Custom Printed T Shirts UK A Complete Guide

Share

So, you've got a killer idea for a T-shirt and want to bring it to life. Whether it’s for a business promotion, a special event, or just a personal project that’s too good to keep in your head, ordering custom printed t shirts uk style is the way to go. This guide is your new best mate, walking you through every single step—from picking the right print method and tee to getting your artwork looking sharp and professional.

Your Roadmap to the Perfect Custom Tee

Welcome to the only guide you'll need for creating your own personalised T-shirts right here in the UK. Think of this intro as your map, breaking down the whole journey from a spark of an idea to a high-quality product you can actually wear or share. We’ll hit all the key decisions you'll need to make along the way.

Personalised gear is massive these days, and for good reason. It's an essential tool for almost everyone. Maybe you're a business owner trying to build a brand that people remember, an event organiser crafting merch that sells out, or an artist who wants to see your work on something other than a screen. Custom tees are a powerful and seriously creative way to make it happen.

Navigating the Custom T-Shirt Journey

The path to your perfect T-shirt has a few important stops. Nailing these upfront will save you time, cash, and the headache of ending up with something that doesn't match what you pictured. We've structured this guide to give you total clarity on:

- Printing Techniques: We’ll put different methods like DTF (Direct-to-Film) and screen printing head-to-head, helping you pick the best fit for how complex your design is and how many you need.

- Choosing Your Garment: The feel and fit of the T-shirt are just as crucial as the print itself. We'll get into materials, weights, and different styles so you can choose wisely.

- Prepping Your Design: This is where the magic happens. Learn how to get your artwork 100% print-ready and dodge common disasters like blurry images or colours that just look wrong.

Our whole mission here is to demystify the ordering process. We want to give you the confidence and know-how to make smart choices, so by the end, you’ll be fully equipped to turn your unique T-shirt ideas into reality.

The demand for personalised apparel is absolutely booming. The UK's custom T-shirt printing market was valued at around £200.1 million in 2023 and is expected to more than double by 2030. That's not just a trend; it's a massive shift towards unique, made-to-order clothing. You can read the full research about custom T-shirt market trends here.

Choosing the Right T-Shirt Printing Method

Picking the right printing technique is hands-down the most important decision you'll make when ordering custom printed t shirts uk. It’s the difference between a shirt that looks killer and one that looks... well, a bit naff. Get it right, and your design will pop. Get it wrong, and you could end up with a washed-out graphic or a bill that’s way higher than you expected.

Think of it like choosing the right tool for a job. You wouldn't use a sledgehammer to hang a picture frame, would you? Same logic applies here. To make sure you’re choosing wisely, let's break down the main players in the UK printing game.

Screen Printing: The Bulk Order Champion

Screen printing is the OG of T-shirt printing, and for good reason. It’s a classic, reliable method that’s been around for ages. The process is a bit like using a really fancy stencil. Ink is pushed through a mesh screen onto the fabric, and a separate screen has to be created for every single colour in your design.

Because of this setup, it’s not the best choice if you just want one or two shirts. But for big batches? It’s unbeatable. If you're kitting out a team, planning a charity run, or ordering for a company event, screen printing is your best friend. The more you print, the cheaper each shirt gets.

- Best For: Big orders (20+ items), simple logos, and designs with just a few solid colours.

- Key Advantage: Insanely cost-effective for bulk orders and creates vibrant, tough-as-nails prints that last.

- Main Drawback: The setup costs make it a poor choice for small runs or one-off tees.

Direct to Garment (DTG): The Detail Specialist

Direct-to-Garment (or DTG) is pretty much what it sounds like. It works just like a high-end inkjet printer, but instead of paper, it prints straight onto the T-shirt. This makes it the perfect weapon for bringing complex, multi-coloured designs to life—we’re talking photographs, intricate illustrations, and painterly gradients.

There are no screens to set up, which means DTG is ideal for small orders or even a single, one-of-a-kind masterpiece. It creates a soft, breathable print that feels like it’s part of the fabric itself, not just sitting on top of it. This is the go-to for artists and brands who want their apparel to feel premium and detailed.

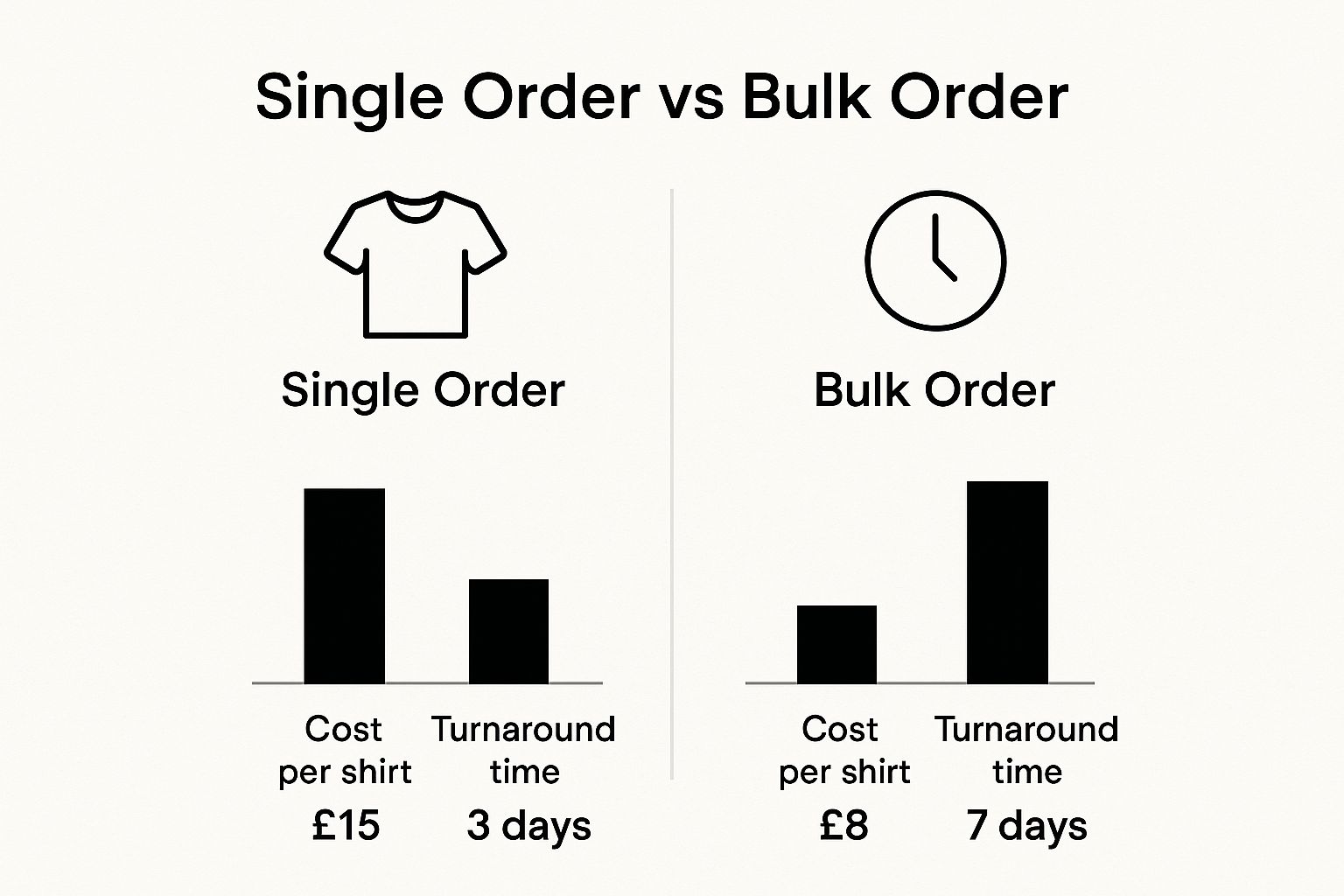

As you can see, the game changes depending on how many shirts you need. Bulk orders slash the cost per item but often take longer to produce because of all the prep work involved.

Direct to Film (DTF): The Modern All-Rounder

Now we get to Direct-to-Film (DTF), the new kid on the block that’s changing the game. DTF is a clever hybrid that takes the best bits from other methods. Your design is printed onto a special film first, then heat-pressed onto the T-shirt. The result? A print that's incredibly vibrant, razor-sharp, and ridiculously durable.

DTF’s superpower is its versatility. It doesn't care what the shirt is made of. Cotton, polyester, weird blends—it works brilliantly on all of them, delivering a consistently stunning finish every time. This makes it a fantastic choice for everything from performance sportswear to high-fashion tees.

This modern technique is fast becoming a favourite because it handles both simple logos and complex, colourful artwork with ease. If you want to get into the nitty-gritty of the process, you can learn more about the tools used by custom T-shirt printers. The final print feels smooth with a slight raised texture, giving it a premium feel that holds up incredibly well in the wash.

Comparing T-Shirt Printing Methods in the UK

Still not sure which way to go? Here’s a quick rundown to help you decide. This table cuts through the noise and shows you which method lines up with your project.

| Printing Method | Best For | Durability | Cost Efficiency |

|---|---|---|---|

| Screen Printing | Bulk orders (20+), simple logos, limited colours | Extremely high | Excellent for large volumes |

| Direct to Garment (DTG) | Detailed, multi-colour designs, photos, small batches | Good (washes well) | Great for one-offs & small runs |

| Direct to Film (DTF) | Complex designs, vibrant colours, almost any fabric | Excellent (very durable) | Versatile for small to medium runs |

Each method has its place. Your choice really boils down to three things: your design's complexity, how many shirts you need, and the type of fabric you're printing on. Choose the one that fits your mission, and you're golden.

Choosing the Right T-Shirt Material and Fit

Let's be real: a killer design on a cheap, scratchy tee is a wasted opportunity. The foundation of a genuinely great custom T-shirt isn't just the print—it's the garment itself. Picking the right material and fit is a crucial first step that separates the legendary merch from the stuff that ends up at the bottom of a drawer.

Before you even get lost in colour palettes and artwork, you need to decide on the fabric. Each material feels different, wears differently, and even takes ink differently. Nail this choice, and your T-shirt won't just look good on day one; it'll feel incredible to wear for years.

When you're browsing options for custom printed t shirts uk, you’ll mainly run into three contenders. Let's break them down.

The Big Three: T-Shirt Materials

Think of the fabric as the canvas for your art. Your decision here impacts everything from comfort and durability to how sharp your final print looks.

- 100% Cotton: The undisputed classic. It’s soft, it's breathable, and it just feels right against the skin. You can't go wrong with cotton for general-purpose tees that everyone will love.

- 100% Polyester: This is the go-to for sportswear and anything performance-related. It's tough, wicks away sweat like a champ, and holds its shape no matter how much you punish it.

- Poly-Cotton Blends: The best of both worlds. You get the soft, natural feel of cotton fused with the durability and moisture-wicking power of polyester. A solid all-rounder.

Beyond the material itself, pay attention to the fabric's weight, measured in GSM (Grams per Square Metre). A higher GSM, say 180-200, gives you a heavier, more durable shirt that feels premium. Lighter tees around 140-160 GSM are perfect for summer drops or one-off promotional events.

Getting the Fit and Style Right

Once you've picked your material, it's time to think about the silhouette. This is all about knowing who you're making these shirts for and the vibe you're aiming for. The cut of a T-shirt completely changes its attitude.

Who is your audience? Are you dropping merch for a streetwear brand, kitting out a corporate team, or making something fun for a hen do? Each one calls for a totally different style.

The right fit makes sure your design gets worn and loved, not just bought and forgotten. It’s the bridge between your creative vision and the person wearing it, turning a piece of clothing into a statement.

These are the most common fits you'll find from UK suppliers:

- Unisex/Classic Fit: Your standard, straight-cut tee. It’s a safe bet that works for pretty much everyone, making it the go-to for event merch.

- Fitted/Slim Fit: Tapered at the waist for a sharper, more modern look. This is a popular choice for fashion brands and retail.

- Oversized/Relaxed Fit: A much looser, boxier cut that screams contemporary streetwear.

Finally, don't forget about sustainable options. More and more UK printers are offering garments made from organic cotton or recycled fabrics. Choosing a greener option can be a massive plus, aligning your project with values that many people really care about these days.

Want to get deeper into the actual printing process? We've got you covered in our complete guide to custom T-shirt printing.

How to Prepare Your T-Shirt Design for Printing

A brilliant idea is only half the battle. Getting that idea onto a T-shirt without it looking like a blurry mess? That’s where the real work begins. One of the most common pitfalls we see when people order custom printed t shirts uk is submitting artwork that just isn't ready for the press.

Think of your digital file as the blueprint for the final shirt. If that blueprint is smudged, low-quality, or uses the wrong specs, the end result is going to be a letdown. Nailing the technical stuff upfront is non-negotiable if you want a professional-looking tee.

First up, let's talk file types. You'll mainly be dealing with two kinds: vector and raster. Understanding the difference is mission-critical for a clean, sharp print.

Vector vs Raster Files Explained

Imagine your logo is a set of instructions. A vector file (like AI, EPS, or SVG) tells the computer "draw a line from here to here, then a curve like this." Because it's based on maths, you can scale it up to the size of a bus and it will never, ever lose quality. This makes vectors the undisputed king for logos, text, and bold graphics.

A raster image (like a JPG, PNG, or GIF) is more like a mosaic made of tiny coloured squares called pixels. It's perfect for photos and super-detailed artwork with lots of gradients. But try to blow up a raster image, and you'll see those little squares. The result? A blurry, pixelated disaster.

For the sharpest prints, especially with a method like DTF, a high-resolution file is everything. Your artwork needs to be created at 300 DPI (Dots Per Inch) at the exact size you want it printed. Anything less is going to look fuzzy and amateur when it hits the fabric.

Getting Your Colours and Placement Right

Here's another classic mistake: designing with the wrong colour mode. Your screen uses RGB (Red, Green, Blue) light to show you colours, which is great for digital displays. But printers don't use light; they use ink. They work in CMYK (Cyan, Magenta, Yellow, Black).

To avoid any nasty surprises when your shirts arrive, design in CMYK from the very beginning. This gives you a much truer preview of how those colours will actually look on the final garment.

Finally, a few practical tips to save you a headache:

- Placement is Key: A design that looks perfect centred on your screen might sit weirdly high or awkwardly low when someone actually wears the shirt. Think about where it's going to land on a real human body.

- Font Readability: If you're using text, pick a font that's easy to read from a few feet away. Super skinny or overly complicated fonts often bleed together and become unreadable on fabric.

- Colour Contrast: This one seems obvious, but you'd be surprised. A dark grey design on a black T-shirt is going to be basically invisible. Make sure your design pops against the shirt colour.

Mastering these basics bridges the gap between a cool idea and a genuinely killer T-shirt. If you want more tips on making your gear stand out, check out our guide to creating t-shirt printing personalised to your exact vision.

Navigating Costs, Shipping, and Turnaround Times

Alright, let's talk about the bit everyone wants to know: how much will it cost and when will it arrive? When you're ordering custom printed t shirts uk, the price tag you see is more than just the cost of a blank tee. It’s a mix of a few key ingredients you can tweak to hit your budget.

The final cost really boils down to your choices. A premium, heavyweight cotton shirt is obviously going to cost more than a standard promo tee. The print method matters too, as does how complex your design is—more colours can mean more work.

But here’s the biggest lever you can pull to manage costs: volume. Ordering in bulk almost always drops the price per shirt, which is a game-changer for events, brands, or merch drops. If you're managing stock, properly selecting the right inventory costing method is crucial for keeping your finances straight.

Understanding Production and Delivery Timelines

"Turnaround time" is just jargon for how long it takes to print your order before it’s handed over to the courier. This can be anything from 1–5 working days, depending on the tech used and how big your order is. A small, simple DTF print run is going to be way faster than a massive screen-printing job with ten different colours.

Once your shirts are printed, they're ready to ship. Most UK printers give you a couple of options:

- Standard Delivery: This is your budget-friendly choice, usually taking 2-4 business days with couriers like Royal Mail.

- Express Delivery: Need them yesterday? This option gets them to you faster, often with next-day delivery, but it'll cost you extra.

If you're really up against it, it's always worth seeing who offers next-day delivery on custom T-shirts. Don't assume it's impossible.

Before you hit "confirm," always—and I mean always—check the supplier's reprint and return policies. Knowing how they handle screw-ups or damaged goods gives you peace of mind and protects your cash.

A Quick Look at Key Cost Factors

So, to recap, when you're budgeting, keep these four things front of mind:

- Garment Quality: Better fabric and bigger brands mean a higher price. Simple.

- Order Quantity: More shirts = a lower price per shirt. Bulk is your friend.

- Design Complexity: A one-colour logo is cheaper and faster to print than a full-colour masterpiece.

- Delivery Speed: You pay a premium for speed. Plan ahead to save money.

Juggling these elements is the key to creating something awesome that doesn't burn a hole in your pocket. Always ask for a detailed quote that breaks down every single cost. No surprises.

Current Trends in the UK Custom Apparel Market

To really get a handle on the world of custom printed t shirts uk, you need to zoom out and see what's actually happening on the ground. This isn't a static industry; it's constantly being shaped by cultural shifts and what people are willing to spend their money on. Knowing these trends gives you an edge, helping you create something that feels fresh, not dated.

One of the biggest forces is the rise of the creator economy. YouTubers, artists, and indie brands are all jumping on print-on-demand. It’s a no-brainer: they can launch merchandise with zero upfront cost, turning their creative spark into cash without the risk of being buried under a mountain of unsold stock. This has blown the doors wide open for thousands of independent creators across the UK.

Sustainability and Actually Giving a Damn

At the same time, a huge wave of conscious consumerism is changing the game. People are smarter and more switched on than ever. They’re actively looking for gear made from organic cotton or recycled materials.

It’s not just about the fabric, either. There's a real hunger for transparency. Where was it made? What kind of inks are you using? Brands that embrace eco-friendly, water-based inks and ethical manufacturing aren't just ticking a box—they're building genuine loyalty. If you can align your custom T-shirt project with these values, you’re already winning.

The modern consumer doesn't just buy a product; they buy into the story and the ethics behind it. Choosing sustainable options is a powerful way to show your brand cares about more than just the bottom line.

The Power of Sports and Big Initiatives

It’s not all grassroots, though. Major events and nationwide initiatives create massive demand. Take government and sports-driven investments—they have a direct knock-on effect on the need for custom teamwear. A perfect example is the Rugby Football Union's 'Impact '25' initiative, which is backed by over £12 million in government funding to get more women into rugby. An investment like that creates an instant, huge demand for personalised kits and supporter gear. For more detail, you can read the full research on the custom T-shirt printing market.

Understanding what’s driving the market—from a single streamer to a multi-million-pound sports campaign—helps you figure out where your project fits into the chaos. For a deeper dive into the craft itself, check out our guide on printing on T-shirts in the UK.

Got Questions? We've Got Answers

Diving into the world of custom printed t shirts uk can throw up a few questions. It’s totally normal. Here are the straight-up answers to the queries we hear most often, so you can lock in your order with zero guesswork.

What’s the Minimum Order for Custom T-Shirts?

This one really comes down to the UK supplier you choose and how they print. The minimum order quantity, or MOQ, isn't a one-size-fits-all thing.

If you’re looking at screen printing, you’ll almost always find a minimum of around 20-25 units. The setup for that method is a serious process, so printing just one or two tees isn’t practical.

But with newer tech like Direct-to-Film (DTF), there's basically no complex setup. That freedom means many printers (like us) can offer single-item orders. It’s perfect if you just want a sample or a one-off gift. Best bet? Always check with your supplier first.

Can I Bring My Own T-Shirts for Printing?

It’s a fair question, and it sounds like an easy way to save a bit of cash. But honestly, most established UK suppliers won't let you provide your own garments. And there’s a solid reason for it.

Printers have their go-to T-shirts—blanks they've tested inside and out to work perfectly with their machines and inks. This is how they guarantee the print will look sharp, feel right, and last through wash after wash.

Bringing your own clothing is a bit of a gamble. The fabric might not take the ink well, leading to a rubbish, faded print or a design that cracks and peels after one wash. For a result you can actually rely on, stick with the supplier's curated options.

How Do I Make Sure My Design Colours Are Spot-On?

Getting colours right is everything. No one wants a neon green that looks more like sludge. To make sure what you see on your screen is what you get on the shirt, here’s what you need to do:

- Get Your Colour Mode Right: Always, always create and save your design file in CMYK (Cyan, Magenta, Yellow, Black). That’s the language of printers. RGB (Red, Green, Blue) is for screens, and the colours will look totally different when printed.

- Use a Pantone Reference: If you have specific brand colours that need to be exact, giving your printer a Pantone (PMS) code is the industry-standard way to nail it. No ambiguity, just the perfect shade.

- Ask for a Proof: For any order that matters, ask for a digital mockup. Even better? If it’s a big run, order a single physical sample first. That way, you can see and approve the colours with your own eyes before going all-in.

Ready to turn your designs into reality with DTF printing that’s built to last? Dive into our collections or get your custom project started today with Psyque. Create your custom printed T-shirts now.