DTF Gang Sheets A Complete Guide to Smarter Printing

Share

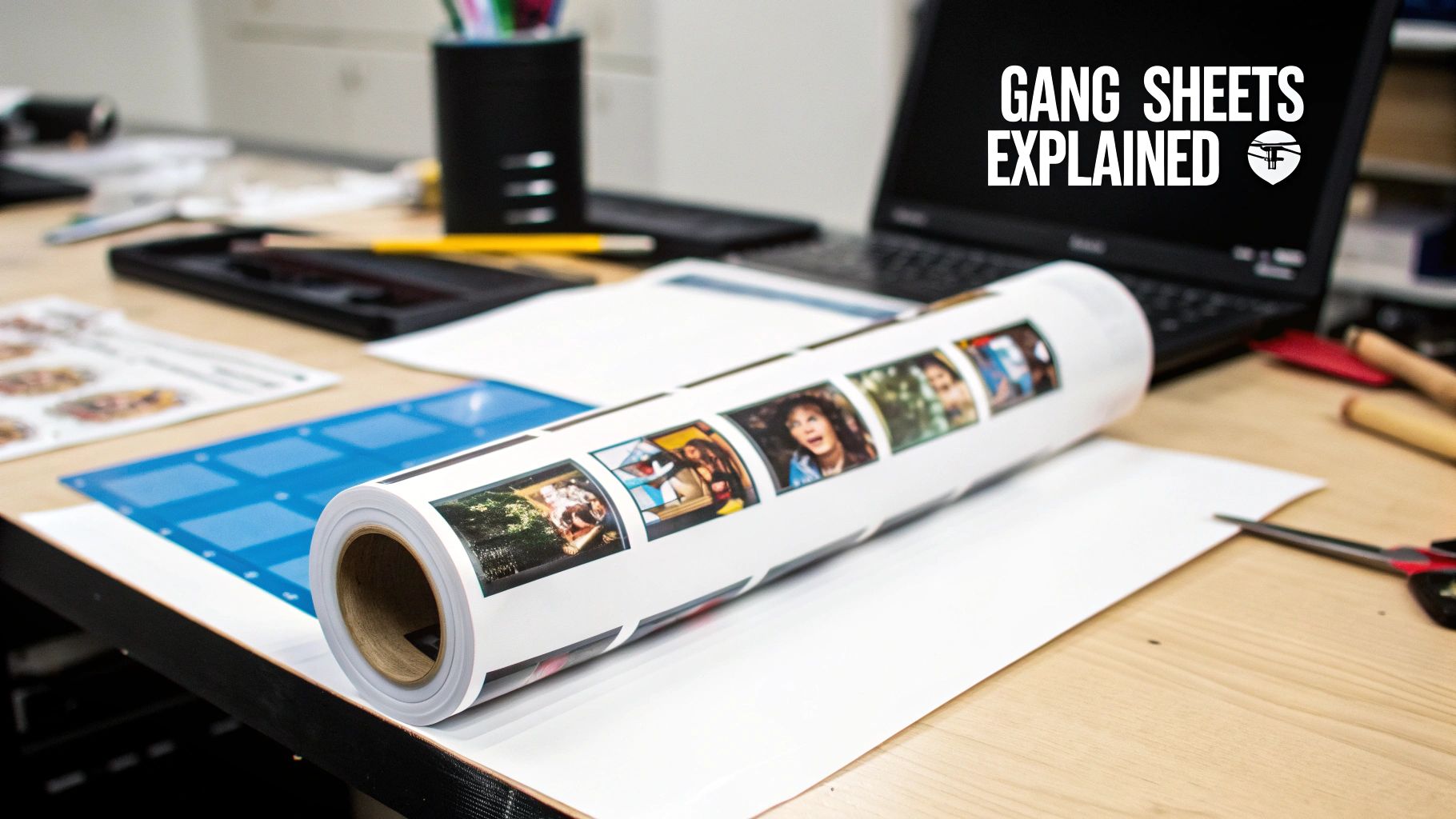

DTF gang sheets are one of the smartest ways to handle apparel printing, letting you group multiple designs onto a single large transfer film. Think of it like arranging different shapes on a sheet of cookie dough to get as many biscuits as possible from one batch. It’s a simple idea that turns lots of little print jobs into one efficient, large-scale run.

Understanding the Power of DTF Gang Sheets

At its heart, a DTF gang sheet is just a large piece of PET film where you've "ganged up" multiple graphics together. Instead of printing one logo at a time, you can fill a whole sheet with different designs for various clients, different sizes, or even different placements on a garment. It’s this clever but straightforward method that makes Direct-to-Film printing both affordable and incredibly productive.

This ganging process has become a cornerstone of the UK’s DTF printing scene. It allows printers to squeeze numerous designs onto one film, maximising every inch of material and cutting waste right down. It’s a huge step up from older methods like screen printing. Since DTF started gaining serious traction around 2019, it has grown rapidly as UK companies have really dialled in the technology.

The Core Concept Explained

Let's break it down with a real-world example. Imagine you’ve got a few small jobs on your plate: ten chest logos for a local café, fifteen sleeve prints for a kids' football team, and five big graphics for the back of some event hoodies. Printing each of these separately would be a nightmare of multiple setups and wasted film.

This is where a gang sheet saves the day. You simply arrange all of these completely different designs onto one big layout. You send a single file to your printer, and everything gets printed in one smooth, continuous pass. Once it’s done, you just cut the individual designs apart, and they're ready to be pressed.

This completely changes your workflow from a stop-start, one-by-one process into a streamlined batch operation. The benefits are impossible to ignore:

- Cost Efficiency: You’re paying for the sheet, not for how many designs you cram onto it. This massively drops your cost-per-print.

- Material Optimisation: By filling up the entire surface, you make sure hardly any film goes in the bin, which is great for your wallet and the planet.

- Time Savings: Printing everything in a single go slashes machine setup and print time, helping you get orders out the door much faster.

The real magic of a DTF gang sheet lies in its beautiful simplicity. It’s a strategy that lets small businesses and independent brands go toe-to-toe with bigger players by producing varied, small-batch orders without the crazy costs usually tied to custom printing.

To get you started, here’s a quick rundown of the fundamentals.

DTF Gang Sheet Fundamentals at a Glance

| Concept | Description | Primary Benefit |

|---|---|---|

| Ganging | Grouping multiple, distinct designs onto a single transfer film. | Maximises the use of every square inch of the film. |

| PET Film | The special carrier film onto which DTF inks and adhesive are printed. | Provides a stable base for the transfers before they're pressed. |

| Batch Printing | Printing all the ganged designs in a single, continuous print run. | Drastically reduces production time and setup costs. |

| Cutting | Separating the individual designs from the sheet after printing. | Prepares each transfer for application onto its respective garment. |

This table shows just how straightforward the process is. Each element works together to make your printing cheaper and faster.

For anyone new to this, learning how to prepare and use these sheets properly is the first step toward getting professional-quality results. A solid understanding of setting up your DTF transfer sheets is what makes the difference between a failed print and a perfect one. This method gives you the freedom to test out new ideas, say "yes" to all sorts of client requests, and ultimately, boost your profit margins on every single garment you produce.

Why Gang Sheets Are a Game Changer for Your Business

Switching to DTF gang sheets isn't just a small adjustment to your workflow; it's a complete overhaul of how you print. For any business, from a one-person startup to a buzzing print shop, this method directly boosts your bottom line, speeds up production, and makes you far more adaptable. The benefits really boil down to three key things: cutting costs, printing faster, and gaining incredible design freedom.

When you shift from a one-design-at-a-time mentality to a batching approach, you unlock efficiencies that just weren't possible before. Think of it like meal prepping for the week instead of cooking every single meal from scratch. One is slow and reactive, the other is smart, saving you heaps of time and money down the line.

Radical Cost Reduction Per Print

The first and most powerful advantage of using DTF gang sheets is the massive drop in what you pay for each design. When you buy a transfer sheet, you're paying for the whole sheet of film, not the number of designs on it. This simple fact is where the magic really happens for your profit margins.

Imagine you’ve got a small chest logo that's 10cm x 10cm. Printing just that one design on a small sheet is pretty wasteful. But on a large gang sheet, you could cram dozens of them on there, right alongside orders for other clients. Your film cost is the same, but now it's spread across all those designs, making each individual transfer a whole lot cheaper.

This approach is a massive win for sustainability, too. Using UK DTF gang sheets helps create a more efficient and greener printing operation. Because one sheet can hold so many different designs, you can cut your film waste by up to 40% compared to printing singles. Plus, these prints are built to last; UK lab tests show they can handle at least 60 washes without any major fading, which blows many traditional heat transfer methods out of the water. You can find more details on DTF durability over at dtftransfers.co.uk.

Accelerated Production Speed and Turnaround

In the custom apparel world, time is money, and speed is your secret weapon. Gang sheets slash the setup and printing time needed to get through multiple orders. Instead of loading, setting up, and printing dozens of separate jobs, you just combine them all into one smooth print run.

This has a brilliant knock-on effect across your entire workflow:

- Less Fiddling with Machines: You only have to set up your printer and software once for the whole sheet.

- Faster Printing: The printer just keeps going, without all the stopping and starting of individual jobs.

- Streamlined Finishing: Applying the adhesive powder and curing the prints happens in one go for the whole batch.

What this really means is you can get more jobs done in a day. Faster turnarounds make for happy clients, which leads to repeat business and gives you the breathing room to take on more work without buying more gear. You become the go-to printer who always delivers on time.

Unmatched Flexibility for Your Business

Maybe the most overlooked benefit of DTF gang sheets is the sheer creative and business freedom they give you. This method breaks down the financial barriers that make small or varied print runs a headache, opening up a world of new opportunities.

By grouping all sorts of jobs onto one sheet, you can finally say "yes" to those small, one-off orders you might have turned away before. That kind of flexibility makes you indispensable to a much wider range of customers.

Just think about the practical side of it:

- Testing New Designs: Got a new graphic you want to try out without committing to a massive run? Just pop one or two onto your next gang sheet. It's a cheap, zero-risk way to see if your customers like it.

- Serving Multiple Clients at Once: A local football club, a coffee shop, and a corporate client can all have their logos printed on the very same sheet, at the same time.

- Offering More Variety: You can easily create themed sheets with several related designs. This lets you offer collections to your customers without you having to sit on piles of expensive stock.

This kind of adaptability lets you react quickly to market trends and what your customers want, making your business stronger and more competitive.

Preparing Your Artwork for a Flawless Print Run

Here’s a truth every seasoned printer knows: the quality of your final print is decided long before you even think about switching on the heat press. Amazing prints are born from amazing artwork, and getting your digital files right is the single most important step to avoid fuzzy graphics, costly reprints, and frustrating delays.

Think of your digital file as the blueprint for your final garment. If that blueprint has blurry lines, incorrect colours, or sloppy dimensions, the finished product will inherit every single one of those flaws. Nailing the technical details from the get-go is how you guarantee that what you see on your screen is exactly what you get on your fabric.

The Non-Negotiables of File Setup

Before you even think about arranging designs on your gang sheet, you need to make sure each individual art file is up to scratch. It's not just about a pretty picture; there are industry standards for a reason. For example, understanding optimal print resolution like 300 DPI is absolutely fundamental for achieving sharp, professional results. A low-resolution image will look pixelated and amateur, no matter how good your printer is.

Here are the absolute must-haves for your artwork files:

- File Format: Always, always use a PNG (Portable Network Graphics) file. This is the gold standard because it supports transparent backgrounds, which is essential for DTF. Using a JPEG will result in your design being printed inside a solid white box—a classic rookie mistake you want to avoid.

- Resolution: Your artwork must have a resolution of at least 300 DPI (Dots Per Inch). This ensures every line is crisp and every detail is sharp. Be warned: most images pulled from the internet are a low-resolution 72 DPI and are completely unsuitable for professional printing.

- Colour Mode: Make sure your file’s colour mode is set to CMYK (Cyan, Magenta, Yellow, Key/Black). This is the colour model that printers actually use, so it ensures the colours on your screen will closely match the final print. Files left in RGB mode can lead to some nasty surprises and colour shifts when they come off the press.

Mastering Your Gang Sheet Layout

Once your individual designs are perfected, it’s time to arrange them on the gang sheet canvas. This part is a mix of art and science. The goal is to maximise every bit of space while making sure each design is easy to cut out and use later on.

Start by creating a new document in your design software (like Adobe Illustrator, Photopea, or even Canva) with the exact dimensions your UK supplier provides—say, 56cm x 100cm. Now you can start placing your perfectly prepared PNG files. It’s like a game of Tetris; you want to fit as many pieces as possible with the least amount of wasted space.

The secret to a profitable DTF gang sheet is treating every square centimetre like valuable real estate. By nesting smaller designs around larger ones and rotating graphics to fit snugly, you directly lower the cost of each individual transfer.

To create an efficient layout, stick to these key principles:

- Nest and Rotate: Tuck your smaller designs, like neck labels or sleeve logos, into the empty spaces around your bigger graphics. Don't be afraid to rotate designs 90 or 180 degrees to find the perfect fit.

- Leave a Cutting Gap: While you want to pack things in tightly, don't let your designs touch. Always leave a small gap of at least 0.5cm to 1cm between each graphic. This gives you enough breathing room to comfortably cut them apart with scissors without accidentally slicing into a neighbouring design.

- Check for Overlaps: Before you finalise anything, zoom in and do a final sweep of your entire layout. Make absolutely sure no parts of different designs are overlapping. Even a tiny overlap can ruin two transfers, wasting both material and money.

By following this checklist, you set yourself up for a perfect print run, every single time. This attention to detail not only guarantees top-quality results for your https://psyque.co.uk/blogs/news/t-shirt-printing-personalised projects but also makes your whole production process smoother, saving you time and boosting your profits.

How to Choose the Right UK Supplier

Choosing the right UK supplier for your DTF gang sheets is a lot more like picking a business partner than just buying a product. Think about it: the quality, speed, and reliability of your printer will have a direct impact on your own reputation and bottom line. A great supplier sends you consistent, vibrant prints on schedule, while a bad one can cause missed deadlines, ruined garments, and seriously unhappy customers.

The first step is to look beyond the price tag. Of course, cost matters, but it's just one piece of the puzzle. You need a partner who gets the fast-paced nature of the custom apparel world and has the setup to support you as you grow. The best suppliers offer a smart blend of quality, speed, support, and value that fits what you actually need.

Evaluating Print Quality and Materials

The actual physical quality of the transfers should be your number one priority. Let's be clear: not all DTF prints are created equal. The final look and feel all come down to the quality of the inks, adhesive powder, and PET film your supplier is using. Don't be shy about asking direct questions about their gear and materials.

When you're checking out a potential supplier, zero in on these key areas:

- Ink Vibrancy and Accuracy: Ask them to send you a sample pack. It's the only way to see for yourself how their colours pop and how well they handle complex designs. Look for deep, rich blacks, bright whites, and smooth colour gradients.

- Adhesive Powder Quality: A top-notch adhesive powder makes sure the transfer bonds properly to the fabric and has enough stretch to avoid cracking. Cheap powder can leave prints feeling stiff or, even worse, peeling after just a couple of washes.

- Film Consistency: The PET film should be high-quality, allowing for a clean and easy "cold peel" after pressing. Inconsistent or cheap film can leave sticky residue behind or turn the peeling process into a complete nightmare.

Speed and Reliability Are Non-Negotiable

In the world of custom printing, speed is a massive competitive advantage. Your ability to offer a quick turnaround for your own customers often hangs entirely on how fast your supplier can get printed DTF gang sheets into your hands.

The UK textile market has jumped on DTF printing in a big way, making DTF gang sheets the go-to for small businesses needing to work efficiently. Many UK suppliers now dispatch orders within just 1-2 business days after the artwork is approved, and some even offer same-day dispatch for those rush jobs.

A supplier’s quoted turnaround time is a promise. Before you commit, dig into their customer reviews or ask other printers about their reliability. Consistent on-time delivery is just as crucial as the print quality itself.

Customer Support and Ordering Process

A simple, straightforward ordering process can save you hours of headaches. Look for a supplier with a user-friendly website that makes uploading your gang sheet a breeze. Do they offer clear file setup guides or templates? A supplier who invests in making things easy for you clearly values your time.

Just as important is their customer support. What happens when a file is rejected or a delivery goes missing? Can you easily get hold of a real person who can actually help you solve the problem? Good support is invisible until you need it—and then it's everything. Our guide on how to find the best DTF near me has more tips on what to look for in a printing partner. Choosing a supplier who is genuinely helpful and responsive is an investment in your own peace of mind.

To help you compare your options, here’s a quick checklist of what to look for when choosing a UK-based supplier.

Comparing UK DTF Gang Sheet Suppliers

| Feature to Compare | What to Look For | Why It Matters |

|---|---|---|

| Print Quality | Request a sample pack. Check ink vibrancy, wash durability, and stretchiness. | This is your product's reputation. Poor quality prints lead to unhappy customers and refunds. |

| Turnaround Time | Look for stated dispatch times (1-2 business days is standard). Check for rush order options. | Fast turnarounds allow you to be more competitive and meet tight deadlines for your own clients. |

| Material Specs | Ask about the brand of ink, film (cold peel vs. hot peel), and adhesive powder they use. | High-quality materials ensure a soft feel, good stretch, and long-lasting durability after washing. |

| Customer Support | Is there a phone number or live chat? How quickly do they respond to emails? | When you have an urgent issue, you need a responsive team that can solve problems quickly. |

| Ordering System | Is the website easy to navigate? Is the gang sheet uploader intuitive and bug-free? | A clunky or confusing ordering process wastes your valuable time and can lead to costly mistakes. |

| Shipping Options | Do they offer reliable couriers (e.g., Royal Mail, DPD)? Are there next-day delivery options? | Reliable shipping ensures you get your transfers when you expect them, avoiding production delays. |

| Customer Reviews | Check Google Reviews, Trustpilot, or industry forums for real feedback. | Reviews from other printers give you an honest look at a supplier's consistency and reliability. |

Taking a few minutes to run through this checklist can save you a world of trouble down the line and help you find a supplier who truly feels like a partner in your business's success.

A Practical Guide to Pressing Your DTF Transfers

You’ve designed your artwork, you’ve got your printed gang sheet in hand, and now it's time for the most satisfying part of the whole process—bringing it all to life on fabric. This is where the magic really happens, turning that thin piece of film into a durable, vibrant design that becomes part of the garment. The heat pressing process itself is pretty straightforward, but getting it perfect comes down to the details: temperature, time, and pressure.

Think of it like the final act of a play. Your design work was the script, printing was the rehearsal, and now the heat press is your opening night. Nail this stage, and you’ll have prints that not only look professional but feel great and will survive dozens of washes.

Setting The Stage: The Pre-Press

Before you even think about laying down your transfer, there’s one step you absolutely cannot skip: the pre-press. It’s simple—just press the empty garment for about 5-10 seconds. It might feel like an extra step, but trust me, it’s the secret to a flawless finish.

Why is it so important? A pre-press does two critical things:

- It banishes moisture: Fabric, especially cotton, secretly holds onto a surprising amount of moisture. If you don't get rid of it, that moisture turns into steam under the press, which can mess with the transfer's adhesive. This is a major cause of peeling later on.

- It smooths out wrinkles: Pressing the garment first gives you a perfectly flat, smooth canvas to work on. This ensures the entire transfer makes even contact, preventing any weird texturing or lifting edges in your design.

Honestly, skipping the pre-press is one of the most common mistakes I see beginners make. It’s such a simple thing, but it makes a massive difference to the quality and longevity of your work.

Dialling In Your Heat Press Settings

Not all fabrics are created equal, and your heat press settings need to reflect that. The last thing you want is to scorch a delicate polyester blend or have an adhesive fail to activate. Your DTF supplier will give you their specific recommendations, but here are the general industry standards for the most common materials.

- 100% Cotton: Aim for a temperature between 150°C and 165°C (300°F to 330°F). A good press time is around 10-15 seconds with medium-to-firm pressure. Cotton is a workhorse fabric, so it's pretty forgiving if you're just starting out.

- Polyester & Blends: These synthetics are much more sensitive to heat. You'll want to lower the temperature to around 135°C to 145°C (275°F to 295°F) and press for a shorter time, about 8-12 seconds. This will stop you from melting or scorching those delicate fibres.

- Pressure Consistency: No matter the fabric, you're looking for medium to firm pressure. A good way to gauge this is that the press should be firm enough to leave a slight outline in the fabric, but not so hard that it squishes the adhesive out from the edges of your design.

The key to a perfect press is consistency. Make sure your heat press gives even heat and pressure right across the platen. Uneven pressure is the number one culprit behind transfers that start peeling at the corners.

The infographic below gives a great overview of what to look for when partnering with a DTF supplier—it’s not just about the prints, but the whole service.

This just goes to show that a reliable partnership is about more than just a good price; it’s about quality materials, dependable service, and solid support when you need it.

Mastering The Cold Peel Technique

After the press, there’s one final, crucial step: removing the carrier film. The vast majority of professional DTF transfers, including those on dtf gang sheets, are designed for a cold peel. The name is literal—you have to let the transfer cool down completely to room temperature before you even think about peeling that film off.

Trying to peel it while it’s still warm (often called a "hot peel") is a recipe for disaster. The ink and adhesive need that cooling time to properly set and bond into the fabric’s fibres. If you peel too early, you risk pulling up parts of the design with the film, leaving you with a patchy, ruined print.

Here’s how to get the perfect cold peel every time:

- Carefully take the garment off the heat press.

- Lay it on a flat, cool surface and just leave it for at least 30-60 seconds, or until it's cool to the touch.

- Once it's cool, start from a corner and peel the film back slowly, keeping it low and rolling it back against itself.

Once the film is off, a great pro tip is to do one last press for 2-5 seconds. Just place a sheet of parchment paper over the design and give it a quick hit of heat. This really locks the transfer in, improves its durability, and gives it a softer, more professional matte finish. For a deeper dive, check out our guide on DTF transfers ready to press, which walks you through the entire process.

Maximising Profit with Smart Gang Sheet Strategies

Using DTF gang sheets is a great starting point, but truly mastering them is how you turn an efficient printing method into a serious profit engine. This means you need to look beyond simply fulfilling orders and start thinking strategically about every single square centimetre of your film. Getting smart with your layouts and costing can unlock hidden revenue and boost your margins on every job.

This approach is all about shifting your mindset. You're not just printing designs; you're actively creating value from what would otherwise be wasted space. It’s about turning a tool into a business strategy.

Turn Gaps into Gains with Stock Designs

Take a close look at your next gang sheet layout. I guarantee you’ll see small, awkward gaps between your main graphics. Most people write this off as unavoidable waste, but a sharp business owner sees an opportunity. These empty spaces are prime real estate for printing small, sellable stock designs.

Fill these gaps with little graphics that are always in demand:

- Pocket Logos: Simple, stylish icons or brand marks that you can sell as standalone add-ons.

- Custom Neck Tags: Offer clients professionally branded tags as a finishing touch for their garments. It's a fantastic upsell.

- Miniature Graphics: Think tiny hearts, stars, lightning bolts, or popular emojis. These can be sold as fun extras for decorating sleeves, hats, or other accessories.

By doing this, you're essentially creating a free inventory of high-margin products from material you’ve already paid for. It’s a dead-simple way to add another revenue stream to your business with zero extra cost.

The most profitable printers understand that a DTF gang sheet isn't just a layout—it's a canvas for creating assets. Every unused space is a missed opportunity to generate extra income.

Batching Orders for Better Pricing

One of the most effective ways to slash your costs is by unlocking volume discounts from your supplier. Instead of sending five separate small jobs throughout the week, group them all together onto one or two larger dtf gang sheets. This batching strategy lets you tap into bulk pricing, which can significantly drop your cost per design.

To push your business performance even further, it's worth exploring valuable insights on effective e-commerce growth strategies that can complement your printing operations. For a more detailed look at sourcing transfers affordably, our guide to finding cheap DTF transfers offers practical tips specifically for UK businesses.

Calculate Your True Cost Per Design

Finally, to price your products with confidence, you absolutely have to know your exact cost for each transfer. A simple formula is all you need to get the clarity required to ensure every sale you make is a profitable one.

- Start with the total cost of your printed gang sheet (don't forget shipping).

- Count the total number of individual designs you managed to fit on that sheet.

- Divide the total cost by the number of designs.

Formula: (Total Sheet Cost) / (Number of Designs) = True Cost Per Design.

This straightforward calculation reveals the real cost of each graphic, taking all your clever layout efforts into account. Once you have this number, you can set your retail prices accurately, guarantee a healthy profit margin, and build a more sustainable and successful printing business.

Got Questions About DTF Gang Sheets? We've Got Answers

Stepping into the world of DTF printing is exciting, but it's totally normal to have a few questions before you hit 'print'. Getting those last few details ironed out is what builds confidence. Think of this as your go-to cheat sheet for the most common queries we hear from both seasoned pros and first-timers.

We've rounded up the questions that pop up most often, covering everything from file prep to fabric choices. Let's clear up any confusion so you can get your project started smoothly.

Your Top Questions Answered

-

What's the best file format for a DTF gang sheet?

Always go for a high-resolution PNG file (300 DPI) with a transparent background. This is the gold standard for a reason. It guarantees your designs have sharp, clean edges, avoiding any of those dreaded white or coloured boxes around your graphics. Stay away from JPEGs—they can't handle transparency and will almost always result in a fuzzy, lower-quality print. -

Can I mix designs for different fabrics on one sheet?

Absolutely! This is one of the best things about DTF. You can stick a logo for a cotton t-shirt right next to a design destined for a polyester hoodie on the same sheet. The transfer itself is incredibly versatile. The only thing you'll need to do is adjust your heat press settings—like temperature and press time—to match the specific garment you're pressing onto.

Planning and Ordering Your Sheets

Getting your designs laid out correctly and understanding the ordering process is just as crucial as getting the files right. Here are a couple of common questions about the logistics.

The smartest way to plan your gang sheet is to treat your design canvas like the real thing. Create a document with the exact dimensions your supplier offers. This simple step removes all the guesswork and shows you precisely how many designs you can fit, so you get the most out of every penny spent.

-

How do I figure out how many designs will fit on my sheet?

The easiest way is to use design software like Adobe Illustrator, Photopea, or even Canva. Just create a new canvas with your supplier's exact sheet dimensions (say, 56cm x 100cm). Then, start dragging and dropping your individual design files onto the canvas. You can move them around, rotate them, and see exactly how much you can squeeze in, helping you maximise the space. -

Is there a minimum order for gang sheets?

Most UK suppliers, including us, don't have a minimum order. You can buy a single sheet or order by the metre, which is brilliant for testing out new ideas or handling small, one-off jobs. That said, almost every supplier offers some chunky volume discounts, so placing larger orders makes each individual design much cheaper.

Ready to bring your unique apparel ideas to life with vibrant, durable prints? At Psyque, we specialise in high-quality DTF printing for businesses, brands, and creators across the UK. Explore our services and see how easy it is to get started at https://psyque.co.uk.