A Guide to T Shirt Transfers Printing

Share

T-shirt transfer printing is your ticket to creating custom gear. At its heart, it’s a simple idea: take a pre-printed design, add some heat and pressure, and apply it directly onto a T-shirt. It’s the go-to technique for everything from one-off creative projects to large-scale merchandise runs, giving you professional results without the fuss of a traditional screen printing setup.

This method puts you, the creator, in complete control of the final product.

Your Starting Point for Custom Apparel

Welcome to the world of custom T-shirts, where your creative ideas finally meet fabric. This guide is here to unpack T-shirt transfer printing, the powerful and surprisingly user-friendly method behind some of the most stunning personalised apparel out there. It’s a technique that has opened doors for everyone from small business owners and independent brands to hobbyists just looking to make something unique.

We’re going to skip the confusing jargon and focus on practical, hands-on knowledge.

We'll be diving into the three core techniques you really need to get your head around:

- Direct-to-Film (DTF): A modern method known for its vibrant, full-colour results and incredibly soft feel, which works brilliantly on all sorts of fabrics.

- Heat Transfer Vinyl (HTV): Absolutely perfect for bold, single-colour graphics, text, and logos. It leaves a durable, slightly raised finish that really pops.

- Screen Print Transfers: The true workhorse of the industry. When you need bulk orders, this method offers incredible durability and becomes super cost-effective.

Why Is This Method So Popular?

Let's face it, the demand for personalised products is booming, and T-shirt printing is right at the heart of it all. The custom T-shirt printing market in the UK is growing at a serious pace, pushed forward by better technology and more and more people wanting to create their own stuff.

In 2023, the market pulled in £160.7 million in revenue and is on track to hit an impressive £337.1 million by 2030. That massive growth shows just how many people are turning their ideas into wearable art. You can dig into more data on the UK custom apparel market from Grand View Research.

By the end of this guide, you won't just know how each method works. You'll understand which one is the perfect fit for your project, your budget, and your creative vision. The goal is to get you printing with confidence.

Whether you're launching a clothing line, making merch for an event, or just designing a one-of-a-kind gift, getting to grips with T-shirt transfers is your first big step. Let's dive in and explore the tools that will bring your designs to life.

Choosing Your T-Shirt Transfer Method

So, you're ready to get your designs onto a T-shirt. Fantastic! But as you step into the world of transfer printing, you’ll quickly realise there are a few different ways to get the job done. How do you know which one is right for your project?

It's a crucial question because not all transfer methods are created equal. Your choice will shape everything—the look, the feel, the durability, and of course, the cost of your final garment. Making a smart decision right from the start will save you a world of time and money, and most importantly, it'll make sure your creative vision comes to life exactly as you imagined it.

Think of it like choosing the right tool from a toolbox. You wouldn't use a sledgehammer to hang a picture frame, would you? In the same way, the best printing method for a hundred team jerseys is completely different from the one you'd pick for a single, super-detailed, photo-realistic T-shirt. We're going to break down the "big three"—Direct-to-Film (DTF), Heat Transfer Vinyl (HTV), and Screen Print Transfers—so you can choose with total confidence.

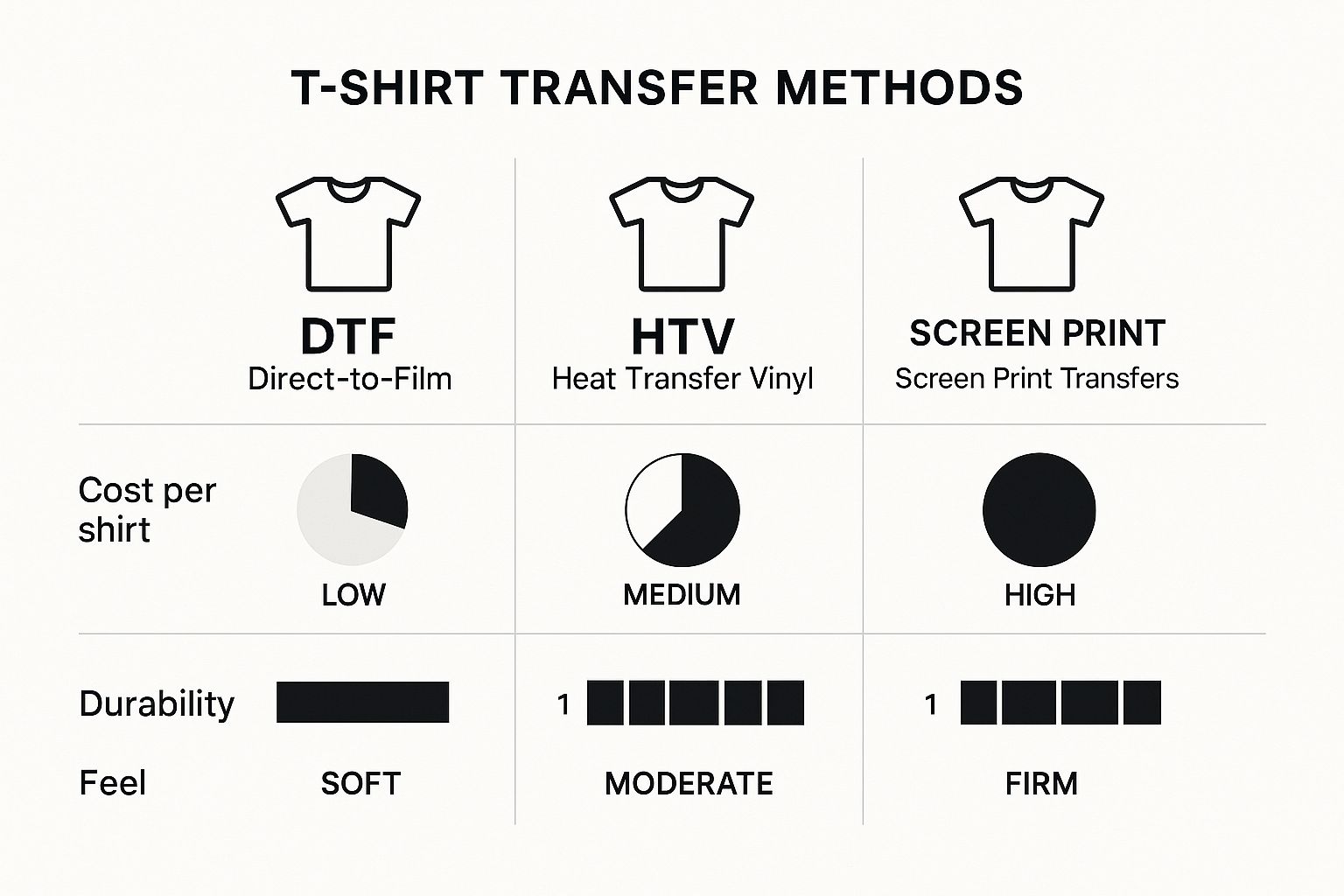

This infographic gives you a quick visual rundown of how these popular methods stack up against each other.

As you can see, there’s a bit of a trade-off. Screen printing is king for durability and low per-shirt costs on big orders, while DTF offers that beautiful soft feel for more complex designs, even in small batches.

Let's take a closer look at what each method brings to the table.

T-Shirt Printing Method Comparison

To make things even clearer, here’s a side-by-side comparison of the three main contenders. This table breaks down the key factors you'll want to consider when making your decision.

| Feature | Direct-to-Film (DTF) | Heat Transfer Vinyl (HTV) | Screen Print Transfers |

|---|---|---|---|

| Best For | Full-colour, detailed photos, and complex graphics | Simple text, logos, and single-colour designs | Large batches of single or limited-colour designs |

| Feel on Fabric | Very soft, flexible, and lightweight | Thicker, often with a plastic-like feel | Durable, slightly raised feel that softens after washing |

| Durability | Good, lasts 25-50 washes with proper care | Excellent, very resilient and long-lasting | Excellent, often outlasts the T-shirt itself |

| Colour Capability | Unlimited colours and gradients in a single print | Limited to the solid colours of vinyl available | Limited by the number of screens (each colour needs its own) |

| Cost | Moderate, cost-effective for small to medium runs | Low for simple, one-off designs; gets pricey for layers | Low per-unit cost on large orders (50+), high initial setup |

| Ideal Order Size | 1-100 shirts | 1-25 shirts | 50+ shirts |

Each method clearly has its strengths. DTF is your versatile artist for small-batch complexity, HTV is the go-to for bold and simple customisation, and Screen Print Transfers are the undisputed champion for large-scale production.

Direct-to-Film (DTF): The Versatile Artist

Imagine you’ve got a stunning, high-resolution photograph or a design packed with dozens of colours and tiny, intricate details. How do you get that onto a T-shirt without losing any of that magic? This is where Direct-to-Film (DTF) really shines.

It’s a clever, modern technique. Your design is first printed onto a special film. This film is then coated with an adhesive powder and heat-pressed directly onto the fabric. Simple as that.

The result is a print that’s incredibly vibrant, sharp, and has a soft, flexible feel that moves with the T-shirt. One of its biggest perks is that DTF doesn't require any pre-treatment for the garment and works beautifully on a huge range of materials—cotton, polyester, and blends of any colour.

DTF is the go-to choice for complex, full-colour artwork, especially for small to medium-sized batches. It eliminates per-colour setup fees, making photorealistic prints accessible without a large upfront investment.

This kind of versatility makes it a dream for independent brands, small businesses, and anyone needing detailed graphics without having to commit to a massive print run. It strikes a fantastic balance between quality, feel, and flexibility.

Heat Transfer Vinyl (HTV): The Bold Specialist

Now, picture the sharp, clean look of a name and number on the back of a football jersey. Or a simple, bold logo on a work uniform. That’s the classic handiwork of Heat Transfer Vinyl (HTV).

This method is exactly what it sounds like. Your design is cut from a sheet of coloured vinyl, and then a heat press is used to bond it firmly to the garment.

Think of HTV as a very precise, ultra-durable sticker that becomes one with the fabric. It’s the perfect choice for single-colour graphics, text-based designs, and logos where you need crisp lines and vibrant, solid colours. While you can layer different colours, it really excels with bold, straightforward artwork.

Its durability is a massive plus. When applied correctly, HTV is extremely resilient and can handle countless washes, which is why it's such a favourite for sportswear and workwear that needs to take a beating.

Screen Print Transfers: The Bulk Workhorse

Finally, let’s talk scale. You’re organising a big event, launching a merchandise line for a band, or need a corporate giveaway with hundreds of identical T-shirts. This is the natural territory of Screen Print Transfers.

This method takes the core principles of traditional screen printing—where ink is pushed through a stencilled screen—and applies it to a special release paper. This pre-printed transfer can then be stored and applied to a shirt later with a heat press.

It’s a two-step process that combines the rock-solid durability and vibrancy of screen printing with the on-demand convenience of transfers. The real knockout benefit here is cost-effectiveness at scale. Sure, there are initial setup costs to create the screen, but the price per transfer plummets as your order quantity goes up. This makes it the undisputed champion for large orders.

If you want to see a full breakdown, our guide on the differences between DTF vs screen printing for graphic tees offers some great insights.

The final print is incredibly durable—often outlasting the garment itself—with that classic, slightly thicker feel you associate with professionally produced apparel. It’s the reliable, time-tested method for achieving top-quality results on big projects.

The Rise of Digital Printing Transfers

The world of custom clothing has been completely shaken up by digital tech, and leading the pack is Direct-to-Film (DTF) printing. This isn't just a minor update; it's a massive leap forward for t shirt transfers printing, giving us an incredible mix of quality, flexibility, and speed that used to be out of reach.

So, how does it work? Think of DTF as the perfect middleman between your digital design file and the actual T-shirt. A special inkjet printer lays down your design in vibrant, textile-grade ink directly onto a clear film.

Once the ink is down, a fine adhesive powder is sprinkled over the wet design. This powder is the magic ingredient, the glue that will permanently fuse your artwork to the fabric. After a quick blast of heat to cure it, the transfer is ready to go, and you can apply it with a standard heat press for a stunning, long-lasting finish.

Unlocking Unlimited Colour and Detail

One of the biggest wins for DTF is how it handles colour. Old-school methods like screen printing need a separate screen for every single colour, which gets complicated and expensive fast. DTF, on the other hand, prints your entire full-colour design in one go. That means you can go wild with a full spectrum of colours, gradients, and subtle shading without any extra setup fees.

This is a complete game-changer for a few reasons:

- Photorealistic Prints: It lets you reproduce high-resolution photos and complex illustrations with incredible sharpness and detail.

- No Colour Surcharges: Your design could have one colour or a million—the price stays the same. This makes it a fantastic, budget-friendly choice for intricate artwork.

- Perfect for Small Runs: With no complicated setup, DTF is ideal for one-off prints, small orders, or testing out samples.

This freedom from colour constraints means designers can create things as vibrant and complex as their imagination allows, without the cost penalties of older methods. Our complete guide to DTF transfer printing dives even deeper into how this process brings complex designs to life.

Versatility Across Fabrics and Textures

Another area where DTF really shines is its incredible versatility. Some printing methods are notoriously fussy about fabrics, but DTF is far more easy-going. It sticks beautifully to a huge range of materials, which opens up a whole world of possibilities for your t shirt transfers printing projects.

DTF technology isn't just for cotton. Its unique adhesive properties allow it to bond securely with polyester, cotton-poly blends, spandex, and even harder-to-print materials like canvas and denim, regardless of the garment's colour.

This adaptability means you can keep your branding and quality consistent across a whole product line, from classic cotton tees to performance sportswear and even tote bags. The final print doesn't just look great; it feels soft and flexible, too. It has a lightweight feel that stretches right along with the fabric, so you don't get that cracking or stiffness you sometimes see with other types of transfers.

Efficiency and Sustainability in Modern Printing

In a world where everyone is looking for smarter, more efficient ways to work, DTF really stands out. The whole process is incredibly streamlined, which cuts down on material waste and production time compared to traditional methods. This efficiency is a huge reason why digital printing is quickly becoming the go-to choice in the custom apparel game.

The shift to digital is happening fast, driven by the clear advantages in speed, cost, and sustainability. In fact, the digital printing market is set to grow by a massive 12.5% annually between 2025 and 2030, which tells you everything you need to know about its popularity. This growth goes hand-in-hand with the booming UK custom T-shirt market, which is thriving thanks to corporate branding, sports merch, and the explosion of e-commerce. As we all move towards more responsible production, DTF offers a genuinely sustainable choice for modern creators and businesses.

Mastering Traditional Screen Print Transfers

While modern digital methods have a lot going for them, the world of T-shirt printing was built on the back of its most classic and powerful technique: screen printing. This is the time-tested champion, the method responsible for the durable, vibrant graphics on band merch, company uniforms, and event apparel for decades.

Think of screen print transfers like a highly sophisticated stencil. The process involves pushing a special plastisol ink through a fine mesh screen that has your design etched into it. This layer of ink lands on a special release paper, creating a transfer that’s ready to be pressed. When you apply heat and pressure, that ink layer permanently bonds with the fabric, becoming a part of the T-shirt itself.

This technique is the undisputed king when it comes to durability. A well-made screen print transfer doesn't just sit on the surface of the fabric; it cures right into it. The result is a finish that’s incredibly tough and can handle washing, stretching, and years of wear and tear. In many cases, the print will actually outlast the T-shirt.

The Power of Bulk Production

The real magic of screen print transfers happens when you need a lot of T-shirts. Picture this: you’re outfitting a sports team, stocking up on merchandise for a festival, or planning a corporate event for hundreds of staff. This is where the economics of screen printing truly shine.

There’s an initial setup cost, as a separate screen has to be made for each colour in your design. But once those screens are ready, the cost per transfer plummets with every extra T-shirt you print. This makes it an incredibly cost-effective option for large orders.

- Economies of Scale: The more you print, the cheaper each T-shirt gets. It's the ideal choice for orders of 50 pieces or more.

- Vibrant, Opaque Colours: The inks used are thick and rich, producing brilliantly bright colours that really pop, even on dark garments.

- Unmatched Durability: The bond it creates is exceptionally strong, making it perfect for workwear, sportswear, and any clothing that needs to withstand a bit of rough handling.

This model makes screen printing the go-to for businesses and organisations that need long-lasting quality and want to keep costs down on big projects. For a full breakdown of how this method compares to newer alternatives, take a look at our guide to printing on T-shirts in the UK.

Understanding the Limitations

Screen printing isn't the right tool for every single job, though. Its strength in bulk orders is also its main weakness for smaller projects. The setup costs for creating the screens can make it far too expensive for one-off designs or really small batches.

A design with six colours requires six separate screens to be made and aligned. This initial investment in time and materials is why screen print transfers are not practical for single-shirt orders or designs with photorealistic complexity.

The process is also less suited for detailed, full-colour photos or designs with subtle gradients, since every single shade would need its own screen. For those kinds of jobs, a digital method like DTF is a much better fit.

Despite these drawbacks, screen printing's grip on the custom apparel market is as strong as ever. In the UK, custom T-shirt printing is a booming sector, and screen printing remains the leading technique. The market, valued at USD 366.63 million in 2024, is expected to climb to an impressive USD 1,004.13 million by 2033. This growth is driven by the consistent demand for personalised clothing and ongoing improvements in printing tech. You can find more data about the UK's custom printing market on Deep Market Insights. It just goes to show that for large-scale, high-durability projects, screen printing is still the industry standard.

Your Essential T-Shirt Printing Toolkit

Alright, let's move from theory to practice and get our hands on the right gear. The absolute centrepiece of any t-shirt transfer setup is the heat press. Think of it as the non-negotiable heart of your operation. It’s the one machine responsible for applying the two most critical ingredients for a perfect print: consistent heat and even pressure.

You might be tempted to just grab a household iron, but trust me, that’s a recipe for disappointment. An iron is notorious for creating hotspots and applying uneven pressure, which leads to transfers that peel, crack, or just don't stick properly. A proper heat press, on the other hand, delivers a precisely controlled temperature across its entire surface, guaranteeing a professional, durable bond every single time.

Choosing Your Heat Press

Not all heat presses are created equal, and your final choice will really come down to your workspace and the kinds of projects you’ll be tackling. The two most common styles have their own distinct advantages, so it's worth getting to know them before you pull the trigger on a purchase.

There are two main types you'll come across:

- Clamshell Press: This design opens and closes just like a clamshell. It's a fantastic space-saver, making it the go-to choice for smaller workshops or home setups. Its simple, top-down motion is super efficient for standard t-shirt printing.

- Swing-Away Press: With this model, the top heated plate swings out to the side, giving you a completely clear, unobstructed view of your workspace. This design seriously reduces the risk of accidental burns and makes it much easier to position thicker items like hoodies or sweatshirts.

Basically, a clamshell is great for speed and saving space, while a swing-away offers better access and versatility for a wider range of garments.

Assembling Your Must-Have Supplies

Beyond the press itself, you’ll need a few other key items to round out your toolkit. Think of this as your essential shopping list for getting started. Having everything organised and ready to go will make your entire workflow smoother and your results far more consistent.

A great print is the result of more than just a good design; it's the combination of the right machine, the right materials, and the right accessories working together in harmony.

Here’s what you’ll need to have on hand:

- Your Transfers: Whether you've opted for DTF, screen print, or HTV transfers, have them organised and ready. Knowing exactly which type you're using is crucial, as each requires specific temperature and time settings. If you're still exploring equipment, our guide on selecting the best t shirt transfer printer offers some deeper insights.

- Blank Apparel: The garment is your canvas. 100% cotton is a classic for a reason—it's soft and breathable. Polyester is incredibly durable and fantastic for sportswear, while cotton-poly blends give you the best of both worlds with softness and resilience.

- Teflon Sheet: This is just a protective sheet that goes between the hot plate and your transfer. It’s a simple but vital accessory that prevents ink from sticking to your press and helps distribute heat evenly, protecting both your gear and your garment.

- Heat-Resistant Tape: This special tape is a lifesaver for holding your transfer perfectly in place on the garment. It can handle high temperatures without leaving any sticky mess behind, ensuring your design doesn't shift an inch during pressing.

Designing Artwork That Prints Perfectly

A brilliant print doesn't just happen at the heat press. Long before you even think about firing it up, the real magic starts with a flawless digital design. Getting your artwork ready for fabric is more than just a creative exercise; it's about nailing a few key technical details to make sure your vision translates perfectly from the screen to the shirt.

Getting this right from the beginning saves you from the classic printing headaches—blurry images, weird colours, or pixelated text. We’ll cut through the jargon and show you what really matters, so your finished T-shirt looks sharp, vibrant, and totally professional.

Resolution: The Foundation of a Crisp Print

If there’s one thing you absolutely have to get right, it's resolution. We measure this in Dots Per Inch (DPI). Think of it like the density of tiny dots that make up your image. Low DPI means fewer dots are packed into each inch, which leads to a blurry, blocky mess when you try to blow it up to fit on a T-shirt.

For any kind of T-shirt transfer printing, the gold standard is 300 DPI. This resolution is dense enough to ensure every line, curve, and tiny detail in your artwork comes out looking clean and clear. An image that looks great on your monitor at 72 DPI will almost always result in a disappointing, fuzzy print on fabric.

Always start your design on a 300 DPI canvas set to the actual size you want to print. You can't magically add quality to a low-resolution image, but you can always shrink a high-resolution one without losing that crispness.

Choosing the Right File Format

The file type you save your design as plays a massive part in the final print quality. Different formats handle image data in their own way, and picking the right one is crucial for keeping your artwork looking exactly as you intended.

Here’s a quick rundown of the best formats for T-shirt design:

- PNG (Portable Network Graphics): This is the go-to for most T-shirt projects. Its superpower is its support for a transparent background. This means only your design gets printed, not a big white or coloured box around it. Perfect.

- SVG (Scalable Vector Graphics): Unlike pixel-based files like PNGs, vectors are built from mathematical paths. This is a game-changer because you can scale them to any size—from a tiny pocket logo to a huge back piece—with zero loss of quality.

- AI (Adobe Illustrator) & EPS (Encapsulated PostScript): These are the professional-grade vector formats that graphic designers live by. If you’re working with a professional print shop, sending your art in one of these formats will make you their favourite customer.

If you're just starting out, a high-resolution PNG with a transparent background is a fantastic and reliable choice. And if you're looking for more tips on creating knockout artwork, have a look at our deep-dive article on crafting effective T-shirt design logos.

Creative Tips for Maximum Impact

Once the technical stuff is sorted, you can get back to the fun part: making a design that really stands out. Placement is everything. A standard chest print is a classic for a reason, but why not play around with an off-centre design, a sleeve print, or something on the upper back to give it a unique feel?

Make sure any text you use is not just readable but also thick enough to print clearly. Super thin or delicate fonts can sometimes get lost in the printing process or look broken after being pressed.

Finally, always think about the colour of the T-shirt itself. A design with dark, moody colours will look completely different on a black shirt versus a white one. Design with the final garment colour in mind from the very start to make sure your colours pop exactly how you imagined.

Got Questions About T-Shirt Printing? We’ve Got Answers.

As you dive into the world of t-shirt transfers, a few key questions almost always pop up. Getting straight answers from the get-go can save you from common mistakes and point you in the right direction. Let's tackle some of the most frequent queries we hear.

A massive concern for everyone is durability. After all, what’s the point of a great design if it doesn't last? The lifespan of a printed tee really comes down to the method you choose.

Screen print transfers are the undisputed champions of longevity, often looking great for the entire life of the garment. DTF transfers are right up there too, offering fantastic resilience for 50+ washes while staying soft and flexible. HTV is also tough, but you'll need to follow the care instructions to prevent it from cracking over time.

Here’s a pro tip: the secret to a long-lasting print isn't just the method; it’s the aftercare. For any transfer type, wash the garment inside out in cold water and tumble dry on low. It's that simple.

This small habit makes a huge difference, preserving the ink's vibrancy and ensuring your custom t-shirt looks brilliant for years.

Can I Use a Home Iron Instead of a Heat Press?

It’s a tempting shortcut, isn’t it? Especially for a small HTV project. But honestly, using a household iron just isn't a reliable substitute for a proper heat press. An iron gives you patchy heat and uneven pressure—the two biggest reasons why transfers peel, crack, or wash off after just a few wears.

A heat press is engineered for one job: to deliver precise, consistent temperature and firm, even pressure. This creates a professional-grade finish that lasts. For DTF and screen print transfers, it’s not just a recommendation; it's essential for the ink to properly cure and bond with the fabric. Think of it this way: investing in a press is investing in quality.

What Is the Cheapest Method for a Small Batch?

Budget is always a big consideration, particularly for small runs or one-off designs. The most cost-effective method really hinges on how complex your design is and how many shirts you're making.

If you’re printing under 20 shirts with a multi-coloured or detailed design, DTF is almost always the most economical choice. That’s because it has no per-colour setup fees, which can quickly add up with screen printing. For simple, single-colour graphics or bold text, HTV is another brilliant budget-friendly option.

Screen printing only really becomes the cheapest route when you get into higher volumes—usually around the 25-50 piece mark for the same design. At that point, the low per-item cost finally overtakes the initial setup expense.

Ready to bring your unique designs to life with professional quality? Psyque specialises in vibrant, durable DTF transfers perfect for any project, big or small. Explore our collections and start creating today at https://psyque.co.uk.