The Ultimate Guide to Choosing a Printer for Clothes

Share

Thinking about getting into custom apparel? It can feel like a massive jump, but the basic idea is actually pretty straightforward. When we talk about a "printer for clothes," it's not a single machine like the one in your office. It's usually a two-part system: a specialised printer creates your design, and a separate heat press bonds it permanently to the fabric.

This duo is what takes a digital file and turns it into a professional, wearable piece of clothing.

Your First Step Into Custom Apparel Printing

Getting started with custom clothing doesn't have to be a headache. The path from a design on your screen to a finished t-shirt is a clear, repeatable process. But if you want professional, long-lasting results that your customers will genuinely love, you need to understand why specialised gear is a must. Let's be blunt: a standard desktop printer and a household iron just won't cut it for a real business.

Think of it like baking a cake. The specialised printer is your piping bag, carefully creating the intricate decoration (your design) onto a special film or directly onto the garment. But at that point, the design is just sitting on the surface, vulnerable. The heat press is the oven; it applies just the right amount of heat and pressure to "bake" the design right into the fabric's fibres. Without that crucial second step, your beautiful work would wash away in the first laundry cycle.

Why Specialised Gear Matters

The number one reason for using a dedicated printer for clothes and a heat press is durability. These systems use specific inks and application methods engineered to bond with textiles. This ensures your creations can handle dozens of washes without cracking, peeling, or fading—the kind of quality that separates a hobby project from a product people will pay for.

Here’s what you get when you use the right equipment:

- Vibrant and Accurate Colours: Special inks are made to pop on all sorts of fabric colours, even dark ones, staying true to your original design.

- Exceptional Durability: The combination of proper ink and a heat press creates a permanent bond that stretches with the fabric and stands up to daily wear and tear.

- Professional Feel: Unlike the stiff, plastic-like feel of old-school iron-on transfers, a professionally pressed design feels much softer and integrates seamlessly with the garment.

- Consistency Across Orders: A calibrated system means the first t-shirt you print will look just as sharp and vibrant as the hundredth. For a deeper dive, our guide on custom t-shirt printing breaks this down even further.

Once you've got your printing setup dialled in, the next big hurdle is getting your creations in front of customers. Knowing how to effectively sell your custom apparel online can be the difference between a fun hobby and a thriving business. This guide will walk you through the technologies that make it all possible, giving you a solid foundation before we explore the specific options.

Comparing The Four Main Clothes Printing Technologies

Choosing the right printer for your clothing brand is a bit like picking the right tool for a job. Each technology has its own strengths, quirks, and ideal purpose, and getting your head around the differences is probably the most important first step you can take. We're talking about the four main players on the field: Direct-to-Garment (DTG), Direct-to-Film (DTF), Dye-Sublimation, and Heat Transfer Vinyl (HTV).

This isn’t just a technical deep-dive; it’s about what your customer will actually hold in their hands. How does the print feel? Will it survive the wash? What fabrics can you even print on? Answering these questions will point you towards the perfect method for your vision, whether you’re dreaming of detailed photographic tees or bold, graphic hoodies.

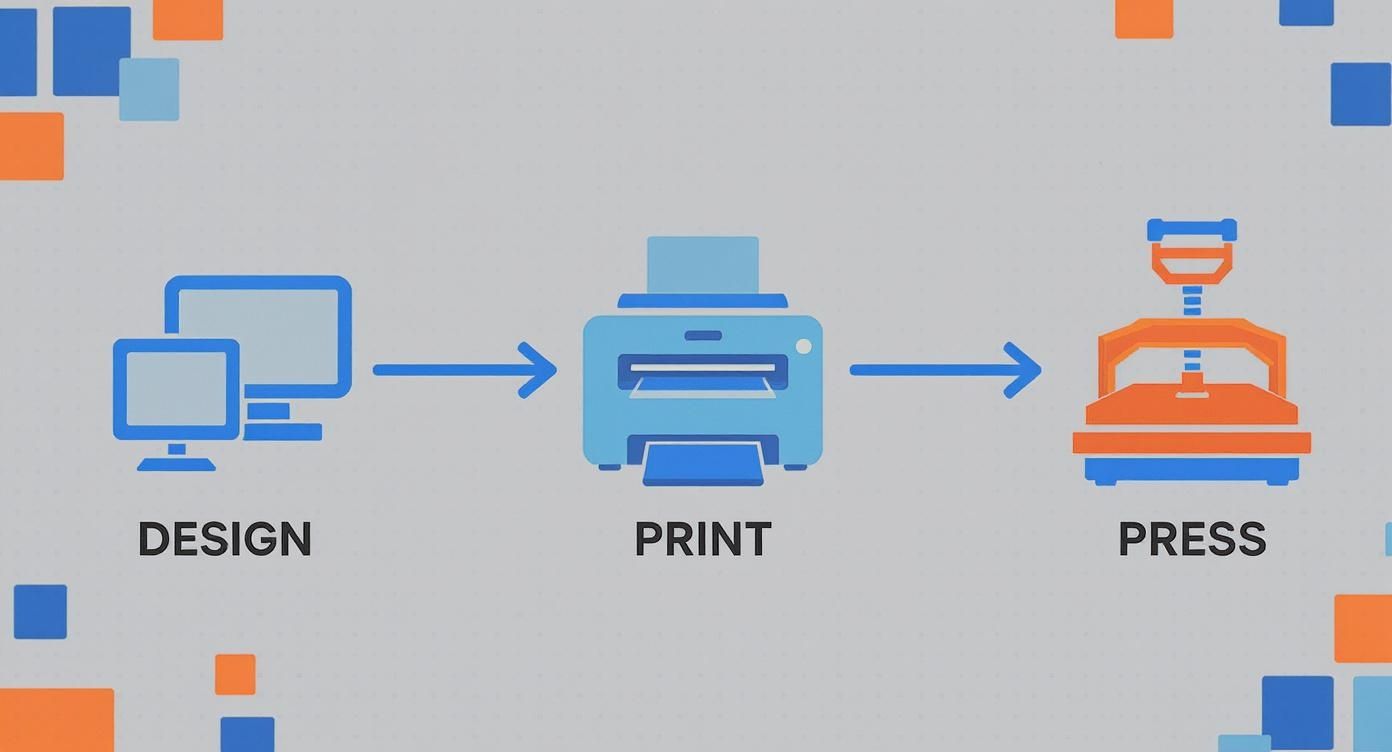

At a high level, the workflow for most of these methods looks pretty similar. You've got your design, your print, and your press.

This simple three-stage process—design, print, and heat application—is the backbone of turning a digital idea into a wearable product, no matter which technology you end up using.

Direct-to-Garment (DTG): The Digital Inkjet

Imagine a specialised inkjet printer, but instead of paper, it prints directly onto t-shirts. That’s DTG in a nutshell. You load a pre-treated garment onto a platen, and the machine sprays water-based inks straight into the fabric’s fibres. The result is a stunningly detailed, soft-to-the-touch print with an incredible colour range, making it perfect for photorealistic images or complex, multi-coloured designs.

Because the ink soaks right into the material, the print feels almost like it's part of the shirt. It’s breathable and flexible, completely avoiding that stiff, plastic feel you get from some older transfer methods. DTG really shines on 100% cotton and high-cotton blends, especially on white or light-coloured garments. When printing on dark fabrics, the machine first lays down a white underbase to make sure the colours pop—a crucial step for vibrancy.

You can learn more about the nuts and bolts in our deep dive into direct printing to garment techniques. It’s no surprise that DTG is a dominant force in the UK's digital textile printing market. With the growing demand for customisation, projections show DTG printing could make up nearly 60.4% of the market share by 2025. It’s efficient and helps cut down on fabric waste compared to older methods, which is a massive win.

Direct-to-Film (DTF): The Versatile Workhorse

If DTG is the specialist, then Direct-to-Film (DTF) is the all-rounder. Instead of printing directly onto the clothing, a DTF printer prints your design onto a special transfer film. This film then gets a light coating of powdered adhesive before being cured with heat. From there, you just place the transfer onto the garment and press it.

This two-step process is what makes DTF so incredibly versatile. It works beautifully on a huge range of materials that DTG can struggle with, including:

- Cotton

- Polyester

- Poly-cotton blends

- Nylon and even treated leather

The final print sits on top of the fabric rather than soaking in, giving it a smooth and incredibly durable feel with a bit of stretch. DTF transfers are known for their brilliant colours and sharp details, and they hold up exceptionally well in the wash. This makes it the go-to choice for businesses printing on diverse items like sportswear, workwear, and hats.

Dye-Sublimation: The Fabric Infuser

Sublimation is less like printing and more like magic. This process uses special inks that, when heated, turn directly from a solid into a gas. This gas then permeates the fibres of polyester fabrics and solidifies, permanently dyeing the material itself.

The key takeaway with sublimation is that the ink becomes part of the fabric. You cannot feel the print at all—it has zero texture. It will never crack, peel, or fade, and will often outlast the garment itself.

However, this magic trick comes with a couple of major limitations. First, it only works on polyester or high-polyester blend fabrics. You simply can't sublimate onto cotton. Second, since the ink is translucent, it must be used on white or very light-coloured garments. Trying to print on a black polyester shirt with sublimation ink would be like drawing with a highlighter on black paper—it just won’t show up. It remains the undisputed champion for sportswear, activewear, and promotional items like mugs and mouse pads that have a special polyester coating.

Heat Transfer Vinyl (HTV): The Craft-Friendly Cutter

Finally, we have Heat Transfer Vinyl (HTV), which takes a completely different approach. This method doesn't involve a printer in the traditional sense. Instead, you use a vinyl cutter (like a Cricut or Silhouette) to cut your design out of a sheet of coloured vinyl. After that, you "weed" away the excess vinyl, place the design on your garment, and apply it with a heat press.

HTV is absolutely perfect for bold, simple graphics with one or two colours, like text, logos, and jersey numbers. It’s a fantastic entry point for crafters and small businesses because the startup cost is relatively low. The final result feels like a thin, flexible layer on top of the shirt. While it's durable, it can be thicker and less breathable than DTG or sublimation prints, especially on larger designs.

Each of these four technologies offers a unique path to creating custom apparel. Your choice will ultimately come down to your business goals, the types of products you want to create, and the audience you're hoping to reach.

To help you see how they stack up side-by-side, we've put together a detailed comparison table.

Detailed Technology Comparison Matrix

This matrix breaks down the key differences across the most important factors, from cost and feel to which materials you can actually use.

| Feature | DTF (Direct-to-Film) | DTG (Direct-to-Garment) | Dye-Sublimation | HTV (Heat Transfer Vinyl) |

|---|---|---|---|---|

| Best For | Versatile printing on almost any fabric, including dark colours. | High-detail, full-colour prints on cotton garments. | All-over prints on 100% polyester, sportswear, hard goods. | Simple, bold graphics like text and logos on any fabric. |

| Feel of Print | Smooth, slightly plastic-like feel that sits on the fabric. | Very soft, breathable, as the ink soaks into the fibres. | No feel at all; the ink becomes part of the fabric. | A tangible layer on top of the fabric; can be thicker. |

| Durability | Excellent. Very resistant to cracking and fading. | Good. Can fade slightly over many washes. | Exceptional. Will not crack, peel, or fade. | Good to Excellent, depending on the quality of vinyl. |

| Colour Vibrancy | Vibrant and opaque, excellent on both light and dark fabrics. | Excellent on light fabrics, good on darks with underbase. | Extremely vibrant, but only on white/light polyester. | Very vibrant, but limited to the colours of vinyl available. |

| Material Compatibility | Cotton, polyester, blends, nylon, leather—almost anything. | Primarily 100% cotton or high-cotton blends. | 100% polyester or polymer-coated items. | Works on cotton, polyester, blends, and many other fabrics. |

| Startup Cost | Medium to High. Requires printer, powder, and heat press. | High. Professional printers are a significant investment. | Medium. Requires a sublimation printer, paper, and press. | Low. A vinyl cutter and heat press are affordable. |

| Complexity/Workflow | Multi-step: print to film, apply powder, cure, then press. | Relatively simple: pre-treat (for darks), print, cure. | Simple: print on paper, then press onto the item. | Multi-step: cut design, weed excess vinyl, then press. |

Hopefully, this table makes it clearer which method might be the right fit for you. Whether you prioritise versatility, feel, or budget, there's a technology out there to bring your creative ideas to life.

Understanding Fabric and Material Compatibility

Picking a printer for clothes without first thinking about the fabric is a recipe for disaster. It's like trying to paint on water—you’ll just end up with a mess and a lot of disappointment. Each printing method has a unique chemical relationship with certain materials, and getting that right is the secret to creating vibrant, durable clothes your customers will actually want to wear.

Think of it like this: different paints need different canvases. You wouldn’t use watercolours on a glossy plastic sheet because they’d just bead up and wipe right off. In the same way, the inks and processes for printing on clothes are specially designed to bond with specific types of fibres. Nailing this match is what separates a professional finish from a costly mistake.

So, let's break down which fabrics work best with each printing method. We’ll look at why some technologies are picky about their materials while others are a bit more flexible.

The Natural Fibre Specialist: DTG

Direct-to-Garment (DTG) printing is at its best when working with natural fibres. The water-based inks it uses are made to soak right into the material, which is what gives it that signature soft-to-the-touch feel. This makes 100% cotton the absolute gold standard for DTG.

- Best Fit: Organic cotton t-shirts, combed cotton hoodies, and other natural-fibre clothing.

- Good Fit: High-cotton blends (think 80% cotton, 20% polyester) can also produce fantastic results.

- Avoid: DTG really struggles with fully synthetic materials like 100% polyester. The ink just can't bond properly with the plastic-based fibres, leading to dull colours and a design that won’t survive the wash.

DTG is also great for printing on both light and dark garments. When you’re working with darker fabrics, the printer simply lays down a white ink underbase first. This creates a solid canvas for the coloured inks to sit on, making sure they pop just as they should.

The Synthetic Superstar: Sublimation

Sublimation printing is a whole different ball game. Here, the ink turns into a gas under heat and pressure, chemically bonding with and dyeing the actual fibres of the fabric. This process only works its magic on synthetic materials.

Sublimation is a one-trick pony, but it’s an incredible trick. It only works on 100% polyester or high-polyester blends (at least 60% polyester). If you try to sublimate on cotton, you’ll get a faded, washed-out image that all but disappears after the first wash.

Because the ink literally becomes part of the fabric, sublimation is also limited to white or very light-coloured garments. The inks are translucent, so they won’t show up on dark backgrounds at all. It's the go-to choice for sportswear, activewear, and any kind of polyester performance gear.

The All-Rounder: DTF

This is where Direct-to-Film (DTF) technology really shines, acting as the ultimate bridge between different types of material. Because the design is printed onto a film first and then transferred as a complete layer, the printer never has to interact directly with the fabric’s chemistry.

This makes DTF unbelievably versatile, happily working on a massive range of materials:

- Cotton (both light and dark)

- Polyester (brilliant for sportswear)

- Poly-Cotton Blends (perfect for hoodies and sweatshirts)

- Nylon and Tri-blends

- Even less common surfaces like treated leather or denim

Just like DTG, DTF handles dark fabrics easily by using a white ink layer printed behind the colours on the film itself. This flexibility makes it an ideal printer for clothes if you’re planning to offer a diverse product line. For those looking at simpler, bold graphics, our guide on vinyl printed shirts explores another highly flexible option. This incredible compatibility is why so many new and established brands are switching to DTF—it’s just so adaptable and delivers reliable results on almost anything you throw at it.

Your Essential Shopping and Setup Checklist

You’ve explored the tech and picked out your dream fabrics. Now for the exciting part: building your very own print station. But buying a printer for clothes is just the start. To get a smooth, efficient, and safe workspace up and running, you'll need a few more key components.

Think of this as more than just a shopping list. It's your strategic guide to investing wisely right from day one. A well-planned setup is the foundation for consistent, high-quality results and helps you dodge those common frustrations that can trip up a new venture.

The Core Equipment

Beyond the printer itself, there are a few bits of hardware that are completely non-negotiable if you want to produce professional-grade apparel. Consider these the essential supporting cast for your star performer.

-

The Heat Press: This is your printer’s most critical partner. A household iron just won’t cut it. A quality heat press delivers the consistent, even temperature and pressure you need to permanently cure inks and apply transfers. Getting this right is so crucial, we’ve put together a detailed guide on how to choose the right heat press machine for t-shirt printing to help you make the perfect choice.

-

Curing Equipment (for DTF): If you've gone down the DTF route, you’ll need a way to melt the adhesive powder onto the printed film before it goes to the press. This could be a small curing oven or even your heat press used in a 'hover' mode. A dedicated unit, however, will make your workflow much, much smoother.

Software and Design Tools

Your physical setup is only as good as the software driving it. To take an idea from a digital file to a wearable reality, you'll need two types of programmes working together.

-

Design Software: This is where the magic begins. Industry-standard tools like Adobe Illustrator or Affinity Designer are perfect for creating sharp vector graphics like logos and text. For photographic or more complex raster images, Adobe Photoshop is the undisputed king.

-

RIP Software (Raster Image Processor): Think of this as the brain of the operation. It’s a specialised bit of software that translates your design file into instructions the printer can actually understand. RIP software is absolutely vital for managing colour accuracy, controlling ink levels (especially that all-important white underbase), and ensuring your prints look exactly how you imagined. Most professional garment printers come bundled with their own recommended RIP software.

Consumables: The Fuel for Your Printer

Your day-to-day work will chew through a steady supply of consumables. Running out of a key item mid-production can grind your entire business to a halt, so it’s always smart to keep a healthy stock of these essentials.

Your first order should include more than just a starter kit. Always budget for at least one full set of backup inks and a generous supply of your main transfer medium (film, paper, or vinyl). Trust us, it’ll save you from a world of unexpected downtime.

Depending on the technology you've chosen, your shopping list is going to include:

- Specialised Inks: DTG, DTF, and sublimation printers all use their own unique ink formulas. Never, ever mix them or use third-party inks that aren't approved by your printer’s manufacturer.

- Transfer Mediums: This will be your DTF film, sublimation paper, or rolls of heat transfer vinyl (HTV).

- Adhesives and Pretreatments: DTF printing requires an adhesive powder. For DTG printing on dark garments, you’ll need a liquid pre-treatment solution to make sure the ink bonds properly to the fabric.

- Maintenance Supplies: Don’t forget the less glamorous stuff! We’re talking cleaning swabs, lint-free cloths, and specific cleaning solutions to keep your printer in pristine condition.

Calculating Your Costs and Return on Investment

Turning a creative passion into a real business means shifting your focus from just designs to the digits on your balance sheet. Getting a grip on the financial side of a clothing printing business isn't just a good idea; it's the only way you'll survive and grow. Let’s crunch the numbers, from the big initial spend to the tiny costs that add up every day, so you can price your products with confidence and see a clear path to making a profit.

The first hurdle is always the initial capital investment. This is a lot more than just the printer itself – it's your entire setup. You might get started with a budget-friendly HTV kit (that’s the cutter and the heat press) for around £500. Stepping up to a professional DTF system will likely set you back somewhere in the £3,000 to £5,000 range. And if you're going all-in with a high-end DTG machine, you're looking at a serious leap, often starting at £10,000 or more.

Think of this upfront cost as the first major piece of the puzzle in figuring out your long-term success.

Deconstructing Your Cost Per Print

Before you can put a price tag on a t-shirt, you have to know exactly what it costs you to produce it. This is your Cost of Goods Sold (COGS), and it’s about way more than the blank garment. Every single print uses up materials, and you need to track every penny.

Your main ongoing costs will be things like:

- Ink: This is a big one. For DTF and DTG, ink is a major running expense. You'll need to figure out the average amount of ink used for a typical A4-sized design.

- Transfer Mediums: With DTF, this is the cost of your film. If you're doing sublimation, it's the special paper you need.

- Adhesives & Chemicals: Don't forget the little things that add up, like the DTF adhesive powder that makes the magic happen or the DTG pre-treatment spray needed for dark fabrics.

- The Garment Itself: More often than not, the blank t-shirt, hoodie, or tote bag will be the single biggest part of your per-item cost.

Add all those up, and you get your true cost per print. For instance, if a blank tee costs you £3.00 and your ink, film, and powder for one design come to £1.50, your basic COGS is £4.50. This number is the bedrock of your entire pricing strategy.

From Break-Even to Profitability

Once you have your costs nailed down, you can start thinking about your Return on Investment (ROI). In simple terms, ROI answers the most important question: "How many t-shirts do I need to sell to pay off my shiny new equipment and actually start making money?"

The road to profitability starts at your break-even point. This is the magic moment when your total sales revenue finally equals your total costs—that’s both your initial setup investment and your ongoing running costs. Every single sale after that is pure profit.

Figuring this out is pretty straightforward. If your total setup cost was £4,000 and you make a £10 profit on every t-shirt, you need to sell 400 t-shirts just to break even. After you’ve accounted for all your expenses, from the big machinery to your website hosting, understanding how to measure ROI is absolutely critical for knowing if your custom apparel business is actually a winner.

This simple calculation helps turn what feels like a massive investment into a manageable, goal-driven plan. It also shines a light on why it's so important to tap into what customers want. The UK’s textile finishing industry, valued at around £1.7 billion, is buzzing again, thanks to shoppers wanting more sustainable, high-quality, locally-made products. If you can align your brand with those values, you're putting yourself in a much stronger position to grow.

When to Outsource vs When to Buy Your Own Printer

Jumping straight into buying a professional printer for clothes isn't always the smartest first step. Deciding whether to invest in your own gear or partner with a print supplier is a huge decision, one that really depends on your business stage, order volume, and where you see yourself in a year or two. Get it right, and you'll save yourself thousands of pounds and a whole lot of operational headaches.

For most new ventures, outsourcing is the perfect way to dip your toes in the water. It lets you test your business idea and validate your designs with next to no financial risk. You can start building an audience and making sales without shelling out for machinery that can easily set you back thousands.

This approach also gives you incredible flexibility. By working with a print-on-demand service, you can offer a massive range of products—t-shirts, hoodies, tote bags—and even dabble in different methods like embroidery, all without buying a single piece of specialised equipment.

The Case for Outsourcing Your Printing

Working with a printing partner makes perfect sense in a few key situations, especially when you're just starting out or want to broaden your product line without needing a bigger workshop.

Think about outsourcing if you:

- Are testing a new brand or design concept. Why drop a ton of cash on equipment before you even know what sells?

- Have low or unpredictable order volumes. This stops you from having an expensive machine gathering dust in the corner.

- Want to offer a wide variety of products. Get access to different printing methods without buying multiple machines.

- Lack the physical space for a full print setup. A proper setup needs a dedicated, well-ventilated room, which isn't always practical.

When Buying a Printer Makes Sense

So, when is it time to take the plunge? The tipping point usually arrives when your order volume is consistent and high enough that the per-print cost of outsourcing starts to seriously dig into your profit margins.

Owning the equipment gives you the final say on quality, lets you turn orders around much faster, and, once you hit a certain scale, offers a much better long-term return on your investment.

A hybrid model can offer the best of both worlds. You could buy your own DTF printer to handle your core line of t-shirts and hoodies but keep outsourcing specialised jobs like big screen printing runs or fiddly embroidery.

This kind of strategic thinking is becoming more popular as the UK fabric printing market continues to boom, with projections hitting nearly £4.5 billion by 2025. This growth is being driven by a big shift towards sustainable, on-demand production.

With the right strategy, you can position your business to ride that wave. Understanding your options and striking the right balance is everything. It's worth seeing how professional custom t-shirt printers run their operations to get a feel for workflow and quality standards. This insight will help you make a smart financial decision that grows with your ambition.

Got Questions? We've Got Answers

Stepping into the world of custom apparel printing can feel a bit overwhelming, and it’s natural to have a few questions. We get it. To help clear things up, we’ve put together answers to some of the most common queries we hear from people just starting out.

Can I Just Use My Normal Printer for Clothes?

It’s a great thought, but unfortunately, the answer is no. That trusty inkjet printer you use for documents just isn't built for fabric. Its ink is designed for paper and will wash straight out of a t-shirt in the first wash, leaving you with a faded mess.

Printers made for clothing use totally different inks—like pigment-based inks for DTG or specialised inks for DTF and sublimation. These are engineered to chemically bond with textile fibres when heat is applied, making your designs stick around for the long haul.

How Much Does a Decent Starter Printer Cost?

This really comes down to which printing path you want to go down. The initial investment can vary quite a bit, so here’s a rough breakdown of what you can expect for a complete entry-level setup:

- Heat Transfer Vinyl (HTV): For a hobbyist-level vinyl cutter and a solid heat press, you can get started for around £500.

- Sublimation: A starter bundle with an entry-level sublimation printer, ink, paper, and a heat press will typically set you back between £600 and £1,500.

- Direct-to-Film (DTF): To get into professional DTF, you’re looking at a bigger jump. A starter system with the printer and curing gear usually begins around £3,000 to £5,000.

- Direct-to-Garment (DTG): This is the heavyweight division. Proper commercial DTG printers are a serious investment, with prices often starting at £10,000 and climbing steeply from there.

What's the Most Durable T-Shirt Print I Can Get?

When it comes to synthetic materials like polyester, nothing beats sublimation. The ink literally becomes part of the fabric's fibres. This means the design can't crack, peel, or fade, and you can't even feel it on the shirt. It’s as durable as the garment itself.

For cotton and other fabrics, a well-made DTF print is an absolute beast. It’s incredibly tough, stretches without cracking, and stands up to countless wash cycles, often outliving the t-shirt. That’s why it has become the go-to for vibrant, long-lasting designs on everyday clothing.

Ready to create apparel that stands out with incredible durability and vibrant colour? Psyque specialises in professional DTF printing to bring your unique designs to life. Explore our collections or get in touch for custom orders at https://psyque.co.uk.