What Are DTF Prints Your Ultimate Explainer Guide

Share

Imagine a high-tech sticker for fabric that’s incredibly vibrant, tough, and can be applied to almost anything. That's pretty much the essence of Direct-to-Film, or DTF prints. This printing method is quickly becoming a favourite for anyone wanting to create custom apparel.

What Are DTF Prints

At its core, a DTF print is a full-colour design printed onto a special transparent film, which is then transferred to a garment using a heat press. Think of it as creating a high-quality, flexible, and durable transfer that can be applied to materials that other methods really struggle with. Unlike techniques that print directly onto the fabric, DTF lets you prepare the design completely separately.

This simple but incredibly effective process is what gives DTF its power. It gets rid of many of the limitations you'd find in older customisation methods. You're no longer restricted by fabric type or colour, which opens up a whole new world of creative possibilities.

Why Is DTF So Popular

The rapid rise of DTF printing isn't just a fluke; it's being driven by its sheer versatility and professional-looking results. For small businesses and independent creators, it offers a way to produce retail-quality goods without a huge initial investment.

The real appeal of DTF is its ability to bridge the gap between complexity and quality. It delivers the vibrant, detailed results of more advanced methods while maintaining a straightforward, accessible workflow for users at all skill levels.

This popularity is reflected in its significant market growth. In Europe, the DTF printing sector was valued at around USD 2.72 billion in 2024 and is projected to hit USD 3.92 billion by 2030, with the UK market seeing steady adoption. If you're interested in the numbers, you can explore more data on this industry growth from Grand View Research.

Key Advantages of DTF Prints

So, what makes this method really stand out from the crowd? Here are a few key benefits that are making it so popular:

- Fabric Freedom: DTF works brilliantly on cotton, polyester, leather, nylon, and all sorts of blended fabrics.

- No Pre-Treatment Needed: Unlike DTG printing, you don't need to apply a chemical pre-treatment to the garment, saving you time, hassle, and money.

- Vibrant on All Colours: The white ink base layer ensures designs look bright and solid, even on the darkest fabrics.

- Durability and Feel: The prints are soft, flexible, and hold up exceptionally well to washing and stretching without cracking.

These factors combine to make DTF printing a practical and powerful choice for a huge range of applications. If you're looking for a deeper dive into how it all works, our complete DTF printing guide has you covered.

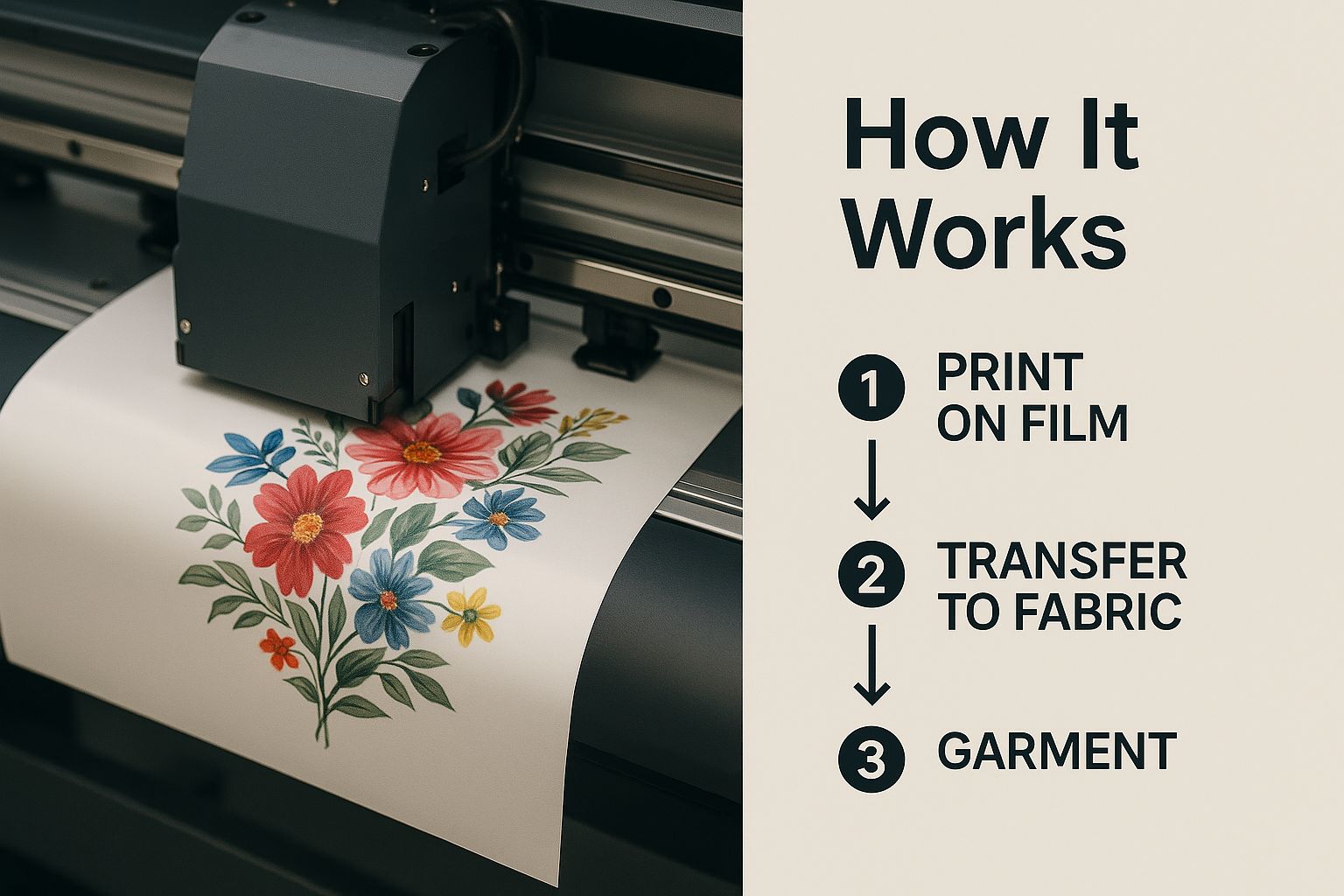

The Step-by-Step DTF Printing Process

Turning a digital file into a vibrant design you can actually wear might sound a bit like magic, but the DTF printing process is a surprisingly straightforward and clever journey. It all comes down to a few key stages, each one building on the last to create a print that’s both durable and seriously eye-catching.

This infographic gives you a bird's-eye view of how a design on a screen starts its life in the physical world.

This is where it all begins, laying down the groundwork for the colour and sharp detail that define top-quality dtf prints.

Stage One: Printing on PET Film

Everything kicks off with a purpose-built DTF printer. Forget your standard office machine; this bit of kit is loaded with special pigment-based inks—cyan, magenta, yellow, black, and the all-important white ink. Your design is printed in full colour directly onto a sheet of Polyethylene Terephthalate (PET) film.

But here’s the clever part. Immediately after the colour layer goes down, the printer lays down a perfectly aligned layer of white ink right on top. This white base is the secret weapon for making designs pop on dark or coloured fabrics. It acts as a solid, opaque canvas, making sure the colours stay bright and true instead of getting lost in the material.

The way DTF prints both the colour and white layers at the same time is a huge part of its efficiency. It completely sidesteps the tricky registration headaches you get with methods like screen printing, guaranteeing a perfect alignment every single time.

The growth in this tech speaks for itself. The global DTF ink market was pegged at around USD 4.56 billion in 2024 and is tipped to grow by 9.6% each year until 2031. This boom is being driven by constant improvements in the vibrancy and toughness of the inks, which you can read more about in this DTF ink market analysis.

Stage Two: Applying the Adhesive Powder

With the design freshly printed and the ink still tacky, the PET film is ready for its next crucial step: the powder. The film gets a coating of a fine, granular hot-melt adhesive powder. This powder is designed to stick only to the wet ink, leaving the rest of the film completely clean.

Any extra powder is simply shaken off, which is what gives the final transfer such a crisp, clean edge. This adhesive is basically the "glue" that will permanently fuse the ink to the garment's fibres in the final stage. It’s the reason dtf prints are known for being so durable and holding up so well in the wash.

Stage Three: Curing and Final Transfer

Before it’s ready for a t-shirt, the powdered film needs to be cured. The film is passed through a curing oven or placed under a heat press that hovers just above its surface. The heat melts the adhesive powder, turning it into a smooth, slightly rubbery layer that seals in the ink.

Once it's cured, the transfer is good to go. The film is positioned on the garment and pressed with a heat press at a precise temperature and pressure. This heat reactivates the adhesive, bonding it deep into the fabric. After a moment to cool, the PET film is peeled away, leaving behind a vibrant, soft, and perfectly transferred design. This simple finishing touch is what makes creating high-quality DTF transfers so accessible.

Your Essential DTF Printing Toolkit

To get those professional-quality DTF prints everyone’s after, you need a specific set of tools and materials all pulling in the same direction. Think of it like a chef’s kitchen; every piece of equipment has its own job to do in creating the final masterpiece. Putting together the right kit is the first real step towards making designs that are vibrant, tough, and ready to sell.

This setup is much more than just a printer and a few bottles of ink. Each bit of gear is designed for a specific part of the DTF process, making sure the final print doesn't just look good, but is built to last. Let's break down the essential gear you’re going to need.

The Core Machinery

At the heart of any serious DTF operation are two main pieces of machinery. They’re usually the biggest upfront cost, but if you want consistent, reliable results, you simply can't do without them.

- Specialised DTF Printer: This isn't your standard office printer. A proper DTF printer is built to handle thick pigment inks and has extra channels just for the white ink. It's cleverly engineered to lay down the colour and white layers perfectly on top of each other on the film.

- Heat Press: This is where the magic happens. The final, make-or-break step relies entirely on a good-quality heat press. This machine provides the exact temperature and even pressure needed to melt the adhesive powder and permanently fuse the design into the fabric. A press that comes straight down (a vertical platen) is often recommended for the most consistent cure.

Getting the right hardware is everything. If you want to dive deeper into the machinery, check out our guide on choosing the best DTF printing machine for what you need.

Essential Consumables

Along with the big machines, you'll need a constant supply of specialised consumables. These are the materials you'll use up with every print, and they're just as crucial as the hardware itself.

- DTF Pigment Inks: These are special water-based textile inks made just for DTF. The set includes Cyan, Magenta, Yellow, and Black (CMYK), plus the all-important White ink. They have a unique elasticity that stops the final print from cracking when the fabric stretches.

- PET Transfer Film: This is the special sheet you print your design onto first. It has a coating that holds the wet ink perfectly but lets it go cleanly when you apply heat during the transfer.

- Hot-Melt Adhesive Powder: This is a fine, sugary-looking polyurethane powder that works as the glue. It only sticks to the wet ink on the film. When you melt it, it creates a powerful adhesive layer that locks the print into the garment’s fibres.

A classic rookie mistake is underestimating how much the consumables matter. Using the right ink, film, and powder is just as critical as having a good printer. Skimping on these almost always leads to dull colours, cracking, and transfers that just peel right off.

Mastering your toolkit means understanding how each part plays a role in the final result. With the right combination of machinery and materials, you’ll be set up to create stunning DTF prints every single time.

How DTF Stacks Up Against Other Methods

Choosing the right printing technique can feel like a bit of a minefield, with each method bringing its own strengths to the table. When you put DTF prints next to industry workhorses like Direct-to-Garment (DTG), screen printing, and even heat transfer vinyl (HTV), you start to see where it really shines. It’s not about finding one single "best" method, but about figuring out which one is the perfect tool for your specific job.

The decision usually boils down to five key things: the feel of the print on the fabric, how vibrant the colours look, what materials you can actually print on, how well it holds up in the wash, and of course, the cost per item. DTF offers a really solid balance across all these areas, making it a powerful contender for all sorts of projects, from one-off custom pieces to much larger commercial runs.

DTF Prints Versus DTG Printing

Direct-to-Garment (DTG) printing is often thought of as DTF’s closest cousin. They both use inkjet technology to create beautifully detailed, full-colour designs. The real difference, though, is in how they're applied and what they can be applied to.

DTG prints ink directly onto the garment, letting it soak right into the fibres. This gives you an incredibly soft finish with almost no feel to it, which is brilliant for designs on light-coloured cotton T-shirts. The catch? DTG has a tough time with polyester and dark garments, which need a chemical pre-treatment that adds extra time, hassle, and cost.

DTF, on the other hand, prints onto a film first. This one simple step is its greatest strength.

- Material Versatility: DTF is the undisputed winner here. It works beautifully on cotton, polyester, leather, nylon, and blends—all without any special pre-treatment.

- Vibrancy on Darks: The solid white ink base used in DTF prints is a game-changer. It makes sure colours pop with consistent brightness on any colour garment, something DTG often struggles with.

- Feel and Finish: This is where you'll notice a difference. DTG has a softer, more integrated feel. A DTF print sits on top of the fabric, giving it a finish that's a little more noticeable but is incredibly flexible and smooth to the touch.

Here's a simple way to think about it: DTG becomes part of the shirt's fibres, while DTF creates a durable, flexible layer that bonds perfectly to the surface. This is what makes DTF a far more adaptable solution for a much wider range of products.

DTF Prints Versus Screen Printing

For decades, screen printing has been the undisputed champion of high-volume T-shirt production. It's famous for creating incredibly durable prints with punchy, vibrant colours. The process involves pushing ink through a mesh screen onto the fabric, one colour at a time, making it super-efficient for massive batches of the same design.

The downside is its complex and costly setup for smaller orders. Every single colour in a design needs its own screen, which makes it totally impractical for photorealistic images or one-off prints. This is where DTF steps in, offering full-colour capability with absolutely zero setup needed per design. If you want to dive deeper, exploring the nuances of DTF vs screen printing for graphic tees can offer some great insights.

Ultimately, screen printing is still the king for huge runs of simple designs. But for small-to-medium businesses that need intricate, multi-colour designs on demand, DTF prints offer a far more cost-effective and flexible way forward.

DTF vs DTG vs Screen Printing at a Glance

With all these options, it can be helpful to see a quick side-by-side comparison. Each technology has its place, and the best choice really depends on what you're trying to create.

Here’s a simple table to help you decide which method fits your needs best:

| Feature | DTF Prints | DTG Printing | Screen Printing |

|---|---|---|---|

| Best For | Small-to-medium runs, multi-colour designs | One-offs, detailed photos on cotton | Large batches (100+), simple graphics |

| Colour Vibrancy | Excellent, especially on dark fabrics | Good on light fabrics, can be muted on darks | Excellent, very opaque and bold |

| Material Compatibility | Very wide (cotton, poly, blends, leather) | Limited (best on 100% cotton) | Wide (cotton, poly, blends) |

| Feel of Print | Soft, flexible layer on top of the fabric | Very soft, no feel as ink is in the fibres | Thicker layer on top of the fabric |

| Durability | High, very resistant to cracking and peeling | Good, but can fade with repeated washing | Extremely high, often outlasts the garment |

| Setup Cost | Low (no per-design setup) | Low (no per-design setup) | High (requires screens for each colour) |

| Cost per Item | Low for small runs, moderate for large | High for large runs, moderate for one-offs | Very low for large runs, very high for small |

Choosing between DTF, DTG, and screen printing isn't about which is "better" overall, but which is better for your specific project's volume, design complexity, and material. This table should give you a good starting point for making that call.

Creative Applications for DTF Prints

While t-shirts might be the first thing that comes to mind, the real magic of DTF prints is just how adaptable they are. This technology completely changes the game for customisation, letting creators put their mark on items that were once a nightmare to print on. It opens up a whole universe of new possibilities.

The secret sauce is in the transfer process itself. Because the design sits on top of the fabric instead of soaking into the fibres, DTF doesn't really care what it's being pressed onto. This makes it the go-to choice for everything from performance sportswear to slick corporate branding.

Beyond the Basic T-Shirt

DTF's incredible versatility means designers and businesses can stop thinking just about standard apparel. Now, you can create entire product lines and unique promotional gear with crisp, consistent branding across a massive range of different surfaces.

Here are just a few places where DTF prints are really making their mark:

- Sportswear and Activewear: Those tricky polyester and nylon jerseys are no longer a problem. Team logos, player numbers, and sponsor branding go on smoothly and, crucially, the print flexes with the fabric without cracking.

- Headwear and Accessories: You can apply intricate logos and detailed graphics perfectly to hats, tote bags, and backpacks, even if they're made from tough canvas or other synthetic materials.

- Tough and Unconventional Materials: DTF is durable enough to work on non-traditional surfaces like leather patches for jeans, nylon jackets, and high-vis workwear vests, offering a rugged branding solution that lasts.

This innovation is being fuelled by a huge demand for personalised gear. To put it in perspective, the wider UK photo printing market—which covers similar custom tech—was valued at a whopping USD 1.1 billion in 2024. It’s set to grow at an annual rate of 13.66% through 2035, which tells you just how much people love unique products. You can dig deeper into the numbers in the UK photo printing market report.

Tapping into Niche Markets

This freedom from material constraints allows brands to serve very specific niches in a way they couldn't before. For instance, a small business can now create a complete range of branded merchandise, from classic cotton hoodies to polyester gym bags, all featuring the exact same vibrant design.

The ability to apply a single, high-quality transfer to virtually any textile product is what makes DTF so powerful. It removes creative barriers and lets entrepreneurs focus on design and market opportunities, not technical limitations.

This opens the door for creating themed collections for specific events or hobbies. If you're looking for a bit of inspiration, check out our guide on creating a unique t-shirt for Halloween to see how a great design can tap into seasonal trends. By using DTF prints, you can confidently expand your product range, knowing your designs will look fantastic on pretty much anything you can think of.

Of course, here is the rewritten section with a more natural, human-written tone.

Answering Your Top DTF Printing Questions

As you dip your toes into the world of custom apparel, it’s completely normal to have questions about how DTF prints actually hold up in the real world. Getting solid answers is the best way to feel confident you're picking the right printing method for your project or business.

We’ve pulled together some of the most common questions we hear to give you straight-up, practical answers. This should help you get a much clearer picture of the durability, requirements, and unique perks of using DTF.

How Well Do DTF Prints Last in the Wash?

This is usually the first question on everyone's mind, and for good reason! The great news is that DTF prints are incredibly tough and made to last. When they’re applied properly, the design has a fantastic amount of stretch and moves with the fabric, which means it can handle dozens of washes without cracking, peeling, or fading away.

The magic is in the combination of the water-based pigment inks and that powerful hot-melt adhesive. Together, they create a seriously strong bond with the fibres of the garment. To get the absolute most life out of your prints, we always suggest washing your gear inside out on a cool cycle and tumble drying on a low heat. Honestly, many people find that the print itself actually outlasts the garment it’s on, making it a perfect choice for commercial-quality clothing that needs to stand up to daily wear and tear.

Can I Just Use My Regular Printer for DTF?

It’s a thought that crosses many minds, but the answer here is a definite no. You can't use a standard office printer or your home photo printer for DTF. The process has some very specific needs that regular printers just aren't built for.

A purpose-built (or professionally converted) DTF printer is non-negotiable for a few key reasons:

- Specialised Inks: They are made to handle thick, pigment-based DTF inks, which are a world away from the thin, dye-based inks found in most desktop printers.

- A Channel for White Ink: The ability to lay down a solid, opaque layer of white ink is absolutely essential. This is what makes your designs pop on dark-coloured fabrics, and standard printers don't have the right channels or printhead tech for it.

- RIP Software: DTF printers need special Raster Image Processing (RIP) software to control the ink layers. It’s what tells the machine to print the colour layer first and then the white layer perfectly on top, all in one go.

Trying to rig a normal printer will just end in frustration and messy results. It simply can’t create the layered, adhesive-ready transfer you need.

What's the Main Edge DTF Has Over DTG?

While they're both brilliant digital printing methods, the single biggest advantage DTF has over Direct-to-Garment (DTG) printing is its unbelievable material versatility. This is where DTF really shines and opens up a much bigger playground for your creative ideas.

DTG printing is at its best on natural fibres, mainly 100% cotton, and almost always needs the fabric to be sprayed with a special pre-treatment liquid first. That adds an extra step and really narrows down the types of products you can customise.

On the other hand, DTF prints can be pressed onto a massive range of materials without any pre-treatment at all. We’re talking cotton, polyester, nylon, leather, denim, and all sorts of poly-cotton blends. This flexibility is a game-changer, letting you put a consistent design across a whole product line—from t-shirts and hoodies to sportswear, caps, and bags.

Is DTF Printing an Eco-Friendly Choice?

Compared to old-school methods like screen printing, DTF is generally seen as a much more environmentally friendly option. The whole process is cleaner and creates a lot less waste, which gives it a smaller ecological footprint.

The green benefits really come from a few key areas. DTF uses non-toxic, water-based inks that are safer for you and the planet. Plus, the process is super efficient; you only print the ink and use the adhesive powder needed for your specific design, so there’s hardly any material wasted. This is a huge difference from screen printing, which uses vast amounts of water and often harsh chemicals just to create and clean the screens between jobs.

Ready to bring your own vibrant, durable designs to life? Psyque offers premium, custom DTF printing services right here in the UK. Whether you're launching a streetwear brand or need branded workwear, we provide the quality and speed you need. Explore our collections and start your custom apparel journey today.