Custom DTF Prints A Complete Explainer

Share

Ever wondered how those incredibly detailed, vibrant designs get onto t-shirts and hoodies with such a soft, durable finish? Chances are, you're looking at a custom DTF print. Think of it as the modern evolution of the classic iron-on transfer, but with photorealistic quality and a professional feel that lasts.

This method involves printing a design onto a special film, which is then heat-pressed onto the fabric. The end result is a flexible, long-lasting finish that’s completely changing the game for custom apparel.

What Exactly Are Custom DTF Prints?

So, what's happening behind the scenes? It’s a bit like a temporary tattoo for your clothes, but one that becomes permanent. Instead of printing ink directly onto a garment, the design is first printed in reverse onto a special transparent material called PET (polyethylene terephthalate) film. This is where the name Direct-to-Film comes from.

This process is what allows for mind-blowingly detailed and colourful graphics—far beyond what you could easily get with older methods. Once the design is on the film, it’s coated with a special adhesive powder. This powder is the secret sauce; it acts as a powerful glue that, when heated, bonds the ink permanently to the fabric fibres.

The Magic of the Heat Press

The final step is where the magic really happens: the heat press. The printed film is laid onto the garment, and a combination of heat and pressure is applied. This melts the adhesive powder and fuses the ink directly into the fabric.

When you peel the film away, your design is left perfectly transferred, feeling smooth and integrated with the material. This is a huge leap forward from old transfer methods that often left a stiff, plastic-like patch on the shirt.

The real beauty of custom DTF prints lies in their versatility and quality. You get the full colour spectrum, including brilliant whites, on almost any fabric type—from cotton and polyester to blends and even tougher materials like denim or leather.

A Growing Trend in the UK

This technology isn't just a niche hobby; it's a rapidly expanding sector. The global Direct-to-Film printing market was valued at USD 2.72 billion in 2024 and is projected to hit USD 3.92 billion by 2030. This growth is particularly relevant here in the UK, where the demand for unique, personalised apparel is booming. DTF's cost-efficiency and adaptability make it a perfect match for this trend.

The process of using a DTF heat transfer marries modern digital precision with a hands-on application, giving creators an incredible amount of control. It allows small businesses and independent designers across the UK to produce professional-grade custom clothing without the steep setup costs tied to other printing methods. Whether you need a small batch of branded tees or a one-off custom piece, DTF delivers consistent, high-quality results every single time.

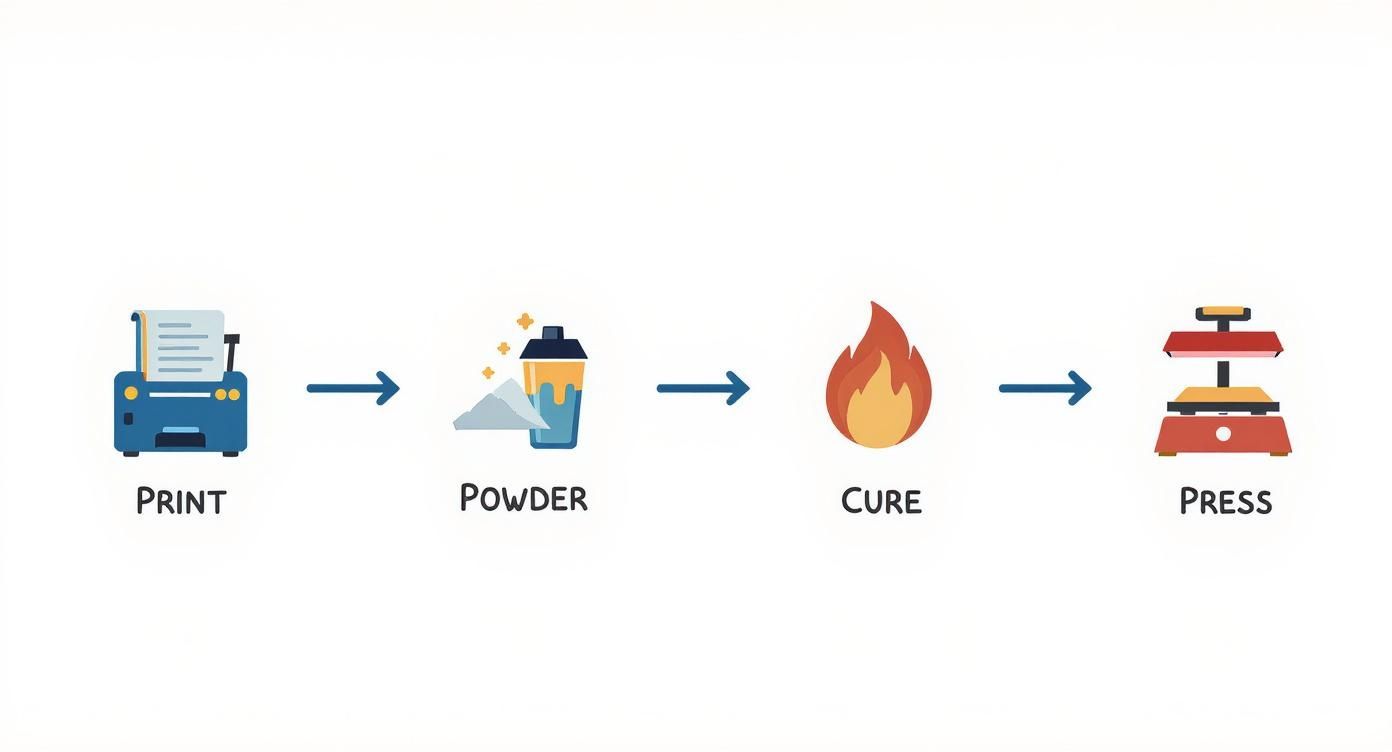

How Your Design Becomes a DTF Transfer

Ever wondered how your digital design actually gets onto a t-shirt, ready to wear? It's not magic, but it’s a pretty clever process that blends high-tech printing with a bit of hands-on skill. Let's pull back the curtain and walk through the steps, from digital file to finished garment.

This journey is what makes DTF prints so special. It's a multi-stage process that ensures your design doesn't just sit on top of the fabric but becomes a flexible, durable part of it. Each step is vital for getting that professional finish that stands up to wear and tear.

Step 1: Printing onto a Special Film

The process doesn't start with fabric. Instead, we begin with a specialised sheet called PET (polyethylene terephthalate) film. You can think of this as the temporary home for your design before it makes its way onto your apparel.

A high-tech DTF printer gets to work, meticulously laying down coloured ink directly onto the film. But here's the clever part: after printing your design in full colour, it adds a final, solid layer of white ink over the top. This white base is the secret sauce that guarantees your colours will be incredibly vibrant, whether they’re on a light-coloured tee or a jet-black hoodie.

This technique allows for stunning detail and colour accuracy, capturing everything from smooth gradients to the sharpest, finest lines with perfect clarity.

Step 2: Applying the Magic Powder

With the ink still wet, the printed film is immediately coated in a fine, white powder. This isn't just any dust; it's a powerful thermoplastic polyurethane (TPU) adhesive that acts like a super-strong, flexible glue.

The powder sticks only to the wet ink, perfectly outlining every part of your design while leaving the rest of the film completely clean. This precision is crucial because it means only your design gets transferred—no messy outlines or unwanted sticky patches around the edges.

The adhesive powder is really the unsung hero of DTF printing. It's what transforms a printed image into a permanent part of the fabric, giving it the flexibility to stretch without cracking and the durability to survive wash after wash.

Step 3: Curing the Ink and Adhesive

Now that the transfer is powdered, it needs to be cured. This involves passing the film through a heat tunnel or placing it under a heat press set to a specific temperature, usually between 100°C and 120°C.

This controlled blast of heat does two things at once:

- It gels the ink, partially drying it so it becomes stable and won’t smudge.

- It melts the adhesive powder, fusing it directly onto the ink layer to create a single, unified sheet.

The result is a dry, durable, and ready-to-press transfer. These finished transfers can be stored for months or used right away, which is a huge advantage for managing stock. To get a better look at how these are made, you can find more information about the finished DTF transfer sheets and how they're prepared for production.

Step 4: Pressing the Design onto Fabric

This is the final and most satisfying step—where your design finally meets the garment. The t-shirt, hoodie, or bag is placed flat on a heat press, and the cured DTF transfer is positioned carefully on top, with the ink side facing down.

The press then clamps down, applying a specific combination of high temperature (typically 150°C to 170°C) and firm pressure for about 10-15 seconds. This heat fully reactivates the adhesive, causing it to create a permanent bond deep within the fabric's fibres.

After pressing, the garment is left to cool for a moment. Then comes the best part: the PET film is peeled away, leaving behind nothing but your perfectly bonded, brilliantly coloured design. The final print feels incredibly soft, stretches right along with the fabric, and is ready for whatever you throw at it.

The Real-World Benefits of Choosing DTF

So, why are so many creators, brands, and businesses making the switch to Direct-to-Film? It's not just hype. The truth is, DTF solves a lot of the common headaches that come with custom apparel printing, delivering on quality, versatility, and cost all at once.

One of the biggest wins for DTF is its incredible versatility. Forget being picky about fabrics. Custom DTF prints work beautifully on a huge range of materials—from classic 100% cotton and athletic polyester to tough poly-blends and even trickier surfaces like denim and leather. This flexibility blows the creative doors wide open, freeing you from annoying material limits.

For businesses wanting to sell custom gear without buying a ton of equipment, the ability to use white label marketing with DTF prints is a massive advantage. This approach lets you sell top-notch custom apparel under your own brand, while a specialist handles all the printing for you.

Unmatched Colour and Detail

When it comes to pure visual punch, DTF is in a class of its own. It excels at reproducing complex, full-colour designs with almost photographic quality.

This process—printing, powdering, curing, and pressing—is precisely how we lock in the vibrant colours and solid durability that DTF has become famous for. Each step is essential.

DTF handles intricate details, fine lines, and smooth colour gradients that other methods just can't manage. And because the design is laid down over a solid white ink base, colours pop with incredible vibrancy, even on the darkest fabrics. It’s a complete game-changer compared to older techniques where designs on dark shirts could end up looking muddy or faded.

Cost-Effective for Every Scale

Another huge draw is the cost, especially when you're not ordering a massive batch. Traditional methods like screen printing come with hefty setup fees for creating the screens—one for each colour! This can make small runs ridiculously expensive.

DTF printing completely sidesteps those setup costs. Because the process is digital, printing a single, unique t-shirt is just as easy as printing a hundred. This makes it the perfect solution for:

- Small Businesses wanting to test new merch without a huge financial risk.

- Event Organisers needing a limited run of custom gear.

- Individuals looking to create a one-of-a-kind personalised gift.

This "no minimum order" approach empowers everyone to bring their ideas to life without breaking the bank. If you're curious about the specifics, our guide on DTF vs. screen printing for graphic tees breaks down the differences between these two popular methods.

Superior Durability and Feel

A brilliant design is only as good as its ability to last. Thankfully, DTF prints are known for their impressive durability, often rated to handle 50+ washes without cracking, peeling, or fading. The ink actually bonds with the fabric fibres, creating a finish that stretches right along with the garment.

And unlike some prints that feel like a thick, plastic shield stuck to your chest, a properly cured DTF print has a surprisingly soft and lightweight feel. The end result is a product that not only looks stunning but is also genuinely comfortable to wear, preserving the natural feel of the fabric itself.

How to Prepare Your Artwork for Flawless Prints

The secret to a jaw-dropping custom DTF print isn’t just in the printer—it all starts with your artwork. Think of your digital file as the blueprint for the final product. A sharp, well-prepared blueprint leads to a stunning result, while a messy one is a recipe for frustration.

Luckily, you don’t need to be a graphic design guru to get it right. By following a few simple rules, you can make sure your artwork is perfectly optimised for printing. Honestly, this prep work is the single most important step you can take to guarantee your design looks as amazing on fabric as it does on your screen.

Your Essential File Checklist

Getting your file print-ready is much easier than it sounds. It really just boils down to a few key technical specs that printers need to produce crisp, vibrant, and accurate prints. Let's break down the absolute non-negotiables.

Your file should always tick these boxes:

- File Format: Always save and send your design as a PNG file. This format is the industry gold standard because it supports transparent backgrounds, which are absolutely essential for DTF.

- Resolution: Aim for a resolution of 300 DPI (dots per inch). This is the magic number that ensures your design will be sharp and clear, without any fuzzy pixelation or blurriness, even when you look at it up close.

- Background: Your design must have a transparent background. If your artwork has a solid white or coloured box around it, that box will get printed right along with it. Transparency makes sure only your actual design gets transferred.

One of the most common mistakes we see is a low-resolution JPG with a white background, but it's so easily avoidable. Taking a moment to double-check these three points will save you a world of hassle later on.

Fine-Tuning Your Design for Perfection

Once you’ve nailed the basic file requirements, a few extra tweaks can take your design from good to flawless. These small adjustments help prevent common printing headaches and ensure every last detail of your artwork transfers correctly.

Think of preparing your artwork like prepping a wall before painting. You wouldn't just slap a coat of paint onto a dusty, uneven surface, would you? You clean it, sand it, and prime it to ensure a smooth, lasting finish. The same principle applies to your digital files for DTF.

A little bit of prep work really does make all the difference. For instance, converting any text elements into outlines or shapes is a crucial step. This essentially locks the font into place, so you don’t have to worry about the printer not having the same font file, which could otherwise cause your design to look completely different.

Another pro tip is to check the thickness of your lines. Any lines or tiny design elements that are ultra-thin (less than 2-3 pixels wide) might not have enough surface area for the adhesive powder to stick to properly. This can mean those fine details don't transfer to the garment at all. By slightly thickening any delicate lines, you ensure every part of your vision makes it onto the final print. This is especially important for anyone creating professional-quality, personalised t-shirt printing that relies on capturing intricate details. Following these guidelines helps you submit a truly print-ready file, preventing delays and ensuring your custom DTF prints are perfect every time.

Inspiring Ideas for Your Custom DTF Prints

Now that you've got a handle on the technology and how to prep your artwork, we can get to the fun part—letting your creativity run wild. The real power of custom DTF prints is their incredible versatility. This tech gives everyone, from indie fashion designers to local sports teams, the tools to bring their wildest ideas to life on almost any fabric you can think of.

So, let's step away from the theory for a bit. It’s time to explore some real-world applications that will spark your imagination and show you what’s truly possible with this game-changing printing method.

Powering Small Businesses and Brands

For small businesses and up-and-coming brands, creating professional-looking merchandise is one of the best ways to build an identity and connect with customers. DTF makes this easier and more affordable than ever.

Imagine running a limited batch of high-quality, branded t-shirts or tote bags for your coffee shop, online store, or even your band. With no minimum order requirements, you can test out new designs without having to sink a load of cash into it. The ability to print vibrant, full-colour logos and detailed graphics means your merch will look just as slick as anything from a major retailer.

This accessibility is a huge driver behind the boom in personalised apparel in the UK, a country celebrated for its dynamic fashion culture. In fact, the UK photo printing market, which covers textile printing like DTF, was valued at USD 1.1 billion in 2024. This sector is tipped to rocket to USD 4.5 billion by 2035, growing at a yearly rate of around 13.66%, all thanks to people wanting unique, top-quality custom gear.

DTF printing is the ultimate tool for brand-building. It lets you create consistent, high-quality uniforms for your staff, promotional items for events, or a full line of merchandise that truly captures your brand's unique style and vision.

Beyond the T-Shirt: Unique Applications

T-shirts are a classic, but don't let your creativity stop there. The real magic of DTF is its knack for sticking beautifully to a massive range of fabrics and items, opening up a whole world of unique possibilities.

Think about these inspiring ideas:

- Custom Headwear: Print detailed logos or bold graphics onto caps, beanies, and bucket hats.

- Personalised Footwear: Add a unique flair to canvas shoes or trainers for a truly one-of-a-kind look.

- Stylish Outerwear: Transform denim or leather jackets with eye-catching, durable back pieces or sleeve details.

- Team and Event Gear: Produce vivid, full-colour kits for local sports teams, complete with names and numbers on polyester jerseys.

- Custom Accessories: Create branded tote bags, aprons for cafes, or even custom cushion covers for home décor.

The soft feel and flexibility of the prints mean they work perfectly on items that need to stretch and move, making them ideal for both fashion pieces and functional workwear.

Once you have some inspiring ideas for your custom DTF prints, you might even consider turning your creativity into a business. It's worth learning how to effectively market and sell custom printed products on Instagram with Shopify to reach a much bigger audience. This is exactly how many successful independent brands get their start—by using social media to show off their unique apparel. With DTF, your creative potential is truly limitless.

Placing Your First DTF Print Order with Confidence

Ready to see your designs come to life? Taking that step from a digital file to a real-world product is always exciting. Ordering your first batch of custom dtf prints should be a smooth and simple process, not a confusing chore. The key is to find the right printing partner and communicate exactly what you need to get the results you've pictured.

Navigating the world of online printing services can feel a bit overwhelming at first, but a few tell-tale signs will help you spot a reliable, high-quality UK-based supplier. The best companies are always transparent about how they work and what things cost.

Choosing the Right UK Printing Service

Before you commit, it’s worth doing a little homework on any potential printer. A trustworthy service will make it easy to find the information you need, so you can place your order with total peace of mind.

Here’s a quick checklist of what to look for:

- Clear and Upfront Pricing: You should never have to guess the final cost. Look for simple pricing structures without any nasty hidden fees.

- Customer Reviews and Examples: Real testimonials and a gallery of previous work are fantastic indicators of quality and customer satisfaction. It shows they're proud of what they produce.

- Sample Availability: The best suppliers often let you order a sample pack. This is a brilliant way to see and feel the quality for yourself before committing to a larger order.

Getting this initial research right is the first step in building a great long-term relationship with a printer who really gets what you’re trying to achieve.

Demystifying the Ordering Process

Once you’ve found a supplier you like, you'll come across a few common terms. One of the most important to understand is the gang sheet.

A gang sheet is a large sheet of transfer film where multiple designs are printed together. This approach maximises the use of space and cuts down on waste, making it the most cost-effective way to order different designs or sizes at once. You pay for the sheet, not for each individual design.

When you place an order, you'll usually select the size of the gang sheet you need and then upload your artwork file with all your designs arranged on it. You'll also need to be clear about how many sheets you want printed. If you want to dive deeper, learning how to effectively buy DTF transfers can save you a good bit of time and money, making sure your first project is perfectly optimised.

The final piece of the puzzle is clear communication. If you're unsure about anything—from how to prepare your files to how long it will take—don't be afraid to ask. A good printing partner will be more than happy to guide you, ensuring your vision is executed perfectly. With this knowledge in your back pocket, you can place your first order not with hesitation, but with the confidence of a seasoned pro.

Your Top Questions About Custom DTF Prints, Answered

Jumping into a new printing method always brings up a few questions. To help you feel confident about getting started, we’ve put together some straightforward answers to the queries we hear most often about custom DTF prints. Getting your head around these key points will show you exactly why so many creators and businesses are making the switch.

One of the first things everyone wants to know is how well the prints last. After all, a brilliant design is only as good as its staying power.

How Durable Are DTF Prints?

This is where DTF really pulls ahead of the pack. When applied properly, these prints are incredibly tough and designed to handle the daily grind of wear and tear, including countless trips through the washing machine. The ink and adhesive create a direct bond with the fabric's fibres, resulting in a finish that’s both strong and surprisingly flexible.

Most high-quality DTF prints can easily take 50 or more washes without cracking, peeling, or fading. If you want to get the absolute most out of your custom gear, just wash it inside out on a cool cycle and skip the high-heat tumble dryer. A little care goes a long way in keeping the design looking fresh for years.

Is There a Minimum Order?

For anyone who’s ever run a small project, this is a huge deal. Traditional screen printing comes with hefty setup costs for each screen, but because DTF is a digital process, there are absolutely no minimum order requirements.

Being able to order just one or a handful of prints is a total game-changer. It means small businesses can test out new merch ideas, you can create a one-off personalised gift, and brands can drop limited-edition runs without a massive upfront investment.

Can I Print on Dark Fabrics?

Yes, you can – and the results are incredible. Getting vibrant colours to show up on dark or black garments has always been a headache for other printing methods, often leading to dull, muddy-looking designs. DTF cleverly solves this with a white ink underbase.

Before your coloured design hits the film, the printer lays down a solid layer of opaque white ink first. Think of it like a primer on a dark wall; this white base ensures that every colour printed on top of it looks bright, bold, and exactly how you envisioned it. This simple step guarantees your custom dtf prints will pop with amazing vibrancy, whether they’re on a light pastel fabric or the deepest black.

Ready to see your designs come to life with prints that truly stand out? Psyque offers premium DTF printing services right here in the UK, perfect for everything from brand merchandise to your own personal projects. Explore our custom apparel solutions at Psyque and start creating something amazing today.