dtf prints for sale: Premium Transfers for Your Projects

Share

If you're searching for DTF prints for sale, you're clearly ready to take your custom clothing projects to the next level. The best way to think about Direct-to-Film (DTF) is like a high-tech, permanent tattoo for fabric. It’s a method that lets you transfer incredibly vibrant and detailed designs onto almost any garment, giving you professional results every time.

What Exactly Are DTF Prints?

At its heart, Direct-to-Film (DTF) printing is a brilliantly simple yet powerful process. It all starts with printing your digital design onto a special transparent film using high-quality, water-based inks. This isn't your average printout; the machine carefully layers the colours, including a critical white base layer. This white ink is the secret sauce that makes your design look bold and bright on any fabric colour, from crisp white to deep black.

After printing, a special adhesive powder is sprinkled over the wet ink on the film. This powder is the magic ingredient, the very thing that will bond your design to the fabric when heat is applied. The film, now holding your design and the adhesive, becomes a "transfer" that’s all ready to press. To get a better handle on the lingo, have a look at our detailed guide on what DTF stands for and what it all means.

From Film to Fabric

The final stage is where your design comes to life on the garment. Using a heat press, the transfer film is positioned on the fabric. A specific combination of heat and pressure activates the adhesive, causing the ink to release from the film and permanently fuse with the fabric's fibres. After a quick cool-down, you peel the film away, and what's left behind is a sharp, flexible, and seriously durable graphic.

The buzz around this method is backed up by some serious numbers. The UK's DTF printing market was valued at USD 192.2 million in 2025 and is on track to hit USD 249.0 million by 2030. This growth really shines a light on how much people want versatile, high-quality printing solutions like DTF. You can dig into more insights about this growing market on grandviewresearch.com.

Why Choose DTF Over Other Printing Methods?

When you’re looking at DTF prints for sale, it's usually because you need something that just works without the usual printing headaches. The biggest draw for DTF is its incredible flexibility. Forget worrying about fabric types.

Unlike screen printing, which really prefers cotton, or sublimation that demands high-polyester content, DTF transfers can be pressed onto almost anything. We’re talking cotton, polyester, poly-cotton blends, and even tougher stuff like canvas or leather. This opens up a massive range of possibilities, from custom tees and hoodies to branded caps and tote bags, all using the same type of transfer.

Durability and Detail

Another huge reason people are switching to DTF is how well the prints hold up and how sharp they look. DTF prints have a soft, flexible feel and fantastic wash resistance, often lasting for 50 washes or more without cracking or fading. The print doesn't just sit on top of the fabric; it becomes part of it, stretching and moving with the garment.

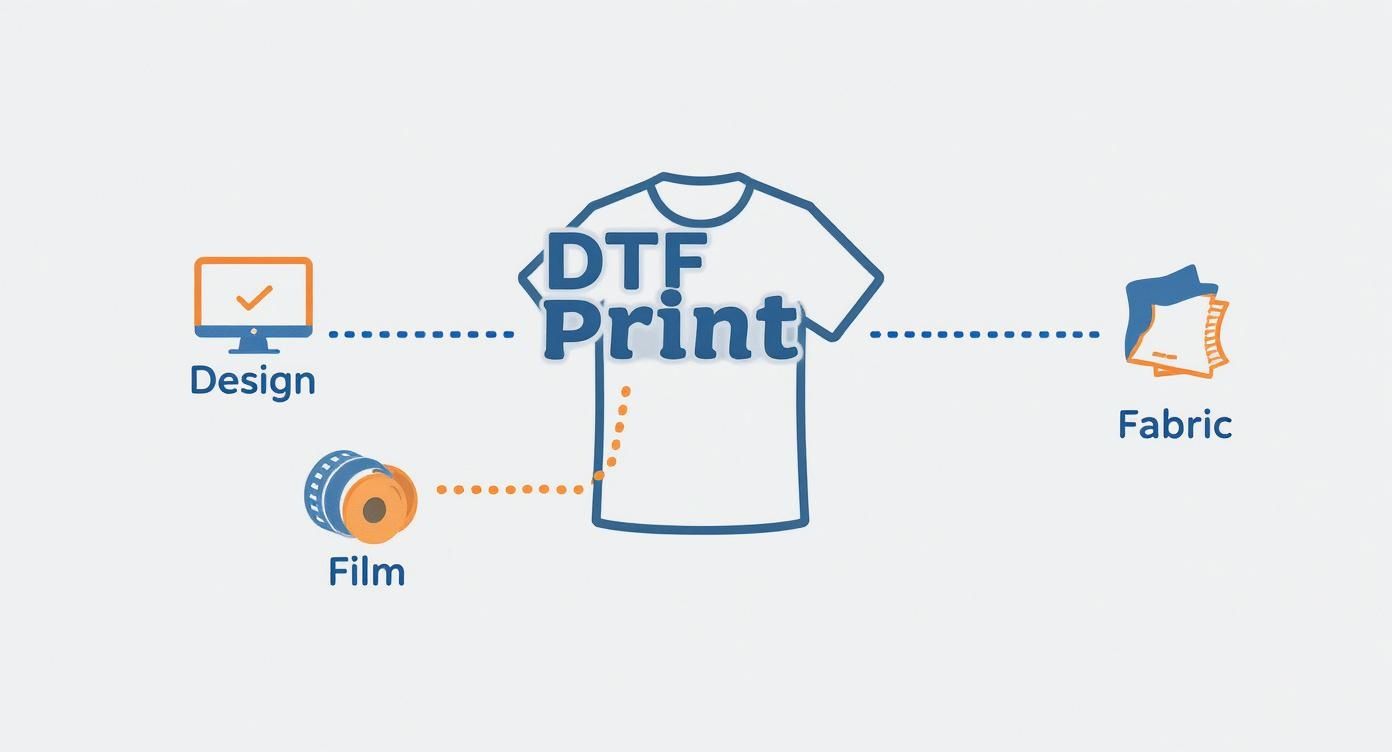

It also nails complex, full-colour designs with photographic quality. DTF can handle fine lines, tiny details, and subtle colour gradients far better than something like heat transfer vinyl (HTV), which is basically just cutting and layering solid colours. This infographic breaks down how a design goes from your screen to a ready-to-press transfer.

As you can see, the process is designed to capture every detail. If you want to get into the nitty-gritty of how it compares to the old-school methods, check out our guide on DTF vs screen printing for graphic tees.

For small businesses and independent brands, the ability to produce high-detail, full-colour designs in small batches without high setup costs is a game-changer. It allows for greater creative freedom and faster turnaround times.

All this makes DTF an easy choice for anyone who needs professional-grade prints without being boxed in by the limitations of older methods.

DTF Printing Compared to Other Methods

To really see where DTF shines, it helps to put it side-by-side with other popular customisation techniques. Each method has its place, but DTF often hits the sweet spot for modern apparel businesses.

| Feature | DTF (Direct-to-Film) | Screen Printing | HTV (Heat Transfer Vinyl) |

|---|---|---|---|

| Fabric Compatibility | Excellent (Cotton, poly, blends, leather, etc.) | Good (Best on cotton/blends, limited on others) | Good (Cotton, poly, blends, some nylons) |

| Design Complexity | Excellent (Full-colour, photos, fine details) | Fair (Best for simple graphics with limited colours) | Poor (Limited to solid colours, hard for intricate designs) |

| Durability | Excellent (Soft, flexible, lasts 50+ washes) | Very Good (Durable but can crack over time) | Good (Can peel or crack, feels thicker on the shirt) |

| Small Run Cost | Low (No setup fees per design, cost-effective) | High (Expensive setup with screens for each colour) | Medium (No setup fees, but vinyl costs can add up) |

| Large Run Cost | Medium (Consistent cost per print) | Low (Very cost-effective for large volumes) | High (Material and labour costs don't scale well) |

As the table shows, DTF's main advantage is its versatility and cost-effectiveness for small-to-medium runs with complex designs, making it a fantastic all-rounder.

Bringing Your Creative Ideas to Life With DTF

Custom t-shirts are a brilliant way to start, but DTF printing truly shines when you step beyond the wardrobe. Imagine turning almost any object into a vibrant canvas that tells your story or amplifies your brand.

With the right DTF prints for sale, you can build a cohesive merchandise collection without breaking a sweat. Picture your business rolling out matching staff uniforms, promotional tote bags, stylish caps and even aprons—all branded to perfection. This is the kind of versatility that gives you a polished, unified look in every detail.

Expanding Your Product Range

The real magic lies in how DTF opens doors to fresh product ideas. Consider these examples:

- Custom Sportswear: Add intricate team logos and sponsor details to polyester jerseys.

- Branded Accessories: Print on canvas shoes, backpacks or denim jackets for unique fashion pieces.

- Event Merchandise: Create memorable hoodies and tote bags for festivals, corporate events or family reunions.

- Workwear: Apply durable logos to high-visibility jackets and heavy-duty work shirts.

This adaptability has driven DTF’s meteoric rise. Here in the UK, personalised apparel leads the charge, with t-shirts representing roughly 41% of the global market revenue in 2024. Discover more insights about this market segmentation on kbvresearch.com.

To really make your products pop, don’t overlook the power of investing in high-quality product photography. And if you’re looking for fresh design inspiration, explore our guide to designing effective t-shirt logos.

Ultimately, DTF gives you everything you need to bring any creative vision to life on nearly any surface you can imagine.

How To Order Custom DTF Prints Like A Pro

Ordering custom DTF prints for sale online is actually a pretty simple process once you get the hang of it. It all boils down to your artwork – get that right, and you're golden. A little bit of prep work on your design files goes a long way in avoiding any printing headaches later on.

If there's one golden rule to remember, it's this: submit your artwork with a transparent background. Seriously. Any white or coloured background left in your file will be printed, so make sure it's gone. This simple check is the key to making sure only your actual design gets transferred onto the fabric.

Preparing Your Artwork For Success

To get those punchy, razor-sharp results that DTF is famous for, your file quality has to be spot on. Just follow these quick guidelines, and you'll be setting your order up for a brilliant outcome:

- File Format: Always, always save and upload your design as a PNG, SVG, or AI file. These guys are your friends because they support transparent backgrounds. JPEGs, on the other hand, will stick a big white box around your image, and nobody wants that.

- Resolution: Aim for a minimum resolution of 300 DPI (dots per inch). Sending over a low-resolution file is a recipe for a blurry, pixelated print that just won't look professional.

- Size Matters: Make sure your design file is created at the exact size you want it printed. Trying to blow up a small image will wreck its quality, guaranteed.

When you're building your brand and selling your DTF creations, figuring out the tech side of things is crucial. This guide on choosing an e-commerce marketing platform has some really useful pointers for getting your online shop humming.

Maximising Value With Gang Sheets

Want to know one of the smartest ways to order DTF transfers? Use a gang sheet. It's basically one large sheet of transfer film where you can arrange, or "gang up," a bunch of different designs. Instead of paying for every single print, you just pay for the whole sheet.

A gang sheet is your secret weapon for cost efficiency. You can fill it with different logos, sleeve designs, neck tags, and main graphics, drastically lowering your cost per print. This is especially useful for small businesses and clothing brands.

By smartly arranging your artwork on a gang sheet, you cut down on waste and squeeze every bit of value out of your order. Our deep dive into DTF transfers for sale has even more tips on how to make your purchase go further.

Applying Your DTF Transfers for Perfect Results

Once your custom DTF prints for sale land on your doorstep, the fun part starts. Getting the application right is the key to that professional, durable finish you're looking for. Believe me, the right tools and a solid technique make all the difference.

Your most important bit of kit is a good heat press. It might be tempting to reach for a standard home iron, but it just won't cut it. An iron can't provide the consistent temperature and even pressure needed for the transfer's adhesive to properly fuse into the fabric fibres.

The Application Process Step by Step

Nailing a flawless application is actually pretty simple once you get the hang of it. Just follow a few key steps, and you’ll get brilliant results every single time.

- Get Your Heat Press Ready: First things first, set your press to the right temperature. You're generally looking at somewhere between 150°C to 160°C, with a medium pressure setting.

- Pre-Press Your Garment: Pop your garment on the press and give it a quick press for about 5-10 seconds. This step is a game-changer—it zaps out any hidden moisture and smooths away wrinkles, giving you a perfect canvas.

- Position and Press: Carefully lay your DTF transfer onto the garment, making sure the design is facing up. Cover it with a Teflon sheet and press down firmly for 10-15 seconds.

- The All-Important Cold Peel: Once the time is up, take the garment off the press and let it cool down completely. When it’s cold to the touch, you can slowly and gently peel the film away.

Mastering the "cold peel" is absolutely essential. If you try to peel the film while it's still warm, you risk ruining the print and ending up with a patchy transfer. A little patience here goes a long way to ensuring a crisp, clean finish.

For an even more detailed walkthrough, check out our guide on using DTF transfers that are ready to press. Follow these steps, and your designs won't just look amazing—they'll stand up to dozens of washes, too.

Got Questions About DTF Prints? We've Got Answers

If you're new to buying DTF prints for sale, it's natural to have a few questions. Here are some quick, straightforward answers to the ones we hear most often.

How Long Do DTF Prints Last on Clothing?

You'll be seriously impressed by the durability. A high-quality DTF print can easily withstand 50-100 washes when you look after it properly. The trick is to wash your garments inside out on a cool cycle and skip the tumble dryer. Honestly, the vibrant print will often outlast the t-shirt itself.

Can I Just Use a Home Iron to Apply DTF Transfers?

While you technically can, we really wouldn't recommend it if you're aiming for professional, lasting results. A home iron just can't deliver the consistent, even pressure and temperature that's crucial for a permanent bond. To properly cure the adhesive and make sure your print stays put, you absolutely need a proper heat press.

What Exactly Is a Gang Sheet?

Think of a gang sheet as the ultimate way to get more bang for your buck. It's a large sheet of transfer film where you can arrange multiple designs—as many as you can fit. You pay for the whole sheet, not for each design individually. This makes it the most cost-effective method for ordering, drastically cutting your cost per print.

Ready to see your designs come to life with prints that are both vibrant and tough? Check out the custom DTF transfer options at Psyque - DTF Print & Press. You'll see just how easy it is to create apparel that looks and feels totally professional.