A Guide to Modern DTF Printing

Share

Direct-to-Film (DTF) printing is a fantastic way to get vibrant, tough-as-nails designs onto just about any fabric you can think of. The easiest way to picture it is creating a high-quality, super-flexible sticker that’s made specifically for textiles. A digital design gets printed onto a special film, which is then dusted with an adhesive powder, and finally heat-pressed to permanently become one with the material.

What Exactly Is DTF Printing?

So, let's break down what’s actually happening behind the scenes. At its heart, DTF printing bridges the gap between a design on your computer and a finished piece of clothing. It offers an incredibly versatile way to transfer complex, full-colour images onto a massive range of materials, sidestepping the limitations that come with older printing methods.

Unlike techniques that print ink directly onto the garment, DTF uses an intermediary – a special PET (Polyethylene Terephthalate) film. This film acts as a carrier for your design, allowing for a unique two-step process that guarantees a crisp, consistent result every time. The final print feels smooth and almost part of the fabric, yet it’s impressively stretchy and holds up brilliantly in the wash.

The Core Components of DTF

To really get your head around how DTF works, it helps to know the key players in the process. Each piece of the puzzle has a very specific job to do, and they all work together to create that professional-quality transfer. Think of it like a recipe where every single ingredient is essential for the final result.

- Specialised DTF Printer: This is no ordinary office printer. It’s built to handle specific textile inks and, crucially, has extra channels for white ink. That white ink acts as a base layer, which is what makes designs pop on dark-coloured fabrics.

- DTF Inks: These are pigmented, water-based inks made to be flexible and durable. They’re designed to bond perfectly with the adhesive powder and survive countless wash cycles without cracking or fading.

- PET Transfer Film: This is the temporary home for your design. The film is engineered to hold the ink with incredible precision and then release it cleanly onto the garment when the heat is applied.

- Hot-Melt Adhesive Powder: This fine, granular powder is where the magic happens. After printing, this powder is sprinkled over the wet ink. It’s then melted to create a powerful adhesive layer that literally locks the print into the fabric’s fibres.

- Heat Press: This is the final step. A heat press applies the perfect amount of heat and pressure to transfer the design from the film to the garment, permanently curing the ink and adhesive in one go.

The growing popularity of this system is easy to see in the market numbers. The global DTF printer market was valued at around $667 million in 2025 and is set to continue its steady climb. This trend is a clear reflection of a wider shift towards on-demand printing solutions here in the UK, especially for entrepreneurs who need flexible and cost-effective ways to create products.

DTF printing is a modern method that builds upon advancements in broader digital printing technologies. It combines the pinpoint accuracy of digital imaging with the satisfying feel of a heat-applied transfer, making it a seriously powerful tool for customising fabrics. If you're curious about how this applies to specific items, you might find our guide on custom t-shirt printing helpful.

How the DTF Printing Process Works

To really get what makes DTF printing so good, you need to understand the journey from a digital file to a finished garment. It’s a bit like assembling high-quality furniture – each step builds on the last. If you get one part wrong, the final product just won’t have the professional finish or durability you’re after.

The whole process is methodical, but it’s not as complex as you might think. It’s built for consistency, ensuring the tenth t-shirt you print looks just as crisp and vibrant as the first. Let’s walk through the entire workflow, from start to finish.

Step 1: Preparing Your Digital Artwork

Before a single drop of ink is used, your design needs to be print-ready. This first stage is absolutely vital for making sure the final print is sharp and looks exactly how you pictured it. Think of it as creating the perfect blueprint before you start building.

Your design file should be high-resolution, ideally 300 DPI (dots per inch), to avoid any fuzziness. The artwork is usually saved as a PNG with a transparent background. This is crucial because the printer only lays down ink where your design is, leaving the rest of the film completely clear. Specialised RIP (Raster Image Processing) software then gets the image ready, managing the colours and creating the all-important white base layer that gets printed first.

Step 2: Printing onto the Transfer Film

With the artwork prepped, it's time to print. A specialised DTF printer takes the design from the RIP software and prints it straight onto a sheet of PET transfer film. This isn't just any old plastic sheet; it’s been chemically treated to hold the wet textile inks perfectly, stopping them from bleeding or running.

One of the cleverest parts of DTF printing is how the ink is layered. The printer first puts down the full-colour (CMYK) design, and then, in the same pass, it prints a perfectly aligned layer of white ink right on top. This white layer does two things: it acts as a base to make the colours really pop on darker fabrics, and it provides a tacky surface for the adhesive powder to stick to.

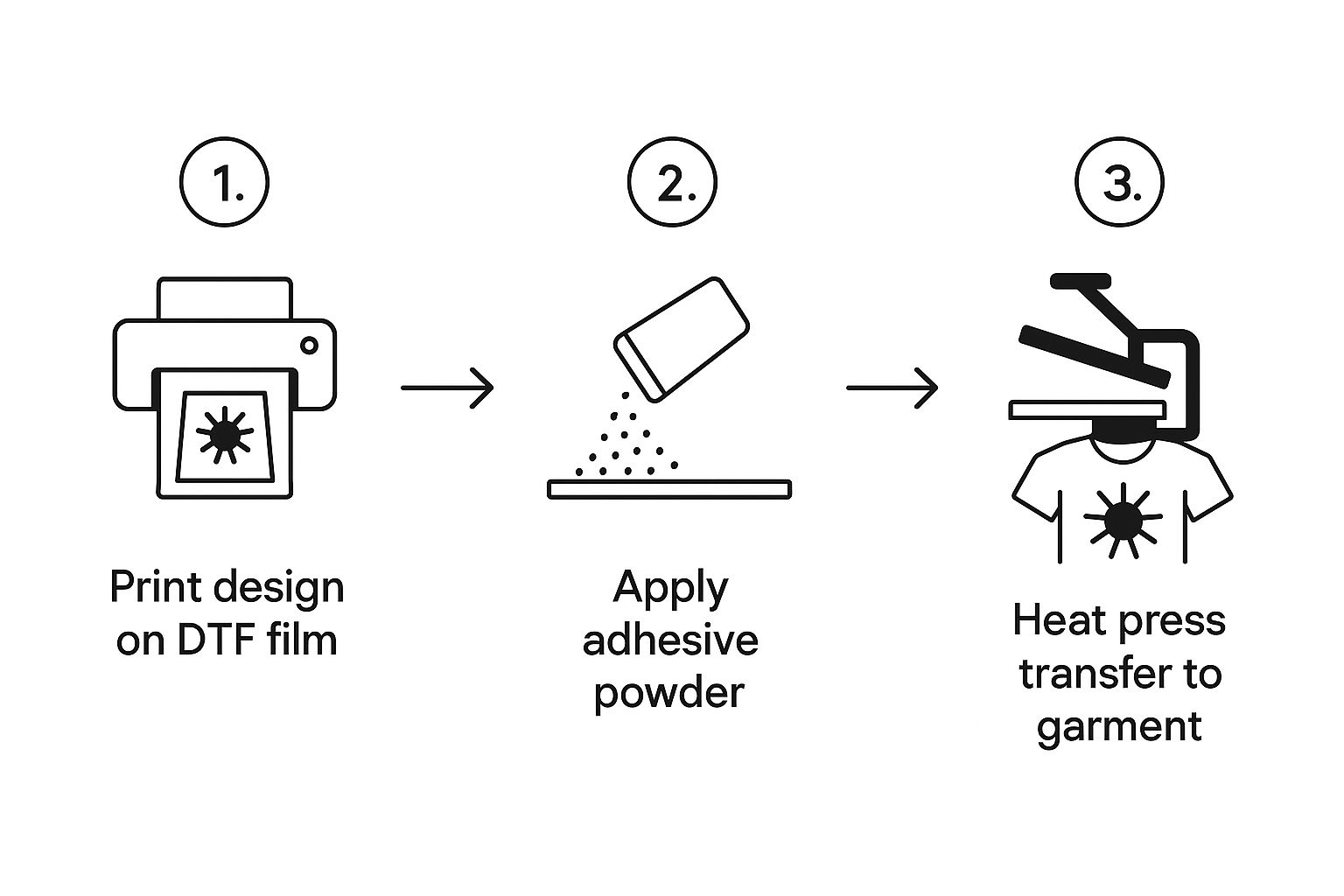

This quick look shows the main stages of getting a design from screen to shirt.

As you can see, the workflow moves logically from printing the design, to applying the adhesive, and finally to pressing it onto the garment.

Step 3: Applying and Curing the Adhesive Powder

While the ink on the film is still wet, it's time for the hot-melt adhesive powder. This fine, grainy polymer is basically the "glue" that will permanently bond your design to the fabric. The film is coated generously with the powder, making sure every last bit of wet ink is covered.

Any extra powder that hasn't stuck to the ink is then shaken off, leaving a clean, precise layer of adhesive only where the design is.

The next part is curing. The coated film is placed in a curing oven or under a heat press that’s hovered just above the surface. The heat melts the powder, turning it from a grainy texture into a smooth, even sheet of adhesive. This is probably the most important step for making sure the print lasts.

Step 4: Heat Pressing the Transfer

Now, the prepared transfer is ready for its final destination. The garment is laid flat on the heat press, and the DTF film is placed design-down onto the fabric. The press is then closed, applying a specific combination of heat (usually around 150-170°C), time, and firm pressure. This heat reactivates the adhesive, letting it melt right into the fibres of the fabric to create an incredibly strong and permanent bond. For those who want great results without buying all the gear, getting professional DTF transfers is a brilliant option.

Step 5: The Final Peel

After pressing, the garment just needs a moment to cool down. The very last step is peeling the PET film away. Depending on the type of film and powder you’ve used, this is known as a "cold peel" or "warm peel". As you pull the film back, the design stays perfectly bonded to the garment, leaving you with a vibrant print that feels soft, stretchy, and is amazingly durable.

Your Essential DTF Printing Toolkit

Putting together your DTF printing setup is a bit like stocking a professional kitchen. You can't just 'make do'—having the right tools is absolutely essential if you want to get consistently brilliant results. Every piece of equipment, from the printer to the powder, plays a critical part in turning that digital file on your screen into a durable, high-quality print you can be proud of.

This guide will walk you through the core components you’ll need, whether you’re just starting a small side hustle from your garage or looking to scale up a full-blown commercial operation. We’ll cover the hardware that does the heavy lifting and the all-important materials that bring your designs to life.

Core Hardware The DTF Printing Machine

The centrepiece of any DTF operation is, of course, the specialised DTF printer. This isn’t your average desktop inkjet. It's a purpose-built machine designed from the ground up to handle pigmented textile inks. Its most important feature? The ability to print with white ink, which is the secret sauce for creating vibrant, opaque designs on dark or brightly coloured fabrics.

When you're shopping for a printer, here are a few key things to look out for:

- Print Width: Entry-level models that handle A3 or A4 sizes are perfect for T-shirts and smaller items. If you're planning for high-volume production, you’ll want to look at larger commercial printers that can manage wide rolls of film.

- Ink System: A reliable white ink circulation system is non-negotiable. This feature is vital for preventing the white ink pigment from settling and clogging the print heads, which is a common and frustrating maintenance headache.

- RIP Software: The printer must come with good Raster Image Processing (RIP) software. This is the brain of the operation, controlling how the ink layers are put down. It ensures the colour and white layers align perfectly and manages colour profiles for accurate, consistent output.

Many people also opt for an all-in-one unit that combines printing, powdering, and curing into a single, automated process. These systems can seriously streamline your workflow, cutting down on manual labour and boosting your output speed.

Consumables The Raw Materials for Success

Beyond the printer, your day-to-day operations will rely on a steady supply of high-quality consumables. Trying to cut corners here is a false economy—it almost always leads to poor print quality, failed transfers, and a lot of wasted material.

Think of your consumables as the high-quality ingredients for a recipe. The final product is only ever as good as what you put into it. Using premium film, ink, and powder is what guarantees that vibrancy, durability, and professional finish every single time.

DTF PET Transfer Film This is the carrier sheet that holds your design until it's pressed. Not all films are created equal; you need a high-quality PET (Polyethylene Terephthalate) film with a specialised coating. A good film holds the ink droplets precisely without any bleeding and will be designed for either a "cold peel" or "hot peel"—referring to when you remove the film after pressing. You can find options like these A4 DTF transfer sheets to get a feel for how they are supplied.

DTF Inks These are specially formulated, water-based pigment inks. They need to be flexible enough to stretch with the fabric without cracking, yet durable enough to withstand wash after wash. A standard set includes Cyan, Magenta, Yellow, and Black (CMYK), plus that all-important White ink.

Hot-Melt Adhesive Powder This fine polymer powder is the magic "glue" that bonds the print to the fabric. After printing, you sprinkle it over the wet ink and then melt it to form a smooth, even adhesive layer. The powder comes in different grades (fine, medium, coarse), and your choice will depend on the level of detail in your design and the fabric you're printing on.

DTF Printing vs Other Methods

Choosing the right way to print on fabric can feel a bit like navigating a minefield. You've got several strong contenders, and each one claims to be the best. Direct-to-Film (DTF) has burst onto the scene in a big way, but to really know if it’s for you, you need to see how it stacks up against the old guard: Direct-to-Garment (DTG), screen printing, and heat transfer vinyl (HTV).

Honestly, there’s no single "best" method. It all comes down to what you’re trying to achieve. The right choice hinges entirely on your specific needs – what fabric you’re using, how complex your design is, the size of your print run, and of course, your budget.

Printing Method Comparison DTF vs DTG vs Screen Printing vs Vinyl

To make sense of the options, it helps to see them side-by-side. Each technique has its own ideal scenario, and what works for a 500-shirt order is completely different from what you'd need for a one-off custom piece.

Here’s a quick breakdown of how these four popular methods compare across the most important factors.

| Feature | DTF Printing | DTG Printing | Screen Printing | Heat Transfer Vinyl |

|---|---|---|---|---|

| Best For | Small-to-medium runs, full-colour graphics, printing on diverse materials | One-offs, small runs, photorealistic prints on cotton | High-volume orders (100+), simple designs with limited colours | Simple text, logos, names/numbers, one-off customisation |

| Fabric Compatibility | Excellent (cotton, polyester, blends, leather, nylon) | Limited (best on 100% cotton; struggles with synthetics) | Very good (works on most fabrics, but ink may need changing) | Excellent (works on cotton, polyester, blends, and more) |

| Feel of Print | Smooth, sits on top of the fabric, slightly plastic-like but flexible | Very soft, breathable, ink soaks into the fabric | Can be thick, but durable; sits on top of the fabric | Thick, especially with layers; can feel stiff and heavy |

| Colour & Detail | Unlimited colours, photorealistic detail, excellent vibrancy | Unlimited colours, fantastic detail, but can look faded on dark fabrics | Limited by the number of screens; each colour adds significant cost/labour | Limited to available vinyl colours; layering is difficult for complex designs |

| Durability | Excellent; very durable and flexible, resists cracking and peeling | Good, but can fade over time with repeated washing | Excellent; one of the most durable methods, often outlasts the garment | Good, but can peel or crack over time, especially with improper application |

| Setup Cost | Low; no per-design setup required | Low; no setup needed, print directly from a digital file | High; requires creating a separate screen for each colour in the design | Low; requires only vinyl and a cutter |

Ultimately, this table shows there's a tool for every job. DTF shines with its incredible versatility, while screen printing remains the undisputed king of bulk production.

DTF vs Direct-To-Garment (DTG)

At first glance, DTF and DTG seem like two sides of the same coin. They’re both digital, brilliant for detailed, full-colour prints, and perfect for small runs without the hassle of a big setup. The real difference, though, is how the ink actually gets onto the shirt.

DTG is basically a fancy inkjet printer for clothes. It sprays water-based inks directly onto the fabric, where they soak into the fibres. The result is a print that feels incredibly soft and breathable. But here's the catch: DTG is a bit of a diva when it comes to materials. It really only performs well on 100% cotton and often needs a pre-treatment liquid to get decent results on anything else, especially polyester.

DTF sidesteps this whole problem. By printing the design onto a film first and then heat-pressing it, DTF gains a massive advantage.

- Fabric Compatibility: DTF wins this one, hands down. It works beautifully on cotton, polyester, nylon, leather, you name it. DTG is pretty much stuck in the cotton camp.

- Print Feel: Because DTG ink becomes part of the fabric, the print feels much softer. A DTF print sits on top, giving it a very smooth, durable feel that’s less breathable but incredibly tough.

- Vibrancy on Dark Colours: Both use a white ink base for dark garments, but DTF often looks brighter and more opaque. The entire design is transferred as a single, solid layer, which really makes the colours pop.

For anyone needing to print on a wide range of products, DTF is a game-changer. It takes the guesswork out of fabric choices and delivers consistently vibrant results every time.

DTF vs Screen Printing

Screen printing has been the heavyweight champion of the t-shirt world for decades, and for good reason. It’s known for creating prints that are tough as nails and incredibly cost-effective for large orders. The process involves pushing ink through a stencilled mesh screen onto the garment, one colour at a time.

And that’s the key difference. Screen printing is an analogue process with a lot of upfront work. Making the screens is a labour-intensive job, making it completely impractical for a small batch or a design with a rainbow of colours. A six-colour design means six separate screens need to be prepped and aligned perfectly.

DTF, being fully digital, has none of that. It can print a photorealistic image with a million colours in one go. This makes it a far smarter choice for small to medium-sized orders. If you want to go deeper on this, our article on DTF vs screen printing for graphic tees really gets into the nitty-gritty.

- Order Size: For bulk orders (think 100+ items), screen printing is still king. The setup costs get absorbed and the price per shirt plummets. For small runs, samples, or on-demand jobs, DTF is the clear winner.

- Colour Complexity: DTF eats complex, multi-coloured designs for breakfast, with no extra cost. With screen printing, every additional colour adds another layer of cost and complexity.

- Durability: This is a close one. Both methods produce prints that can easily outlast the garment itself. Screen printing ink bonds deep into the fibres, while a properly applied DTF transfer forms an incredibly strong, flexible layer on top.

DTF vs Heat Transfer Vinyl (HTV)

Heat Transfer Vinyl, or HTV, is the go-to for many hobbyists and for simple, bold graphics. The process is straightforward: you cut your design from a sheet of coloured vinyl, then use a heat press to stick it to the garment.

It’s fantastic for things like names and numbers on sports jerseys or single-colour logos. But the moment your design gets more complex, HTV starts to show its limitations. Every single colour needs to be cut from a separate piece of vinyl and then carefully layered on top of the others. It's slow, fiddly, and getting the alignment just right can be a nightmare.

DTF swoops in and solves all of these problems. It gives you the same easy heat-press application but with the power to produce a detailed, full-colour graphic in a single step. There’s no cutting, no weeding tiny pieces, and no layering. This not only saves a huge amount of time but also results in a final print that’s much thinner and more flexible than a bulky, multi-layered vinyl design.

The Real Advantages of DTF Printing

When you're looking at different printing methods, it’s easy to get bogged down in technical jargon. What really matters is knowing the actual benefits you’ll see every day, and just as importantly, the headaches you might run into. DTF printing has a lot going for it, but like any technology, it has its own quirks. Let’s take a proper, balanced look at what you can really expect.

The biggest win for DTF is its incredible versatility. Other methods can be notoriously fussy about fabrics, but DTF is the jack-of-all-trades of the printing world. It handles cotton, polyester, nylon, treated leather, and tricky poly-blends without batting an eyelid. This immediately opens up a massive catalogue of items you can print on, from the usual t-shirts to jackets, hats, and tote bags.

For businesses here in the UK, this flexibility is a huge advantage. Being able to print vibrant, full-colour images on almost any fabric lets you tap into all sorts of markets, from fashion to corporate wear. This versatility, along with a pretty efficient workflow, also fits nicely with the growing demand for more sustainable production. You can read more about its growth in the global direct-to-film printing market forecast.

Unpacking the Key Benefits

The perks go way beyond just working with different materials. The quality and durability of the finished print are where DTF really begins to shine, producing results that can easily go toe-to-toe with older, more established techniques.

- Exceptional Detail and Colour Vibrancy: Because the ink goes onto the film first, it doesn't soak into the fabric and look dull. This simple step leads to amazingly sharp lines and photorealistic detail. The white ink base acts as a primer, making sure colours pop with brilliant opacity, even on the darkest garments.

- Impressive Durability: A DTF transfer that’s been applied correctly is built to last. The print holds up incredibly well against washing, stretching, and cracking. The flexible layer of ink and adhesive bonds so strongly with the fabric that it often outlasts the garment itself.

- No Pre-Treatment Required: This is one of the biggest time-savers. Methods like DTG demand a messy and slow pre-treatment stage, especially for dark clothing. DTF skips this step entirely, saving you time, money, and a lot of hassle.

The real magic of DTF is how it makes complex jobs simple. It gives you the full-colour, no-weeding benefits of DTG but with the material freedom of screen printing, creating a best-of-both-worlds situation for small-to-medium print runs.

Acknowledging the Drawbacks

Of course, no technology is flawless. Jumping into DTF printing means you need to be aware of the challenges to avoid getting frustrated later on. Knowing what you’re in for is the key to running a smooth operation.

One of the main hurdles is the initial equipment investment. While it’s much cheaper than a full commercial DTG setup, a quality DTF printer, curing unit, and heat press still represent a significant upfront cost for a small business.

You also have to think about the ongoing cost of consumables. You'll need a steady supply of specialised inks (especially white ink), PET film, and adhesive powder. While these costs are manageable, they are a recurring expense that needs to be factored into your pricing.

Finally, disciplined maintenance is absolutely non-negotiable. The white ink in DTF printers is notorious for clogging the print heads if the machine isn't used and cleaned regularly. Skipping this daily and weekly routine is the quickest way to end up with costly repairs and major downtime. For most newcomers, mastering the maintenance schedule is the steepest learning curve, but it’s essential for long-term success with DTF printing.

Your Top DTF Printing Questions, Answered

As you start digging into the world of DTF printing, you're bound to have questions. It’s a fantastic technology, but getting your head around the practical side of things is what really makes the difference between a good print and a great one. We’ve pulled together some of the most common queries to give you clear, no-nonsense answers.

Think of this as your go-to guide for the hands-on stuff. It’s here to cut through the confusion and help you feel more confident, whether you’re troubleshooting your first job or just trying to decide if DTF is the right fit for your brand.

Just How Durable Are DTF Prints?

This is usually the first thing people ask, and for a very good reason. The short answer? Extremely durable. When it’s done right, a DTF print will often last the entire life of the garment it's on. The real magic happens during the heat press stage, where the hot-melt adhesive forms a powerful bond with the fabric’s fibres.

This bond gives the print incredible elasticity, so it can stretch and move with the fabric without cracking or peeling. It also holds its own against fading, even after dozens of wash cycles. When it comes to sheer toughness, DTF goes toe-to-toe with traditional screen printing, offering similar longevity but with the huge advantage of full-colour, complex designs without all the extra setup.

Can I Use My Regular Printer for DTF?

In a word, no. You absolutely cannot use a standard home or office inkjet printer for DTF printing. The whole process hinges on specialised bits of kit that your average printer just doesn’t have.

Here’s why it won't work:

- Specialised Inks: DTF uses unique, water-based textile inks engineered for flexibility and staying power on fabric. Standard printer ink would literally wash down the drain.

- A White Ink Channel: This is probably the biggest deal-breaker. To get colours to pop on dark garments, you need to print a white underbase first. Standard printers simply aren't built to handle white ink.

- RIP Software: DTF printers rely on special Raster Image Processing (RIP) software to manage the ink layers, making sure the colour and white layers line up perfectly. This software isn't compatible with regular printers.

Trying to bodge it with the wrong equipment will only lead to clogged print heads, prints that won't stick, and a whole lot of frustration.

What’s the Biggest Challenge for Beginners?

For most people starting out, the single biggest hurdle is getting into a solid, consistent maintenance routine. The white ink in DTF printers contains titanium dioxide pigments which are heavier than the other colours. If the machine is left to sit, these pigments can settle and clog up the print heads.

The most important thing you can do for long-term success is to establish a non-negotiable daily and weekly cleaning schedule. It’s simple stuff, like shaking the ink cartridges and running head cleans. It might feel a bit tedious, but it’s what prevents costly repairs and annoying downtime.

Another common stumbling block is nailing the final press. Finding that sweet spot of temperature, pressure, and time for different fabrics takes a bit of trial and error. For a much deeper look at this, check out our comprehensive heat press temperature guide, which breaks down the right settings for all sorts of materials.

Is DTF Printing an Eco-Friendly Choice?

Compared to traditional methods like screen printing, DTF is often seen as a much more environmentally friendly option. The main reason is that it generates almost zero water waste. Screen printing requires huge amounts of water to wash screens between each colour and job. DTF, on the other hand, is a completely dry process.

The inks themselves are typically water-based and often Oeko-Tex certified, meaning they've been tested and confirmed to be free from harmful chemicals. This makes the finished garments safe for both adults and children.

That said, it isn't without its environmental footprint. The process uses PET films and polymer adhesive powders, which are plastic-based. The good news is that as the industry evolves, more sustainable and recyclable options for these materials are hitting the market, making it an increasingly responsible choice for eco-conscious businesses.

Ready to bring your own vibrant designs to life with professional-grade quality? Psyque offers top-tier DTF printing services and custom apparel, perfect for everything from streetwear brands to corporate merchandise. Explore our collections and see the difference for yourself at https://psyque.co.uk.