Your Guide to DTF Transfer UK Printing

Share

Direct-to-Film, better known as DTF, is a game-changing way to print stunning, long-lasting designs. The process involves creating the design on a special film first, which is then heat-pressed onto a garment. For anyone looking for a dtf transfer uk supplier, it’s a seriously flexible and high-quality option for customising almost any fabric you can think of.

So, What Are DTF Transfers and Why Is Everyone Talking About Them?

The best way to think of a DTF transfer is as a modern, supercharged version of the classic iron-on patch. But forget those thick, stiff patches that sit awkwardly on a t-shirt. A DTF transfer is soft, flexible, and feels like it’s actually part of the fabric. It all comes down to the process: special inks print your design onto a clear film, a fine adhesive powder is applied, and then a heat press permanently bonds it to the material.

This method has absolutely exploded in popularity across the UK, powering everything from small craft businesses on Etsy to major workwear companies. Why the sudden buzz? It's all down to a perfect mix of versatility, quality, and efficiency that neatly solves the headaches that came with older printing techniques.

The Magic of Printing on Almost Anything

One of the biggest wins for DTF is its incredible adaptability. While some methods chain you to 100% cotton, DTF plays nicely with a huge range of materials.

- Cotton and Polyester: It sticks perfectly to the two most common fabrics in the apparel world.

- Blends: DTF handles poly-cotton blends—which can be a real pain for other methods—without breaking a sweat.

- Beyond the Wardrobe: You can even press transfers onto less conventional surfaces like leather, nylon, and denim.

This unlocks a massive world of creative freedom. A brand can put the exact same crisp, colourful logo on a cotton tee, a polyester sports top, and a denim jacket, and get consistent, brilliant results every single time.

The real beauty of DTF is that it just breaks down barriers. It lets creators and businesses print what they want, on whatever they want, without having to sacrifice colour or durability. That kind of flexibility is a massive deal in the custom clothing industry.

Unbeatable Print Quality and Feel

The final result is where DTF really pulls ahead of the pack. The technology delivers incredibly sharp details and a massive spectrum of vibrant colours, meaning it can reproduce complicated designs and even photos with amazing accuracy. Because the ink is fused to the fabric with a strong but pliable adhesive, the final print can stretch and move without cracking or peeling away.

This durability means the design will still look great after dozens of washes, making it a reliable choice for everything from everyday fashion to heavy-duty work uniforms. If you want to get into the nitty-gritty of the tech, our guide explaining what DTF stands for and how it works has you covered. It's this one-two punch of stunning visuals and lasting performance that has so many UK businesses making the switch.

How The DTF Printing Process Actually Works

To really get why DTF prints look so good, it helps to understand the journey from a digital file to a finished piece of clothing. It's not just a simple point-and-click job; it's a careful, multi-stage process where each step builds on the last to create something durable and vibrant. Think of it like a master chef crafting a signature dish—every single ingredient and action is crucial for that perfect result.

It all starts with your digital artwork. Before any ink even touches the film, the design file needs to be prepped meticulously. This means making sure the resolution is high (typically 300 DPI), the background is completely transparent, and the colours are calibrated just right. This first step is the foundation for everything that follows, ensuring the final print is crisp, clean, and professional.

From Digital Design To Physical Transfer

Once the artwork is ready to go, the real magic begins. The file is sent over to a specialised DTF printer, which is the heart of the entire operation.

-

Printing on PET Film: The printer doesn't put the ink straight onto the fabric. Instead, it lays the design down onto a special sheet of PET (polyethylene terephthalate) film. It first prints all the colours of your design (the CMYK layers), and then, in a second pass, it prints a perfect layer of white ink right on top. This white base is the secret sauce that makes the colours truly pop, especially on darker garments.

-

Applying the 'Magic Dust': As soon as the design is printed, while the ink is still wet, the film gets a coating of fine, grainy thermoplastic polyurethane (TPU) adhesive powder. This stuff only sticks to the wet ink, and it's the bonding agent that will eventually fuse the design permanently to the fabric.

-

Curing the Transfer: Next, the powdered film is passed through a curing oven or placed under a heat press. This melts the adhesive powder, turning it into a smooth, even layer that seals the ink. This stage is absolutely vital for creating a transfer that’s tough enough to handle stretching and countless washes.

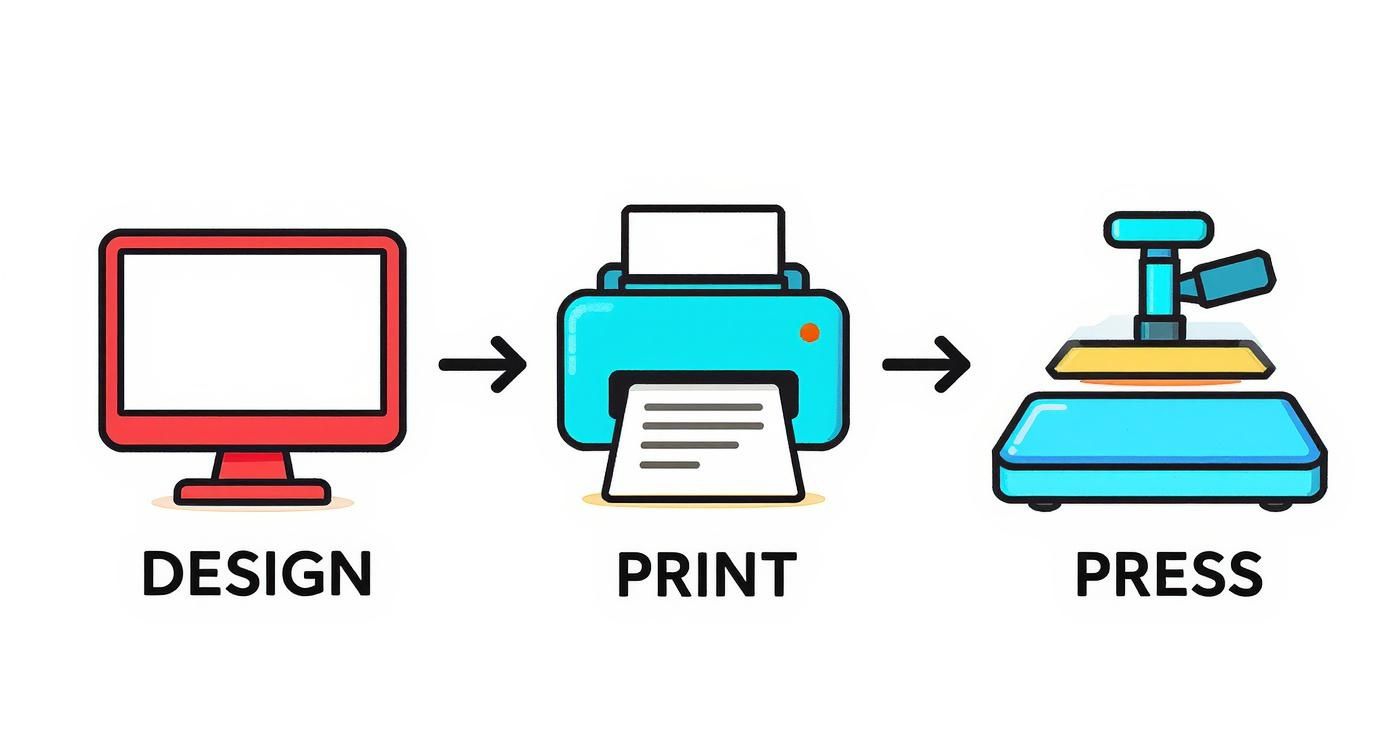

This infographic breaks down the core stages, from design to the final press.

As you can see, the process is a smart blend of precise digital printing and hands-on physical steps, all designed to get the transfer ready for its final home.

The Final Application

At this point, you have a finished transfer that’s ready to press, which is what dtf transfer uk suppliers can ship directly to their customers. The final stage is the application onto the garment itself, a job for a commercial heat press.

The heat press is what brings it all together, applying exact temperature and pressure to activate the cured adhesive. This permanently bonds the ink deep into the fabric's fibres, creating the signature soft feel and incredible durability that DTF is known for. The print truly becomes one with the garment.

The garment is laid flat on the press, the transfer is positioned perfectly, and heat is applied for a short time—usually around 10-15 seconds at a temperature between 150-165°C. Once it's done, the PET film is peeled away, leaving just the beautiful, resilient design on the fabric.

If you're curious about the different types of film used in this process, you can learn more in our guide to understanding DTF transfer sheets and their unique properties. It's this careful, step-by-step process that guarantees a premium finish every single time.

The Key Advantages of Using DTF Transfers

When you're weighing up your printing options, DTF transfers make a seriously compelling case. They don't just offer minor tweaks; they solve some of the biggest headaches that come with older methods, marking a real step forward in quality, efficiency, and creative freedom for UK businesses and designers.

One of the most talked-about benefits is its incredible versatility. Unlike Direct-to-Garment (DTG) printing, which is at its best on 100% cotton, DTF is far less fussy. It sticks beautifully to a huge range of fabrics—cotton, polyester, nylon, leather, and even those tricky poly-cotton blends.

What this means in practice is that you can apply the same design across a whole product line, from t-shirts and hoodies to workwear and caps, and get the same great result every time. For anyone offering custom apparel, that kind of flexibility is a game-changer.

Unmatched Print Quality and Durability

DTF really shines when it comes to producing designs with genuine visual punch. The process allows for unbelievably vibrant colours and razor-sharp details, meaning it can handle everything from a simple logo to a complex, photo-realistic image with stunning accuracy.

Because the ink is printed onto the film first, the colours stay pure and bright, even when they’re pressed onto dark or brightly coloured garments.

The final print is also impressively tough. It has a soft, flexible feel that stretches with the fabric without cracking or peeling. This resilience means the garment can handle dozens of washes, making it a reliable choice for everything from high-fashion pieces to rugged, everyday workwear. For a business, that means you're delivering a premium product that speaks volumes about your brand's quality. To see how it stacks up against other methods, check out our guide on DTF heat transfer applications.

Cost-Effectiveness for Modern Demands

Another massive plus is how economical DTF is, especially for small to medium-sized print runs. Traditional screen printing requires a costly and time-consuming setup for every single colour in a design, which makes small, multi-coloured jobs ridiculously expensive. DTF completely sidesteps this problem.

With DTF, there are no screens to prepare or complex colour separations to worry about. This total lack of setup cost makes it the perfect solution for producing anything from a single item to a hundred, all with full-colour designs, offering incredible value and accessibility.

This model is a perfect fit for the UK's thriving independent design and e-commerce scene. The UK is a major player in the European market, which is currently the biggest region for DTF technologies. This growth is fuelled by the fashion industry’s need for quick customisation and the fact that DTF is so much more cost-effective than other methods. If you're looking to get started, finding a reliable dtf transfer uk supplier is a smart first step for any growing brand.

DTF Compared to Other Printing Methods

Stepping into the world of custom apparel printing can feel a bit like walking into a maze. With so many different techniques out there—DTG, screen printing, vinyl—how do you know which path to take? Choosing the right one is crucial for getting the results you want for your project.

DTF has carved out a fantastic niche for itself by offering a powerful middle ground. It blends the material versatility of vinyl with the incredible full-colour detail you get from digital printing.

Unlike DTG, which is famously picky and really only loves 100% cotton, DTF is happy to work with almost any fabric you throw at it. This makes it a seriously reliable choice if you need a consistent look across a whole range of products, from polyester sports kits to cotton-blend hoodies.

Head-to-Head Comparison

Every printing method has its moment to shine. Think of them as different tools in a workshop—you wouldn't grab a sledgehammer to tap in a finishing nail. The best choice always comes down to the specifics of your job: your design, the fabric, how many you need, and the final look you're after.

To help clear things up, let's put the four most popular methods side-by-side. This quick breakdown will show you exactly where each one excels, helping you pick the perfect match for your needs, whether you're just starting out or kitting out a whole team.

DTF vs DTG vs Screen Printing vs Vinyl

| Feature | DTF Transfer | DTG (Direct-to-Garment) | Screen Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|---|---|

| Fabric Compatibility | Excellent (Cotton, poly, blends, leather) | Limited (Best on 100% cotton) | Good (Most fabrics, but inks vary) | Excellent (Most fabrics) |

| Feel on Garment | Soft & flexible, sits on top of fabric | Very soft, ink soaks into fabric | Can be thick, especially with many colours | Varies, can be thicker than DTF |

| Durability | Excellent (Resists cracking & fading) | Very Good (Can fade over time) | Excellent (Very long-lasting) | Good (Can peel if not applied correctly) |

| Ideal Order Size | Small to medium (1-500+) | Small (1-50) | Large (100+) | Small (1-20) |

| Best For | Full-colour on any fabric | Photos on cotton t-shirts | Simple, large-volume orders | Names, numbers, simple logos |

Practical Scenarios

Sometimes, seeing these methods in a real-world context makes all the difference. Let's walk through a couple of common scenarios to see where a DTF transfer UK service would be the perfect fit, and where you might be better off with something else.

-

Scenario 1: The Local Football Club

A local team needs 30 polyester jerseys printed with their detailed, full-colour club crest. DTG is out immediately—it just doesn't play well with polyester. HTV could technically work, but layering multiple colours for a complex crest is a nightmare. Screen printing would be far too expensive for a small run with that many colours. DTF is the clear winner here. It delivers vibrant, durable results on polyester at a great price for a small batch. -

Scenario 2: The Charity Fun Run

An organiser needs 500 cotton t-shirts with a simple, two-colour logo. DTF could absolutely get the job done, but for a large quantity with a simple design, screen printing is the most economical choice. The setup costs get spread thin across the big order, making the price per shirt much, much lower. If you're weighing these two options, our guide comparing DTF vs screen printing for graphic tees is a great read.

DTF shines brightest where versatility meets complexity. It's the go-to solution for detailed, multi-coloured designs on small-to-medium runs, especially when you need to print on fabrics that other methods can't handle.

At the end of the day, understanding these differences is what allows you to invest your money wisely. It ensures you pick the printing technique that will truly bring your vision to life without any compromises.

Popular Uses for DTF Transfers in the UK

You can really see the power of DTF transfers out in the real world, where their versatility is bringing all sorts of creative and commercial ideas to life across the UK. This tech is being used for so much more than just basic t-shirts, fuelling everything from rugged workwear to independent fashion startups.

One of the biggest areas we see them used is for creating durable, branded uniforms for tradespeople. Think of electricians, plumbers, and construction workers whose gear needs to survive some serious daily wear and tear. DTF’s toughness means a company logo stays sharp and vibrant on a high-vis polyester jacket, even after months of hard graft and countless washes.

This isn't just a niche trend; the market itself reflects this growth. The UK's direct-to-film printing sector is on a steady climb, with projections showing it will grow from $192.2 million in 2025 to $249.0 million by 2030. That’s a clear sign of how much UK industries are coming to rely on this technology. You can dig deeper into the UK's growing DTF market on Grand View Research.

Fuelling Creative and Local Ventures

The creative scene has also jumped on DTF, mainly because it handles intricate, multi-coloured designs without the hefty setup costs of older methods. This makes it a perfect fit for small-scale, high-quality production runs.

-

Local Sports Clubs: Amateur football and rugby teams can finally get professional-looking kits. We're talking full-colour crests and sponsor logos on modern synthetic fabrics that other print methods just can't handle properly.

-

Band and Event Merchandise: Musicians and event organisers can produce limited runs of merch with complex artwork. It allows them to offer fans high-quality gear without having to sink a massive upfront investment into stock.

-

Independent Fashion Brands: Small fashion startups and Etsy sellers can bring their detailed, artistic visions to life on a whole range of garments, from classic cotton hoodies to trendy denim jackets.

DTF’s real strength is how it empowers small-scale creators. It completely removes the financial barriers of traditional printing, letting anyone with a great idea produce professional-grade apparel and build a brand from the ground up.

This accessibility is a huge reason why so many UK businesses are now looking for a DTF transfer UK supplier. It offers a practical and genuinely affordable way to create premium custom clothing, whether you're kitting out a team of ten or dropping a limited-edition fashion line. The technology is just a brilliant match for the dynamic needs of modern British businesses and creative entrepreneurs.

Common Questions About DTF Transfers

Even after getting the hang of the process and its benefits, it's completely normal to have a few practical questions before you're ready to hit 'order'. Getting these final details ironed out is the key to feeling confident that DTF is the right move for your project.

Let's tackle some of the most common queries we hear from customers looking for a DTF transfer UK supplier. We'll give you clear, straightforward answers to help you get your custom apparel plans off the ground.

How Durable Are DTF Prints And How Should I Care For Them?

This is usually the first thing people ask, and for good reason—you want your designs to last! The simple answer is that DTF transfers are incredibly durable. They're engineered to handle dozens of wash cycles without cracking, peeling, or fading. In many cases, the print will actually outlast the garment it's on.

Of course, a little bit of care goes a long way in getting the most life out of your print.

- Washing: Always turn the garment inside out before washing. Stick to a cool wash, ideally at 30°C.

- Detergents: Try to avoid harsh detergents, fabric softeners, or bleach. These can slowly break down the print's adhesive over time.

- Drying: You can tumble dry on a low heat setting, but air drying is always the best bet for keeping the print in perfect condition.

- Ironing: Never, ever press a hot iron directly onto the design. If you need to iron the garment, turn it inside out or pop a protective cloth over the print first.

Follow these simple steps, and your custom gear will stay looking sharp and vibrant for years to come.

What Kind Of Artwork File Do I Need For The Best Results?

This is a big one. The quality of your final print is 100% tied to the quality of the artwork file you start with. If you want a sharp, professional-looking result, you absolutely need to provide a high-resolution file with a transparent background.

The gold standard is a PNG file with a resolution of at least 300 DPI (dots per inch), saved at the exact size you want it printed. This ensures every tiny line and detail is captured perfectly, with zero blurriness or pixelation.

Whatever you do, avoid grabbing low-resolution images from the web. They will almost always result in a poor-quality, fuzzy print. Most DTF providers will have specific artwork guidelines on their website, so it's always smart to have a quick look before placing your order.

Is There A Minimum Order For DTF Transfers In The UK?

Here’s where DTF really shines. One of its biggest advantages is the complete lack of a minimum order quantity (MOQ). Unlike screen printing, which requires costly setup for each colour in a design, DTF is built for flexibility.

This makes it the perfect solution for UK-based small businesses, independent creators, and anyone just wanting to make something unique. You can order a single transfer to test a new design, create a one-of-a-kind gift, or produce a small batch for a limited-edition drop without being hit with high setup fees. If you're looking to explore your options, you can learn more about how to buy DTF transfers for your next project right here.

This on-demand approach cuts down on waste and means you don't have to hold huge amounts of stock, making it a much smarter, more modern way to create custom apparel.