Best Heat Press Machine for T Shirt | Ultimate Buying Guide

Share

So, you've got a brilliant idea for a T-shirt and you're ready to bring it to life. What's the secret ingredient that turns a great design into a professional-quality piece of clothing? A heat press machine for t shirt printing.

Think of it like this: a heat press is the professional, heavy-duty cousin of your household iron. It's a specialised piece of kit designed to apply a design onto a garment using a perfect combination of heat and pressure, making sure your creations are vibrant, durable, and flawlessly finished, every single time.

Your Guide to T-Shirt Heat Press Printing

Welcome to the exciting world of custom T-shirt creation! If you've ever dreamt of turning your unique ideas into tangible, wearable art, then you’re in exactly the right place. The heat press machine is the cornerstone of this whole process, the bridge between your digital file and a finished garment you can be proud of.

It offers a level of precision and consistency that a standard iron just can't touch.

This guide will walk you through everything you need to know. We’ll cover the basics of how these machines work and help you figure out which one is right for your projects. Let's demystify the technology and show you why it’s the go-to choice for hobbyists and businesses alike.

Why Choose a Heat Press

What really makes a dedicated heat press so much better than the alternatives? It all boils down to three key things that guarantee professional results:

- Consistent Heat: An iron is notorious for having hot spots, leading to patchy transfers. A heat press has a solid platen that distributes heat perfectly evenly, so every inch of your design adheres correctly.

- Uniform Pressure: The clamping mechanism applies firm, even pressure across the entire design. This is absolutely critical for bonding the transfer material deep into the fabric's fibres, creating a print that will last wash after wash.

- Precise Control: Forget guesswork. With digital controls for time and temperature, you can dial in the exact settings required for different transfer types and fabrics, which drastically reduces the chance of costly mistakes.

This level of reliability is fuelling some serious growth here in the UK. The custom T-shirt printing market was valued at USD 310.48 million in 2023 and is projected to skyrocket to USD 526.78 million by 2032. It's a massive opportunity for creative entrepreneurs.

A heat press machine isn't just a tool; it's an investment in quality and consistency. It’s what separates a homemade craft from a professional product that people will love to wear and buy.

Whether you're starting a small business or just diving into a creative passion, getting to grips with this equipment is your first step toward success. Our complete guide to custom T-shirt printing offers even more insight into the different methods out there.

And once you've nailed the printing process, knowing how to craft compelling product descriptions is the next crucial step to making your creations stand out and sell. This guide is designed to give you that foundational knowledge to get started.

How a Heat Press Machine Actually Works

On the surface, a heat press machine for t shirt printing looks pretty simple. At its heart, though, it’s a precision tool that uses a specific recipe to permanently bond a design to fabric. Think of it like baking a cake – get the temperature, timing, or ingredients wrong, and you won’t end up with something you're proud of.

In our world, those ingredients are time, temperature, and pressure. Getting this trio just right is the real secret to creating professional, long-lasting prints that don't peel, crack, or fade away after the first wash. This is the simple science that makes the whole thing work so well.

The Three Pillars of a Perfect Press

To really get to grips with your heat press, you need to understand how these three critical elements work together. Finding the perfect balance is everything, as the ideal settings can change dramatically depending on the materials you're using.

-

Temperature: This is the heat coming from the top platen. Every type of transfer needs a specific temperature to properly activate its adhesive. For instance, your standard Heat Transfer Vinyl (HTV) might only need about 150°C for a cotton tee, whereas sublimation on polyester requires a much higher heat of around 200°C.

-

Time: This is simply how long the heat and pressure are applied. Too little time, and the design won't bond properly. Too much, and you risk scorching the fabric or burning the adhesive, which can completely ruin the finish and durability of your print.

-

Pressure: This is the force the machine clamps down with. The right amount of pressure ensures the design embeds itself into the fabric's fibres, creating a smooth, durable finish. Not enough pressure leads to a weak bond, while too much can cause the adhesive to ooze out from the edges, creating a messy outline.

Nailing these three elements is what separates an amateur transfer from a professional-grade product.

The Role of the Platen

The heart of any heat press is its platen—that flat, heated surface that does all the heavy lifting. The quality of your prints is directly linked to the quality of this component. Its most important job? To deliver consistent, even heat across its entire surface.

Imagine a platen with "cold spots." If one corner is cooler than the rest, that part of your design won’t get enough heat to stick properly. This is a classic problem with cheaper machines and explains why you sometimes see prints where one part starts peeling away long before the rest. A quality platen ensures every square centimetre of your design gets the exact temperature it needs.

A great heat press doesn’t just get hot; it gets hot evenly. This consistency is non-negotiable for producing reliable, high-quality garments that you can be proud of and that your customers will love.

Why Different Fabrics Need Different Settings

The T-shirt's material plays a huge role in dictating your settings. A delicate polyester blend simply can't handle the same high heat as a tough, 100% cotton shirt. Throwing too much heat at synthetics can easily cause the fibres to melt or discolour.

This is why having precise digital controls is so important. They let you dial in the exact "recipe" for each specific project. For a closer look at the different materials, our guide on heat transfer printing offers a more detailed breakdown.

Ultimately, using a heat press successfully is less about guesswork and more about following a proven formula for your chosen fabric and transfer type.

Comparing the Different Types of Heat Press Machines

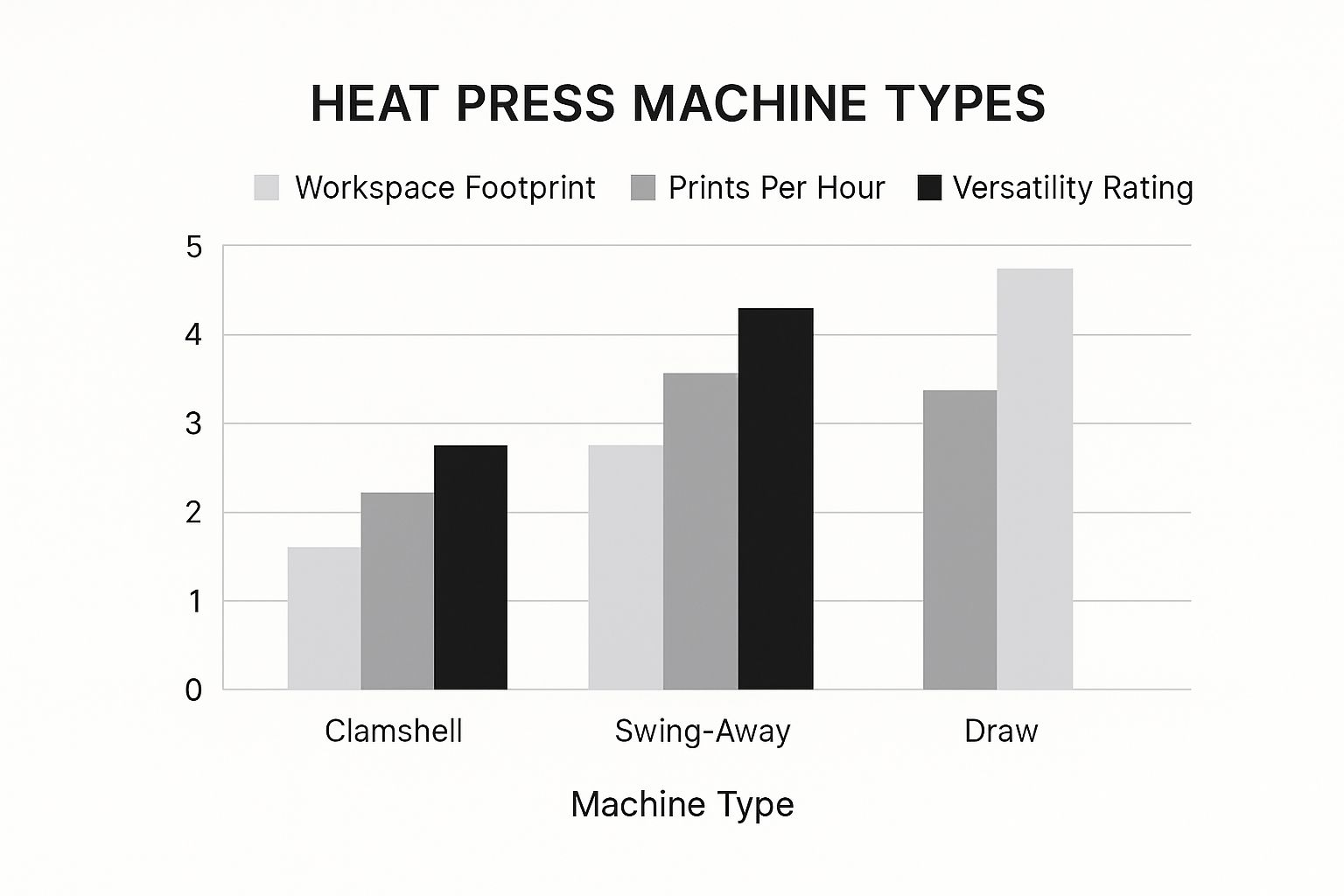

Picking the right heat press machine for t shirt printing is a bit like choosing a new car. What works wonders for a city commute might be completely wrong for someone who needs to haul heavy loads. The best machine for you really boils down to your workspace, how many shirts you need to press, and what kinds of products you’re planning to make. To help you figure it out, we’ll break down the three main players: Clamshell, Swing-Away, and Draw presses.

Each style has its own unique way of working, and that mechanism brings different strengths to the table. Getting a handle on these differences is the first step to finding a machine that will feel like a natural extension of your workflow, whether you’re a hobbyist working out of a spare bedroom or a small business ready to ramp up production.

The Space-Saving Clamshell Press

For beginners or anyone tight on space, the clamshell heat press is usually the go-to option. Just as the name implies, it opens and closes on a hinge, a lot like a clam's shell. The top platen simply lifts up, giving you access to the lower platen where you place your T-shirt and transfer.

This design has the smallest footprint by far, which makes it perfect for a home studio or a packed workshop. It's also generally quicker to operate for high-volume jobs because the up-and-down motion is fast and doesn't require a lot of movement from the operator.

But there is a catch. The heated platen is always hanging directly over your workspace. This can make it a little nerve-wracking to line up your T-shirt and transfer perfectly without accidentally brushing against the hot surface. That constant proximity to the heat means you have to be extra careful while you work.

The Accessible Swing-Away Press

A swing-away heat press takes a completely different approach. Instead of lifting straight up, the top heated platen swings out to the side, moving completely away from the bottom platen. This motion gives you a totally clear, unobstructed view and access to your entire work area.

This wide-open access makes it much easier—and safer—to position your garments and place detailed designs without the constant worry of getting burned. It's also the top choice for pressing thicker items like hoodies, ceramic tiles, or plaques because it applies pressure straight down, ensuring an even finish.

The biggest trade-off here is space. Since the top platen needs room to swing all the way out, these machines demand a much larger work area than a clamshell with the same platen size. The two-step process of swinging the platen out and then lowering it also makes it a tad slower for really rapid, back-to-back pressing.

For projects that need pinpoint accuracy or for anyone working with a mix of thick and thin items, the swing-away design is a versatile workhorse that offers fantastic control and safety.

The Ergonomic Draw Press

The draw press is a clever hybrid that gives you the best of both worlds. While the top platen lifts up like a clamshell, the bottom platen slides out toward you, just like a drawer. This gives you that same open, heat-free workspace to arrange your T-shirt and transfer that you'd get with a swing-away, but without needing all that extra side-to-side room.

This design combines the safety and easy layout of a swing-away with a much more compact footprint. It's a brilliant choice for anyone who craves accessibility but can't sacrifice too much space. The ergonomic bonus of not having to reach under a hot plate is a huge plus for comfort and safety, especially during long printing sessions. You can learn more about how transfer types influence your setup in our guide to the T-shirt transfer printer process.

If you're thinking about investing in a new machine, you'll find some great reviews and recommendations in this guide to the best heat press machine for shirts.

The infographic below gives a quick visual rundown of how these three machines stack up in terms of their footprint, print capacity, and versatility.

As you can see, your choice really comes down to a trade-off between speed, space, and versatility. Thinking about your specific goals will help you decide which machine's strengths are the right fit for you.

Essential Features Every Good Heat Press Needs

So, you've figured out whether a Clamshell, Swing-Away, or Draw press is the right fit for your space and workflow. Now it’s time to get into the nitty-gritty—the specific features that make the difference between a reliable workhorse and a piece of kit that just causes headaches.

Think of this as your essential checklist. Knowing what to look for will help you cut through the marketing jargon and understand exactly what you're getting. These aren't just fancy extras; they're the core components that dictate the quality and consistency of every single item you produce. Getting these right from the start will save you a world of frustration later on.

Platen Size and Material

The platen is the heart of the machine. Its size literally defines the canvas you have to work with. A smaller, more compact press with a 9"x12" platen is perfect if you’re focusing on children’s clothes, tote bags, or small chest logos. They’re budget-friendly and won’t take over your entire workspace.

But if you’re planning to print on standard adult T-shirts or chunky hoodies, you’ll need to think bigger. A 15"x15" press is a brilliant all-rounder and a common industry standard. For anything oversized or for those big, bold full-frontal designs, a 16"x20" machine is what you need to avoid having to press the same garment multiple times.

Also, check that the platen has a non-stick coating. Most are coated with Teflon, which is a lifesaver for stopping stray ink or adhesive from sticking and makes cleanup a breeze.

Digital Time and Temperature Controls

When it comes to professional printing, guesswork is your enemy. That's why precise digital controls for both time and temperature are an absolute must-have. Old-school analogue dials are notoriously inconsistent, but a digital display lets you lock in the exact settings your transfer needs, right down to the degree and the second.

This level of accuracy is the key to consistency. A T-shirt pressed at 155°C will look noticeably different from one pressed at 160°C, affecting everything from colour vibrancy to how well the design holds up in the wash.

A machine with reliable digital controls is the foundation of a repeatable, professional workflow. It ensures that the first T-shirt you press looks identical to the hundredth.

If you want to get into the weeds of why specific settings are so crucial for different fabrics, our heat press temperature guide breaks down the science behind the numbers in detail.

Pressure Adjustment and Distribution

Even, consistent pressure is just as important as the right temperature. A good heat press will have a simple, easy-to-use pressure adjustment knob, letting you dial the clamping force up or down depending on what you’re pressing. A thick, fleecy hoodie needs a completely different pressure setting than a thin cotton tee.

Even more crucial is how that pressure is distributed. Cheaper machines can have weak spots, especially around the corners of the platen. A quick way to test for this is to place four small slips of paper at each corner, clamp the press down, and then try to pull them out. If any of them slide out easily, you’ve got an uneven pressure problem that will lead to patchy, failed prints.

Versatility and Interchangeable Platens

While a standard flat press is your go-to for T-shirts, your ambitions might grow. Some of the more advanced models come with interchangeable platens, which is a fantastic feature that lets you swap out the base for specialised attachments.

This means you can easily switch to pressing other items, like:

- Cap Platens: Curved to fit the shape of a baseball cap.

- Mug Platens: Cylindrical attachments for printing on mugs and other drinkware.

- Plate Platens: Circular bases for decorating ceramic plates.

- Sleeve/Leg Platens: Long, narrow platens perfect for sleeves or trouser legs.

This kind of versatility transforms one machine into a complete customisation station. Investing in a press with these capabilities opens up entirely new product lines and ways to grow your business, making it a smart move for any entrepreneur.

Matching Your Press with the Right Transfer Type

Your heat press is a seriously capable bit of kit, but it’s only half of the creative puzzle. The real magic happens when you pair it with the right type of transfer. Think of the press as the oven and the transfer as your ingredients—the one you choose will completely define the look, feel, and lifespan of your finished T-shirt.

This choice is what unlocks the incredible versatility of a single machine. It's the difference between knocking out a bold, single-colour logo for a local sports team and printing a complex, photo-realistic design for a fashion brand. Get to know the most popular transfer types, and you'll turn your heat press machine for t shirt printing into a gateway for endless creative projects.

The Classic Choice: Heat Transfer Vinyl (HTV)

Heat Transfer Vinyl, or HTV as it's known, is usually the first stop for anyone dipping their toes into custom apparel. It’s a polyurethane material that comes on a clear backing sheet. You cut it into shapes or letters with a vinyl cutter (like a Cricut or Silhouette), then "weed" away the bits you don't need, leaving just your design ready for the press.

HTV is the undisputed champ for simple, bold graphics. It’s brilliant at producing sharp lines and solid blocks of colour, making it perfect for:

- Text and Numbers: Spot-on for personalising team jerseys with names and numbers.

- Simple Logos: Great for company uniforms or promo gear with clean, one or two-colour logos.

- Layered Designs: You can press multiple colours of HTV on top of each other to build up more complex images.

The result is a design that sits slightly raised on the fabric, often with a smooth, almost plastic-like feel. It comes in a mind-boggling variety of finishes, from matte and glossy to glitter, flock (which has a lovely fuzzy texture), and even holographic effects.

The Full-Colour Powerhouse: Direct-to-Film (DTF) Transfers

While HTV is fantastic for straightforward graphics, Direct-to-Film (DTF) transfers are what you need for intricate, multi-coloured designs. A DTF transfer starts life on a special printer that prints your design directly onto a transparent film. A powdered adhesive is then sprinkled over the back of the ink and cured with heat.

This printed film is what you get, ready to go. The application process is incredibly simple: position the transfer, press it, let it cool down, and peel away the film. What you're left with is a stunning, full-colour design that feels soft and flexible on the shirt.

DTF technology bridges the gap between simple vinyl cuts and complex screen printing. It lets anyone with a heat press produce vibrant, photorealistic prints without the steep learning curve or expensive setup of other methods.

This makes DTF a complete game-changer for small businesses and creators. You can achieve incredible detail, smooth gradients, and an unlimited colour palette, which is perfect for everything from detailed illustrations to actual photographs. If you want to dive deeper, our guide on what DTF transfers are takes a closer look at the tech.

Other Popular Transfer Methods

Beyond HTV and DTF, there are a couple of other key players in the world of heat pressing.

-

Sublimation: This method is unique because it only works its magic on polyester fabrics (or items with a special poly-coating). The process uses special ink that turns into a gas under high heat, permanently dyeing the fibres of the garment. The result is a print you can’t feel at all—it has zero texture—with incredible vibrancy and durability.

-

Screen-Printed Transfers: Think of these as a traditional screen print, but done onto a special release paper instead of directly onto the T-shirt. You get the classic look and feel of a screen print but with the convenience of applying it later with your heat press. They become really cost-effective when you're doing large batches of the same design.

The growing popularity of these methods points to a wider trend. The UK dye sublimated apparel market, which relies heavily on heat press technology, was worth USD 232.1 million in 2023 and is projected to more than double to USD 545.8 million by 2030. This shows a clear demand for vibrant, personalised clothing, as you can see in more detail about the custom apparel market here. At the end of the day, the transfer type you choose dictates your creative limits, so matching it to your project is the key to a perfect result.

Got Questions About Heat Press Machines?

Getting ready to dive into the world of T-shirt printing? It's totally normal to have a few questions buzzing around. This last section is all about tackling those common queries we hear all the time, giving you clear, straight-up answers so you can start with confidence.

Think of this as your go-to guide for those practical, day-to-day hurdles. Getting these basics right from the start will save you a world of time, wasted materials, and frustration. Let's make sure your first projects are a massive success.

What Is the Best Temperature for a T-Shirt Heat Press?

This is a classic question, but the truth is, there’s no single magic number. The perfect temperature setting completely depends on the transfer material you’re using and the fabric of the garment. Every combination has its own unique recipe for success.

For instance, if you're working with standard Heat Transfer Vinyl (HTV) on a cotton tee, you'll likely be in the 150-160°C range. But if you switch to sublimation printing on a polyester shirt, you’ll need to crank the heat way up, often to around 200°C. It's a totally different ball game.

The golden rule here? Always, always check the instructions that came with your vinyl or transfer paper. The manufacturer’s guidelines are your best friend for a flawless, long-lasting press.

Can I Use a Regular Household Iron Instead of a Heat Press?

It's tempting, I get it, especially if you're just doing a one-off project. But honestly, if you're after professional or durable results, using a household iron is a bad idea. The biggest problem is a total lack of consistency.

A regular iron just can't deliver the two things that are absolutely essential: uniform pressure and precise, even temperature. A heat press machine for t shirt printing is built to do exactly that. This consistency is what properly bonds the design deep into the fabric's fibres, which is why iron-on projects so often peel, crack, and fade after just a couple of washes.

How Do I Avoid Scorch Marks on My T-Shirts?

Ah, the dreaded scorch mark. Learning to prevent them is a vital skill, especially when you're working with delicate fabrics or light colours where every little mistake shows. Luckily, the fix is pretty simple.

The most effective trick is to place a protective layer between the hot platen and your T-shirt. Here are the top choices:

- Teflon Sheet: This is the pro's choice. It's a reusable, non-stick sheet that gives you brilliant heat protection.

- Parchment Paper: A great alternative that you can probably find in your kitchen. It's disposable but works just as well.

And always double-check your temperature settings! Make sure they aren't too high for the material you’re pressing. A quick test on a scrap piece of fabric is a smart move that could save you from ruining a perfectly good garment.

Is a More Expensive Heat Press Always Better?

Not always, but you definitely get what you pay for. A machine's price tag often reflects its build quality, reliability, and how accurate its features are. More expensive models usually have much better heat distribution across the platen, which means no "cold spots" that can completely ruin a transfer.

They also tend to have more precise digital timers and temperature controls, plus a sturdier frame that’s built to handle constant, heavy use. For a small business that's looking to grow, investing in a quality mid-range machine is a wise move. It'll pay you back in consistency and durability, making sure every single product you send out is up to scratch.

Ready to create vibrant, durable custom apparel that stands out? At Psyque, we specialise in high-quality DTF transfers that bring your most complex designs to life. Explore our unique collections and start your printing journey today at https://psyque.co.uk.