Your Complete Guide to DTF Transfers UK

Share

Direct-to-Film transfers, or DTF transfers as they’re known in the trade, are a seriously impressive way for UK businesses and creators to print vivid, tough designs onto almost any fabric you can think of.

Imagine a professional, next-gen iron-on. One that feels soft to the touch, stretches with the garment, and is built to last. That’s DTF. It’s completely changing the game for custom apparel.

What Are DTF Transfers and Why Are They a Game Changer?

What if you could print any full-colour design—from a simple logo to a photorealistic image—and press it onto a cotton t-shirt, a polyester sports top, or even a rugged nylon jacket with the exact same brilliant result? That’s the magic of DTF transfers. It’s no wonder this method is quickly becoming a favourite for UK creators, from small Etsy sellers to big merchandise brands.

The core technology is beautifully simple but incredibly effective. Your design gets printed onto a special transparent film, which is then coated with a fine adhesive powder and cured with heat. This creates a ready-to-press transfer that, once heat is applied, fuses the ink directly into the fabric's fibres.

The end result is a design that feels like it’s part of the garment itself, not just a stiff sticker sitting on top. If you want to dive deeper into the nuts and bolts, check out our guide on what DTF stands for and how the process works.

The Rise of DTF in the UK Market

The demand for customised clothing has absolutely exploded, and DTF technology is perfectly timed to meet it. We're seeing this first-hand, but the numbers back it up too. The UK's direct-to-film printing market hit a revenue of USD 192.2 million in 2025 and is on track to reach USD 249.0 million by 2030. This growth is all down to how versatile and cost-effective DTF is compared to the older methods.

DTF cleverly sidesteps the limitations that used to hold creators back. It has some major advantages:

- Fabric Freedom: It works on a massive range of materials—cotton, polyester, blends, nylon, even leather—and it doesn’t matter if the garment is light or dark.

- No Colour Limits: You can print incredibly detailed, multi-coloured designs without the headache and expense of setting up separate screens for each colour.

- Exceptional Detail: DTF is brilliant at reproducing fine lines, tiny text, and smooth gradients, making your designs look crisp and professional every time.

- Soft and Durable Finish: The final print is lightweight, flexible, and can handle dozens of washes without cracking, peeling, or fading.

DTF Transfers vs Other Printing Methods

So, how does DTF really stack up against the other big names in custom printing? It helps to see them side-by-side. Each method has its place, but DTF often hits that sweet spot of quality, versatility, and cost.

| Feature | DTF Transfers | Screen Printing | Heat Transfer Vinyl (HTV) | Direct-to-Garment (DTG) |

|---|---|---|---|---|

| Fabric Versatility | Excellent. Works on cotton, poly, blends, leather, nylon. | Good. Best for cotton/blends, but needs special inks for others. | Good. Different vinyls needed for different fabrics. | Limited. Mainly for 100% cotton or high-cotton blends. |

| Colour & Detail | Unlimited colours, photorealistic detail, fine lines. | Limited by the number of screens. Best for bold, simple designs. | Limited to solid vinyl colours. Layering is complex. | Unlimited colours and great detail, like DTF. |

| Feel on Garment | Soft, flexible, and lightweight. Stretches with the fabric. | Can be heavy, especially with many colours. Sits on the fabric. | Can feel thick and plasticky, like a sticker. | Very soft, as ink soaks into fibres. The softest feel. |

| Durability | Excellent. Withstands 50+ washes without cracking or fading. | Very durable, but can crack over time with heavy ink layers. | Good, but can peel or crack eventually, especially corners. | Good, but can fade faster, particularly on darks. |

| Best For | Small-to-medium runs, complex multi-colour designs, any fabric. | Large runs (100+) of simple, low-colour designs. | One-offs, names/numbers, simple shapes and logos. | One-offs, detailed prints on light-coloured cotton. |

| Setup Cost | Very low. No screens or weeding needed per design. | High. Requires a separate screen for each colour in the design. | Low. Just need vinyl and a cutter. | Medium. Requires expensive machinery and pre-treatment. |

Ultimately, DTF combines the best of all worlds: the fabric freedom of HTV, the vibrant colours of screen printing, and the incredible detail of DTG, all rolled into one easy-to-use package. It's the perfect solution for on-demand printing.

Once you’ve got your garments perfectly printed, showing them off professionally is the next crucial step. Knowing how to dress a mannequin like a pro can make all the difference in showcasing your custom apparel and grabbing customer attention. It's this mix of great production and slick presentation that really sets successful brands apart.

So, What Are the Real Advantages of DTF Transfers?

When you first start looking into custom apparel, the sheer number of options can feel a bit overwhelming. But Direct-to-Film (DTF) transfers really do stand out from the crowd for a few powerful reasons, offering a unique mix of quality, flexibility, and efficiency that other methods just can't quite match. It’s no surprise so many UK businesses and hobbyists are making the switch.

One of the biggest draws is its incredible versatility. Just imagine being able to use the very same transfer for a 100% cotton tee, a polyester sports jersey, a poly-cotton blend hoodie, and even a tricky nylon bag. With DTF, this isn't a fantasy—it's just how it works. This ability to work flawlessly across a huge range of materials and colours, often without any special pre-treatment, is a genuine game changer.

Unmatched Print Quality and Feel

Beyond just working on different fabrics, the look and feel of a DTF print is superb. The technology is brilliant at producing incredibly vibrant colours and capturing the finest details. Everything from razor-sharp text to subtle gradients and photorealistic images comes out looking crisp and professional.

How? It’s because the ink is printed onto the film first, which allows for a perfect base layer of white to be applied underneath the colour. This white base is the secret sauce that makes the colours pop with intensity, even on the darkest fabrics.

The final result isn't a thick, plastic-like layer sitting stiffly on top of the garment. Instead, a well-applied DTF transfer has a remarkably soft, flexible finish that moves and stretches right along with the fabric. It almost becomes part of the garment, offering a premium feel that customers notice straight away.

Cost-Effective for Modern Needs

Let's be honest, traditional printing methods like screen printing often come with hefty setup costs. Creating a separate screen for every single colour in a design is time-consuming and expensive, which makes it a non-starter for small or medium-sized orders with intricate, multi-coloured artwork. This is where DTF truly shines.

With DTF transfers UK suppliers, you typically won't find any setup fees tied to the number of colours. You can print a single design with one colour or a hundred colours for the exact same price. This makes it an incredibly cost-effective solution for:

- Small Businesses: Perfect for fulfilling smaller batch orders without a massive upfront investment.

- Indie Brands: Launch new designs with full-colour graphics without needing to order hundreds of units.

- One-Off Prototypes: Test out complex designs before committing to a larger production run.

For a detailed breakdown of how these costs stack up, our article on DTF vs screen printing for graphic tees offers some really valuable insights. This economic model just makes sense for the on-demand world of modern e-commerce.

The UK's DTF printing market is directly shaped by the growth of e-commerce and fast-paced fashion. Globally, the demand for cost-effective customisation and high-resolution outputs is fuelling market expansion. This trend is mirrored in the UK, where there's a rising need for personalised clothing and promotional items, further supported by investments in textile production to keep up with fashion trends. Learn more about the factors driving the growth of the DTF printing market on SphericalInsights.com.

Built to Last Through Wear and Tear

Finally, the durability of a properly applied DTF transfer is exceptional. The magic is in the combination of specialised ink and adhesive powder, which creates a powerful bond with the fabric's fibres when cured under a heat press.

This means the design is built to withstand the rigours of daily life. It can endure dozens and dozens of wash cycles—industry tests often show longevity of 50+ washes—without cracking, peeling, or fading. This resilience makes DTF an ideal choice not just for fashion but also for durable workwear, team uniforms, and promotional items that need to look good for a long, long time.

Your Step-by-Step Guide to a Perfect Application

Applying a DTF transfer might seem straightforward on the surface, but getting it spot-on every single time is an art form. It's this precision that turns a great design into a professional, long-lasting piece of clothing.

Mastering this simple workflow is key. It ensures the adhesive bonds perfectly, giving you that soft, flexible finish that makes DTF so popular. I’ll walk you through each stage, from prepping your garment to the final press that locks everything in place. With the right technique, you’ll be achieving commercial-grade results right from the get-go.

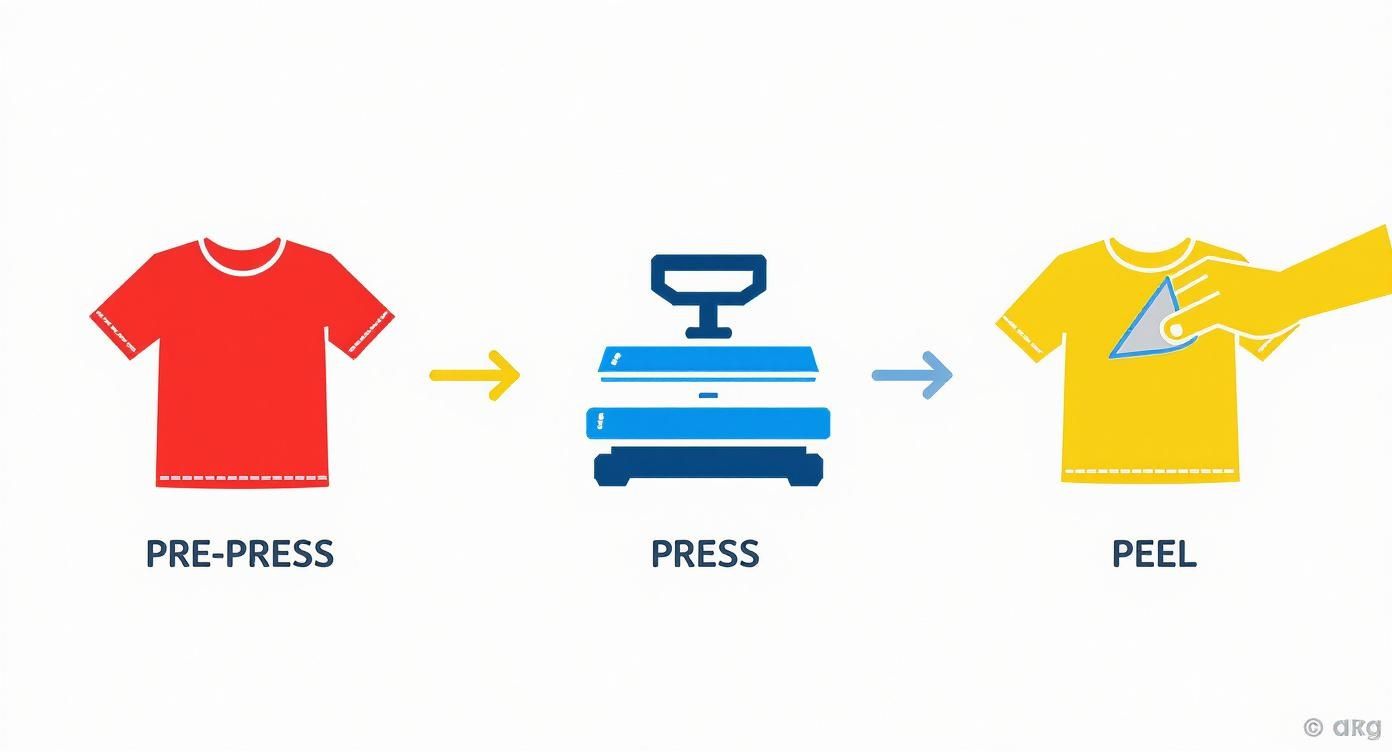

This visual guide breaks down the core DTF application process into three simple, crucial stages.

As you can see, the whole journey from a plain tee to a finished product comes down to three things: preparing, pressing, and peeling. Let's dive into what that actually looks like.

Step 1: Prepare Your Heat Press and Garment

First things first, get your heat press dialled in. For most cotton and poly-blend fabrics, you’ll want to be somewhere between 140°C and 160°C. It’s always a good idea to check the specific advice from your DTF transfers UK supplier, though, as their unique film and adhesive might have slightly different needs.

While the press is warming up, lay your garment flat on the platen. You’re aiming for a perfectly smooth, dry canvas for your transfer.

Now for a crucial little trick: give the garment a quick "pre-press" for about 5-7 seconds. This does two vital things. It irons out any stubborn creases, but more importantly, it zaps any moisture hiding in the fabric. Moisture is the number one enemy of a good transfer; it messes with the adhesive and can cause peeling down the line.

Step 2: Position and Press the Transfer

With your garment prepped and ready, it’s time for the main event. Carefully place your DTF transfer exactly where you want it, making sure the printed side is facing down against the fabric. The film is clear, which makes lining things up perfectly a breeze.

Once you’re happy with the placement, cover the transfer with a sheet of parchment paper or a Teflon sheet. This is just a simple protective layer to stop the film from melting and sticking to the hot upper platen of your press.

Now, press it. Close the heat press and apply a firm, even pressure for 10-15 seconds. This is where the magic happens. The heat activates the adhesive powder on the back of the ink, causing it to melt and fuse securely into the fibres of your garment.

Step 3: The Peel and Final Finish

After that first press comes the most critical part of the whole process: the peel. The vast majority of DTF transfers ready to press are what we call "cold peel," and that means you absolutely must let the transfer cool down completely before you even think about removing the film.

Rushing the peel is the single biggest mistake I see people make. If you peel while the transfer is still warm, you risk lifting the ink right off the garment and ruining your work. Patience is your best friend here.

Let the garment cool right down to room temperature. Once it's cool to the touch, start peeling the film away from one corner with a smooth, steady motion. If you've followed the steps, the film should lift off cleanly, leaving behind a crisp, vibrant design perfectly bonded to the fabric.

For a professional matte finish that really boosts durability, do one last press. Just cover the design with your parchment paper again and press for another 5-10 seconds. This final touch helps embed the ink even further into the material, improving its soft feel and making it tough enough to handle plenty of washes.

How to Choose the Right UK Supplier for DTF Transfers

Let's be honest, the quality of your finished products hinges entirely on the transfers you start with. Finding a solid, reliable UK-based supplier isn't just a simple admin task—it's probably the most important partnership you'll build for your brand.

A great partner will deliver vibrant, consistent prints on time, every time. A bad one? Well, they can leave you with missed deadlines, piles of wasted garments, and seriously unhappy customers. Your success truly depends on finding someone who feels like an extension of your own business. It's about looking beyond the price tag and seeing the whole picture: print quality, turnaround times, customer service, and how easy they make the whole process.

Always Start with Print Quality—Get a Sample

Before you even think about placing a proper order, you need to get a physical sample in your hands. A supplier's website can show you all the glossy mock-ups in the world, but a sample pack tells the real story. It's the single best way to vet a potential partner for DTF transfers UK services.

When that sample pack arrives, don't just give it a quick look. Put it to the test.

- Press It: Get that sample onto a spare T-shirt or piece of fabric. See how it behaves under your own heat press.

- Feel It: What’s the texture like? Is it soft and flexible, or does it feel thick and plasticky? A quality transfer should feel like it's part of the garment itself.

- Stretch It: Give the fabric a gentle pull. The design needs to stretch right along with it, without any signs of cracking or peeling.

- Wash It: Chuck it in the washing machine a few times. This is the ultimate test of durability and will quickly reveal any issues with peeling or fading.

Check Their Turnaround Times and Communication

In the fast-paced world of on-demand apparel, speed and reliability are everything. You need to ask potential suppliers about their standard production times. A good UK-based supplier should be able to get your order printed and dispatched within 1-3 working days. Anything more than that could start causing serious delays in your own workflow.

Just as important is their customer service. Before you commit, send them a quick email with a question about their artwork setup or file types. How fast do they reply? Is their response actually helpful and easy to understand? A supplier who is quick and clear before you're a customer is far more likely to be a supportive partner when you really need them.

A supplier’s communication style is a direct reflection of their business standards. If they're slow to respond or give you vague answers during the vetting process, consider it a massive red flag for how they’ll handle problems with a live order.

Understand Their Artwork Rules and How to Use Gang Sheets

A professional supplier will have simple, clear guidelines for submitting artwork. They should tell you exactly what file formats they need (usually a 300 DPI PNG with a transparent background) and the right colour profiles to use. A slick, intuitive upload process is a huge bonus—it saves you time and cuts down on the chances of making a mistake.

To get the absolute best value for your money, you need to get to grips with the gang sheet. This is essentially a large sheet of transfer film where you can arrange multiple designs to be printed all at once. Instead of paying per design, you pay for the whole sheet, which dramatically lowers your cost per print. A good supplier will offer different gang sheet sizes and might even have online tools to help you build your sheet without wasting any space. This is the perfect way to maximise your budget, especially if you have lots of smaller logos or designs. If you're looking for more options, you can explore different places offering DTF transfers for sale to find a supplier that suits your needs.

When you're doing your homework on potential suppliers, it’s a good idea to create a simple checklist to keep your thoughts organised. This helps you compare everyone on a level playing field, ensuring you don't miss any critical details.

UK DTF Supplier Checklist

| Evaluation Criterion | What to Look For | Why It Matters |

|---|---|---|

| Print Quality | Order a physical sample pack. Check for colour accuracy, feel, stretch, and wash durability. | This is non-negotiable. You can't judge quality from a screen; you need to see and feel the real thing. |

| Turnaround Time | Look for a standard dispatch of 1-3 working days. Check if they offer express options. | Speed is crucial for on-demand businesses. Delays from your supplier mean delays for your customers. |

| Customer Support | Send a test email. Are they responsive, helpful, and clear in their communication? | Good support shows they're a reliable partner who will help you solve problems, not create them. |

| Artwork Process | Clear guidelines (300 DPI PNG), easy upload system, and helpful resources. | A smooth artwork process saves you time and reduces the risk of costly printing errors. |

| Gang Sheet Options | Variety of sizes available and tools to help you build your sheet efficiently. | Gang sheets are the key to keeping your costs low. The more control you have, the more you save. |

| Shipping Costs | Transparent and reasonable UK shipping fees. Look for free shipping thresholds. | Hidden or high shipping costs can eat into your profit margins, so factor this into your total cost. |

| Customer Reviews | Check independent platforms like Trustpilot or Google Reviews for recent, honest feedback. | Real customer experiences will tell you what it's really like to work with them, beyond the marketing talk. |

Finally, before making your choice, always have a look at recent customer reviews on independent sites. Search for patterns in what people are saying about print quality, shipping speeds, and how the company handles things when they go wrong. By mixing this research with a hands-on sample test, you can confidently pick a UK supplier who will genuinely help your brand grow.

Getting to Grips with UK Pricing and Shipping

Before you dive in and place your first order for DTF transfers UK wide, it’s smart to understand the costs and logistics. The good news is that the pricing is usually refreshingly straightforward and offers incredible value, especially once you know the ropes. Let's break down the real-world costs and shipping details so you can budget for your projects with complete confidence.

The standard way UK suppliers charge for DTF transfers is by the sheet, which you’ll hear called a gang sheet. Picture it as a blank canvas of transfer film where you can cram in as many different designs as you can possibly fit. This is an incredibly budget-friendly way to work because you’re only paying for the total area of the sheet, not for every single design on it.

This method is a game-changer for small businesses and independent creators. You can squeeze company logos, little sleeve details, neck labels, and multiple full-size t-shirt graphics all onto a single sheet, driving your cost-per-print way, way down.

What Shapes the Final Price?

A few key things will influence the total cost of your order. The most obvious one is order quantity. As you'd expect, buying more gang sheets in one go usually unlocks some tasty bulk discounts, lowering your price per sheet.

The type of film you choose can also make a difference. While the standard film is brilliant for most jobs, some suppliers offer speciality options like glitter, holographic, or even UV-reactive films for an extra fee. They're fantastic for creating apparel that really pops, but they will naturally bump up your costs. If you're looking to keep things lean, exploring cheap DTF transfers by simply packing a standard gang sheet to the brim is the smartest move you can make.

Your final price is a direct result of how efficiently you use your gang sheet space. Maximising every square inch is the single best way to reduce your per-design cost and increase your profit margins.

The UK's DTF printing scene is a big part of a much larger European boom. The global DTF market was valued at USD 2.72 billion in 2024 and is on track to hit USD 3.92 billion by 2030. This growth is fuelled by the ever-growing demand for custom clothing and better printing tech. As a major player, the UK market benefits directly from these trends, with a really strong focus on dedicated DTF printing services.

Understanding UK Shipping and Turnaround Times

So, you’ve placed your order. What happens now? One of the biggest perks of using a UK-based supplier is the sheer speed of delivery. Most reputable outfits will print and dispatch your orders within 1-3 working days, which is a massive help for keeping your own production line moving.

Your transfers will be shipped securely to make sure they arrive in pristine condition. You'll usually find them sent either flat-packed in a tough cardboard envelope or carefully rolled inside a postal tube to prevent any creases or damage on their journey.

Common couriers used by UK suppliers include:

- Royal Mail: A go-to for standard and tracked services, offering solid nationwide coverage.

- DPD or Evri: Often the choice for next-day delivery or for larger, heavier orders.

For businesses that might be sourcing materials from overseas or even selling transfers internationally, getting a handle on logistics is crucial. You might find it useful to read up on the cheapest shipping options from the USA to the UK to help manage those international costs. It's always a good idea to double-check your supplier’s shipping policies for the specifics on their couriers, costs, and delivery estimates.

Common Questions About DTF Transfers UK

As you start planning your next custom clothing project, it’s completely normal to have a few questions. Direct-to-Film is a pretty straightforward process, but getting to grips with the finer details is what separates a good result from a truly professional one. This section is all about giving you quick, clear answers to the most common queries we hear from creators across the UK.

We’ll tackle some of the big ones, from how these prints really hold up in the real world to the nitty-gritty of artwork files and whether this printing method is a responsible choice for your brand. Our goal is to give you the confidence to move forward, making sure your first order with a DTF transfers UK supplier is a massive success. Let's clear up any lingering questions so you can get back to what you do best: creating incredible designs.

How Long Do DTF Transfers Last on Clothing?

This is usually the first question on everyone's lips, and rightly so. You want your hard work to last. The good news is, when applied correctly, a DTF transfer is incredibly durable. It’s engineered to handle dozens and dozens of washes without cracking, peeling, or fading. In fact, it’s not uncommon for the print to outlast the garment it’s pressed onto.

The secret to this longevity is all in the application. Using a quality heat press with the right temperature, pressure, and time is non-negotiable. This process ensures the special adhesive melts perfectly and bonds deep into the fabric's fibres. A quick final press after peeling the film also works wonders, locking the design in and improving both its feel and its resilience.

To give your prints the longest life possible, a few simple care instructions go a long way.

- Wash Inside Out: Turning the garment inside out before washing protects the print's surface from friction.

- Use a Cool Cycle: Washing at 30°C is much gentler on both the fabric and the transfer.

- Avoid the Tumble Dryer: Air drying is always your best bet. If you absolutely have to use a dryer, stick to a low heat setting.

Follow these simple steps, and your designs will stay vibrant and intact for years. This impressive durability is a huge reason why DTF has become the go-to for everything from high-end fashion brands to tough, everyday workwear.

Can I Use a Home Iron for DTF Transfers?

While it might be tempting to reach for your trusty home iron, we strongly advise against it if you want anything close to a professional or lasting result. An iron simply can't provide the two most crucial elements for a successful DTF application: consistent temperature and even pressure.

A heat press is specifically designed to maintain a precise temperature across its entire heated plate, meaning every part of your transfer gets the exact same amount of heat. An iron, however, is full of hot spots and cooler areas, which leads to the adhesive curing unevenly.

Using a home iron is the fastest way to ruin a print. It almost always results in a patchy application where bits of the design don't stick properly, and it will inevitably start peeling after the very first wash.

On top of that, a heat press lets you clamp down with firm, consistent pressure across the whole design at once—something you just can't replicate by hand with an iron. For that commercial-grade quality, soft feel, and long-term durability that makes DTF so popular, a heat press isn't just a recommendation; it's essential.

What Artwork File Do I Need to Order?

To get the sharp, professional-looking print you're aiming for, the quality of your artwork file is everything. As the old saying goes, garbage in, garbage out. Most reputable DTF transfers UK suppliers will have clear guidelines on their site, but the industry standard is to provide a high-resolution file ready for print.

The absolute best format is a vector file, like an AI (Adobe Illustrator), EPS, or PDF. Vectors are brilliant because you can scale them to any size—from a tiny chest logo to a massive back piece—without losing a single bit of quality. That said, the most common format we see, which works perfectly well, is a high-resolution PNG file with a transparent background.

Here’s what to aim for when getting your art ready:

- Resolution: Your file must be 300 DPI (dots per inch) at the exact physical size you want it printed.

- Background: The background must be transparent. If you save your design on a white background, it will be printed with a white box around it.

- File Type: PNG is ideal for standard images, while AI, EPS, or PDF are the top choices for vector graphics.

Submitting a low-quality file, like a blurry JPEG you’ve pulled from a website, will only ever give you a pixelated and unprofessional-looking transfer. Always double-check your supplier's specific artwork requirements before you order to avoid any delays or disappointment.

Is DTF Printing an Eco-Friendly Choice?

In the world of custom clothing, sustainability is a bigger deal than ever for both brands and their customers. When you stack it up against traditional methods like screen printing, DTF is widely seen as a more environmentally conscious option for a few key reasons.

First off, DTF printing almost exclusively uses water-based inks. These are much less harsh on the environment than the plastisol inks common in screen printing, which often contain PVC and phthalates.

Secondly, the process itself creates very little waste. You only print the transfers you actually need, which is a world away from the screen printing setup. Screen printing demands huge amounts of water and chemicals to clean screens between each colour and job, creating a lot of wastewater. With DTF, that entire messy step is completely gone. For UK businesses looking to make greener choices, DTF offers a practical and more sustainable way to create top-quality custom apparel.

Ready to bring your own custom apparel ideas to life with the highest quality prints? At Psyque - DTF Print & Press, we combine state-of-the-art DTF technology with unique, artist-driven designs to deliver garments that truly stand out. Whether you need a single bespoke piece or a full run for your brand, we're here to help.