small batches far too expensive to even consider. DTF flips that script completely.

Because there are no screens to prepare, the setup is practically zero. This makes DTF incredibly cost-effective for small-to-medium-sized orders.

This is a genuine game-changer for independent brands and small businesses. You can now test a new design with a small run of just ten shirts without a huge financial gamble. If you're weighing up the options, our detailed comparison of DTF vs screen printing breaks down exactly where each method shines. This kind of accessibility allows creators to be nimble, creative, and much more responsive to what their customers want.

How to Choose the Right DTF Transfer Sheets

Picking the right DTF transfer sheets is easily one of the most important calls you'll make on your printing journey. It's not just about grabbing any old film; it's about finding the perfect match for your project to get that flawless, lasting finish you're after. Think of it like a baker choosing the right type of flour—the final cake depends entirely on starting with the correct core ingredient.

The rise of DTF here in the UK goes hand-in-hand with the explosion in bespoke garment printing, a market that’s been booming since around 2018. Small businesses and creative entrepreneurs all over the country have turned to wholesale DTF transfer sheets to whip up everything from custom tees and hoodies to one-of-a-kind home decor. It's all about meeting that ever-growing hunger for personalised gear. For a deeper dive into how UK brands are using this tech, the folks at Research and Markets have some great insights.

Your biggest decision will come down to two main types of film: hot peel and cold peel. Each has its own personality and is suited to different ways of working and different final looks. Getting to grips with what makes them tick is the key to mastering your craft.

The Great Debate: Hot Peel vs Cold Peel

The names "hot peel" and "cold peel" are pretty self-explanatory—they tell you when to remove the PET film from the garment after pressing it. Do you rip it off straight away while it's still piping hot, or do you let it cool down completely? That one simple difference changes everything, from your production speed to the final texture of the print.

Let's break down what really sets them apart.

Comparison of Hot Peel vs Cold Peel DTF Sheets

Deciding between hot and cold peel film really comes down to what you value more: speed and a soft feel, or pinpoint detail and a glossy finish. This table lays out the core differences to help you choose the right tool for the job.

| Feature | Hot Peel Film | Cold Peel Film |

|---|---|---|

| Peeling Time | Immediately after pressing (while hot) | After the transfer has completely cooled |

| Final Finish | Typically results in a softer, more matte finish | Often produces a glossier, shinier finish |

| Production Speed | Much faster workflow, ideal for high-volume jobs | Slower process due to the cooling wait time |

| Best For | Bold, simple designs and large production runs | Highly detailed or intricate designs with fine lines |

As you can see, hot peel films are all about efficiency. The ability to press and peel in one fluid motion makes them a firm favourite for anyone needing to churn out a high volume of items quickly. The print you get tends to have a softer hand-feel and a more matte look, which is perfect for fashion and retail-quality clothing.

On the flip side, cold peel films demand a bit of patience. You absolutely have to wait for the transfer to cool to room temperature before you even think about peeling off the film. It slows you down, sure, but it gives you an unbeatable edge when working with complex artwork. The adhesive gets more time to properly bond with the fabric, making sure every tiny, delicate detail transfers perfectly without lifting. This makes cold peel the undisputed champion for photorealistic prints or designs with fiddly, fine text.

Beyond the Peel: Other Factors to Consider

While the hot vs. cold peel choice is a big one, a few other details about your DTF transfer sheets can make a world of difference to your final prints and your sanity.

Film Thickness and Coating

The thickness of the PET film, usually measured in microns, affects how stable it is. A slightly beefier film (around 75-100 microns) is often much easier to handle and less likely to curl up when it feels the heat from your printer or curing unit. It's also worth looking for sheets with a high-quality matte coating on one side.

- Ink Absorption: A good coating helps the ink sit neatly on the surface without bleeding, which means you get sharper, crisper prints.

- Powder Adhesion: It also makes sure the adhesive powder sticks only to the inked areas, stopping stray powder from making a mess of your transfer.

Anti-Static Properties

Ever noticed tiny flecks of adhesive powder clinging to the clear parts of your film? That’s usually static electricity playing havoc. The best DTF transfer sheets are treated with an anti-static coating to stop this exact problem in its tracks.

An anti-static property is one of those small features that makes a massive difference. It guarantees a cleaner transfer by repelling stray powder, saving you the headache of prints that feel rough and sandy or have a faint, unwanted outline.

Choosing sheets with this feature leads to a cleaner peel and a far more professional finish, instantly elevating the quality of your work. If you're just starting out, trying a reliable option like our high-quality A4 DTF Transfer Sheets can give you a solid foundation for getting brilliant results from your very first press.

Troubleshooting Common DTF Printing Problems

Even with the best gear, you're going to hit a few snags. Don't think of these moments as failures; see them as your official initiation into the world of hands-on DTF printing. This section is your go-to guide for sorting out the most common issues you'll likely run into with your dtf transfer sheets.

From colours that look a bit off to prints that just won’t stick, pretty much every problem has a logical cause and a straightforward fix. We’ll walk through the most frequent challenges, pinpoint what’s likely going wrong, and give you clear, actionable steps to get your production back on track.

: This is pretty much what it sounds like—an inkjet printer for fabric. The ink is sprayed directly onto the garment and soaks into the fibres. The result is a super soft feel, but it works best on 100% cotton and needs a pre-treatment liquid, especially on dark colours. DTF completely sidesteps this by printing onto a film first, which is why it works on such a massive range of materials.

-

Sublimation: This is a bit of printing magic. The special ink turns into a gas under heat, permanently dyeing the fabric's fibres. You get an incredibly durable print with absolutely no feel to it, but here’s the catch: it only works on light-coloured, 100% polyester fabrics. DTF transfer sheets blow these limitations out of the water, working on any colour and just about any fabric you can throw at it—cotton, polyester, blends, you name it.

Can I Use a Regular Printer for DTF Sheets?

In a word: no. Your standard desktop printer just isn't built for the job. It simply can't handle the specialised pigment inks, and it's missing the most crucial ingredient—the white ink layer.

A proper DTF printer is purpose-built. It's designed to manage thick, water-based inks and print them in the right order (colour first, then white) onto the PET film. Trying to MacGyver it with a regular office printer would just lead to a sticky mess, a useless print, and a very unhappy, likely broken, machine.

What Kind of Durability Can I Expect?

This is where DTF really shines. A quality DTF transfer is seriously resilient. When you apply it correctly, that print is designed to stick around for the life of the garment.

A properly pressed DTF transfer can easily handle 50+ washes without any major fading, cracking, or peeling. The trick is all in the application—getting the temperature, pressure, and time just right, then giving it a final press to really lock the design in place.

This level of durability makes DTF transfer sheets a brilliant choice for everything from everyday fashion tees to tough workwear and team sportswear. The print actually flexes with the fabric, so it keeps looking great wash after wash, all while staying soft and vibrant.

Ready to bring your own unique designs to life with unmatched quality and durability? Explore the endless creative possibilities with Psyque and see how our premium DTF printing services can elevate your next project. Get started at https://psyque.co.uk.