Your Ultimate Heat Press Machine UK Buying Guide

Share

Welcome to your no-nonsense guide for UK creators and entrepreneurs. A quality heat press machine in the UK is the absolute heart of any custom apparel business, the final step that turns a great design into a product people will love to wear.

Whether you're diving into DTF printing for the first time or scaling up your Etsy shop, getting the press right is non-negotiable. This guide will walk you through exactly what you need to know.

Your Roadmap to Choosing a Heat Press Machine

So, what is a heat press? Think of it less like an iron and more like a high-tech, precision tool designed to give you perfect, repeatable results every single time. It applies an exact amount of heat and pressure for a specific duration, permanently bonding your designs to fabrics.

For small businesses and creators here in the UK, choosing the right machine from the get-go is critical. A reliable press means your products look professional, feel great, and can survive the weekly wash. On the flip side, a cheap, poor-quality machine is a recipe for disaster—wasted materials, unhappy customers, and a damaged reputation before you've even started.

Why a Quality Press Matters for Your UK Business

The success of your DTF (Direct to Film), sublimation, or vinyl printing business really does come down to the consistency of your press. Here’s what a great machine delivers:

- A Professional Finish: Even heat and pressure across the entire platen (the hot bit!) prevents peeling, cracking, or those dreaded faded patches.

- Built-to-Last Durability: When applied correctly, your designs will withstand dozens of washes. This builds customer trust and brings people back for more.

- Real-World Efficiency: A dependable machine smooths out your workflow, letting you fulfil orders quickly and confidently without having to scrap failed prints.

- Future-Proof Versatility: The right press doesn't just do t-shirts. It opens the door to hoodies, tote bags, cushion covers, and so much more.

This guide is your roadmap. We’ll cut through the technical jargon, compare the essential models, and show you what to look for in a UK supplier. We’ll cover everything from compact clamshell models perfect for a home studio to the more industrial swing-away machines.

A classic startup mistake is focusing only on the printer and underestimating the press. Your transfer can be flawless, but without the right heat and pressure, the final garment will fail. Your heat press isn't just a piece of kit; it's your partner in quality control.

We'll break down the features that actually matter, like platen size, digital controls, and pressure systems, so you can achieve those professional results you're after. Whether you’re looking for a complete t-shirt print machine setup or just the press itself, this guide will give you the clarity you need.

By the end, you'll be ready to make a confident investment, choosing the right heat press machine in the UK to truly bring your creative vision to life.

How a Heat Press Actually Works

Before you start looking for the perfect heat press machine in the UK, it helps to get your head around what’s actually going on inside one. At its heart, a heat press is a precision-engineered tool, a bit like a super-powered, intelligent iron. Its entire purpose is to deliver flawless, repeatable results that you could never, ever get with a standard household iron.

Think of it like baking a cake. You can't just throw it in the oven at a random temperature for a "while" and hope for the best. A heat press operates on the same principle, but its success hinges on three critical elements working together perfectly: temperature, time, and pressure.

When you get this trio right, you kick off a reaction that permanently fuses your DTF transfer’s ink and adhesive into the very fibres of the fabric. This is the secret to a professional, long-lasting print that won’t crack, fade, or peel off after a couple of washes. Nailing this ‘golden triangle’ is the key to mastering your craft.

The Three Pillars of a Perfect Press

Imagine these three factors are the legs of a stool. If one is off—even by a little bit—the whole thing becomes unstable. You end up with inconsistent prints, wasted materials, and a lot of frustration. A good quality machine gives you rock-solid control over each one.

-

Precise Temperature: The heated top plate, known as the platen, needs to hit an exact temperature and stay there. For most DTF transfers, you're looking at around 150°C. If it's too cold, the glue won't activate properly. Too hot, and you risk scorching the t-shirt or dulling the vibrant colours of your design.

-

Controlled Time: How long you press for is just as crucial. A digital timer makes sure every single garment gets the exact same amount of heat, typically between 10-15 seconds for DTF. This consistency is impossible to get right by just counting in your head, and it’s what allows you to produce reliable, identical products for your customers.

-

Consistent Pressure: This is what really separates the pros from the hobbyists. A proper heat press clamps down with firm, even pressure across the entire design, literally pushing the ink and adhesive deep into the fabric's weave. Without that consistent force, you’ll get patchy results where the corners start peeling away after the first wash.

This whole process is fundamental to modern garment printing. If you want to dive a bit deeper, our complete guide to heat transfer printing explains how different methods compare.

Why Digital Controls Are Non-Negotiable

The brain of any modern heat press is its digital control panel. This is where you punch in the exact temperature and time, and on better models, you can even see a pressure reading. Steer clear of cheap presses with flimsy analogue dials or poor-quality digital displays that can’t hold a steady temperature.

A heat press with an inaccurate temperature gauge is a recipe for disaster. One study on budget machines found the actual platen temperature could be off by as much as 20°C from what the screen was showing. That level of inaccuracy makes consistent, quality printing virtually impossible.

A reliable digital controller is your best friend. It guarantees the temperature you set is the temperature you get, right across the entire platen, with no annoying "cold spots" at the edges. This accuracy takes all the guesswork out of the equation, saving you time, money, and headaches. When you're ready to invest in a heat press machine in the UK, make sure this is right at the top of your list.

Comparing Heat Press Types For Your Business

Not all heat presses are built the same, and picking the right one for your UK business is a big deal. It’s a decision that will shape your workflow, the kinds of products you can create, and even how you use your workspace. The market is flooded with options, but they mostly boil down to a few key types, each with its own pros and cons. Getting your head around these differences is the first step to making a smart investment.

The most common models you’ll come across are Clamshell, Swing-Away, and Draw-style presses. I like to think of it like picking a vehicle: a small hatchback is perfect for zipping around the city (Clamshell), an estate car gives you more versatile space for bigger jobs (Swing-Away), and a van is for heavy-duty, repetitive work (Automatic). Each one is brilliant for its intended purpose.

To help you get a clearer picture, here’s a quick comparison of the main contenders.

Heat Press Machine Type Comparison for UK Businesses

This table breaks down the most common heat press types to help you figure out which is the best fit for your workspace, product range, and budget.

| Machine Type | Best For | Pros | Cons | Typical UK Price Range |

|---|---|---|---|---|

| Clamshell | T-shirts, tote bags, thin items, small workspaces, and beginners. | Space-saving, affordable, fast operation for simple jobs. | Awkward access, risk of burning knuckles, not great for thick items. | £150 - £400 |

| Swing-Away | Hoodies, thicker garments, sublimation on hard surfaces, and safety-conscious users. | Full, clear access to the platen; even pressure; safer to use. | Needs much more space to operate, often slower workflow. | £250 - £700 |

| Draw-Style | Precise placement, high-volume work in limited spaces, and working with bulky items. | Easy access like a swing-away but with a smaller footprint. | More moving parts can mean more maintenance; higher cost. | £300 - £800 |

| Automatic | High-volume production shops where speed and consistency are everything. | Reduces operator fatigue, increases output, ensures consistent pressure. | Requires an air compressor, significantly more expensive, overkill for small businesses. | £1,500+ |

Choosing the right machine is about matching its features to your daily reality. A high-volume shop has very different needs from a home-based business just starting out.

The Compact Clamshell Press

The Clamshell heat press is the classic starting point for countless startups and home-based businesses across the UK. Its design is brilliantly simple: the top platen lifts straight up from the bottom one, just like a clamshell opening and closing. This makes it incredibly space-efficient because you don’t need any extra room at the sides.

It’s the perfect machine for pressing thin, flat items like t-shirts, tote bags, and tea towels. If you’re working out of a spare room or a cramped workshop, the clamshell’s tiny footprint is a game-changer. They’re also usually the most affordable, giving you an accessible way into the world of custom apparel.

The main drawback? That angled opening. It can be a bit fiddly to position transfers perfectly, and you have to be careful not to singe your knuckles on the hot upper platen when working with thicker garments like hoodies.

The Versatile Swing-Away Press

For businesses that need a bit more flexibility, the Swing-Away heat press is a fantastic step up. Just like the name says, the top platen swings out horizontally, moving completely away from the lower platen. This gives you a totally clear, unobstructed view of your workspace.

This design brings two massive benefits:

- Safety: With the heat source moved right out of the way, the risk of accidental burns drops dramatically. It’s much less stressful when you’re carefully lining up garments and transfers.

- Versatility: The straight-down pressure and open workspace make it a breeze to work with thicker items like hoodies, sweatshirts, and even things like ceramic tiles or plaques.

The trade-off, of course, is space. You need enough clearance for that top platen to swing out, so it demands a much larger operational footprint than a clamshell of the same size. That’s something you really need to measure up for in a smaller workshop.

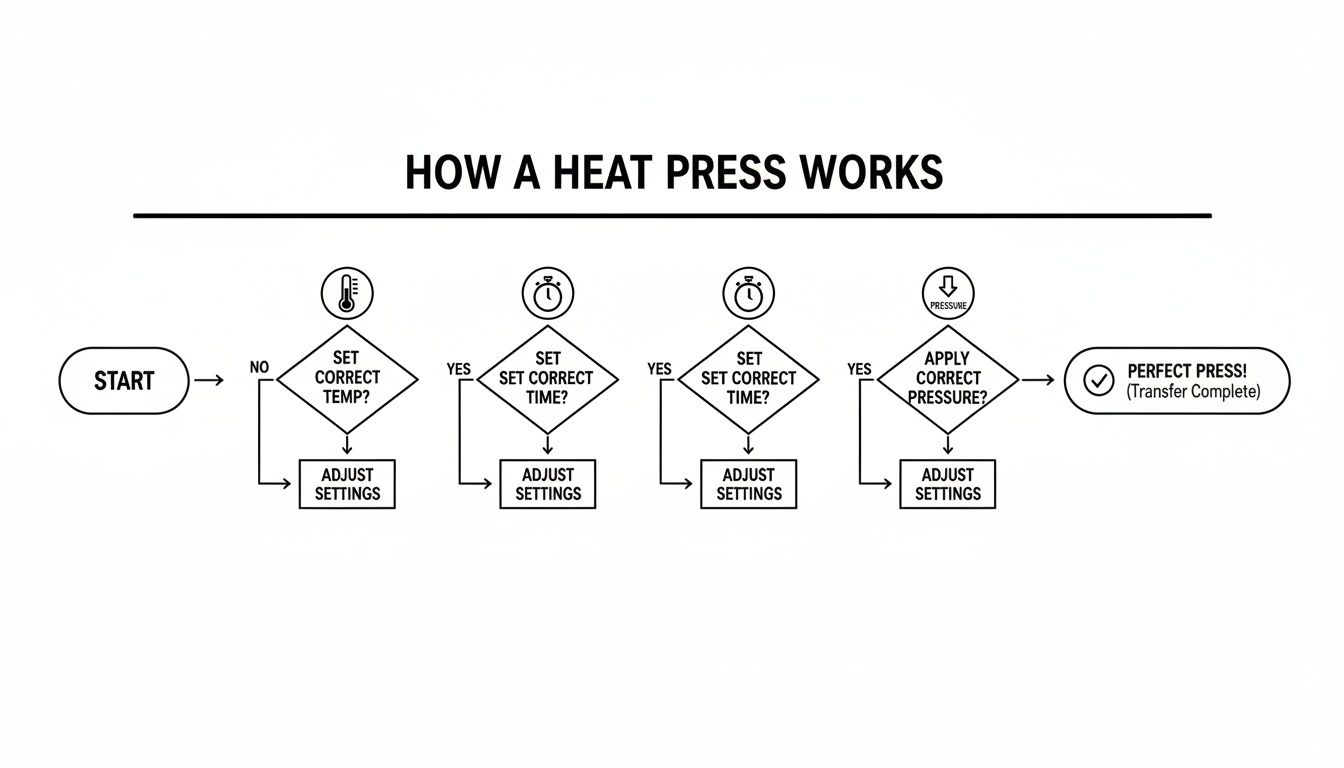

This flowchart below breaks down the three core pillars—temperature, time, and pressure—that every single heat press, regardless of type, relies on to get a perfect print.

Once you grasp this simple process, you can see how each machine’s design is really just a different way of delivering those three elements consistently.

The Efficient Draw-Style Press

A Draw-style heat press offers a really clever hybrid solution. With this design, the bottom platen slides out towards you like a drawer. You get the same easy, safe access as a swing-away, but without needing all that extra side clearance. It’s a brilliant space-saving alternative if you need to work with bulky items.

You can lay out your garment and transfer safely away from the heat, then just slide the drawer back in and bring the press down. This design is fantastic for nailing precise placement and cutting down on operator fatigue. They’re often a bit pricier than a basic clamshell, but the improvement to your workflow is significant. If you’re also looking into other printing methods, our guide on choosing a heat press for sublimation has some extra insights that apply here too.

Manual vs. Automatic Presses

Finally, you’ve got to decide between a manual and an automatic press. Manual presses are the standard; you have to physically clamp the machine shut and open it again. This is perfectly fine for small to medium volumes.

Automatic or semi-automatic presses, on the other hand, use magnets or air compressors to clamp down and often pop open by themselves when the timer is done. This seriously reduces physical strain and is a must-have for high-volume print shops. It frees you up to prep the next garment while the current one is pressing, dramatically speeding up your output. It’s an upgrade that makes total financial sense once your order volume is consistently high and speed becomes a top priority.

Essential Features Every Buyer Should Check

Alright, let's move beyond the basic types of machines and get into the details. This is where you separate a reliable workhorse from a costly mistake. When you’re comparing different heat press machines in the UK, the spec sheet can look like a wall of numbers and jargon. It’s easy to get overwhelmed.

But don’t worry. By focusing on just a few key features, you’ll be able to cut through the noise and make a choice you feel good about.

Think of it like buying a car. You know you need four wheels and an engine, but it's the specifics—like fuel efficiency, boot space, and safety features—that really matter for your day-to-day life. It's the same deal here; the right features will make your production process smoother, more efficient, and far more professional.

Decoding Platen Size

The first thing to look at is the size of the heated upper platen. This single measurement directly controls the maximum size of the designs you can press in one go. UK suppliers usually list these sizes in both inches and centimetres, and a few standards tend to pop up everywhere.

- 9"x12" (approx. 23x30cm): This is a compact, smaller size. It’s perfect for children's clothing, babygrows, tote bags, or pressing smaller chest logos onto adult garments.

- 15"x15" (approx. 38x38cm): This is widely seen as the industry standard. For a new business, it's easily the most versatile option, big enough for most adult t-shirt and hoodie designs without taking up a massive amount of space.

- 16"x20" (approx. 40x50cm): If you're planning on doing oversized prints or working with larger items like blankets or XL garments, this size gives you that extra breathing room you'll definitely appreciate.

Choosing the right size is a balancing act between your product ambitions and your workspace. For most UK startups, a 15"x15" press is the sweet spot, offering maximum flexibility right from the get-go.

The Importance of Accurate Digital Controls

We've touched on this already, but it’s so important it’s worth saying again: reliable digital controls are non-negotiable. Cheap machines with dodgy temperature readouts are the number one cause of failed prints. A quality digital controller ensures the temperature you set is the temperature you actually get, every single time.

DTF transfers are especially fussy about temperature. Too cool, and the adhesive won't bond properly, meaning it'll start peeling after the first wash. Too hot, and you can scorch the fabric or even dull the vibrancy of your design. For a deep dive into dialling this in, our comprehensive heat press temperature guide breaks down the ideal settings for all sorts of materials.

A classic problem with budget presses is a massive temperature drop the moment the cold garment and platen meet. A well-built machine recovers to its target temperature quickly. A cheap one will struggle, leaving you with an under-cured, faulty transfer.

Look for a machine with a clear, easy-to-read digital display for both time and temperature. It takes all the guesswork out of the process and is absolutely fundamental for creating consistent, high-quality products people will want to buy.

Ensuring Even Heat Distribution

This is probably the most critical feature, but also the hardest to judge from a product page: the evenness of heat across the platen. This is where high-quality machines really earn their price tag. In cheaper models, the heating elements inside the platen can be spaced too far apart, creating "cold spots," especially around the edges.

This inconsistency is a recipe for disaster. You’ll press a design and find the centre has stuck perfectly, but the corners and edges just peel away because they never got hot enough.

So, how can you check for this?

- Read Reviews: Look for what other UK buyers are saying, specifically about heat consistency.

- Ask the Supplier: A reputable UK supplier should have no problem telling you about the quality and layout of the heating elements in their platens.

- Invest in Quality: Higher-end presses often use thicker platens made from better-grade metal. They also feature more densely packed heating coils, which guarantees a uniform temperature from corner to corner.

A warped platen is another major culprit, often found in machines built with flimsy, low-grade metal. Over time, the constant heat and pressure can cause the metal to bend slightly. This prevents the platen from making flat, even contact with your garment, leading to uneven pressure and, you guessed it, a failed print.

Investing in a machine with a solid, well-constructed platen isn't just buying a tool; it's an investment in your business's reputation.

Finding and Buying Your Heat Press in the UK

You’ve done the research and have a solid idea of the type of press you need. So, what’s next? Actually getting your hands on one. This is where a lot of new business owners face their first big decision: do you buy from a dedicated UK supplier, or take a chance on a cheaper machine from an overseas marketplace?

While the low prices from international sellers can look incredibly tempting, that initial figure often hides a minefield of extra costs and logistical headaches. For anyone just starting out, buying from a reputable UK company is almost always the smoother, safer, and smarter route.

UK Suppliers vs. Overseas Imports

The pull of a bargain is strong, I get it. But when you’re looking at an imported press, you have to think about the total cost, not just the ticket price. When you buy direct from overseas, you're not just a customer—you're the importer, and that comes with a whole lot of responsibility.

- VAT and Import Duties: This is the big one that catches people out. Any heat press shipped from outside the UK will have VAT added (currently 20%), and you might get hit with import duties on top. These fees are calculated on the total value, including the shipping cost, which can add a nasty surprise to your final bill.

- Shipping Delays and Costs: International shipping isn't just expensive; it's unpredictable. Your new machine could get stuck in customs for weeks, bringing your business plans to a screeching halt. That initial saving doesn't seem so great when you're losing out on orders.

- Electrical Safety: This is non-negotiable. UK suppliers have a legal duty to sell machines that meet our safety standards, complete with the correct plug for our 240v system. An import might not be certified, turning your money-saving machine into a genuine fire hazard.

Let’s be blunt: the single biggest reason to buy locally is support. At some point, something will go wrong, probably right in the middle of a big order. Having a UK-based warranty and a real person you can call for help is priceless. Waiting for a spare part to arrive from the other side of the world just isn’t a viable option for a serious business.

If you are still thinking about importing, it pays to do your homework on the logistics. You can learn more about the different shipping options when importing from China to the UK to see what’s involved. For most startups, though, the peace of mind you get from a local supplier is worth every penny.

What to Look For in a UK Supplier

Choosing the right supplier is just as crucial as choosing the right press. You're not just buying a piece of metal; you're looking for a partner who can support your business as it grows.

Start by looking for suppliers with a genuine reputation in the UK printing community. Dig around for real reviews on places like Trustpilot or dedicated forums. A good company will be upfront about stock levels, delivery times, and exactly what their warranty covers.

Key Questions to Ask Before You Buy

Don’t be shy about getting in touch before you part with your cash. A supplier's attitude to pre-sales questions is often a good indicator of how they'll handle any problems later on.

Here are a few must-ask questions:

- What does the warranty actually cover? Ask about parts, labour, and the full term.

- Where are repairs handled? Make sure it’s here in the UK, so you're not facing massive shipping costs and delays if things go wrong.

- Do you offer technical support? Is there a phone number you can call when you’re stuck?

- Do you keep spare parts in stock? Knowing you can get a new heating element or controller quickly will save you a world of stress down the line.

When you choose a UK-based supplier with solid support and a proper warranty, you're not just buying a machine. You’re making a safe investment in your business, giving yourself the reliable foundation you need to handle whatever comes your way.

Perfecting Your DTF Prints with a Heat Press

So, you've unboxed your new heat press machine in the UK – the exciting bit is about to begin. The real magic of DTF printing isn't just in the equipment, but in mastering the application itself.

Achieving that flawless, professional finish that keeps customers coming back is all about getting the recipe right: a precise mix of temperature, time, and pressure. Nail this trio, and your prints will look vibrant, feel great, and stand up to countless washes.

While the perfect settings can shift a bit depending on your fabric and transfers, a solid starting point for most cotton and poly-blend garments is a temperature between 150°C to 160°C. Aim for a press time of around 10 to 15 seconds with medium to firm pressure.

Here's a pro tip: always give your garment a quick pre-press for 3-5 seconds. This little step irons out wrinkles and zaps any moisture, creating the perfect smooth canvas for your transfer.

Hot Peel vs Cold Peel Technique

One of the first things you need to get your head around is whether your transfer film is a 'hot peel' or a 'cold peel'. This tiny detail completely changes your workflow and can be the difference between a perfect print and a frustrating failure.

-

Hot Peel: Just like it sounds, you peel the film away immediately after the press pops open, while everything is still piping hot. It’s quick and brilliant for knocking out big orders, but it takes a bit of practice to get a confident, smooth peeling motion.

-

Cold Peel: With these transfers, you have to be patient and wait for the garment and transfer to cool down completely before you even think about peeling. This process gives the adhesive time to properly bond with the fabric fibres, often leaving a beautifully smooth, matte finish.

Rushing a cold peel is a classic rookie mistake that causes bits of the design to lift off. Always double-check the instructions from your transfer supplier. To get it right every time, have a look at our detailed guide on using DTF transfers that are ready to press, which dives deeper into these techniques.

Ever had the edges of a design refuse to stick properly? It's a common frustration for beginners. Nine times out of ten, this is down to uneven pressure, usually caused by a warped platen on a cheap press. A quality machine guarantees that firm, even contact right to the very corners.

Troubleshooting Common DTF Issues

Even with the best gear, you'll eventually run into a hiccup. It happens to us all! Here’s a quick rundown of how to fix the most common problems.

-

Transfer Isn't Sticking: The usual suspects here are not enough pressure or heat. Crank up the pressure first. If that doesn't solve it, nudge the temperature up in 5°C increments until it sticks.

-

Scorch Marks on Garments: Seeing a slight yellowing or browning? That’s a tell-tale sign of too much heat. Drop the temperature down or, better yet, use a Teflon protective sheet between the hot platen and your garment.

-

Colour Bleeding (Dye Migration): This is a real pain, especially on brightly coloured polyester fabrics where the garment's dye "bleeds" into your print. The fix is often to press at a lower temperature for a slightly longer time. This helps lock your design in without activating the fabric's dyes.

Got Questions? We’ve Got Answers

Stepping into the world of heat presses can feel a bit daunting at first. It's only natural to have a few questions buzzing around. Let's tackle some of the most common ones we hear from UK business owners just like you.

What Size Heat Press Is Best for a UK Startup?

For most UK startups dipping their toes into t-shirts and small apparel, a 15"x15" (38x38cm) press is the undisputed sweet spot. It’s got enough surface area to handle the vast majority of adult-sized garments without gobbling up all your workspace.

This size really is the perfect middle ground, giving you plenty of capability while still being manageable enough for a small workshop or even a home-based setup.

Can I Just Use a Normal Iron Instead?

Look, while you could technically use a household iron for a one-off hobby project, it's a definite no-go for any kind of professional work. An iron simply can't deliver the consistent, even pressure and rock-solid temperature control you need for a durable DTF transfer.

The result? Prints that start peeling and cracking after the very first wash, which is a fast track to unhappy customers and a damaged reputation.

Trying to run a business with an iron is like trying to bake a wedding cake in a microwave. You might get something that vaguely resembles the finished article, but the quality and consistency your customers expect just won't be there.

Will I Need Special Wiring for a Heat Press in the UK?

Thankfully, no sparks will fly for most setups. The majority of small to medium heat presses from UK suppliers are designed to run on a standard UK 240v household socket and come fitted with a 13-amp plug. It's always smart to double-check the machine's power requirements before you buy, just to be safe.

A quick pro tip: plug your press directly into a wall socket rather than an extension lead. This ensures it gets a steady, uninterrupted flow of power to maintain that crucial stable temperature. If you're eyeing up a larger, industrial-grade beast, it might need its own dedicated circuit, so always have that chat with the supplier beforehand.

Ready to pair that perfect press with professional-grade DTF prints? Psyque offers vibrant, durable, and ready-to-press transfers that bring your vision to life. Explore our collections or request a custom design today.