Custom T Shirt Printing London Your Ultimate Guide

Share

Tracking down high-quality, reliable custom t-shirt printing in London is the first step to bringing your big idea to life. Whether it’s for a business, a band, or a personal project, you need a local printer that gets it—one that mixes modern tech with real-world craftsmanship to deliver apparel that looks sharp and is built to last.

Why Custom T-Shirts Are Thriving In London

In a city as loud and creative as London, a custom t-shirt is way more than just clothing. It’s a walking billboard, a statement, and a way to connect with your tribe. From the packed-out markets in Camden to the slick corporate offices in Canary Wharf, personalised gear has become a non-negotiable tool for branding and self-expression.

And this isn't just a vibe; the numbers back it up. The UK's custom t-shirt printing market pulled in £158 million in 2023, and that figure is expected to more than double by 2030. This isn't just a trend. It shows a real need for tangible, unique ways to stand out in a seriously crowded city.

A Canvas For London's Creativity

London’s culture is powered by a massive army of independent creators, small businesses, and event organisers who all rely on custom merch to make their mark. Just think about all the ways these tees show up across the capital:

- For Startups and Small Businesses: A branded t-shirt instantly turns your staff into brand ambassadors, creating a unified look at events or in your shop. It’s a simple but effective way to nail those essential branding tips for small business without breaking the bank.

- For Bands and Artists: Merch is everything. It’s a vital source of income and lets fans wear their loyalty on their chests. A killer tee becomes a piece of memorabilia that carries the buzz of a live show long after the lights go down.

- For Events and Charities: Custom t-shirts are the uniform for everything from charity fun runs to massive festivals, instantly creating a sense of community and shared purpose among thousands of people.

The real power of a custom t-shirt is its ability to turn an idea—a brand, a band, a cause—into something tangible that people can actually wear and connect with.

The best part? Modern printing tech has completely levelled the playing field. What used to be reserved for huge, expensive orders is now accessible to everyone. You can learn more about the different methods out there in our guide on printing on t-shirts in the UK. This freedom empowers London's creators to bring their visions to life, one shirt at a time.

Choosing Your Printing Method DTF Or Screen Printing

When you’re looking to get custom t shirt printing london, you'll run head-on into two main contenders: Direct-to-Film (DTF) and screen printing. Both can give you incredible results, but they’re completely different beasts. Picking the right one all comes down to what you're trying to achieve.

Think of DTF as a modern digital weapon. Your design is printed onto a special film, then heat-pressed directly onto the shirt, fusing the ink right into the fabric. This method is a total game-changer for complex, multi-coloured designs—even if you only need a single tee.

Screen printing is the OG, the traditional craft. Imagine a high-grade stencilling process where each colour in your design gets its own screen. Ink is pushed through that screen onto the fabric, one colour at a time. It's legendary for producing vibrant, almost bulletproof prints with a classic feel.

When DTF Is Your Best Bet

DTF's real power is its insane flexibility and detail. It's a digital process, so there's almost zero setup. This makes it perfect for small runs or one-of-a-kind custom jobs that need to look sharp.

You should go with DTF if your project has:

- Photographic or Intricate Designs: DTF nails gradients, super-fine lines, and a massive spectrum of colours with killer accuracy.

- Small Order Quantities: If you need fewer than 20 shirts, DTF is almost always the smarter financial move. No screen setup fees means no wasted money.

- Multiple Fabric Types: This technique works brilliantly on pretty much anything you throw at it—cotton, polyester, blends—without losing any of that punchy colour.

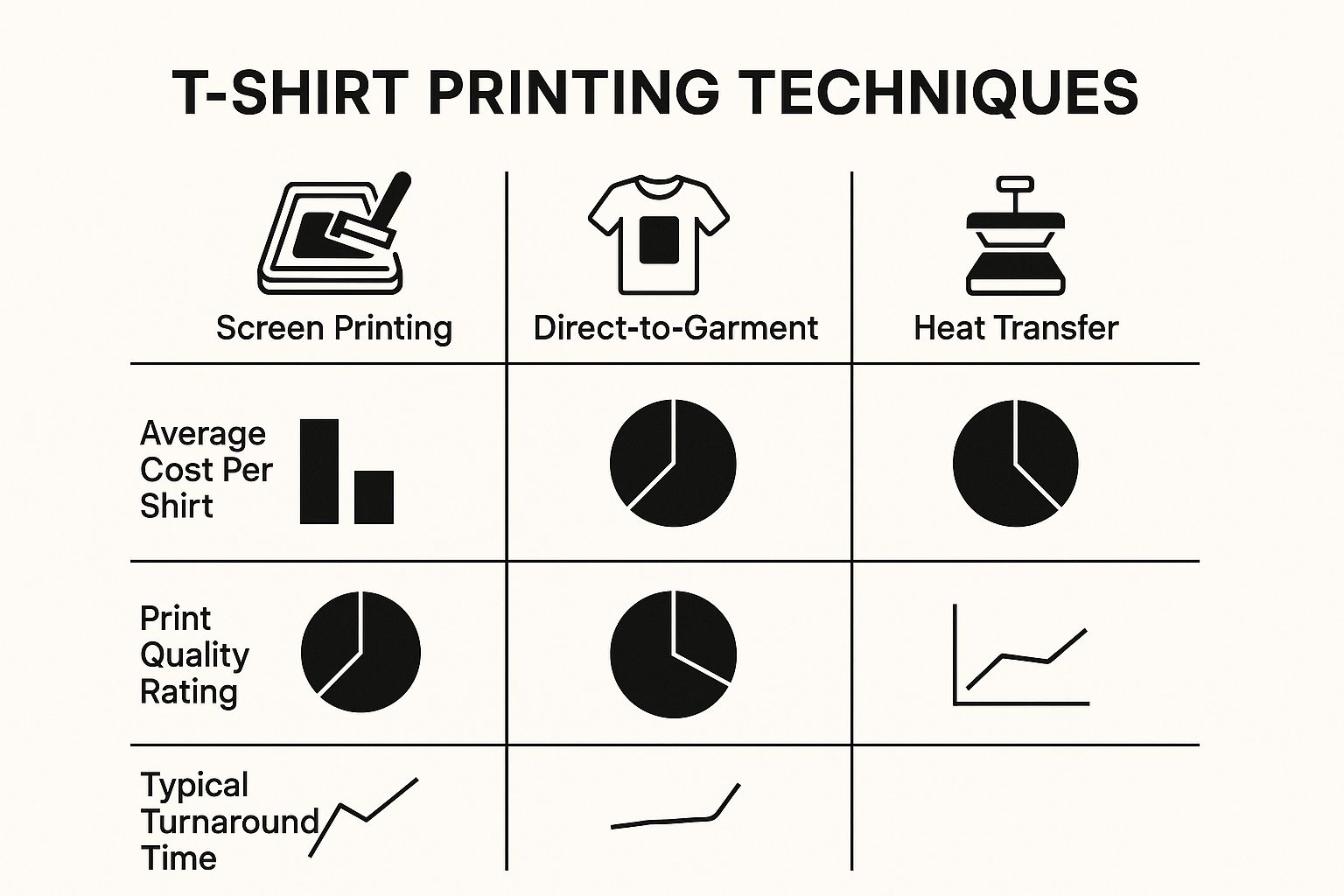

This gives you a quick visual breakdown of the different methods, comparing costs, quality, and typical turnaround times.

You can see how old-school methods like screen printing only get cheap when you're ordering a ton, while digital printing absolutely dominates on quality for smaller, more detailed jobs.

Why Choose Screen Printing

Screen printing has ruled the industry for decades for a reason: nothing beats its durability and cost-effectiveness when you go big. Yeah, the setup is more involved, but once you're printing in bulk, the cost per shirt plummets.

Screen printing is your go-to when:

- You Need a Large Batch: For orders of 25 shirts or more, screen printing is the undisputed king. It’s built for band merch, company gear, or event apparel.

- Your Design Has Few Colours: The process is most efficient for bold designs with one to four solid colours. No gradients, no fuss.

- Vibrancy is Key: The thick layer of ink lays down exceptionally bright and solid colours that pop like crazy, especially on dark fabrics.

To help you decide, here’s a quick head-to-head comparison.

DTF Printing vs Screen Printing A Quick Comparison

| Feature | DTF (Direct-to-Film) Printing | Screen Printing |

|---|---|---|

| Best For | Small batches, full-colour photos, and complex designs. | Large batches (25+) with simple, bold graphics. |

| Colour Limit | Virtually unlimited. Perfect for gradients and shades. | Limited. Each colour needs its own screen, adding cost. |

| Fabric Compatibility | Excellent on cotton, polyester, blends, and more. | Best on cotton but can work on other fabrics. |

| Feel of Print | Soft and flexible, sits on top of the fabric. | Can be thicker, becomes softer after washing. |

| Cost | More cost-effective for one-offs and small runs. | Much cheaper per shirt for large volume orders. |

| Durability | Very durable with proper care, holds colour well. | Extremely durable, often outlasts the garment itself. |

This table cuts through the noise. If you need a few shirts with a wild, colourful design, DTF is your weapon of choice. If you're outfitting an army with a bold logo, screen printing is the only way to go.

Ultimately, this isn't about which method is "better." It's about which tool is right for your specific vision. For a full-on technical assault on the differences, check out our in-depth guide comparing DTF vs screen printing for graphic tees. Nailing this choice is the first step to getting a pro-quality custom shirt that actually looks the way you imagined it.

How To Prepare Your Artwork For Printing

A killer t-shirt idea deserves a killer print file to match. Getting your artwork ready for production is hands down the most important step to make sure what you see on screen translates perfectly onto the fabric. It's a common rookie mistake to skip this bit, and it's the fastest way to end up with blurry images, weird colours, and a whole lot of disappointment.

Think of your design file as the blueprint for your t-shirt. If the blueprint is smudged or has the wrong measurements, the building is going to be a mess. Same deal here. A low-quality file will always produce a low-quality print, no matter how fancy the printer is.

Raster vs Vector: The Two File Types

First things first, you need to get your head around the two main types of digital images: raster and vector. They act very differently, especially when you try to change their size.

- Raster files (PNG, JPEG): These are made of tiny squares called pixels. They're brilliant for photos and graphics with lots of detail and colour. The catch? If you try to blow up a raster image too much, it gets all pixelated and blurry.

- Vector files (AI, EPS, SVG): These are built from maths—lines and curves, not pixels. This means you can scale them to any size you want, from a postage stamp to a bus ad, with zero loss of quality. They’re perfect for logos, text, and graphics with solid blocks of colour.

For most custom t shirt printing london projects, especially those with complex colours and gradients, a high-resolution PNG file is the way to go. But if your design is a clean logo or just some text, a vector file will guarantee the absolute sharpest lines possible.

Getting Your File Print-Ready

Once you know what file type you need, the next job is making sure it meets the technical specs. Trust me, poor file prep is the number one cause of printing delays and surprise costs. A few minutes of checking now can save you a massive headache later.

Your print file is the direct instruction manual for the printing machine. Vague or dodgy instructions will result in a flawed final product. Clean, high-quality artwork is everything if you want a professional finish.

Run through this quick checklist to dodge the most common artwork mistakes:

- Check Your Resolution: For raster images like PNGs, the industry standard is 300 DPI (dots per inch) at the actual size you want it printed. An image you've just saved from a website will almost certainly look fuzzy when it's on a shirt.

- Use a Transparent Background: This is a big one. Unless you actually want a solid box of colour printed behind your design, always save your final artwork as a PNG with a transparent background. This tells the printer to only print your graphic.

- Outline Your Fonts: If you're working in a vector program like Adobe Illustrator, convert all your text to outlines. This turns the text into a fixed shape, so you don't have to worry about the print shop not having the right font installed.

- Consider Your Colours: If you can, design in CMYK colour mode, because that’s what printers use. The colours you see on your screen (which are in RGB) can sometimes look a bit different when they’re printed on fabric.

Nailing these steps sets your project up for success from the get-go. For a deeper dive into the creative side of things, check out our complete guide to custom t-shirt printing.

Here's the rewritten section, crafted to sound like an experienced human expert, following the provided style guide and requirements.

Choosing the Perfect T-Shirt for Your Project

Let's get one thing straight: the t-shirt you choose is just as important as the design you print on it. A killer graphic on a cheap, flimsy tee completely misses the point. It’s like putting a masterpiece in a shoddy frame. The right garment affects everything—comfort, durability, and even how bold your colours look.

Think of the t-shirt as the canvas. The texture, weight, and quality are all part of the final product. Your first big decision? The fabric. Each material has a totally different feel and purpose, and understanding them is key to getting the result you want for your custom t shirt printing london order.

Getting a Feel for Fabric Types

You’ll mainly run into three options. Each has its own personality, so let's break them down.

-

100% Cotton: The OG. The timeless classic. Cotton is soft, breathable, and just feels good against your skin. It’s also a fantastic surface for printing, soaking up ink to give you those rich, deep colours. If you want that traditional, high-quality feel, this is your go-to.

-

Poly-Cotton Blends (e.g., 50/50): This is where you get the best of both worlds. Mixing cotton with polyester gives you a shirt that’s tougher, less likely to shrink or wrinkle, and wicks away moisture. It’s the perfect workhorse for sportswear, uniforms, or anyone who’s constantly on the move.

-

Tri-Blends (Cotton/Polyester/Rayon): If you’re after ultimate softness, this is it. The rayon in the mix gives the fabric an incredible drape and a lightweight, almost silky feel. It often creates that slightly heathered, vintage look you see in high-end retail and fashion brands. It just feels premium.

The global custom t-shirt market is worth around USD 4.07 billion in 2024, and the big story right now is sustainability. Here in the UK, printers are leaning heavily into organic cotton and other eco-friendly materials because that's what people want. It’s a conscious choice, and you can explore more about these market trends to see where things are headed.

Why Weight and Fit Make All the Difference

Fabric is sorted, but you’re not done yet. Two final things to consider are the garment's weight and its fit. T-shirt weight is measured in GSM (Grams per Square Metre). A lower GSM, say 140-160, gives you a lighter, airier tee that’s perfect for summer. A higher GSM, like 180-220+, feels much more substantial and durable—a real heavyweight champ.

And finally, the fit. This pulls the whole look together. Are you going for a classic fit with its standard, relaxed shape? Or maybe a slim fit that’s more contoured and modern? You could even go for an oversized fit for that current streetwear vibe. The right fit isn't just about comfort; it's about making sure the final shirt speaks your brand’s language and connects with the people you want to wear it.

Getting Real About Costs And Turnaround Times

Alright, let's cut to the chase and talk about the two things that really matter: how much will this cost, and when can I get my shirts? The price for your custom t shirt printing london order isn't a simple one-size-fits-all number. It’s a mix of a few key ingredients.

The biggest factor is the print method. As we've covered, screen printing is the undisputed king for massive bulk orders. The more you print, the cheaper each shirt gets because you're spreading the setup cost across hundreds of units. DTF, on the other hand, is your go-to for smaller batches. There are no setup fees, making it perfect for one-off prints or testing out a new design without committing to a huge run.

Next up are your design and the garment you choose. A simple one-colour logo on a standard cotton tee is always going to be easier on the wallet than a full-colour photograph printed on a premium, super-soft tri-blend shirt. Think of it like ordering a coffee – a straight black Americano is always cheaper than a fancy latte with three different syrups and oat milk.

Setting Realistic Production Timelines

Knowing your timeline is just as crucial as nailing down the budget. Here in London, a standard turnaround for most print jobs lands somewhere between 5 to 10 working days. This clock starts ticking the moment you sign off on the final design proof. That window gives the print shop enough breathing room to get your job on the schedule, prep the materials, and run quality checks without cutting corners.

But hey, life moves fast and sometimes you need things yesterday. Most printers get it and offer rush services for an extra fee. This can slash your wait time down to just a few days, but you have to be upfront about your deadline from the very beginning to see what's actually possible.

Local logistics and even big city-wide events can throw a spanner in the works. Think about it—if a massive sporting event is happening, demand for team gear skyrockets across the capital, which can slow down the queue for smaller orders.

This is a real thing in the UK. When the government pumps money into sports programmes, like the Rugby Football Union’s 'Impact 25' initiative, it creates a massive surge in demand for team apparel. That wave ripples through the entire local printing industry.

At the end of the day, clear communication with your printer is everything. Be straight with them about your budget and deadline from the get-go, and you'll find a solution that works. To get a better handle on who to talk to, check out our guide on choosing the best custom T-shirt printers for your project.

Your Step-by-Step Ordering Guide

Ready to bring your t-shirt idea to life? Ordering custom t shirt printing in London is actually pretty straightforward once you know the ropes. This guide will walk you through it, step by step, so you can go from a design on your screen to a finished product in your hands without any of the guesswork.

Think of it as a team effort between you and your printer. You bring the vision, and they bring the expertise to make it happen. A little bit of prep on your end makes the whole process faster and smoother for everyone.

It all starts with getting your ducks in a row. Before you even think about hitting 'send' on an email to a print shop, you need to have the essentials locked down.

Step 1: Finalise Your Core Details

This first stage is all about making the key decisions that define your entire project. Nailing these details down first means you'll get a quick, accurate quote and avoid any back-and-forth later.

- Artwork Finalisation: Your design file needs to be 100% complete and ready to print. That means setting it to 300 DPI at the size you want it printed, and saving it as a PNG file with a transparent background.

- Garment Selection: Decide on the exact t-shirt you want. What style? What fabric? What colour? Know if you're after a premium heavyweight cotton tee or something lighter like a poly-blend.

- Quantity Breakdown: Get a clear list of how many shirts you need in each size. This is crucial for pricing, especially if you're considering screen printing.

Once you’ve got all that sorted, you're ready to actually talk to a printer and get the ball rolling.

Step 2: Submit Your Order and Review the Proof

With your details organised, you can confidently send over your request. The printer will take your artwork and specs and create a digital mock-up for you. This is called a proof.

This proof is your last line of defence against mistakes. Check it like your life depends on it. Scrutinise the spelling, the colours, the placement, and the size of the graphic. If you approve a proof with an error, that mistake is going into production on your dime.

Once you give the green light on the proof and sort out the payment, your job officially hits the production queue. From there, it's over to the printers to work their magic and bring your design from screen to fabric.

Clear communication and a thorough check at this stage are the real secrets to a flawless final product. For a deeper dive into getting your designs just right, check out our guide to getting your t-shirt printing personalised.

Got questions? Good. Getting into custom t-shirt printing always brings up a few things, so let's clear the air. We’ve pulled together the most common queries we get from people printing tees in London, so you can order with zero guesswork.

What’s The Minimum Order?

This really boils down to the printing tech. For newer methods like DTF printing, most London shops (including us) have no minimum order quantity. That's a game-changer if you just want one prototype, a killer one-off gift, or a small run for your crew.

Screen printing is a different beast entirely. Because of the heavy setup involved for each colour, it only makes sense financially when you're printing in bulk. For that method, you're usually looking at a minimum of around 20-25 shirts.

Can I Supply My Own T-Shirts?

Look, we get why you'd ask, but most pro print shops will want to supply the garments themselves. There are solid reasons for this – it’s not just about making an extra buck. They’ve spent ages testing specific tees with their inks and machines to make sure the final print is sharp, durable, and won't flake off after one wash.

Using their own tried-and-tested garments means the quality is guaranteed. It stops common disasters like ink refusing to stick or colours looking washed out on untested fabrics. This is how you get a result that looks genuinely professional.

It just takes all the "what ifs" out of the equation and ensures the final shirt is something everyone's proud of. It’s all about quality control.

How Do I Look After My Custom T-Shirt?

Taking care of your custom print is easy, and it'll keep it looking fresh for years. Just stick to these three golden rules to protect the design:

- Wash It Inside-Out: No exceptions. Always flip the tee inside-out before it hits the machine.

- Go Cold & Gentle: Stick to a cold wash (around 30°C) and skip the harsh detergents or bleach.

- Air Dry If You Can: Tumble dryers are the sworn enemy of custom prints. Hang your shirt up to air dry. This keeps the ink vibrant and stops it from cracking.

And if you absolutely have to iron it, do it on the reverse side. Never, ever put a hot iron directly on the print itself.

Ready to turn your design into something real with DTF printing? At Psyque - DTF Print & Press, we live for this stuff, combining top-tier tech with a serious passion for creating gear you’ll actually want to wear. Check out our collections or get your own custom project rolling today. Find us at https://psyque.co.uk.