My Design on a T Shirt Printing Methods Compared

Share

Turning your digital design into a real-life, wearable t-shirt comes down to two things: prepping your artwork properly and picking the right print method. It can feel a bit overwhelming, but this guide will cut through the noise and give you a clear path from file to fabric. We're going to break down the big three technologies—Direct to Film (DTF), Screen Printing, and Direct to Garment (DTG)—and show you exactly how each one affects your final product.

Bringing Your T-Shirt Design to Life

This intro is your starting point for a proper comparison, helping you get to grips with what really matters for your project. By the end, you'll know exactly which technique is the right tool for the job. And as you start bringing your t-shirt design to life, it’s a smart move to create brand guidelines to keep your visual identity sharp and consistent.

Key Printing Technologies at a Glance

Before we get into the nitty-gritty, let's get a feel for the main players. Each method has its own strengths and is built for different kinds of jobs, whether you’re printing a single tee or a batch of one hundred.

The table below gives you a quick snapshot of how Direct to Film (DTF), Screen Printing, and Direct to Garment (DTG) stack up against the most important factors when you want to put my design on a t shirt.

| Feature | Direct to Film (DTF) | Screen Printing | Direct to Garment (DTG) |

|---|---|---|---|

| Best For | Vibrant, detailed prints on any fabric | Large batches of simple designs (1-4 colours) | One-off, full-colour prints on cotton |

| Feel of Print | Smooth, flexible, slightly raised layer | Heavier ink layer, can feel thick | Soft, breathable, ink infused in fabric |

| Colour Vibrancy | Excellent, especially on dark fabrics | Very high, with bold, solid colours | Good, but can be less vibrant on darks |

| Durability | High; resistant to cracking and fading | Extremely durable, lasts for years | Good, but can fade with repeated washes |

This comparison immediately flags the core differences. You can see right away that DTF is the all-rounder, working brilliantly on cotton, polyester, and blends without breaking a sweat.

For anyone starting out, DTF offers a powerful middle ground. It combines the full-colour detail of DTG with the fabric versatility that screen printing can't match, all without the high setup costs for small orders.

That makes it a seriously accessible yet professional choice for bringing your vision from screen to shirt.

Understanding Core Printing Technologies

Before you can get your design onto a t-shirt, it’s worth knowing how it gets there. The printing method you choose is just as important as the artwork itself. Each technique has its own quirks, strengths, and ideal use cases. Getting your head around the basics is the key to picking the right weapon for your creative battle.

The UK's appetite for custom gear is exploding. The market was valued at around USD 58.4 million in 2024 and is projected to climb to USD 79.7 million by 2033. This isn't just a trend; it's a full-blown movement fuelled by a demand for unique, personalised products. In other words, now is the perfect time to bring your t-shirt ideas to life. You can dig deeper into these numbers with the UK fashion market insights on imarcgroup.com.

Direct to Film (DTF) Printing

Direct to Film, or DTF, is the modern workhorse of the custom tee world. It's a killer method that’s become insanely popular for good reason. The process is pretty slick: we print your design onto a special film, hit it with an adhesive powder, and cure it.

That film is then heat-pressed directly onto the t-shirt, transferring the design in one go. The result is a super vibrant, durable print that sits on top of the fabric with a smooth, flexible feel. Best of all, it works brilliantly on almost anything—cotton, polyester, and blends.

Traditional Screen Printing

Screen printing is the OG of t-shirt printing. It's a classic, time-tested technique that’s unbeatable for big orders with designs that aren't ridiculously complex. It works by creating a stencil (a "screen") for every single colour in your design. Ink is then pushed through each screen, one colour at a time, to build the final image.

Because every colour needs its own screen, the setup costs can be steep for small runs. But once you’re printing in bulk, it becomes incredibly cheap per shirt. The prints are thick, bold, and tough as nails, which is why it's the go-to for band merch and company uniforms. For a full breakdown, check out our guide comparing DTF vs screen printing for graphic tees.

Key Takeaway: Screen printing is a numbers game. It's built for volume. The more you print, the cheaper it gets, but the complex setup makes it a total non-starter for one-off prints or designs with a ton of colours.

Direct to Garment (DTG) Printing

Think of Direct to Garment (DTG) printing as a high-tech inkjet printer built specifically for clothes. The t-shirt gets loaded into the machine, and the printer sprays water-based inks directly into the fibres of the fabric.

This makes DTG perfect for super-detailed, full-colour designs like photos or intricate illustrations. Since the ink becomes part of the shirt itself, the print feels incredibly soft and breathable. The catch? DTG performs best on 100% cotton and can look a bit washed out on dark fabrics unless a white base layer is printed first.

Comparing Printing Methods For Your Design

Choosing the right printing method is where the idea of putting my design on a t shirt gets real. This decision is everything—it dictates how your artwork looks, feels, and whether it survives the wash. We're going to skip the generic lists and dig into how DTF, Screen Printing, and DTG actually perform when it comes to getting a quality finish.

Each technique plays with fabric and ink in its own way, leading to completely different results. Think about it: a detailed, photographic image on a polyester blend is a world away from a simple, bold logo on a classic cotton tee. Getting these details right is the key to making sure the final shirt actually matches what you had in your head.

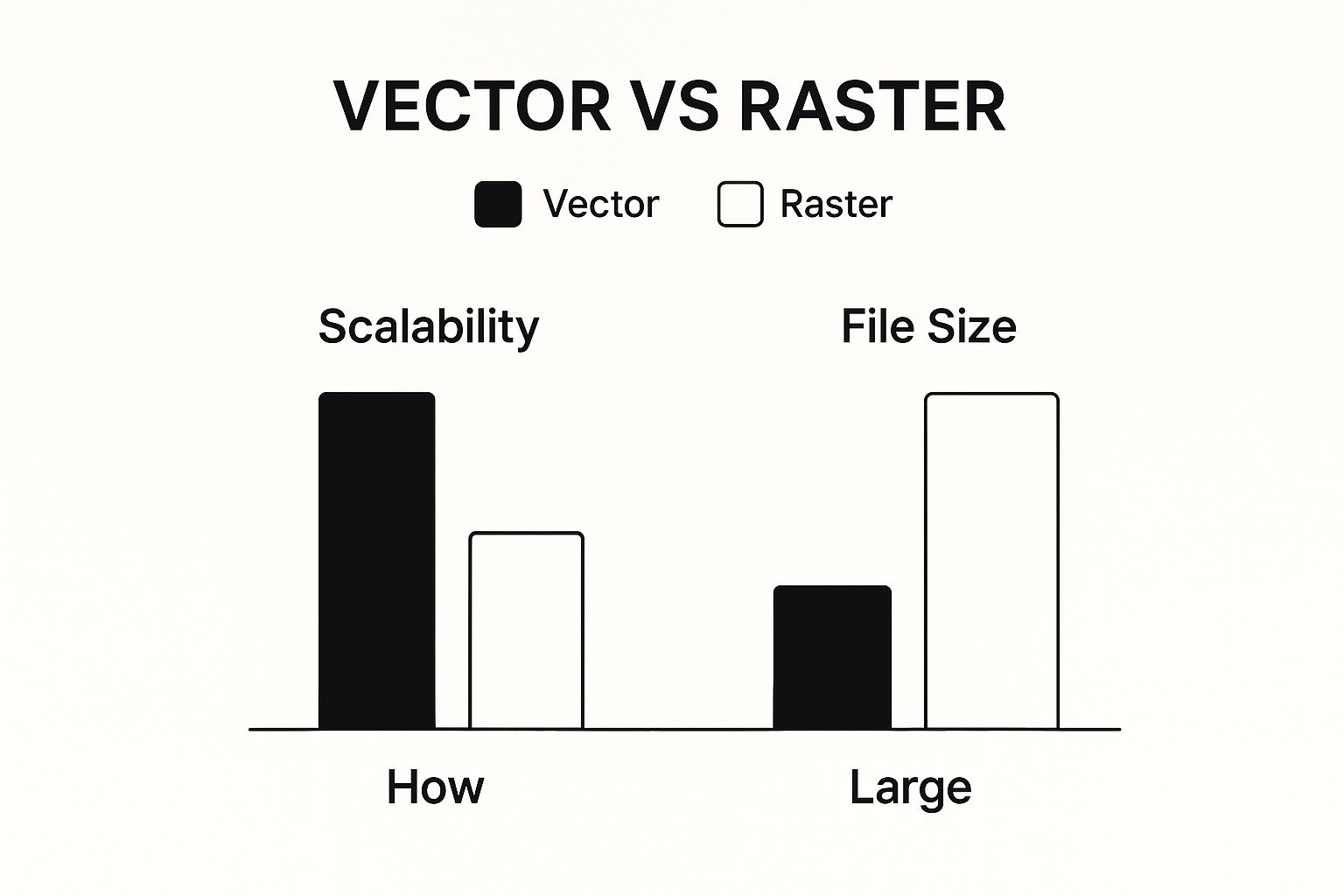

This breakdown shows why the file type you use is so critical for print quality.

As you can see, vector graphics are the clear winner for designs that need resizing without turning into a blurry mess—a non-negotiable for clean, sharp prints.

To really nail down the best method for your design, let's compare them side-by-side on the features that matter most to designers and creators.

T-Shirt Printing Method Feature Comparison

| Feature | Direct to Film (DTF) | Screen Printing | Direct to Garment (DTG) |

|---|---|---|---|

| Colour Vibrancy | Excellent, especially on dark fabrics | Excellent, bold and opaque colours | Good, best on light-coloured cotton |

| Detail & Gradients | Highest detail reproduction | Poor, not ideal for photos | Excellent, reproduces fine detail |

| Feel on Fabric ("Hand") | Smooth, flexible layer on top | Heavy, thick ink layer | Softest, ink soaked into fibres |

| Fabric Compatibility | Very versatile (cotton, poly, blends) | Good (best on cotton/blends) | Limited (best on 100% cotton) |

| Durability | High, resistant to cracking/fading | Highest, industry standard for longevity | Moderate, can fade with washing |

| Best for Small Runs | Yes, cost-effective for one-offs | No, high setup costs | Yes, ideal for single prints |

| Best for Large Runs | Good, but can be slower | Yes, most cost-effective at scale | No, slower process per shirt |

This table gives you a quick snapshot, but the real devil is in the details. Let's break down what those differences mean for your specific project.

Colour Vibrancy And Detail Reproduction

When your design is loaded with gradients or photorealistic details, you can't afford to lose colour accuracy. Direct to Film (DTF) is the champion here. It prints your design onto a film first, which is then heat-transferred. The result? Insanely bright and precise prints, even on tricky dark or synthetic fabrics like polyester. A white ink underbase ensures colours scream, no matter the shirt's colour.

Screen printing, on the other hand, is all about bold, punchy colour. Each ink colour is mixed and pushed through a separate screen, creating a super-vibrant, thick layer. But this is also its weakness. It chokes on complex gradients and photos because every single shade needs its own screen, making it a costly nightmare for intricate artwork.

Direct to Garment (DTG) is like a high-end inkjet printer for fabric. It nails detail, reproducing millions of colours and subtle gradients directly onto cotton. Its Achilles' heel is vibrancy on dark shirts, where colours can sometimes look a bit muted compared to what DTF can pull off.

Feel Of The Print And Fabric Compatibility

The "hand"—how the print actually feels—is a massive part of a custom tee's appeal. DTG prints have the softest feel, hands down. The ink soaks right into the cotton fibres, becoming one with the fabric. This gives you a breathable, barely-there finish that’s perfect for fashion-forward apparel where comfort is king.

A DTF print sits on top of the fabric, creating a smooth, flexible layer you can feel. Don't worry, modern DTF transfers are incredibly thin and tough, striking a great balance between a noticeable design and a comfortable shirt you actually want to wear. Plus, it works on almost anything: cotton, polyester, and blends.

Screen prints have the heaviest hand. Those thick layers of plastisol ink are built to last but don't breathe well. While it’s perfect for a bold logo on workwear or a tour shirt, it can feel like a stiff plastic sheet if the design covers a large area. If you want to dive deeper into how these methods match up with specific needs, there's a ton of great info in guides on custom t-shirt printing.

For small batches or one-off prints with unlimited colours, DTG provides excellent detail and cost-effectiveness. It shines when you want a soft-feeling print on 100% cotton garments.

Durability And Longevity

A killer design deserves to last more than a few washes. Screen printing has long been the gold standard for durability. Its thick ink layers can take a beating, surviving countless wash cycles without fading or cracking. This makes it the go-to for uniforms and merchandise that needs to endure heavy use.

DTF is a seriously strong contender, offering impressive durability that rivals screen printing. The adhesive powder creates a rock-solid bond with the fabric, making the print highly resistant to cracking, peeling, and fading. It holds up exceptionally well through dozens of washes, keeping its colour and integrity intact.

DTG prints, while soft, are the most delicate of the three. The water-based inks can fade over time with repeated washing, especially if you're not careful with them. They offer decent durability for personal or occasional wear, but they probably aren't the best choice for a shirt that's going to see the inside of a washing machine every other day.

Choosing the Right Method for Your Project

Technical specs are one thing, but getting my design on a t shirt the right way comes down to picking the right tool for the job. Your goal, your budget, and how complex your artwork is will ultimately point you to the best printing method. Let's translate the data into real-world situations.

Making the right call is more important than ever. The UK t-shirt market hit an estimated value of $1.8 billion in 2024, a 4.9% jump from the year before, which shows people are still hungry for great tees. But consumption has dipped slightly, hinting that buyers are getting pickier. For a deeper dive, check out the full UK t-shirt market analysis on indexbox.io.

Launching a Small Merchandise Brand

If you're starting a new brand, you need two things above all else: flexibility and quality. You want killer prints that look good on different fabrics without being forced to buy a mountain of stock you might not sell.

Recommended Method: Direct to Film (DTF)

DTF is the obvious winner here. It lets you produce small batches—or even just one item at a time—without breaking the bank. You get full-colour, super-detailed prints that work across cotton, polyester, and blends. That means you can offer a whole range of gear, from tees to hoodies, using the exact same process.

Creating a Single High-Detail Gift

When you're making a one-of-a-kind gift, like a t-shirt with a family photo on it, the feel of the print and the sharpness of the image are everything.

Recommended Method: Direct to Garment (DTG)

DTG is king for reproducing photorealistic images and tiny details with millions of colours. The ink soaks right into the cotton fibres, so the final print is incredibly soft and breathable. It's the perfect choice for a comfortable, high-end custom gift and was basically designed for these kinds of one-off jobs.

For projects where the feel of the garment is just as important as the visual design, DTG's ability to infuse ink directly into the fabric makes it the superior choice for single, premium-quality cotton t-shirts.

Economical Choice for Event Staff Uniforms

For big events or company uniforms, you need something that lasts and doesn't cost a fortune, especially if you're just printing a simple logo or text in one or two colours.

Recommended Method: Screen Printing

For bulk orders, screen printing is the undisputed champion. The initial setup cost for each colour is higher, but the price per shirt plummets as your order size grows. The ink is thick and tough, so the design will survive endless washes, making it ideal for staff uniforms that need to last. This method was built for volume and simplicity, delivering bold, durable results at a great price.

Preparing Your Design File for Flawless Printing

This is where so many great t-shirt ideas die. The jump from a bright screen to actual fabric can turn a killer concept into a blurry, pixelated mess if the source file isn't spot on. Nailing this step is the difference between a pro-quality garment and a cheap-looking disappointment when you want to get my design on a t shirt.

Look, your printer isn’t a miracle worker. The final print quality is a direct reflection of your file quality. We constantly see people submit a low-res graphic they saved from a website and then wonder why it doesn't look sharp. It never will.

Resolution and File Type: The Non-Negotiables

Here’s the single biggest rule: your design file must be created at 300 DPI (dots per inch) at its final print size. This is the industry standard for a reason. It guarantees your artwork looks crisp and detailed, not fuzzy or jagged.

Just as critical is the file format you use. JPEGs are fine for Instagram, but they're terrible for printing because they compress image data and can't handle transparency. Stick to these formats:

- PNG: The go-to for pixel-based art. Why? It supports transparent backgrounds, which is essential if your design isn't just a big rectangle.

- AI (Adobe Illustrator) or SVG: These are vector files. Instead of pixels, they're made of mathematical paths. This means you can scale them from a tiny chest logo to a massive back piece without losing an ounce of quality.

- PSD (Adobe Photoshop): A solid choice for complex raster artwork, as long as it’s saved at 300 DPI with a transparent background.

The golden rule for putting your design on a t-shirt is simple: use vector files (AI, SVG) whenever you can for total scalability. For everything else, a high-resolution PNG with a transparent background is your best bet. This one habit prevents the most common and expensive printing disasters.

Colour Mode and Fabric Realities

Another technical bit that trips people up is colour mode. Your screen displays colours in RGB (Red, Green, Blue), but professional printers often use CMYK (Cyan, Magenta, Yellow, Black). Good news: our DTF process is optimised to handle your RGB files perfectly, so what you see on screen is what you get on the tee—vibrant and accurate.

This adaptability works like a charm across different fabrics, too. For instance, the UK women's t-shirt market is dominated by polyester, which held around 51.67% of the market share back in 2021 because it's so durable. Our printing methods make sure your design pops just as hard on polyester as it does on classic cotton.

For personalised apparel, knowing these details ensures your final product is flawless. You can find more tips in our guide to getting personalised t-shirt printing just right.

Here are a few common questions that always seem to pop up right before someone is ready to get their design printed on a t-shirt. Getting these last-minute details sorted is the final step to making sure you get a professional, long-lasting print you’ll actually want to wear.

We've pulled together the most frequent questions to give you the answers you need, all in one place. Let's clear up any doubts so you can order with confidence.

What Is the Most Durable Printing Method for T Shirts?

When you’re talking about pure, rugged longevity, traditional screen printing has always been the king. The thick layers of plastisol ink basically melt into the fabric, creating a bond that can survive years of abuse. It’s built tough, which is why it’s the go-to for workwear and band merch that needs to last a hundred gigs.

That said, Direct to Film (DTF) is hot on its heels, offering durability that seriously rivals screen printing. The heat-pressed adhesive creates a print that’s both strong and flexible, so it’s incredibly resistant to cracking, peeling, or fading. If your design is full of colour and detail and you don't want to sacrifice toughness, DTF is an absolutely killer modern option.

How Much Does It Cost to Print One T Shirt in the UK?

The price for a single custom tee can swing wildly depending on how it’s printed. For a one-off job, methods with huge setup costs like screen printing are a non-starter. You’d be paying a ridiculous amount for just one shirt.

For a single shirt, your best bets are Direct to Garment (DTG) or Direct to Film (DTF). Both are built for printing on demand with no minimum order. In the UK, you can expect to pay somewhere between £15 and £25 for a single, high-quality custom tee using either of these methods. The final price usually depends on how complex the design is and the quality of the blank shirt you choose.

When you're only printing one shirt, the choice between DTG and DTF often boils down to fabric. DTG is perfect if you want that super-soft feel on a 100% cotton tee. DTF, on the other hand, gives you more vibrant colours and better durability across a much wider range of materials, including polyester and blends.

Can I Print a Photograph on a Dark Coloured Shirt?

Absolutely, but the method you choose is everything. To make a detailed photo look good on a dark t-shirt, you need a technique that can lay down a layer of white ink first. Think of it like a primer on a dark wall—it stops the shirt’s colour from dulling your design and makes the photo’s colours pop.

Both DTG and DTF are brilliant for this. They each use a white ink base to create a solid foundation before printing the full-colour image over the top. DTF really excels here, producing unbelievably vibrant and sharp photographic prints on dark cotton, polyester, and pretty much anything else you throw at it. Screen printing just isn’t cut out for photorealistic images.

Which T Shirt Materials Produce the Best Print Quality?

The right material is completely tied to your print method and the final look you're after. Each technique plays differently with fabric, so matching them up is key to getting a great result.

- 100% Cotton: This is the undisputed champion for DTG printing. The natural fibres soak up the water-based inks perfectly, leaving you with a soft, breathable print. It also works great for screen printing and DTF.

- Polyester and Blends: This is where DTF printing really shows its strength. It sticks perfectly to polyester, tri-blends, and 50/50 cotton/poly mixes, delivering bold, durable prints where other methods would fail.

- Ringspun Cotton vs. Standard Cotton: No matter which method you use, a smoother fabric like ringspun cotton will always give you a sharper, more detailed print than standard heavy cotton. A smoother surface just allows the ink to lay down more cleanly, keeping all those fine details crisp.

Ready to bring your vision to life with a printing method that delivers stunning vibrancy, insane detail, and unbeatable durability? At Psyque, we specialise in professional DTF printing to make your custom apparel stand out from the crowd.