Your Guide to DTF Custom Transfers

Share

DTF custom transfers are, in essence, ready-to-press graphics for your clothing. They let you take vibrant, highly detailed designs and apply them to all sorts of fabrics using just a heat press. It’s a method that delivers professional-grade results without the massive setup, making it a go-to for small businesses and creators.

The Modern Solution for Custom Apparel

Think of Direct-to-Film (DTF) as the perfect link between a design on your screen and a finished piece of wearable art. Older printing methods often came with strings attached—complex setups, fabric limitations, you name it. But DTF custom transfers change the game by offering genuine creative freedom.

The process is pretty clever. Your design is printed onto a special film, then coated with an adhesive powder and cured. What you're left with is a durable, flexible graphic, all set to be heat-pressed onto almost any garment you can think of.

This technology has quickly found its feet in the custom apparel world. You only have to look at the numbers to see its impact. The global DTF printing market was valued at around USD 2.72 billion in 2024, and t-shirts alone account for a huge 41% of that. With Europe, including the UK, holding the largest market share, it’s clear how vital this method has become for local brands and entrepreneurs.

Why Are They So Popular?

So, what's behind the buzz? The real magic of DTF lies in its blend of quality, versatility, and efficiency. It neatly sidesteps the hurdles that used to make custom printing a headache for smaller-scale operations.

Here’s what makes it stand out:

- Fabric Versatility: DTF isn't picky. It works beautifully on cotton, polyester, blends, leather, and even some hard surfaces. This opens up a whole world of possibilities far beyond the basic t-shirt.

- Vibrant, Full-Colour Prints: There are no colour limits here. DTF can reproduce photorealistic images, smooth gradients, and the finest details with incredible clarity.

- Exceptional Durability: When applied correctly, these transfers are stretchy, soft, and tough. They resist cracking and fading, often lasting as long as the garment itself.

- Cost-Effective for Small Runs: Unlike screen printing, there are no painful setup fees for each colour in your design. This makes it affordable to produce one-off items or small batches, which is perfect for trying out new ideas.

In short, DTF gives everyone from an Etsy seller to an established brand the power to produce retail-quality clothing on demand. It cuts out the need for massive inventory and complicated production lines.

If you want to get to grips with the terminology, you can learn more about what DTF stands for in our detailed guide. Understanding the basics is the first step to seeing why this method is such a game-changer.

How the DTF Printing Process Works

So, how do you get a digital design onto a t-shirt so it looks like it was always meant to be there? The magic behind DTF custom transfers is a fascinating, multi-step journey. It’s less like your desktop printer spitting out a document and more like a high-tech assembly line for creating vibrant, ready-to-wear graphics.

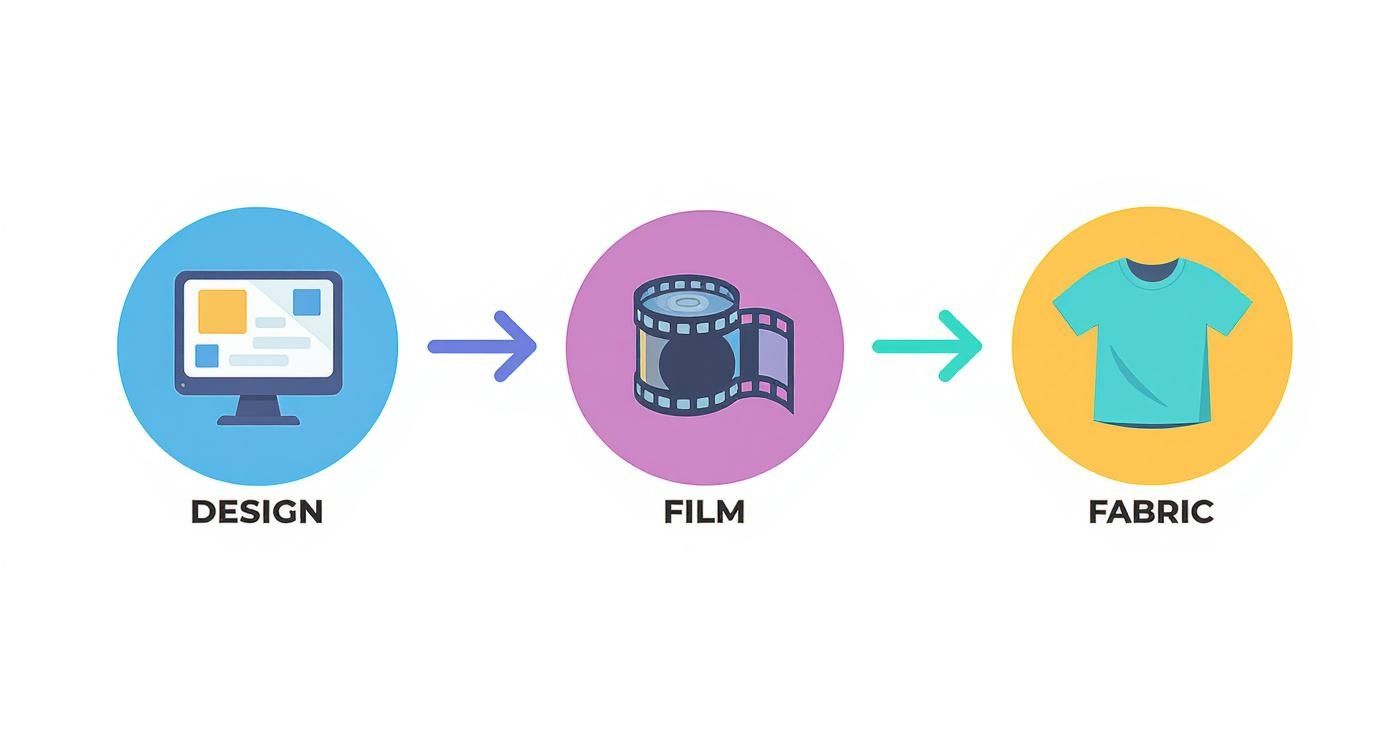

This infographic gives you a bird's-eye view of the whole operation, from a digital file to a finished piece of clothing.

As you can see, the whole thing relies on a smooth flow between the design, the special film, and finally, the garment itself. Let’s walk through what’s happening at each stage.

Step 1: Printing the Design on PET Film

It all starts with a very particular type of printer. This isn't your standard office machine; it’s a dedicated DTF printer using pigment-based inks—cyan, magenta, yellow, black, and most importantly, a brilliant white ink. Your design is printed in full colour directly onto a sheet of polyethylene terephthalate (PET) film.

But here’s the clever part. Straight after the colour layer goes down, the printer lays down a solid layer of white ink right on top. This white base is a game-changer. It not only makes your colours seriously pop on dark fabrics but also acts as the perfect canvas for the adhesive that comes next.

Step 2: Applying and Curing the Adhesive Powder

While the ink is still wet on the film, a fine, sugary-looking powder is sprinkled evenly over the entire design. This is a special thermoplastic polyurethane (TPU) adhesive. It’s designed to stick only to the wet ink, so any excess can simply be shaken off.

Getting an even coat of this powder is absolutely crucial. Think of it as the 'glue' that will permanently fuse your design into the fabric's fibres during the heat press stage. It's what gives the final print its durability and soft feel.

With the powder in place, the film takes a trip through a curing oven (or under a heat press hovered just above it). This quick blast of heat melts the powder, turning it into a smooth, solid sheet of adhesive that perfectly covers the ink. Just like that, you have a finished, press-ready DTF transfer.

If you're keen to get into the nitty-gritty, you can learn more in our guide on the complete DTF printing process.

Step 3: Heat Pressing the Transfer to the Garment

Now for the final, satisfying step. The finished transfer is carefully positioned on the garment. It's then pressed with a heat press at a precise temperature and pressure, usually for about 10-15 seconds.

The heat instantly activates that cured adhesive, causing it to bond deep into the fabric's fibres. Once the time is up, the PET film is peeled away, leaving behind nothing but your crisp, colourful, and incredibly durable design on the garment. It’s ready to wear straight away.

Choosing DTF Over Other Printing Methods

Trying to pick the right printing method for your custom apparel can feel a bit like choosing a car for a road trip. You’ve got a few options—Direct-to-Garment (DTG), screen printing, and DTF custom transfers—and while they're all great, the best one really depends on where you're headed.

Let's say you want to launch a small collection of hoodies with a really complex, multi-coloured design. If you take that idea to a traditional screen printer, you’ll likely hit a roadblock. Every single colour in your design needs its own screen and a separate setup process. That means high upfront costs, which makes a small run of just 10-20 items pretty much a non-starter financially.

This is exactly where DTF printing comes into its own. It works more like a high-end office printer, handling unlimited colours and tiny details in one go, with no extra setup fees tacked on. That makes it the clear winner for small-batch orders, one-off prototypes, and any print-on-demand business where you need to be flexible and keep a tight grip on costs.

Fabric Versatility and Print Feel

Another huge factor is what you're actually printing on. DTG, for example, is brilliant but it’s at its best on 100% cotton. It can have a hard time producing really punchy, vibrant colours on polyester or blended fabrics, especially darker ones, because the ink is made to soak into the natural fibres.

DTF transfers, on the other hand, are much more easy-going. The design gets printed onto a special film first, then applied on top of the fabric using a heat-activated adhesive. This technique works amazingly well across a massive range of materials:

- Cotton and organic cotton

- Polyester and synthetic blends

- Canvas, denim, and even leather

This incredible versatility means you can offer the same sharp, high-quality print across your entire product line—from classic cotton t-shirts to polyester sportswear and sturdy canvas tote bags. The feel is different too; the print sits on the fabric, creating a soft, flexible layer that’s smooth to the touch and seriously resistant to cracking. For a deeper dive, check out our in-depth comparison of DTF versus screen printing for graphic tees.

Here’s a simple way to picture it: DTG becomes part of the cotton fibres, while DTF bonds to the surface of almost any fabric. That small difference opens up a huge world of creative and commercial possibilities.

A Clear Comparison for Your Business

To help you decide, let's break down how these methods stack up against each other on the points that matter most to a UK business owner. Getting to grips with these differences will help you pick the perfect tool for every project, making sure you get top-notch quality at the best possible price.

Here's a straightforward look at how DTF compares to the other big players in the printing world.

DTF Transfers vs Other Printing Methods

| Feature | DTF Custom Transfers | Screen Printing | DTG (Direct-to-Garment) | Heat Transfer Vinyl (HTV) |

|---|---|---|---|---|

| Best For | Small to medium batches, full-colour designs, and varied fabrics. | Large bulk orders (100+ items) with simple, limited-colour designs. | Small runs on 100% cotton garments, especially light colours. | Simple, bold graphics like names, numbers, or single-colour logos. |

| Fabric Compatibility | Excellent on cotton, polyester, blends, leather, and more. | Best on cotton and blends, but needs special inks for synthetics. | Primarily for 100% cotton; struggles with polyester and dark blends. | Good on cotton, polyester, and blends. Not ideal for delicate fabrics. |

| Colour Vibrancy | Outstanding on both light and dark fabrics due to a white ink base. | Very vibrant, but each colour adds significant setup cost. | Good on light fabrics; can look less vibrant on dark garments. | Very vibrant, but limited to the colours of vinyl available. No gradients. |

| Durability | Highly durable and flexible, resists cracking and fading through many washes. | Extremely durable, often outlasts the garment itself. | Good durability, but can fade faster than other methods if not cared for. | Durable, but can crack or peel over time with repeated washing. |

| Cost-Effectiveness | Highly affordable for small runs; no per-colour setup fees. | Very cost-effective for large volumes, but expensive for small orders. | Moderate cost for small runs, but pricier per-unit than DTF. | Cost-effective for one-offs, but time-consuming for larger orders. |

Ultimately, choosing the right method comes down to your specific needs. But as you can see, DTF custom transfers offer an unbeatable combination of flexibility, quality, and cost-effectiveness that's hard to ignore, especially for modern apparel brands.

Preparing Your Artwork for Perfect Prints

The quality of your final print hinges entirely on the quality of your artwork. It’s that simple. Before you even think about pressing a transfer, getting your design file right is the single most important step to ensure your DTF custom transfers look sharp, vibrant, and totally professional.

Think of it as the blueprint for your project. A shaky blueprint leads to a wonky building, and a poor-quality art file leads to a disappointing print.

The first rule is non-negotiable: your artwork has to be high resolution. We always recommend a file with 300 DPI (dots per inch), which is the gold standard for a reason. This level of detail guarantees every line is crisp and clear, avoiding that pixelated or blurry mess you get from grabbing a low-res image off the internet.

Your design file also needs a transparent background. Saving your artwork as a PNG or another compatible format without a background ensures that only your design gets printed—not a clunky white box around it. This is absolutely essential for a clean, seamless look on any colour garment.

Key Technical Checks for Your Design

Beyond resolution and transparency, a few quick technical checks can save you from common printing headaches. Taking a moment to run through this pre-flight checklist for your creative vision will save you time, money, and a lot of frustration down the line.

- Convert Text to Outlines: If your design features any text, always convert it to outlines or curves. This clever step turns the font into a vector shape, so the printer doesn’t need to have your specific font installed. It guarantees your typography looks exactly how you intended.

- Check Your Line Thickness: Super thin lines and tiny details can be tricky. They might not print correctly or hold enough adhesive to transfer properly. As a rule of thumb, make sure all lines are at least 0.018 inches thick to ensure they’re robust enough for the process.

- Manage Your Colours: For the most accurate results, design in a CMYK colour profile. The colours you see on your bright RGB screen can look quite different once they’re mixed with ink and put on film. CMYK gives you a much truer preview of the final product.

Think of your artwork file as the detailed blueprint for the final print. Every pixel, line, and colour choice in that file will be faithfully reproduced, so ensuring its accuracy from the start is the secret to a flawless finish every time.

Nailing these small steps is what separates amateur results from professional ones. For a bit more creative fuel and ideas on what kind of designs really connect with people, check out our guide to personalised t-shirt printing to see some popular styles and themes.

Why DTF Is a Smart Move for Your UK Business

Breaking into the custom apparel market here in the UK is an exciting prospect, but let's be honest—it can be intimidating. Traditional methods often feel like a closed door for newcomers. Screen printing demands large minimum orders, and a full-blown DTG setup is a serious financial commitment.

This is exactly where DTF custom transfers change the game. They offer a brilliant, low-risk way into the industry without the hefty price tag. Instead of shelling out thousands for printers, ink, and maintenance, you simply order the ready-to-press designs you need, right when you need them. It’s an approach that lets small businesses and solo creators go toe-to-toe with established players on both quality and design variety, minus the crippling overheads.

The model is perfectly built for modern e-commerce, especially if you're running a print-on-demand store. You can launch and test new designs with absolutely zero inventory risk. A customer places an order, and only then do you order the transfer. It’s a nimble, clever way to run your business, completely avoiding dead stock and tied-up cash.

Unlocking Impressive Profit Margins

The numbers behind DTF are what really make you sit up and take notice. Because you can order transfers in tiny batches, your initial costs are kept to a minimum, but the potential for profit is massive. This structure lets you keep healthy margins, even when you're just selling one item at a time.

Let’s talk figures. Analysis of the UK market shows that making a dozen A5-sized transfers yourself costs around £3.60 in materials alone. When you outsource, you can buy these for as little as £1.99 each in bulk. The best part? That transfer on a finished garment sells for much, much more. It's not uncommon to see a gross profit margin of around 85% and markups clearing 500%.

By switching to DTF transfers, you’re not just changing a printing method; you're transforming your entire business model. You move from being a bulk producer to an agile, profit-focused brand with the power to offer an endless product range without holding any physical stock.

Building a Scalable and Visible Brand

Starting out with DTF transfers means you can build your brand on a foundation of professional-quality products from day one. As your business picks up steam, scaling up is a breeze. You can go from ordering single sheets to massive rolls without changing a single thing in your setup—all you ever need is that heat press.

- Test the Market: Launch a limited-edition collection or a seasonal drop without committing to a huge print run. See what sticks!

- Offer Customisation: Easily say "yes" to those one-off requests for stag dos, local sports teams, or corporate events.

- Expand Your Range: That awesome design you made for a t-shirt? Now you can effortlessly put it on hoodies, tote bags, and even workwear.

Of course, having fantastic products is only half the battle. To make sure your DTF custom transfer business really takes off, people need to be able to find you online. Getting a handle on search engine visibility is crucial, which is where a solid Ecommerce SEO Checklist becomes your best friend. It’s the key to bringing in organic traffic and connecting with the customers looking for exactly what you create. This technology gives you the tools to make incredible things; a smart online strategy ensures they get seen.

Applying and Caring for Your DTF Transfers

You’ve got your vibrant, ready-to-press DTF custom transfers in hand, and now comes the fun part: bringing your design to life. Getting a professional finish is all about precision, but don't worry—it’s a straightforward technique that ensures your designs look brilliant and last wash after wash.

The secret to a perfect, durable bond is a quality heat press. While a home iron might seem tempting, it just can't deliver the consistent temperature and even pressure needed. A heat press melts the adhesive properly, fusing it deep into the fabric’s fibres for maximum durability.

Your Step-by-Step Application Guide

Nailing the application is easy when you follow a few simple steps. Here’s how to get a perfect press every single time:

-

Pre-press the Garment: First things first, pop your t-shirt or hoodie on the press and give it a quick press for 5-7 seconds. This little step is a game-changer; it removes moisture and any pesky wrinkles, giving you a perfectly flat, dry canvas to work with.

-

Position Your Transfer: Now, carefully place the DTF transfer onto the garment, design-side down. Take a moment to check its placement—make sure it’s straight and centred exactly where you want it to be.

-

Press with Precision: It's time for the main event. Press the transfer using medium to firm pressure. For most cotton and polyester blends, a temperature of around 140-160°C (284-320°F) for 10-15 seconds is the sweet spot. Every fabric is a bit different, so for a full rundown, check out our complete heat press temperature guide for specific settings.

-

Master the Peel: This is a crucial step that can make or break the finish. Depending on the film, you’ll either do a "cold peel" or a "warm peel." A cold peel means letting the transfer cool down completely before removing the film, which is brilliant for highly detailed designs. A warm peel lets you remove the film while it's still slightly warm to the touch.

-

The Final Finish: Once the film is off, place a Teflon sheet over the design and press it one last time for another 5-7 seconds. This final press locks the design in, boosts its durability, and gives it a lovely smooth, matte finish.

Long-Lasting Aftercare Instructions

To keep your creations looking fresh and vibrant for ages, a little bit of care goes a long way. Pass these simple instructions on to your customers:

- Wait 24 hours before the first wash to let the design fully cure.

- Always turn the garment inside out before washing.

- Use a cold machine wash and a mild detergent.

- Steer clear of bleach and fabric softeners, as they can damage the print.

- Tumble dry on a low setting or, even better, hang it up to dry.

- Never iron directly over the print.

Your DTF Questions, Answered

Jumping into a new printing method always sparks a few questions. To make sure you feel totally comfortable with dtf custom transfers, we’ve put together some straightforward answers to the queries we hear most often.

How Well Do DTF Prints Actually Last?

In a word: brilliantly. When you apply them correctly and look after the garment, DTF prints are incredibly tough and flexible. They form a solid bond with the fabric that resists cracking, peeling, and fading, even after dozens of washes.

In fact, many wash tests show their performance is right up there with traditional screen printing—and sometimes even better. It’s not uncommon for the print to outlast the t-shirt itself.

Can I Just Use My Home Iron to Apply Them?

We really, really advise against this. Your standard home iron just can't deliver the two critical things needed for a perfect application: consistent, even temperature across the whole design, and firm, uniform pressure.

A heat press is engineered specifically for this job. It ensures the adhesive melts perfectly and sinks deep into the fabric fibres for a permanent bond. Trying to use an iron is almost guaranteed to give you a patchy finish that will start peeling off after the first wash.

Think of it like this: a heat press properly bakes the design into the fabric. A home iron just sort of warms it on the surface. For that professional, lasting result you’re after, a heat press is essential.

Is There a Minimum Order?

Nope! This is one of the biggest perks of DTF. There are no high minimum order quantities (MOQs) to worry about. The whole process is just as efficient for one transfer as it is for a few hundred.

This makes dtf custom transfers the ideal choice for:

- Trying out a new design without a big financial commitment.

- Creating unique, one-off personalised gifts.

- Running small batches for a new business or local event.

This flexibility means you can order precisely what you need, exactly when you need it.

Ready to create stunning, durable custom apparel with unmatched flexibility? Explore the vibrant, Japanese-inspired collections at Psyque or upload your own design to see the quality for yourself. Start your project today at https://psyque.co.uk.