Choosing Your T Shirt Print Machine

Share

Thinking about jumping into the world of custom clothing? It can feel a bit overwhelming at first, but everything really boils down to one essential tool: the t shirt print machine. This bit of kit is what turns a digital idea into a piece of wearable art, giving creators and businesses the power to bring their designs to life.

Your Guide to T-Shirt Printing

The hunger for personalised gear has blown the doors wide open for entrepreneurs, artists, and even established brands. Whether it's for a unique fashion statement or branded company workwear, being able to print custom designs on demand is a seriously powerful skill to have.

You only have to look at the numbers to see how big this is. The UK's custom t-shirt printing scene alone brought in a massive USD 200.1 million in revenue in 2023, and it's on track to hit an incredible USD 419.6 million by 2030. That's not just a trend; it's a booming market.

Think of this guide as your map. We're going to pull back the curtain and demystify the tech that makes it all happen.

Core Printing Technologies Explained

At the heart of it all, there are three main technologies you need to get your head around. Understanding what makes each one tick is the first step to picking the right machine for what you want to achieve.

- Direct-to-Garment (DTG): The easiest way to think about this is like a high-tech inkjet printer, but for fabric. It sprays water-based inks straight onto a cotton t-shirt. The result? Soft, highly detailed, full-colour prints that feel great to wear.

- Direct-to-Film (DTF): This is a slightly different beast. Here, you print your design onto a special film, cover it with an adhesive powder, and then use a heat press to transfer it onto the garment. The big win for DTF is its sheer versatility—it works on almost anything, from cotton and polyester to blends.

- Heat Press: This is your essential finishing tool. It doesn't actually print anything itself. Instead, it uses a combination of heat and pressure to permanently bond pre-made designs—like vinyl cut-outs or those DTF transfers we just mentioned—onto the fabric.

A t shirt print machine isn't just a piece of hardware; it's an engine for creativity and commerce. It allows solo creators to launch a brand from their spare room and enables large companies to produce professional merchandise at scale.

Once you’re up and running in the exciting world of custom tees, you'll quickly realise that making great products is only half the battle. Knowing how to improve e-commerce conversion rates is vital for turning your passion into a proper business. Success is just as much about selling effectively as it is about creating. For a deeper dive into building your brand from the ground up, our comprehensive guide on custom t-shirt printing can give you some brilliant insights.

Our goal here is to arm you with the knowledge you need to find the perfect machine, unlocking all the incredible creative and business opportunities that are waiting for you.

Comparing Core T-Shirt Printing Technologies

Choosing the right t shirt print machine isn’t about finding the “best” one. It’s about finding the right one for you. The three titans of the industry—Direct-to-Garment (DTG), Direct-to-Film (DTF), and the classic Heat Press—each offer a completely different way to create custom apparel. Getting your head around how they differ is the single most important step you can take.

Let’s break it down with a simple analogy:

- Direct-to-Garment (DTG) is like a high-end office printer that’s been redesigned to print directly onto fabric. It’s incredibly precise, capable of amazing detail, and fuses the ink right into the cotton fibres.

- Direct-to-Film (DTF) is more like creating a modern, vibrant decal that’s both super durable and flexible. This decal can then be applied to almost any kind of material, making it a master of versatility.

- The Heat Press is the essential finishing tool. It doesn’t print anything itself but acts like a professional, industrial-grade iron. It uses perfectly controlled heat and pressure to make designs from methods like DTF or vinyl permanent and professional-looking.

This section will walk you through a direct comparison of these technologies, focusing on the factors that really matter: how the print feels, colour vibrancy, durability, what materials you can use, and how many items you can produce.

Print Feel and Texture

How a design feels on a shirt is a massive part of its perceived quality. Each method leaves a completely different texture, or "hand," on the final garment.

When it comes to a soft-hand feel, DTG printing is the undisputed champion. Because the water-based inks soak directly into the cotton fibres, the print literally feels like it’s part of the shirt. You can barely feel any texture, which is perfect for high-end fashion or any brand where comfort is a top priority.

DTF, on the other hand, creates a print that sits on top of the fabric. The result is a smooth, slightly rubbery feel that is remarkably flexible and can stretch without cracking. Modern DTF transfers are impressively thin and lightweight, but you can definitely feel they’re there. This tactile quality is ideal for sportswear and workwear where durability is non-negotiable.

Colour Vibrancy and Detail

The ability to produce bright, eye-catching colours and tiny details is another critical point of comparison.

DTG is brilliant at reproducing photorealistic images, complex colour gradients, and designs with millions of shades. Just like an inkjet paper printer, it can create subtle tones and fine lines with stunning precision, especially on white or light-coloured garments.

DTF technology is famous for producing exceptionally vibrant and bold colours, even on the darkest fabrics. Because the design is printed onto a white film base first, the colours appear incredibly bright and opaque. This makes DTF a fantastic choice for punchy, graphic-heavy designs that absolutely need to pop.

Think of it like this: DTG is a watercolour painting that becomes one with the canvas, while DTF is a brilliant acrylic painting that sits boldly on the surface. Each has its own artistic merit and purpose.

Durability and Washability

A great t-shirt design is only as good as its ability to survive the wash. Durability is a major factor separating professional results from amateur ones.

- DTG Prints: These are reasonably durable and can often last for 50+ washes before showing any signs of fading. Their longevity really depends on getting the pre-treatment and curing process just right.

- DTF Prints: Known for their exceptional durability, DTF transfers are incredibly resistant to cracking, peeling, and fading. They can often outlast the garment itself, staying vibrant through countless wash cycles.

- Heat Press (Vinyl): High-quality Heat Transfer Vinyl (HTV) is also extremely durable. Think of the names and numbers on football jerseys—that’s HTV, and it's built to last through intense wear and tear.

Material Compatibility and Versatility

Your choice of a t shirt print machine will heavily influence the types of products you can create. This is where the technologies really go their separate ways.

DTG is a specialist. It performs best on natural fibres and needs a high cotton content (ideally 100% cotton) for the ink to bond properly. This limits its use on popular polyester sportswear or blended fabrics.

DTF is the ultimate all-rounder. Its superpower is its ability to stick to a massive range of materials, including:

- Cotton

- Polyester

- Cotton/Poly Blends

- Leather

- Nylon

- Even hard surfaces like wood (with the right technique)

This makes DTF an incredibly flexible solution for any business wanting to decorate everything from standard tees to hats, bags, and performance wear. The heat press is the tool that makes this possible, applying not just DTF but also vinyl and sublimation transfers to their respective compatible materials.

T-Shirt Printing Machine Technology Comparison

To make things even clearer, here’s a side-by-side look at how these three core technologies stack up against each other. Each has its strengths, and the best choice for you will depend entirely on what you want to create.

| Feature | DTG (Direct-to-Garment) | DTF (Direct-to-Film) | Heat Press (Vinyl/Sublimation) |

|---|---|---|---|

| Print Feel | Extremely soft, breathable, feels like part of the fabric. | Smooth, slightly rubbery feel. Sits on top of the fabric. | Varies. Vinyl has a distinct layer, sublimation has no feel. |

| Colour & Detail | Excellent for photorealism and complex colour gradients. | Exceptionally vibrant and opaque colours, even on darks. | Bold, solid colours (Vinyl). Photorealistic (Sublimation). |

| Durability | Good. Lasts 50+ washes with proper care. Can fade over time. | Excellent. Resists cracking and peeling; often outlasts the garment. | Excellent. Very durable and built for performance wear. |

| Fabric Compatibility | Best on 100% cotton; struggles with synthetics. | Highly versatile. Works on cotton, poly, blends, leather, nylon. | Vinyl works on most fabrics. Sublimation for polyester only. |

| Best For | High-detail, full-colour prints on cotton tees for fashion. | Versatile printing across many products; bold, durable graphics. | Simple logos, text, numbers on sportswear; polyester apparel. |

As you can see, the decision involves a trade-off. You might sacrifice the soft feel of DTG for the incredible versatility of DTF, or choose the straightforward durability of vinyl for team uniforms. It all comes back to your specific goals.

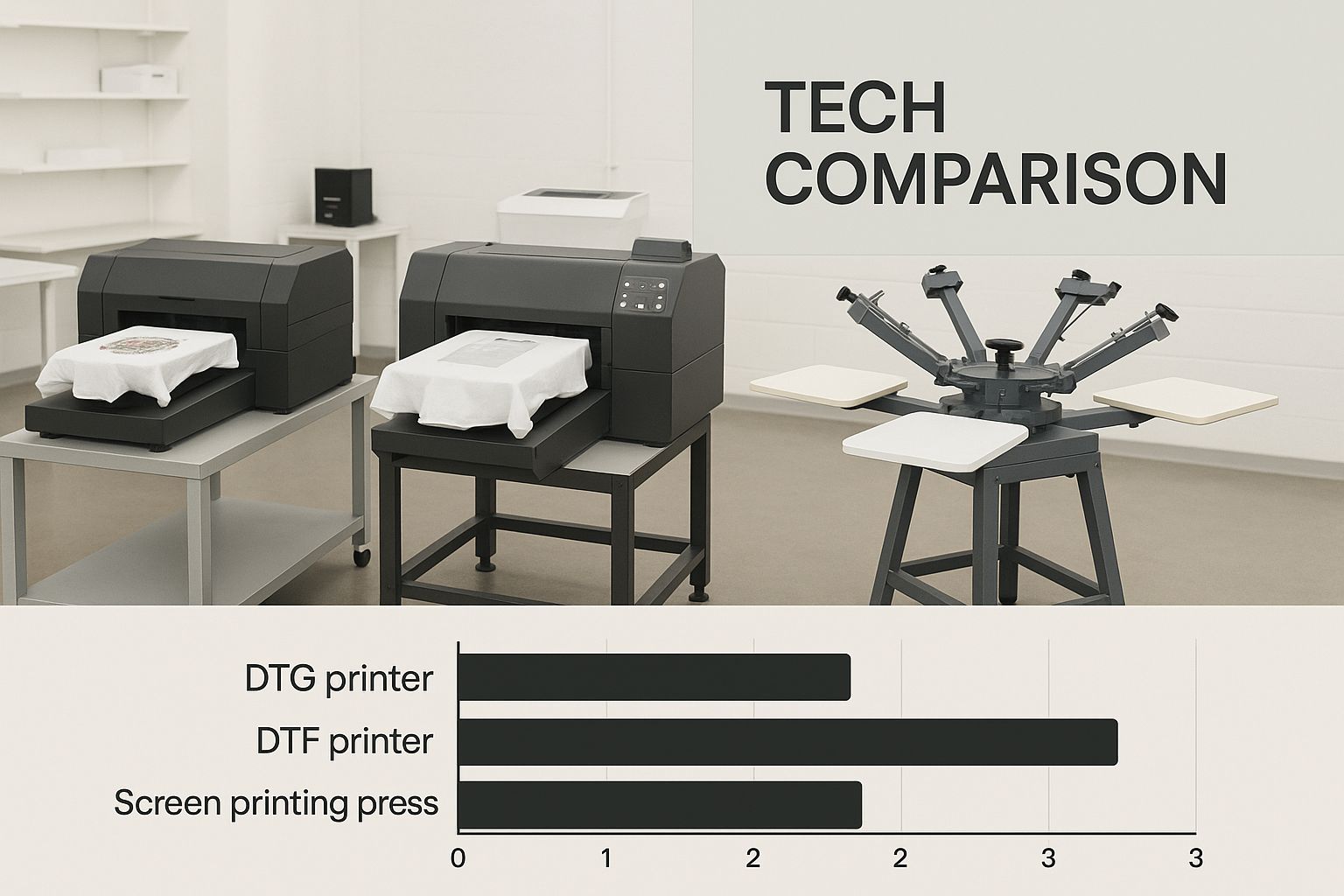

This graphic provides another clear visual breakdown of how these technologies stack up against one another.

As the infographic illustrates, the choice between these machines involves balancing fabric compatibility, print feel, and design complexity.

This versatility is a key driver behind the industry's growth. In fact, the UK custom t-shirt printing market is projected to expand at a compound annual growth rate of 11.84% from 2025 to 2033, largely fuelled by just how accessible and flexible these printing technologies have become. To get a better sense of this expanding market, you can discover more insights about custom apparel trends on Deep Market Insights. Before you dive in, it’s worth exploring the practical steps involved in getting my design onto a t-shirt.

A Deep Dive Into Direct to Garment (DTG)

Direct to Garment, or DTG, is where digital printing and clothing really come together. The easiest way to think about it is like your home inkjet printer, but instead of feeding it a sheet of paper, you're loading a t-shirt. This t shirt print machine uses special water-based inks that soak directly into the fabric's fibres, resulting in designs with stunning detail and a feel that's incredibly soft to the touch.

Unlike other methods that stick a layer on top of the material, DTG makes the design a part of the garment itself. This means the final print is breathable and won't have that stiff, almost plastic-like feel you sometimes get. It’s the undisputed champion for printing photorealistic images, super-intricate patterns, and designs with smooth, complex colour gradients.

The DTG Printing Process

Getting that perfect, soft print from a DTG machine isn’t a one-click job. It involves a few crucial steps, and each one plays a big part in making sure the colours pop and the design lasts wash after wash.

-

Garment Pre-Treatment: Before a single drop of ink is applied, the t-shirt is sprayed with a pre-treatment fluid. Think of this as a primer for fabric. It helps the water-based inks grab onto the fibres properly and stops them from bleeding. On dark-coloured garments, this step is absolutely essential for creating a solid white base layer for the colours to sit on.

-

Digital Printing: The pre-treated shirt is then carefully smoothed onto the machine's flatbed, known as a platen. The digital design file is sent over, and the printer gets to work, spraying the CMYK inks (and white ink, if needed) directly onto the fabric, recreating the artwork with millions of colours.

-

Curing the Ink: Once the print is finished, the shirt is carefully moved to a heat press. Here, it’s heated to a specific temperature for a set amount of time. This process cures the ink, permanently locking the design into the garment’s fibres and ensuring it’s durable enough to wear and wash.

Where DTG Excels and Its Limitations

DTG technology is at its absolute best when printing on 100% cotton or fabrics with a very high cotton content. The natural fibres just drink up the water-based inks, which is how you get that brilliant colour and soft finish. This has made it a firm favourite for premium fashion brands and independent artists who put quality first. It's also the backbone of most print-on-demand businesses, allowing them to produce single, high-quality garments as orders come in, without needing to hold any stock.

A DTG printer gives creators the freedom to offer limitless colour options and incredibly complex designs with zero setup costs per design. This flexibility is perfect for launching new ideas quickly and testing the market without a huge financial risk.

However, DTG isn't a silver bullet. The cost per print is typically higher than other methods, so it's not the most economical choice for massive bulk orders. It also doesn't play well with synthetic fabrics like polyester, as the inks just aren't designed to bond with those materials. For a closer look at the technical side, exploring the details of direct printing to garment can give you a much deeper understanding.

Despite these few drawbacks, when it comes to creating high-detail, full-colour masterpieces on cotton, DTG is still in a league of its own.

Digging into Direct to Film (DTF)

Direct to Film, or DTF as everyone calls it, has really shaken up the custom apparel scene. It's the perfect middle-ground, solving problems that other print methods can't. The easiest way to think of it is like making a super high-quality, flexible decal for fabric. Instead of a t shirt print machine printing ink straight onto the garment, it prints the design onto a sheet of special film first.

That simple difference is where the magic happens. Once your design is on the film, it gets coated with a fine adhesive powder which is then melted, creating a transfer that’s ready to go. The final step is to heat press this transfer onto the t-shirt, permanently bonding the design to the fibres.

The result is a print that feels smooth and sits beautifully on top of the fabric. It's also incredibly flexible and can stretch along with the garment without cracking, which is a huge plus for clothing that gets a lot of use.

The Superpower of Versatility

If DTF has one standout advantage, it’s the sheer range of materials it can handle. While other popular methods, like DTG, are picky and usually need a high cotton content to work well, DTF is the ultimate all-rounder. Its ability to stick to almost any fabric is what's made it explode in popularity.

This technology works beautifully on just about anything:

- Cotton and Cotton Blends: The bread and butter, from your standard tees to cosy hoodies.

- Polyester: Perfect for sportswear and performance gear where other inks just won't stick.

- Leather and Denim: This opens up a whole new world of customisation for jackets, bags, and unique fashion pieces.

- Nylon: Great for branded windbreakers or promotional items like tote bags.

This adaptability means a single DTF setup can tackle almost any order that comes through the door, making it a seriously smart investment for a growing business. It performs just as well on light fabrics as it does on dark ones, delivering punchy, vibrant colours every single time.

You could call DTF printing the Swiss Army knife of the apparel world. It gives you the multi-material freedom of heat transfer vinyl but with the full-colour, detailed prints of high-end digital printing, all in one streamlined process.

Where It Shines in the Real World

The versatility of DTF isn't just a technical talking point; it translates directly into profitable, real-world products. We're not just talking t-shirts here. It's a full-blown solution for branding and customisation across a huge range of items.

Think about it: a local sports team can get their complex, multicoloured logo printed perfectly onto polyester jerseys. A construction firm can brand its high-vis workwear with durable, vibrant logos. An indie fashion label can decorate cotton t-shirts, denim jackets, and canvas bags all using the exact same DTF transfers.

Being able to keep your branding and quality consistent across different materials is a massive win. To get a better feel for the whole workflow, taking a closer look at DTF printing will give you some great insights into the nuts and bolts of the process. It's what allows a business to say "yes" to more jobs, whether it's a one-off custom piece or a bulk order for a corporate event. The consistency and durability make it a go-to for professional-grade results.

Mastering the Essential Heat Press

While you might see it lumped in with other equipment, the heat press isn't strictly a t shirt print machine. It's something different, something more fundamental. Think of it as the unsung hero of the custom apparel world. It doesn’t actually print anything. Instead, it applies pre-made designs using a perfect combination of heat and pressure.

The easiest way to understand it is to picture a super-powered, industrial-grade version of a household iron. An iron gives you patchy heat and uneven pressure, which is fine for getting wrinkles out. A heat press, on the other hand, delivers precise, consistent results every single time. That consistency is what separates a homemade craft from a professional product people will actually pay for.

Core Applications of a Heat Press

This machine is a true workhorse, essential for bringing several different printing methods to life. Its versatility is what makes it a must-have for just about any print shop, from a one-person Etsy store to a massive production facility.

Here's where it really shines:

- Applying Heat Transfer Vinyl (HTV): This is the classic way to get bold, solid-colour graphics onto a garment. It's the tech behind the names and numbers on your local sports team's jerseys and perfect for durable, simple logos on workwear.

- Finalising DTF Transfers: As we've already touched on, every single DTF print needs a heat press to finish the job. The press melts the adhesive powder on the back of the film, permanently fusing the vibrant ink into the fabric. Without it, the DTF process simply wouldn't work.

- Sublimation Printing: When you're decorating polyester goods like sportswear or mugs, the heat press is vital. It heats special sublimation ink to the point where it becomes a gas, infusing it directly into the item's fibres. This creates a permanent print you can't even feel.

Why Every Print Business Needs One

The heat press is so much more than just a starter tool. It's a long-term asset. Because it's so affordable and reliable, it’s easily one of the smartest first investments you can make. Even massive print shops that specialise in high-end DTG printing will have a bank of heat presses ready for curing prints or adding special effects with vinyl.

The heat press is the great enabler in the printing world. It unlocks the potential of multiple technologies, from simple vinyl to advanced DTF, giving businesses the flexibility to offer a diverse range of products without needing a different machine for every job.

This versatility is your ticket to growth. With a single press, you can start out making simple vinyl tees and then, as your confidence and customer base grow, you can easily expand into creating full-colour DTF transfers. If you're wondering what to look for, a good guide on the best heat press machine for t-shirt printing is a great place to start. It’s a foundational piece of kit that scales with your ambition, ensuring professional results from your very first press to your thousandth.

How to Choose Your First T-Shirt Print Machine

Taking all this technical information and turning it into a decision can feel a bit overwhelming. But here’s the secret: choosing your first t-shirt print machine isn’t about finding the single “best” one out there. It’s about finding the one that’s the perfect fit for your specific goals, budget, and the business you want to build.

To get there, you need to ask yourself some honest questions. Your answers will create a practical roadmap, helping you invest with confidence and sidestep those costly beginner mistakes.

First Things First: Define Your Products and Niche

Before you even glance at a machine’s spec sheet, you need a clear picture of what you want to sell. Your product vision should drive the technology you choose, not the other way around.

Start by sketching out who you’re creating for and what you’ll be making.

- Who is your customer? Are you outfitting local sports teams with customised jerseys? Launching a fashion brand with detailed, artistic designs? Or are you creating branded merchandise for corporate events?

- What will you print on? Will you be sticking to super-soft, 100% cotton tees, or do you need the flexibility to print on polyester sportswear, hoodies, tote bags, and more?

Think about it: a business churning out bold, single-colour logos for polyester workwear has completely different needs than an artist selling photorealistic prints on premium cotton. The first could easily get by with a simple heat press and vinyl cutter, while the second would absolutely need a DTG printer to get the quality right.

Be Realistic About Your Budget and Production Volume

Your starting budget and how many shirts you expect to produce are the next critical pieces of the puzzle. It’s vital to be honest with yourself about what you can afford upfront and how many items you can realistically create and sell.

Let’s talk startup capital. A good-quality heat press can get you in the game for a surprisingly low cost, often under £500. This makes it the perfect entry point for hobbyists or anyone just wanting to test the market. On the other hand, a professional DTF or DTG setup is a serious investment, easily running into many thousands of pounds.

Next, think about your orders.

Are you planning to make one-off custom shirts for your Etsy shop, or are you aiming to fulfil bulk orders of 50+ identical items for local businesses and events? Your answer will point you toward the most cost-effective machine for your model.

Matching the Right Machine to Your Business Model

Once you have your goals nailed down, the right choice becomes much clearer. Let’s walk through a few common scenarios to see how this plays out in the real world.

Scenario 1: The Hobbyist or Etsy Seller

If you’re starting small, focusing on unique one-off designs, and working with a tight budget, a heat press is your best friend. When you pair it with quality vinyl or ready-made DTF transfers, you can create professional-looking products with a tiny initial investment. It gives you total freedom to experiment without the financial weight of a bigger machine.

Scenario 2: The Growing Apparel Brand

For a business that needs to be versatile and produce durable prints, the choice often boils down to DTF versus DTG. A DTF system is the ultimate all-rounder, giving you the power to print vibrant, full-colour designs on a massive range of fabrics. That kind of flexibility is a game-changer for brands wanting to offer everything from cotton tees to polyester performance gear. And the demand is definitely there—research shows that one in five consumers is willing to pay a 20% premium for personalised apparel. You can learn more about trends in successful t-shirt printing to see just how much customisation is driving the market.

Scenario 3: The Premium Print-on-Demand Specialist

If your entire brand is built on exceptional quality, photorealistic detail, and the softest possible feel on 100% cotton, then a DTG printer is the undisputed champion. It’s a bigger investment, no doubt. But for a high-end fashion line or an art-focused brand, the incredible print quality justifies the cost and lets you command a much higher price for your products.

Your T-Shirt Printing Questions, Answered

Jumping into the world of custom apparel always sparks a few questions, especially when it comes to picking the right t shirt print machine. Let's clear up some of the most common queries we hear from people just starting out and from businesses looking to grow.

Which Machine Is Best for a Beginner?

If you're an absolute beginner and watching your budget, a quality heat press paired with a vinyl cutter is your best bet. It’s a wonderfully straightforward way to get started. This combo is perfect for creating simple, bold designs with text and graphics, and the low initial cost makes it ideal for dipping your toes in the water.

But what if you're aiming for full-colour designs right out of the gate? If you have a bit more to invest, a Direct to Film (DTF) system offers incredible versatility. It’s a fantastic all-rounder that works across tons of different fabrics and is generally seen as more forgiving for newcomers than a full-on Direct-to-Garment (DTG) setup.

How Much Does a Professional Machine Cost?

This is where things can vary quite a bit, depending on the technology you go for.

- Heat Press: You can get a reliable, professional-grade heat press for anywhere between £300 and £800.

- DTF System: A complete entry-level DTF package, which includes the printer and curing gear, usually starts in the £5,000 to £15,000 range.

- DTG Printer: Professional DTG printers are a serious investment. Expect starting prices around £10,000, with high-production models easily soaring past £20,000.

Don't forget to factor in the ongoing costs. Things like ink, film, vinyl, and essential maintenance are all part of the bigger picture when you're planning your budget.

Can I Print on Dark-Coloured Shirts?

Absolutely, but you need the right tool for the job. Getting colours to look bright and punchy on dark fabrics requires specific technology. Both DTG and DTF machines are brilliant for this because they lay down a layer of white ink first, creating a base that makes your colour design really pop.

A heat press using sublimation ink won't work here, as the ink is transparent and can only be used on light-coloured polyester. However, you can still use a heat press with opaque heat transfer vinyl (HTV) to create stunning solid-colour graphics and text on dark garments. For vibrant, full-colour photos on dark cotton, DTG or DTF is the way to go.

At Psyque, we live and breathe the vibrant, versatile world of DTF printing, crafting top-quality custom apparel that truly stands out. Come and explore our unique collections to see the power of DTF for yourself at https://psyque.co.uk.