A Guide to Cheap DTF Transfers UK

Share

Getting your hands on cheap DTF transfers doesn't mean you have to compromise on quality. Not at all. The secret is to find smart UK suppliers who use the latest printing tech and buy their materials in bulk. This way, they can pass those savings right on to you, making top-notch, budget-friendly prints a reality for everyone.

This approach has completely opened the doors for everyone from Etsy sellers to established brands, giving them access to professional-grade customisation without the hefty setup costs that come with traditional screen printing.

Why Affordable DTF Transfers Are a Game Changer

Let's get one thing straight: the word 'cheap' often gets a bad rap. It can make you think of something flimsy, poorly made, or destined to fall apart after one wash. But when we're talking about DTF (Direct to Film) transfers, 'cheap' really just means cost-effective. Thanks to massive leaps in printing technology and more efficient UK supply chains, producing vibrant, durable transfers now costs a fraction of what it used to.

This shift has unlocked a world of possibilities for creators and small businesses. Not so long ago, if you wanted a detailed, full-colour design on a t-shirt, you were looking at expensive screen printing setups with seriously high minimum order quantities. That barrier alone priced out countless small businesses, independent designers, and hobbyists.

The Rise of Accessible Customisation

DTF printing completely changed the game. It offers a flexible, wallet-friendly alternative that empowers anyone to bring their creative ideas to life on fabric. This accessibility is a huge reason why the UK's direct-to-garment printing market is on track to jump from $130.8 million to a staggering $274 million by 2030. The brilliant cost-effectiveness of DTF is a major force behind this growth, making it the go-to for personalised clothing. For a deeper dive into these numbers, you can check out the market analysis from Grand View Research.

This guide is here to help you make the most of this fantastic technology. We're cutting through the noise to give you real-world, actionable advice for your business or creative projects.

Searching for cheap DTF transfers isn't about cutting corners—it’s about making a smart business decision. Once you understand what affects the price, you can find high-quality products that fit your budget and make your brand look amazing.

So, what makes DTF so appealing, especially if you're watching your budget?

- No Minimum Orders: Unlike screen printing, most DTF suppliers are happy to print just one transfer if that's all you need. This means no waste and no big upfront investment.

- Full-Colour Prints at No Extra Cost: Forget being charged for every extra colour. With DTF, you can print complex, photorealistic designs for the same price as a simple one-colour logo.

- Works on Almost Anything: DTF is incredibly versatile. It sticks brilliantly to a huge range of fabrics like cotton, polyester, and blends, giving you far more creative freedom.

To get a full picture of how it all works, our comprehensive guide on DTF transfers will walk you through the entire process. It’s solid proof that you don't need to break the bank to get professional results.

Finding The Best UK DTF Transfer Suppliers

Choosing the right supplier for your custom apparel is a huge decision. You’re not just buying a product; you’re finding a partner. The best UK suppliers for cheap DTF transfers know how to strike that perfect balance between cost and exceptional quality, making sure your final product looks brilliant and is built to last.

Your goal is to find someone who feels less like a faceless corporation and more like a dedicated partner who's genuinely invested in seeing your project succeed.

This all starts with doing your homework. A quick online search is a good jumping-off point, but don't stop there. Dig deeper than the first page of results and look for genuine customer reviews on independent platforms, not just the hand-picked testimonials on their website. Pay close attention to what people are saying about print vibrancy, durability after washing, and, crucially, customer service.

Vetting Potential Suppliers

Once you’ve got a shortlist, the real work begins. Honestly, the single most important thing you can do is order a sample pack. You can browse websites for hours, but nothing beats the real-world experience of holding a physical transfer in your hands.

When the samples arrive, it's time to put them through their paces:

- Colour Accuracy: Does the print actually match the digital file you sent over? Hold it up to your monitor and check for any noticeable colour shifts.

- Feel and Flexibility: A quality DTF transfer shouldn't feel thick or like a sheet of plastic. It should be soft, flexible, and stretch naturally with the fabric without cracking.

- The Wash Test: This is non-negotiable. Press a sample onto a spare t-shirt and run it through the wash—multiple times. A high-quality transfer should easily handle 50+ washes without any fading, peeling, or cracking.

Taking this hands-on approach can save you from a bulk order disaster. Just imagine ordering 100 transfers for a client, only to discover they start falling apart after the first wash. A small investment in samples is a brilliant way to protect both your reputation and your bank balance.

Understanding Pricing Models

To get your hands on genuinely cheap DTF transfers, you need to get your head around how suppliers structure their prices. The two most common models are charging per transfer or charging per sheet (often called a 'gang sheet').

Pro Tip: For anyone ordering more than just a few designs, gang sheets are an absolute game-changer for value. By arranging multiple logos and graphics onto a single large film, you slash your cost per individual transfer.

Think of it this way: a startup brand needing a small run of various intricate designs for a new collection would get incredible value from a gang sheet. On the other hand, a local sports club needing a massive order of one simple logo might find a straightforward per-transfer price easier, especially if they can negotiate a volume discount.

Always ask for a clear price breakdown and remember to factor in delivery fees to work out your true 'landed cost' per item. Finding a local supplier can also make a huge difference in speed and shipping costs; our guide on finding DTF services near you is a great place to start that search.

The UK is a massive player in the custom apparel scene, making a huge contribution to a European industry that leads the world in DTF printing revenue. This market, valued globally at $2.72 billion, shows just how widely DTF technology has been adopted right here in Britain. For a deeper dive into these trends, you can explore the full market analysis from Grand View Research. This thriving local industry means you have plenty of competitive options right on your doorstep.

Optimizing Your Own DTF Production Costs

If you're running your own DTF setup, getting a firm grip on production costs is the difference between a side hustle and a proper business. Every failed print or wasted metre of film is money straight out of your pocket. It's not enough to just own the gear; you have to master the process to make every single transfer count.

This means you've got to dig deeper than the basics. It's about fine-tuning your entire workflow, from the consumables you order to the daily upkeep of your machinery. You'd be surprised how small, consistent tweaks can stack up into major savings over time. Of course, none of this matters if you aren't tracking your spending properly, so implementing effective business expense tracking is non-negotiable.

Smart Material Choices and Gang Sheet Mastery

Your quest for cheaper in-house prints starts with your raw materials. It's always tempting to grab the cheapest film and powder you can find, but this is often a classic false economy. That low-quality adhesive powder might not cure right, leading to transfers that peel after one wash. Suddenly, you're dealing with unhappy customers and costly reprints.

The smart money is on finding a balance between price and performance. Bulk-buying reliable, mid-range consumables is usually the sweet spot. You get the consistent results you need to keep customers happy, but without paying for the premium brand name. Most importantly, you drastically cut down on the print failures that quietly eat away at your profit margins.

Now, for the single most powerful trick in the book: mastering the gang sheet. This is simply the art of arranging as many different designs as you can onto one sheet of film before you hit 'print'.

- Fill Every Gap: Use smaller designs, like neck labels or sleeve logos, to tuck into all the awkward empty spaces between your main graphics.

- Plan Ahead: Start batching jobs from different clients. If you have three small orders on the books, printing them all together on one sheet is vastly cheaper than running three separate jobs.

- Software Is Your Friend: Your design software can be a huge help here. Use its nesting features to automatically arrange designs for maximum film usage—it's far more efficient than trying to eyeball it.

Getting your gang sheets right isn't just a neat trick; it's a core production strategy. A well-organised sheet can slash your material cost per design by over 70%. You're literally turning wasted film into pure profit.

Making informed choices on consumables is a huge piece of this puzzle. Here’s a quick breakdown of where you can save and where you should invest.

Cost-Saving DTF Material Choices

| Consumable | Budget Option (Pros/Cons) | Premium Option (Pros/Cons) | Cost-Saving Tip |

|---|---|---|---|

| DTF Film |

Pro: Low upfront cost. Con: Can have inconsistent coatings, leading to ink bleeding or poor powder adhesion. |

Pro: Excellent ink absorption and consistent quality for sharp, reliable prints. Con: Higher price per metre. |

Buy mid-range film in bulk rolls instead of individual sheets to get a better price without sacrificing too much quality. |

| Adhesive Powder |

Pro: Very cheap. Con: Poor melt/adhesion can cause transfers to crack or peel after washing. High failure rate. |

Pro: Superior elasticity and durability, ensuring a long-lasting, soft-feel print. Con: Costs significantly more per kilogram. |

Find a reliable mid-grade powder. The reduction in failed prints and customer complaints will easily offset the slightly higher cost. |

| DTF Ink |

Pro: Lowest price per litre. Con: Inconsistent pigments can lead to colour shifts and, worse, clog your expensive print heads. |

Pro: Vibrant, consistent colours and formulated to prevent clogging. Con: The most expensive consumable. |

Don't skimp on ink. Use manufacturer-approved ink to protect your print head, but calibrate your printer to find the most efficient ink usage setting. |

Ultimately, your material choices should be driven by the quality you promise your customers, not just the initial price tag.

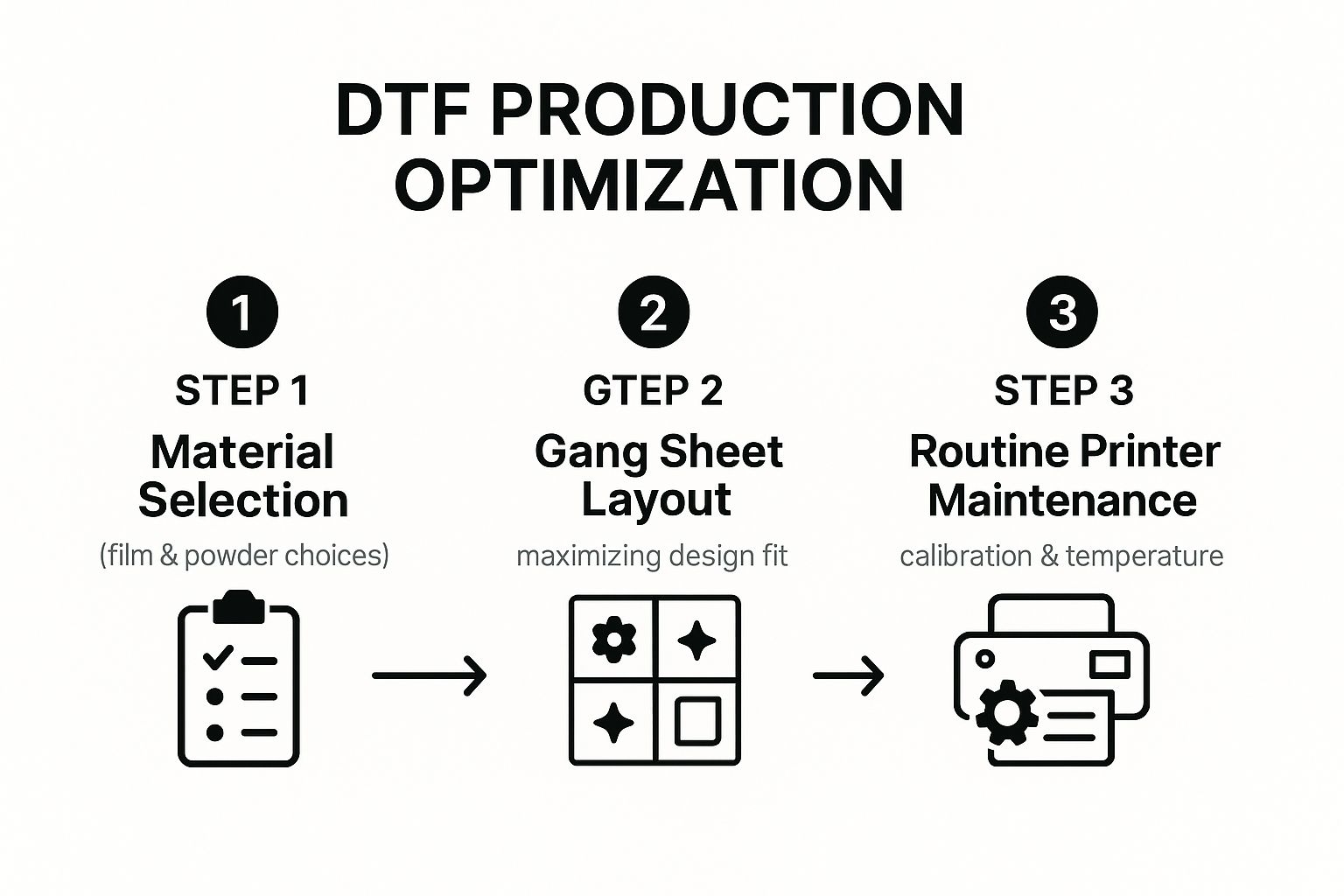

The infographic below puts these ideas into a simple visual flow, from picking your materials to keeping your printer happy.

As you can see, it's about how all these elements—strategic buying, efficient layouts, and regular maintenance—work together to bring your costs down.

Essential Maintenance for Cost Efficiency

A well-maintained printer is a profitable printer. It’s that simple. If you neglect routine care, you’re asking for clogged print heads, patchy ink flow, and entire batches of prints in the bin. These are all expensive, avoidable problems.

Get into the habit of running through a weekly maintenance checklist. This should absolutely include cleaning the print head, checking all your ink lines, and double-checking that your curing oven or heat press is holding a consistent temperature. A miscalibrated heat press, for instance, can ruin dozens of transfers before you even spot the issue. If you're still in the market, researching the right DTF printing machine and understanding its specific maintenance needs is a vital first step.

Finally, take a look at your ink settings. Most printers have an 'economy' or 'draft' mode that uses less ink, but you need to know if the quality is still good enough. Run some tests. Find the absolute lowest ink setting that still produces a vibrant, sellable print. Shaving even 10-15% off your ink consumption on every single job adds up to massive savings over the year.

Preparing Your Artwork to Dodge Hidden Print Costs

Some of the most frustrating (and expensive) issues with DTF transfers have nothing to do with the printer. In my experience, they almost always start right on your computer screen.

Getting your artwork print-ready from the get-go is the single best way to avoid hidden fees and disappointing results. It's the secret to getting the cheap DTF transfers you were hoping for without sacrificing quality.

Think of your digital file as the blueprint for the final print. A flawed blueprint means a flawed building. Sending a low-quality, pixelated image to your printer is like giving a master builder a blurry sketch and expecting a perfect house. It just won’t happen.

The Non-Negotiable File Requirements

First up, and this one's a biggie: resolution. Your artwork absolutely must be created and saved at 300 DPI (dots per inch) at the exact size you want it printed. A 72 DPI image you've pulled from a website might look okay on your screen, but it will print as a blurry, jagged mess on a t-shirt. There's no magic button a printer can press to add detail that isn't there.

Another common pitfall I see all the time is fonts. If you've used a cool, unique font but forget to convert it to outlines or curves, the printer's computer will just swap it for a default font. Your carefully crafted design is ruined in an instant. Always, always convert your text to shapes before saving. It’s a single click that prevents a massive headache.

Remember, print suppliers often charge an artwork fee to fix these common issues. By getting your file right the first time, you avoid these extra costs and speed up your order. It's a direct way to keep your transfer costs low.

Beyond the technical stuff, it's also vital to focus on avoiding copyright infringement in your designs. Trust me, legal troubles are a hidden cost you definitely want to avoid.

A Quick Pre-Flight Checklist

Before you hit 'send' on that email to your supplier, run through this quick mental checklist. It'll save you both time and money.

- Transparent Background: Is your background actually transparent? A white box that’s invisible on your white screen will print as a solid white box on a coloured shirt. Double-check this.

- Colour Mode: Have you saved your file in CMYK or with a CMYK-ready profile? DTF printers can handle a wider range of colours, but starting with a CMYK mindset helps manage your expectations between what you see on screen and what ends up on the fabric.

- File Format: Are you sending a high-quality format like a PNG, TIFF, or a vector file like AI or EPS? Please, avoid sending low-quality JPEGs. They just don't cut it for professional results.

Getting this process down ensures your vision is what actually ends up on the final garment. For more ideas on how this applies to different projects, our guide on personalised t-shirt printing has some extra insights you might find helpful.

Smart Ordering Strategies to Lower Your Costs

How you place your DTF transfer orders is just as important as what you order. Some of the biggest savings aren't found in the sticker price of a single print, but in the logistics of how you buy. To unlock the best value, you need to think like a business, even if you're just a one-person show.

The quickest way to slash your per-unit cost is to batch your jobs together. Almost every supplier offers a better deal for bulk orders. Instead of firing off five small orders throughout the month, get organised and combine them into one larger purchase. This simple change can dramatically lower your cost per transfer and cut your total delivery fees.

Plan Your Print Runs

For smaller businesses, creating a 'print run schedule' is a game-changer. Dedicate a specific day each week or fortnight to placing all your transfer orders. This forces you to consolidate jobs, turning a handful of high-cost, low-volume orders into a single, much more affordable bulk purchase.

Picture this: an on-demand shop needing a rapid turnaround for a single t-shirt is always going to pay a premium. But an event planner who knows they need 200 shirts in six weeks can order well ahead of time, batching the job for a far better price. That kind of foresight is your best money-saving tool.

When you schedule and consolidate your orders, you’re not just saving on the transfers. You’re also wiping out repeat delivery charges, which can quietly add £5-£10 to every small order you place.

This approach takes a bit of planning, but the savings add up quickly and directly boost your bottom line. It’s a disciplined habit that separates hobbyists from profitable businesses. For a deeper dive into creating apparel that actually sells, our guide on producing custom printed t-shirts in the UK is packed with valuable tips.

UK Suppliers Versus Overseas Sourcing

The idea of sourcing from overseas can be tempting, especially when you see those incredibly low initial prices. Before you jump in, though, it’s crucial to work out the true ‘landed cost’.

Keep these factors in mind when looking abroad:

- Shipping Delays: International shipping can be a lottery, with potential delays stretching for weeks. If you’ve got client deadlines, this can be a complete deal-breaker.

- Import Duties and VAT: A cheap-looking price can balloon once you add surprise import taxes and VAT when the package lands in the UK.

- Communication Barriers: Time zone differences and language barriers can turn a simple order into a nightmare, particularly if there’s a problem with your artwork or print quality.

For most small to medium-sized UK businesses, sticking with a local supplier is often the more reliable and genuinely cheaper option in the long run. You get faster turnarounds, transparent pricing with no hidden nasties, and the peace of mind that comes with clear communication. That convenience and reliability are often worth far more than the savings you think you're getting from an overseas quote.

Your Top Questions About Affordable DTF Transfers

When you're hunting for a good deal on DTF transfers, a few questions always pop up. It's only natural. You want to make sure you're getting a quality product that's going to last, without any nasty surprises along the way. Let's tackle some of the most common queries we see from people just like you.

Think of this as your cheat sheet for buying with confidence. We'll cover everything from durability to the DIY debate, cutting through the jargon to give you straight, honest answers.

Are Cheap DTF Transfers as Durable as Expensive Ones?

This is the big one, isn't it? And the answer might surprise you: yes, absolutely. The longevity of a DTF transfer has almost nothing to do with its price. It all boils down to two key factors: the quality of the adhesive powder and how accurately it’s applied with a heat press.

A properly pressed transfer, even an inexpensive one, can easily handle 50+ washes without a hint of cracking, peeling, or fading. The best suppliers offering great prices aren't cutting corners on materials; they're just more efficient, buying their supplies in huge volumes to drive their costs down.

The only way to be truly sure is to test it yourself. Order a sample pack from a potential supplier. Press it onto an old t-shirt and throw it in the wash a few times. It's a small step that gives you undeniable proof of quality and saves you from a costly mistake down the line.

What Is a Gang Sheet and How Does It Save Money?

If you want to slash your printing costs, gang sheets are your secret weapon. A gang sheet is simply a large roll of DTF film where you can arrange—or "gang up"—multiple designs to be printed at the same time. You pay for the sheet, not for each individual design.

This completely flips the script on pricing. Imagine fitting two big t-shirt designs, a handful of smaller breast pocket logos, and a dozen tiny neck label graphics all onto a single metre of film. By using every last bit of space, your cost per individual transfer plummets. It’s the single best money-saving trick in the book, especially if you're printing more than one design.

What Hidden Costs Should I Look Out For?

While there are plenty of genuine bargains out there, you've got to keep your wits about you to avoid hidden costs that can quickly sour a deal. Always work out your "total landed cost" – the final price you pay per transfer once it's in your hands.

Here are a few things to watch for:

- Delivery Fees: A low price per transfer can look great until you're hit with steep delivery charges, particularly on smaller orders.

- Artwork Setup Charges: Some printers will sting you with a fee if your artwork isn't 100% print-ready, forcing them to fix things like low resolution or incorrect file types.

- VAT: Always double-check if the price you're quoted includes VAT. If it doesn't, you'll need to add another 20% to your final bill.

- Minimum Order Quantities: That fantastic price might only be available if you order a huge quantity, which might not work for your business.

And if you're ordering from overseas, don't forget to account for potential import duties and customs delays. These can add unexpected costs and headaches.

Is It Cheaper to Make My Own DTF Transfers?

For the vast majority of small businesses, clothing brands, and hobbyists, the answer is a firm no. It is almost always far cheaper to buy your transfers from a dedicated UK supplier.

The initial outlay for a decent in-house DTF setup is serious money. You're looking at thousands of pounds for a reliable printer, powder shaker, and curing oven. Then you have the ongoing costs of consumables like ink, film, and powder, not to mention the time you'll sink into maintenance, calibration, and fixing inevitable printing errors.

Making your own transfers only really starts to make financial sense when you reach a very high volume, we're talking hundreds of prints every single week. For everyone else, outsourcing is the smarter, faster, and more budget-friendly path.

Ready to bring your designs to life with vibrant, durable, and affordable DTF prints? Psyque offers top-quality transfers with fast UK delivery, perfect for your brand, business, or creative project. Explore our services and see how easy custom apparel can be at https://psyque.co.uk.