Your Guide to a DTF Printing Machine

Share

A DTF printing machine is a game-changer for anyone in the custom apparel world. In simple terms, it's a clever system that creates full-colour, ready-to-press graphics that can be applied to almost any type of fabric. Designs are first printed onto a special film, coated with an adhesive powder, and then heat-pressed onto clothing. The result is a vibrant, durable, and incredibly flexible finish.

What's Really Going On Inside a DTF Printing Machine?

At its heart, a DTF printing machine takes the complexity out of professional garment decoration. Unlike Direct-to-Garment (DTG) printing, which applies ink straight onto the fabric, DTF cleverly separates the printing from the application. This small tweak is exactly what gives the technology its incredible versatility.

One of the biggest wins is that it eliminates the need for fabric pre-treatment. That’s a notoriously time-consuming step for DTG, especially on dark-coloured clothing. With DTF, all the magic happens on the film first, creating a transfer that’s ready to go on a huge range of materials.

Before we dive deeper, here's a quick snapshot of what makes DTF printing tick.

DTF Printing At a Glance

| Characteristic | Description |

|---|---|

| Printing Method | Digital inkjet printing onto a special PET film. |

| Materials | Works on cotton, polyester, nylon, leather, blends, and more. |

| Colour Capability | Full-colour CMYK + White ink for vibrant prints on any colour garment. |

| Feel | Soft, flexible, and slightly raised on the fabric surface. |

| Durability | Excellent wash resistance and elasticity. |

| Ideal For | Small to large batches, intricate designs, and hard-to-print items. |

This table gives you the headlines, but the real power of DTF comes from how its components work together.

The Core Components of a DTF System

To really get a handle on how a DTF machine works, you need to look at its key parts. Each one has a critical job in turning a digital file into something you can actually wear. A full setup usually includes:

- The DTF Printer: This is no ordinary office printer. It's a purpose-built inkjet machine that uses special textile inks, laying down a full-colour layer first and then a solid white ink base on top.

- PET Transfer Film: This is the carrier sheet where the design is born. It's engineered to hold the ink perfectly and then release it cleanly onto the fabric when heat is applied.

- Adhesive Powder: Once the design is printed, a fine thermoplastic powder is sprinkled over the wet ink. This powder melts during the curing stage and becomes the glue that bonds the print to the garment.

- A Curing Oven or Heat Press: This piece of kit is used to melt the adhesive powder on the film, getting the transfer ready for its final journey onto the t-shirt, hoodie, or bag.

This modular system is a huge reason for the technology's explosion in popularity. The numbers back it up; in the UK, the wider film printing sector is forecast to hit a value of USD 5.2 billion by 2034, with DTF advancements being a major driver of that growth.

The real secret sauce of the DTF process is its independence from the final fabric. By creating the graphic on a film first, you unlock the freedom to decorate materials like polyester, nylon, and tricky blends that often give other digital printing methods a headache.

Why It's a Go-To Choice for So Many

This blend of versatility and straightforward operation makes the dtf printing machine a fantastic option for businesses of all shapes and sizes. It’s just as suitable for a startup printing small batches of custom tees as it is for a large-scale company churning out branded workwear.

The process of creating ready-to-press DTF transfers is efficient and repeatable, giving businesses a way to produce top-quality custom apparel with a relatively low barrier to entry. It’s this perfect balance of quality, flexibility, and operational simplicity that keeps pushing its adoption across the entire customisation industry.

The Complete DTF Printing Workflow Step by Step

To really get your head around how a DTF printing machine works, it’s best to walk through the entire journey, from a simple digital file to a finished piece of clothing you can wear. It's a surprisingly satisfying process, with each stage building on the last to create something vibrant and long-lasting.

Let's break down exactly what happens to your artwork.

The whole workflow is logical and repeatable, which is a huge part of its appeal for businesses needing consistent, high-quality results. Forget messy pre-treatments or the tedious weeding you get with vinyl – the DTF process is clean, contained, and efficient.

Stage 1: Preparing and Printing Your Design

It all begins with your artwork on a computer. Using specialised RIP (Raster Image Processing) software, you get your design file ready for printing. This bit of software is essentially the brains of the operation, telling the printer exactly how to layer the inks to get the best possible result, no matter the colour of the fabric.

Once the file is good to go, the printing starts. But here's the clever part: the DTF machine doesn't print directly onto the garment. Instead, it prints onto a special PET transfer film. It first lays down the colours (Cyan, Magenta, Yellow, and Black), then follows up with a perfectly aligned layer of opaque white ink right on top. This white base is absolutely crucial – it’s what makes your design truly pop on any fabric, from bright white to jet black.

Stage 2: Applying Adhesive Powder and Curing

With the ink still wet on the film, it's time to add the "glue" that will bind the design to the garment. The printed film gets a dusting of a fine thermoplastic adhesive powder. This stuff is designed to stick only to the wet ink, so the rest of the film stays clean.

Bigger, automated setups use a shaker to apply the powder and knock off the excess, but you can also do it by hand in a smaller operation. The end result is your design, perfectly coated in a layer of potential adhesive.

To activate that adhesive, the film needs to be cured. It's either passed through a small curing oven or placed under a heat press that's hovering just above the surface, not touching it. This melts the powder, turning it into a smooth, slightly rubbery layer that seals the ink in. At this point, you've got a finished, ready-to-use DTF transfer.

The curing stage is a make-or-break moment in the DTF process. It’s where the ink and powder fuse into a single, durable, and flexible transfer sheet. Nailing this step is key to getting that soft feel and fantastic wash resistance in the final product.

Stage 3: Heat Pressing and the Final Peel

This is the final step, where your transfer finally meets the fabric. The cured film is placed onto the garment—whether it's a t-shirt, a hoodie, or a tote bag—and pressed with a standard heat press. The combination of heat and pressure fires up that adhesive layer, permanently bonding the ink into the fabric's fibres.

To get this critical step just right, our comprehensive heat press temperature guide gives you detailed settings for different materials, helping you get a perfect application every time. After pressing for about 15 seconds at a temperature of around 160°C, the magic is nearly complete.

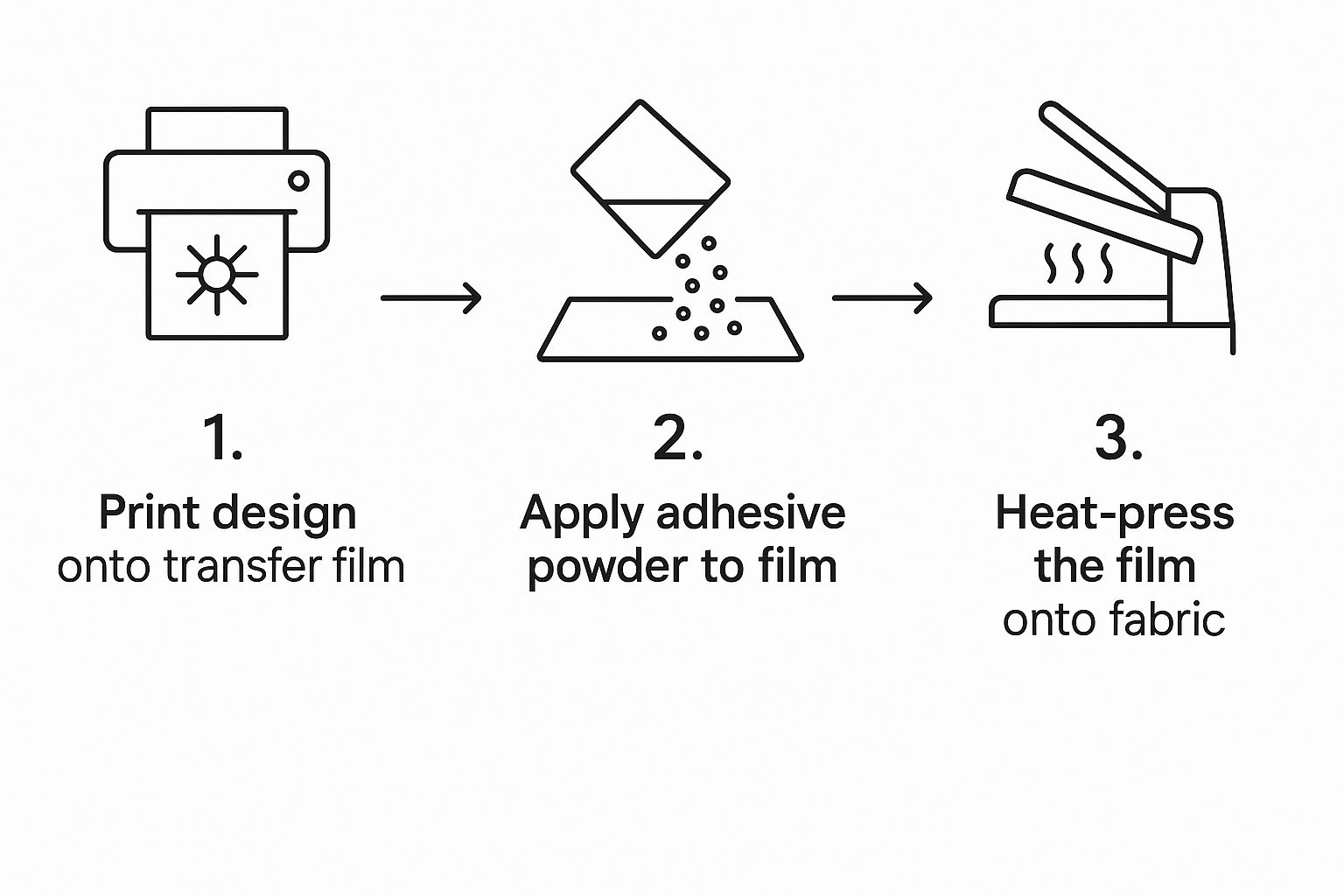

The infographic below gives a great visual summary of this core three-part process, showing the journey from film to fabric.

This shows exactly how each phase—printing, powdering, and pressing—links together to create the final product.

The process ends with the "cold peel." Once the garment has fully cooled down, you simply peel away the PET film. What you're left with is your crisp, full-colour design, now beautifully part of the fabric. The result is a professional-grade print that not only looks fantastic but is also incredibly soft, flexible, and tough enough to last through dozens of washes without cracking or fading.

How DTF Printing Stacks Up Against Other Methods

Choosing the right way to decorate a garment can feel like a massive decision. Each technique has its own personality, with a unique set of strengths and weaknesses. A DTF printing machine brings some incredible skills to the workshop, but to really get why it's a big deal, you need to see how it compares to the other giants of the industry.

This isn't about finding one "best" method that rules them all. It's about finding the right tool for the job you need to do, whether that's fulfilling online orders, stocking a retail shop, or growing your brand. So, let’s put DTF head-to-head with its main rivals: Direct-to-Garment (DTG), traditional screen printing, and heat transfer vinyl (HTV).

The momentum behind DTF is impossible to ignore. By 2022, DTF machines already accounted for about 44.5% of all garment printing equipment used across the globe. Forecasts suggest that figure could climb to a massive 64.4% by 2027, largely thanks to its efficiency and lower running costs.

DTF Printing vs Direct-to-Garment (DTG)

At a glance, DTF and DTG look like twins. They’re both digital processes that can produce stunning, full-colour prints with no minimum order quantities. The real difference, though, is in how the ink actually gets onto the fabric.

DTG printers work by spraying ink directly onto the garment, where it soaks into the fibres. This gives the print an incredibly soft feel, but it comes with a major catch: it really only works well on 100% cotton. It also demands a messy and time-consuming pre-treatment process, especially for darker garments.

DTF flips this on its head by printing onto a film first. This transfer-based approach means it couldn't care less what the fabric is made of, and that’s DTF’s superpower.

- Fabric Freedom: DTF is a champion on polyester, nylon, and blends—materials that often make DTG machines stumble.

- No Pre-Treatment: The DTF workflow completely skips the pre-treatment step, which is a huge saving in time, mess, and labour.

- Vibrancy: Because the ink sits on top of the fabric instead of soaking in, DTF prints often look punchier and more vibrant.

DTG prints feel softer because the ink literally becomes part of the fabric. DTF creates a thin, flexible layer on the surface. While modern DTF transfers feel great, there's a definite difference you can feel with your hands.

DTF Printing vs Screen Printing

Screen printing is the undisputed king of high-volume apparel production. For decades, it has been the go-to for creating durable, vibrant prints by pushing ink through a mesh screen. If you need to print thousands of t-shirts with a simple one or two-colour design, screen printing is almost always the cheapest per piece.

But its setup process is a beast. You have to create a separate screen for every single colour in a design, which makes it totally impractical and expensive for small batches or detailed, photographic prints.

This is exactly where a DTF printing machine comes into its own.

- Full-Colour Simplicity: DTF handles unlimited colours in a single pass with zero extra setup.

- Small Batch Efficiency: It's perfect for one-off custom jobs or small orders because the setup cost per design is effectively zero.

- Fine Detail: DTF can reproduce tiny details and smooth gradients that are a real headache for screen printing.

Screen printing embeds the ink deep into the fabric, while DTF bonds a transfer to the surface. You can dive deeper into this matchup in our article comparing DTF vs screen printing for graphic tees.

DTF Printing vs Heat Transfer Vinyl (HTV)

Heat Transfer Vinyl, or HTV, involves cutting your designs out of coloured vinyl sheets and then using a heat press to apply them. It’s a hugely popular choice for simple things like text, numbers, and blocky graphics—think personalising football jerseys or making a one-off funny t-shirt.

While HTV is easy for hobbyists to get into, it becomes incredibly tedious for anything complex or multi-coloured. Every single colour has to be cut, "weeded" (the painstaking process of picking out the unwanted bits of vinyl), and pressed as a separate layer.

DTF offers a far more professional and efficient solution. You get the full-colour freedom of a digital process without any of the soul-destroying labour of weeding vinyl. A complex, multi-coloured company logo that could take an hour with HTV can be printed and pressed with DTF in just a few minutes.

DTF vs DTG vs Screen Printing Comparison

To make things even clearer, we've put together a simple table. This gives you an at-a-glance summary of how these popular methods compare across the factors that matter most to any custom apparel business.

| Feature | DTF Printing | DTG Printing | Screen Printing |

|---|---|---|---|

| Best For | Versatility, all fabrics, full colour | Soft feel on cotton, photos | High volume, simple designs |

| Fabric Range | Excellent (cotton, poly, blends, etc.) | Limited (best on 100% cotton) | Good (most fabrics work) |

| Colour Ability | Unlimited colours, one pass | Unlimited colours, one pass | Limited by screen count |

| Durability | Very good (50+ washes) | Good (can fade over time) | Excellent (industry standard) |

| Feel of Print | Soft, flexible layer on fabric | Extremely soft, no feel | Varies (can be thick) |

| Setup Cost | Low (no cost per design) | Low (no cost per design) | High (screens are expensive) |

| Small Batches | Highly efficient and profitable | Highly efficient and profitable | Very inefficient and costly |

As you can see, each method has a clear place in the market. While screen printing remains the powerhouse for bulk orders, and DTG excels on cotton, DTF has carved out a huge space as the ultimate all-rounder.

Choosing the Right DTF Printing Machine

Jumping into DTF printing by buying your own machine is a huge move for any business. It's the difference between buying transfers and taking full control of your entire production line. It’s a decision that really deserves some careful thought.

To make a choice you’ll be happy with, you need to look past the price tag. It's about understanding the core features that will shape your daily workflow, the quality of your prints, and what it’s actually going to cost you to run in the long term. This isn't about finding the 'best' machine out there, but the best one for you.

Let's break down the critical bits and pieces to look at, turning all that technical jargon into practical business sense.

Print Head Technology Explained

The print head is the heart and soul of any DTF machine. It’s the component that precisely fires ink onto the film, and its quality is what determines your speed, resolution, and day-to-day reliability. You'll often see model names like Epson i3200 or XP600 thrown around in the specs. These aren't just random numbers; they represent completely different levels of performance.

An Epson i3200 print head, for instance, is a proper commercial-grade workhorse. It's known for its speed and durability, making it the go-to for businesses that are pushing out high volumes of prints every day. On the other hand, an XP600 is a more budget-friendly option you'll find in entry-level or desktop models. It offers great quality for smaller setups but runs at a much slower pace.

Think of the print head like the engine in a car. An XP600 is like a reliable city car engine—perfect for daily errands and smaller jobs. The i3200 is a high-performance engine built for the motorway—designed for speed, endurance, and consistent output day after day.

Print Width and Production Scale

The maximum width your machine can print is what sets your production scale and the kinds of products you can make. DTF machines generally come in a few common sizes:

- A3/A4 Desktop Models (Approx. 30cm): These are compact and don't break the bank. They're perfect for startups, small Etsy shops, or businesses mainly making smaller items like custom t-shirts or tote bags.

- Medium-Format (Approx. 60cm): This is the sweet spot for a lot of growing businesses. A 60cm width lets you print multiple designs side-by-side (what we call 'ganging'). This massively boosts your efficiency and makes you a top contender when it comes to finding the best custom t-shirt printers for B2B work.

- Large-Format (Over 60cm): These are industrial beasts, built for serious, high-volume production. They’re designed to run around the clock, churning out thousands of transfers daily.

Picking the right width is all about balancing your ambition with your budget and space. A wider machine means higher output and a lower cost per print, but only if you have the orders to justify it.

The Non-Negotiable White Ink System

White ink is the secret sauce in DTF, but it's also the biggest maintenance headache you'll face. The titanium dioxide particles that make the ink so brilliantly opaque are heavy. They love to settle at the bottom of the tank, and that leads to clogged print heads—a repair that is both costly and incredibly frustrating.

This is exactly why a White Ink Management System (WIMS) is an absolutely essential feature. A good WIMS continuously circulates or agitates the white ink, stopping those particles from settling and keeping everything in a print-ready state. Cheaper machines might skimp on this, but trust me, it’s a false economy that will almost certainly lead to downtime and expensive repairs down the line.

Workflow and Automation Features

Think about how the machine will actually fit into your day-to-day work. Many commercial systems are now "all-in-one" solutions where the film rolls straight out of the printer and into an automated powder shaker and curing unit. This creates a seamless, hands-off process from the moment you hit 'print' to having a finished transfer ready to press.

For any piece of industrial kit, DTF printers included, it's wise to consider the potential industrial energy consumption. An automated system doesn't just save you on labour; it can often be more energy-efficient than running and powering multiple separate pieces of equipment.

Finally, don't overlook the RIP software that comes with the machine. This software is the brain of the whole operation. It controls your ink levels, manages colour profiles, and figures out how to lay down the white and colour inks perfectly. A quality RIP like CADlink or neoStampa gives you precise control, ensuring you get vibrant colours and use your ink efficiently, which directly impacts your final print quality and, of course, your profit margins. A machine bundled with powerful, user-friendly software is a massive head start.

Real-World Applications for DTF Printing

Theory is one thing, but seeing how a DTF printing machine performs in the real world is where you really start to see the magic. This technology isn't just for slapping logos on basic tees; its incredible versatility opens up a massive range of creative and commercial opportunities for all kinds of businesses.

From hard-wearing sportswear to high-fashion pieces, DTF printing is a powerful way to decorate items that other methods just can't touch. Let's look at some of the exciting ways this machine becomes a proper business-building tool.

Custom Sportswear and Performance Gear

Athletic gear has always been a headache to print on. Most of it is made from polyester, nylon, or spandex blends—materials that famously don't play well with the water-based inks used in DTG printing. Screen printing can work, but the inks often feel thick and heavy, which is the last thing you want on stretchy, breathable fabric.

This is exactly where DTF shines. A DTF transfer bonds perfectly to synthetic fabrics, creating a design that is:

- Incredibly stretchy: The print moves and flexes with the fabric without cracking or peeling, which is essential for performance wear.

- Vibrant and sharp: Colours stay bold and bright, even on materials that are notoriously difficult to print on.

- Durable: It can handle the tough life of sports gear, from muddy pitches to frequent washes.

This makes DTF the go-to choice for creating custom football kits, running vests, and gym wear that looks professional and performs brilliantly.

Being able to print on polyester without any pre-treatment is arguably DTF's biggest advantage. It unlocks the entire sportswear and athleisure market, a massive sector that remains a huge challenge for most other digital printing techniques.

Professional Branded Workwear

Companies need their branding to be consistent and tough, especially on workwear that gets put through its paces every single day. From high-vis jackets for construction workers to polo shirts for corporate events, the garments need to look sharp and last.

A DTF printing machine is perfectly built for this job. It can reproduce detailed company logos with perfect colour matching, and the prints are robust enough to withstand industrial laundering. This means staff uniforms keep looking professional for much, much longer.

The apparel sector, particularly for things like personalised T-shirt printing, was the biggest end-user for DTF in 2023. This demand is driven by UK businesses needing reliable, on-demand customisation for their promotional merchandise and staff uniforms.

Fashion and Independent Clothing Brands

For fashion designers and independent streetwear brands, freedom is everything. They need to be able to experiment without being tied down by huge setup costs or minimum order quantities. DTF gives them the perfect platform for creativity, allowing them to produce complex, full-colour designs on a massive variety of garments.

Designers can print intricate, photographic-quality images onto anything from cotton hoodies to denim jackets. For a closer look at the possibilities, you can check out our guide on t-shirt printing personalised for your brand. This flexibility makes small-batch releases and limited-edition drops not just possible, but easy—a must for staying ahead in the fast-moving fashion world.

Beyond Apparel: Accessories and More

But it doesn't stop with clothing. The same process that works on a t-shirt works just as well on a whole host of other fabric-based products, making it simple for businesses to branch out and diversify what they offer.

Some popular non-apparel items include:

- Tote Bags and Backpacks: Create vibrant, durable promotional bags or unique retail products.

- Hats and Caps: DTF transfers are flexible enough to be applied to the curved surfaces of headwear with ease.

- Leather Patches: The adhesive works surprisingly well on treated leather, creating premium-looking patches for jackets and bags.

- Canvas Shoes: Customise footwear with unique, eye-catching designs that would be impossible with other methods.

This ability to print on almost anything opens up endless possibilities for creating unique and profitable product lines.

Common Questions About DTF Printing Machines

Jumping into any new printing technology is a big decision, and it’s totally normal for questions to pop up. When you’re thinking about investing your hard-earned money into a DTF printing machine, you want to have all the facts straight.

This section is all about tackling those common queries and concerns head-on. We'll give you clear, straightforward answers to help you get a real feel for what it's like to own and operate one of these powerful machines.

How Durable Are DTF Prints Compared to Screen Printing?

This is easily one of the first questions people ask, and the answer is great news. DTF prints are incredibly durable, often lasting just as long—and sometimes even longer—than many traditional screen prints.

When you apply the transfer properly with a good quality heat press, the adhesive layer creates a seriously strong bond with the fabric fibres. This makes the print highly resistant to cracking, peeling, and fading, and you can expect it to hold up for 50+ washes without any major breakdown.

The feel is often softer and more flexible than those thick, heavy plastisol screen prints, especially on designs with lots of colours. While screen printing ink soaks into the fabric, the clever adhesives in DTF create a powerful yet flexible bond on the surface that performs brilliantly for almost any apparel you can think of.

What Is the Average Cost to Get Started with a DTF Setup?

The initial investment for a full DTF setup can vary quite a bit, depending on the size and automation you're after. It's helpful to think about it in a few different tiers.

An entry-level desktop system, perfect for small businesses, Etsy sellers, or hobbyists, will typically set you back between £3,000 and £7,000. This price usually gets you the printer, a manual powder and curing solution, and the essential RIP software.

If you’re ready for a more commercial-grade setup with a wider printer (like a 60cm model) and an all-in-one automatic powder shaker and dryer, you’re looking at a range of £10,000 to £25,000 or more. And don't forget to budget for your first batch of supplies!

- DTF Ink: Specialised textile inks (CMYK and White).

- PET Film: The transfer rolls you print your designs on.

- Adhesive Powder: The clever thermoplastic "glue" that makes it all stick.

You should probably set aside an extra £500 to £1,000 for these initial consumables to get your production started without a hitch.

A common mistake is just looking at the printer's price tag. Always remember to factor in the cost of a high-quality heat press, a computer that can handle the RIP software, and proper ventilation, as the curing process can create fumes.

What Are the Main Maintenance Tasks for a DTF Printer?

This is a big one: consistent, daily maintenance is absolutely vital for keeping a DTF printing machine running smoothly. The main challenge is the white ink, and honestly, skipping these simple tasks is the number one reason people run into print quality problems and costly repairs.

The daily jobs are non-negotiable but only take a few minutes. You’ll need to clean the print head capping station, the wiper blade, and the area around the print head to stop ink from building up and drying out. Firing off a quick nozzle check print each morning is another key habit to make sure every channel is ready to go.

Most modern printers have a White Ink Management System (WIMS) which automatically circulates the ink to stop the heavy white pigment from settling and clogging the lines. Even so, it's a good idea to give the ink cartridges a gentle shake yourself, especially if the machine hasn't been used for a day or two.

Can I Really Print on Almost Any Fabric with DTF?

Yes, this isn’t just marketing fluff—the fabric versatility is genuinely DTF's superpower. It's the single biggest advantage it has over most other printing methods.

The technology works beautifully on a huge range of materials. Of course, it nails all the basics like 100% cotton, polyester, and poly/cotton blends. But it also shines on trickier fabrics like nylon, denim, canvas, and even certain types of treated leather.

Unlike DTG printing, which needs natural fibres and a pre-treatment spray, the DTF transfer method works perfectly on both light and dark garments without changing a thing. This makes it an ideal all-in-one solution for anyone looking to decorate a wide variety of items, from sportswear and workwear to promotional gear where other methods just can't compete. This incredible adaptability is what makes a DTF printing machine such a valuable tool for any customisation business.

Ready to bring your own creative ideas to life with the power of DTF? At Psyque - DTF Print & Press, we use this incredible technology to produce vibrant, durable, and unique apparel. Explore our collections or get in touch for your own custom project by visiting us at https://psyque.co.uk.