What Does DTF Stand For and How Does It Work

Share

Alright, let's cut straight to it. DTF stands for Direct to Film printing. The simplest way to think of it is like creating a high-tech, ultra-durable sticker for your clothes. Instead of printing ink directly onto a t-shirt, a special printer lays your design onto a transparent film. That film is then heat-pressed onto the garment, and voilà.

So How Does DTF Printing Actually Work?

This modern technique is quickly becoming a go-to for custom apparel because it neatly sidesteps many of the headaches that come with older methods. It opens the door to brilliant, full-colour designs on a massive range of fabrics—from classic cotton to tricky polyester—without all the complicated prep work.

Its growth in the UK has been nothing short of explosive. In fact, dedicated DTF printers recently held a 45.01% share of the market segment, which shows you just how quickly people are getting on board. You can read more research on the UK's DTF printing market to get a sense of its real-world impact.

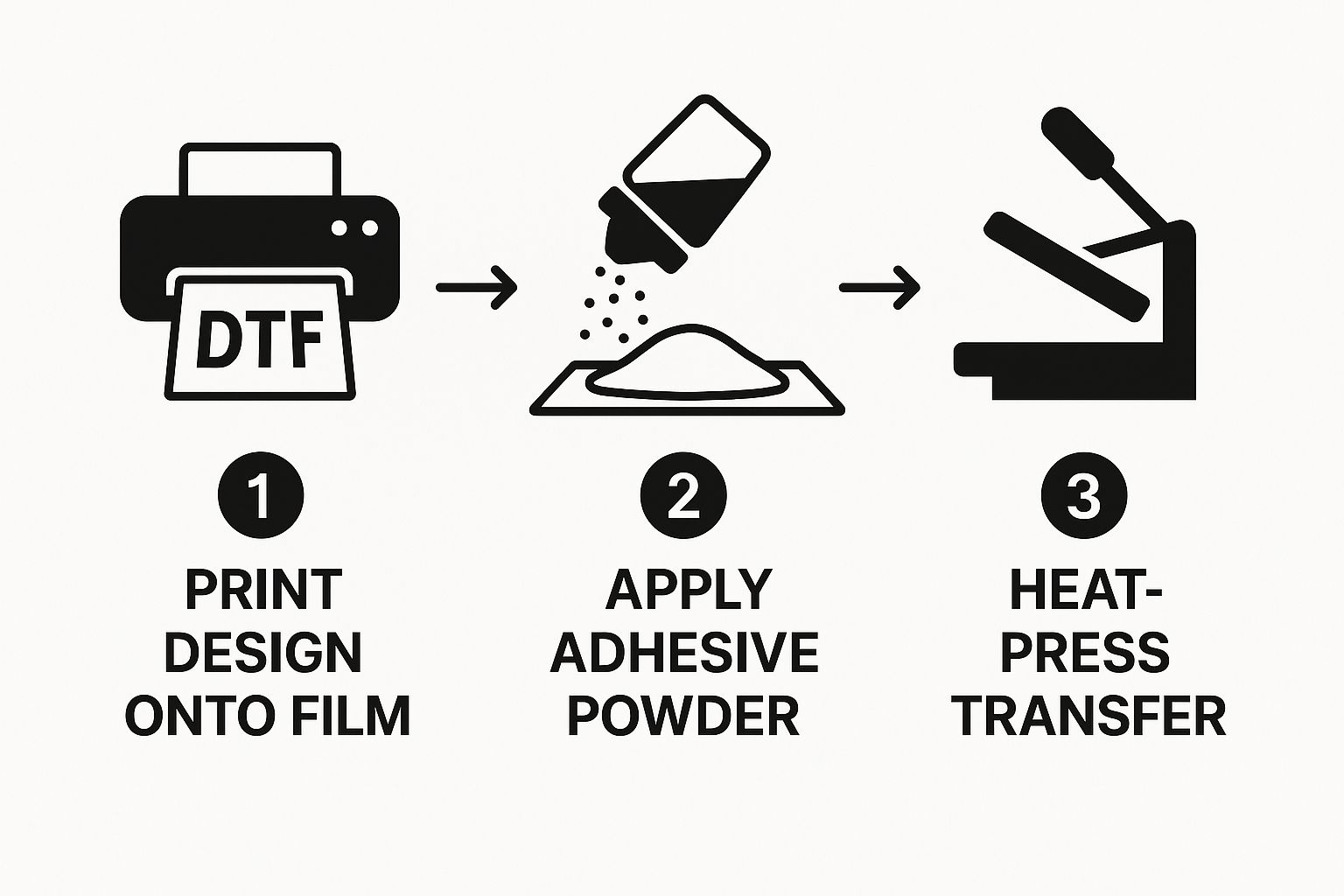

At its heart, DTF printing is a three-step dance: a digital design is printed onto a special film, coated with an adhesive powder, and then bonded to the fabric using heat and pressure. It’s a straightforward process that unlocks some seriously impressive creative potential.

This infographic breaks down the workflow, showing how you get from a digital file to a finished product.

As you can see, it's a very efficient method that condenses the whole process into three distinct, manageable steps. We're about to dive into exactly how this unfolds and why it's making such waves in the industry.

And if you want to see what this technology is capable of, feel free to explore our full range of custom DTF prints available for your own projects.

How A Digital Design Becomes A Wearable Print

So, how does a simple image file on a computer screen end up as a vibrant, tough-as-nails print on your favourite t-shirt? The whole process is a clever mix of digital smarts and hands-on application. It's a bit like baking, where your digital design is the recipe and the printer is your high-tech oven.

It all starts with a very specific type of inkjet printer. This isn't your average office machine; it's loaded with special DTF inks that print your design directly onto a sheet of transparent PET film. This film acts as a temporary carrier, holding onto the design until it's ready to make the jump to fabric.

The Magic Powder And Curing Process

Once the design is printed onto the film (in reverse, like a mirror image), it gets a dusting of a fine adhesive powder. This white, granular stuff is the real secret sauce. It’s essentially the glue that’s going to permanently bond the ink to the clothing fibres.

Next, the powdered film goes for a quick trip into a curing oven or under a heat press. The heat melts the powder, turning it into a smooth, even adhesive layer that perfectly covers the ink. The result is a finished transfer, all prepped and ready to go. For those who want to skip these steps, you can find professional, ready-made https://psyque.co.uk/blogs/news/dtf-transfer-sheets that are good to go right out of the box.

To break it down, here’s a quick look at the main stages of the process.

The DTF Printing Process at a Glance

This table summarises the journey from a digital file to a finished print.

| Step | Action | Key Component |

|---|---|---|

| 1. Print | The design is printed in reverse onto a special PET film. | DTF Printer & Inks |

| 2. Powder | The wet ink is coated with a fine adhesive powder. | Adhesive Powder |

| 3. Cure | The film is heated to melt the powder into an adhesive layer. | Curing Oven / Heat Press |

| 4. Press | The film is placed on the garment and pressed with heat. | Heat Press |

| 5. Peel | After cooling, the PET film is peeled away, leaving the print. | The Finished Garment |

Each step is crucial for creating a print that not only looks great but also lasts.

The Final Application

This is where the magic really happens. The cured film is positioned carefully on the garment – whether that's a cotton tee, a polyester hoodie, or even a canvas tote bag.

A heat press then clamps down, applying just the right amount of heat and pressure. We're typically talking around 160°C for about 15-20 seconds. This blast of heat reactivates the adhesive, fusing the ink deep into the fabric's fibres for good.

After letting it cool for a moment, the film is peeled back, and voilà! You're left with a crisp, full-colour print that feels great and is built to last. Since this entire method relies on quality digital files, it always pays to streamline the digital asset management workflow to keep your designs organised and ready for the printer.

Why Are So Many Creators Choosing DTF Printing?

So, what’s all the fuss about? Why is DTF becoming the go-to choice for everyone from small business owners to established apparel brands? It really comes down to a few powerful advantages that solve genuine, real-world printing headaches. The biggest draw for creators is its incredible versatility.

Unlike other methods that can be a bit picky about fabrics, DTF printing works brilliantly on almost anything you can throw at it. You can press stunning, vibrant designs onto cotton, polyester, nylon, and all sorts of blends with equally fantastic results. This flexibility unlocks a whole world of creative possibilities far beyond just t-shirts—think hoodies, hats, bags, and more.

Unmatched Visual Quality and Durability

DTF really shines when it comes to producing photorealistic images and razor-sharp text across a massive spectrum of colours. Because the design is printed onto a special film first, every tiny detail is captured perfectly before it even touches the garment. The result? Consistently crisp and vibrant prints, every single time.

Of course, great looks don't mean much if they don't last. DTF transfers are well known for their durability, creating a bond with the fabric that’s both strong and flexible. These prints hold up against cracking and fading, often lasting for 50+ washes without losing their original brilliance, which makes them perfect for everything from hard-wearing workwear to high-end fashion.

The real power of DTF is its unique ability to blend detailed, colourful artwork with the freedom to print on nearly any fabric. It’s this combination that tears down creative barriers, making professional-quality customisation accessible to everyone.

A Cost-Effective Solution for Modern Needs

For small-to-medium print runs, DTF is often the most budget-friendly option out there. It completely gets rid of the costly setup fees and complex screen prep that comes with traditional screen printing. This means you can order a small batch of ten different designs for almost the same cost per item as a single run of one hundred.

This financial accessibility is a complete game-changer for many. Unlike direct-to-garment printing, DTF doesn’t need any fabric pre-treatment and works with a much broader range of materials commonly found in the UK market—a key reason for its growing popularity here.

Loads of creators now use DTF to produce merchandise that fuels powerful user-generated content strategies for DTC sales, giving their engagement a massive boost. To get a better handle on the practical side of this method, have a look at our guide to DTF transfer printing for more insights.

DTF Printing Compared to Other Methods

To really get why DTF printing is turning heads, it helps to put it side-by-side with the old guard of garment decoration. The two main players you'll hear about are Direct to Garment (DTG) and traditional Screen Printing. Each has its own lane, but they solve different problems.

Think of DTG as being like your office paper printer, but for t-shirts. It sprays water-based inks straight into the fibres of the fabric, which gives you a super soft, breathable print. This method is brilliant for complex, multi-coloured designs on 100% cotton, especially for one-off jobs.

Screen printing, on the other hand, is the undisputed champion of bulk orders. It works by pushing ink through a stencilled mesh screen onto the fabric, one colour at a time. It’s incredibly efficient for large runs of simpler designs, producing vibrant, durable prints you can really feel.

DTF vs DTG vs Screen Printing: A Head-to-Head Comparison

So, where does DTF fit into this picture? It’s the ultimate problem-solver, bridging the gap between DTG’s detail and screen printing’s versatility. It shines exactly where the others fall short, especially when it comes to fabric choice and small-to-medium batch sizes.

The real magic of DTF is its ability to print the full-colour, intricate detail of DTG onto almost any fabric you can think of—including polyester and blends—without the hefty setup costs of screen printing.

This makes it a perfect match for modern creators and businesses. To see how your own artwork could look on a garment, you can learn more about preparing my design on a T-shirt for printing.

To help you decide which method is right for you, here’s a quick comparison of the three most popular printing techniques. Each has its strengths, making them suitable for different projects and budgets.

| Feature | DTF (Direct to Film) | DTG (Direct to Garment) | Screen Printing |

|---|---|---|---|

| Best For | Small-to-medium runs, full-colour designs on any fabric type. | One-offs or small batches, highly detailed photographic prints on cotton. | Large bulk orders (100+ items) of simple designs with few colours. |

| Fabric Compatibility | Excellent. Works on cotton, polyester, nylon, leather, blends, and more. | Limited. Best on 100% cotton or high-cotton blends; struggles with dark polyester. | Good. Works on most fabrics, but may require different inks for each type. |

| Print Feel | Smooth, flexible, and soft. Sits on top of the fabric like a thin vinyl layer. | Very soft and breathable. The ink soaks directly into the fabric fibres. | Can be thick and heavy, especially with multiple colours. |

| Colour & Detail | Fantastic. Produces vibrant, full-colour prints with sharp details. | Excellent for photorealistic detail and unlimited colours. | Good for solid, vibrant colours. Each colour adds cost and complexity. |

| Durability | Highly durable. Resists cracking and fading well through many washes. | Good, but can fade over time, especially on darker garments. | Extremely durable. Often outlasts the garment itself. |

| Setup Costs | None. Digital process means no setup fees per design. | None. Ideal for printing single items on demand. | High. Requires a separate screen for each colour, making small runs costly. |

| Cost-Effectiveness | Great for small-to-medium batches. More economical than DTG for runs of 10+. | Best for single items or very small orders. | The most affordable option for large quantities of the same design. |

Choosing the right method really comes down to your specific needs: your design complexity, the type of fabric you're using, and how many items you need to print. DTF has carved out a valuable middle ground, offering a fantastic blend of quality, versatility, and affordability that suits a huge range of modern projects.

Real World Applications for DTF Transfers

Understanding the theory behind DTF is great, but seeing how it works in the real world is where you really grasp its power. This isn't just a niche technique for craft fairs; it's a genuine game-changer for businesses and creative people across dozens of industries.

From small indie fashion labels to large construction firms, DTF printing offers a seriously practical solution. Its knack for producing rich, multi-coloured designs makes it a favourite for streetwear brands needing to print complex graphics. At the same time, its incredible durability makes it the perfect choice for branding tough workwear that needs to survive a bit of rough and tumble.

That kind of flexibility is exactly what makes DTF so useful day-to-day.

From Uniforms to Unique Merchandise

The sheer range of applications is huge, all thanks to DTF's core strengths. Just think about these common scenarios where DTF really shines:

- Branded Workwear: Durability is everything for tradespeople. DTF transfers are perfect for high-vis jackets, rugged polo shirts, and overalls, giving a professional finish that won't crack or peel after a hard day's graft.

- Sports Team Kits: Need custom names and numbers on polyester jerseys? That's a perfect job for DTF. It sticks brilliantly to synthetic fabrics where other print methods often struggle, keeping team logos and player details looking sharp.

- Fashion and Accessories: Independent designers are using DTF to bring their complex artwork to life on tote bags, hats, and hoodies. Because there are no hefty setup fees, they can do small, experimental runs without a massive financial risk.

The real magic of DTF is its ability to deliver detailed, long-lasting prints on almost any fabric you can throw at it. This adaptability is precisely why it’s popping up everywhere, from building sites to fashion studios.

DTF printing is also becoming a key part of the wider UK print sector, which is a massive industry employing around 138,867 people across 10,540 companies. With a turnover of £14.25 billion, it provides a solid economic base for exciting technologies like DTF to grow. You can discover more insights about the UK print industry from the British Printing Industries Federation.

Common Questions About DTF Printing

As you start to get your head around what DTF printing is and how it all works, a few practical questions are bound to pop up. To help you get your projects off the ground, we’ve put together some of the most common queries we hear about Direct to Film.

This tech is becoming much more common, but it’s still smart to get a handle on the details before you jump in. From how the print actually feels on a shirt to its environmental impact, these answers should give you the confidence you need.

How Durable Are DTF Prints?

DTF prints are famously tough. The magic is in the combination of the specialised ink and the adhesive powder, which creates a strong but flexible layer that properly bonds to the fabric. A quality DTF print can easily handle 50+ washes without cracking, peeling, or fading, as long as you look after it.

This longevity makes it a brilliant choice for items that get a lot of wear and tear, like work uniforms or sports kits. Its resilience is often on par with high-end screen prints and generally outlasts standard DTG prints, which can start to fade a bit quicker over time.

The key thing to remember is that DTF prints don't just look great on day one—they’re built to last. The print often stays in fantastic condition for the entire lifespan of the garment itself.

Can I Do DTF Printing At Home?

Technically, yes, but setting up for DTF printing at home is a serious investment and needs a dedicated space. You’d need a specialised DTF printer, the right inks, PET film, adhesive powder, a curing oven, and a heat press. It’s a professional-grade operation that just isn’t practical for most hobbyists.

For most people or small businesses, a much easier and more cost-effective route is to order pre-made transfers. You can find a local company by searching for "DTF printing near me" and simply press the ready-made designs onto your garments with your own heat press.

What Is The Feel Of A DTF Print On A Shirt?

A DTF print feels soft, smooth, and flexible—often compared to a "soft-hand" screen print. Unlike DTG, where the ink soaks right into the fabric, a DTF transfer sits on the surface.

Don't let that put you off, though. Modern DTF technology produces transfers that are incredibly thin and stretchy. This means they move with the fabric, feel light, and are really comfortable to wear, completely avoiding that thick, plastic-like feel you might remember from older vinyl transfers.

Ready to bring your unique designs to life with the power and versatility of DTF printing? At Psyque, we specialise in creating high-quality, durable, and vibrant custom apparel. Explore our collections and start your project today.