A Guide to Vinyl Printed Shirts

Share

So, what exactly is a vinyl printed shirt? In a nutshell, it’s a design made using Heat Transfer Vinyl (HTV). A machine cuts your graphic from a special sheet of vinyl, and then a heat press permanently bonds it to the fabric. It’s the go-to method for creating those bold, solid graphics you see on everything from custom tees to sports jerseys.

If you want a design with killer durability and colours that pop, this is your weapon of choice.

Understanding the Basics of Vinyl T-Shirt Printing

The easiest way to think about vinyl printing is like creating a super-durable, high-tech sticker that's made specifically for fabric. Unlike printing methods that dye the actual fibres, a vinyl design sits on top of the garment. This creates a crisp, solid layer of colour that looks just as vibrant on a black shirt as it does on a white one.

The whole process kicks off with a digital design. A computer-guided cutting machine, known as a plotter, then gets to work, precisely carving the design out of a sheet of HTV.

This isn't just any old vinyl, either. It comes in a massive range of finishes. You've got your standard matte and glossy looks, but then you get into the good stuff: glitter, metallic, and even a soft, suede-like material called flock. Once the excess vinyl is stripped away (a process we call "weeding"), the design is ready for the final step.

The Magic of Heat and Pressure

This is where it all comes together. The vinyl graphic is positioned on the garment and placed inside a heat press. With the right mix of high temperature and firm pressure, the machine activates the adhesive on the back of the vinyl, fusing it deep into the fabric's weave.

This bond is incredibly tough. It's why vinyl printed shirts can take a beating in the wash and come out looking sharp, without the design fading or peeling off.

The real power of vinyl printing is its flexibility and how cost-effective it is for smaller orders. It lets you create complex single-colour designs or even multi-layered graphics without the complicated and expensive setup that screen printing demands.

This easy access has made it a massive hit for anyone wanting personalised gear. As more people crave unique clothing, the market is exploding. The UK's custom T-shirt printing scene is expected to jump from £245 million in 2023 to over £415 million by 2032. You can get more details on this trend and other insights from Credence Research.

If you're just getting into custom apparel, it pays to know what's out there. Our guide on custom T-shirt printing methods is a great place to start and breaks down all the different options available.

How We Turn a Digital File Into a Killer Vinyl Shirt

Making a vinyl printed shirt isn't like hitting 'print' on a piece of paper. It's a hands-on craft that mixes digital precision with a bit of old-school technique. The whole journey, from a raw idea to a finished tee, has a few key stages. Get any of them wrong, and the whole thing falls apart.

It all starts on the computer. Every design, whether it's a simple logo or some bold text, gets finalised in design software. This file is the blueprint that tells our cutting machine exactly where to slice.

From Screen to Blade

Once the design is locked in, we send it over to a vinyl cutter. This machine doesn't use ink. Instead, a tiny, ultra-precise blade cuts the design out of a sheet of Heat Transfer Vinyl (HTV). It's smart enough to only slice through the vinyl itself, leaving the clear plastic carrier sheet underneath perfectly intact.

That carrier sheet is the unsung hero of the process. It holds all the cut pieces of the design in place, like a frame keeping a puzzle together before it's glued down.

Next up is the most hands-on (and sometimes nerve-wracking) part: weeding. This is where we manually remove all the unwanted bits of vinyl that aren't part of the final graphic. Using a sharp, hook-like tool, we carefully peel away all the negative space, leaving just the design stuck to the carrier sheet.

For really detailed graphics, weeding requires a surgeon’s steady hand and a ton of patience. One wrong move, and you can tear a crucial part of the design. It’s a real test of focus.

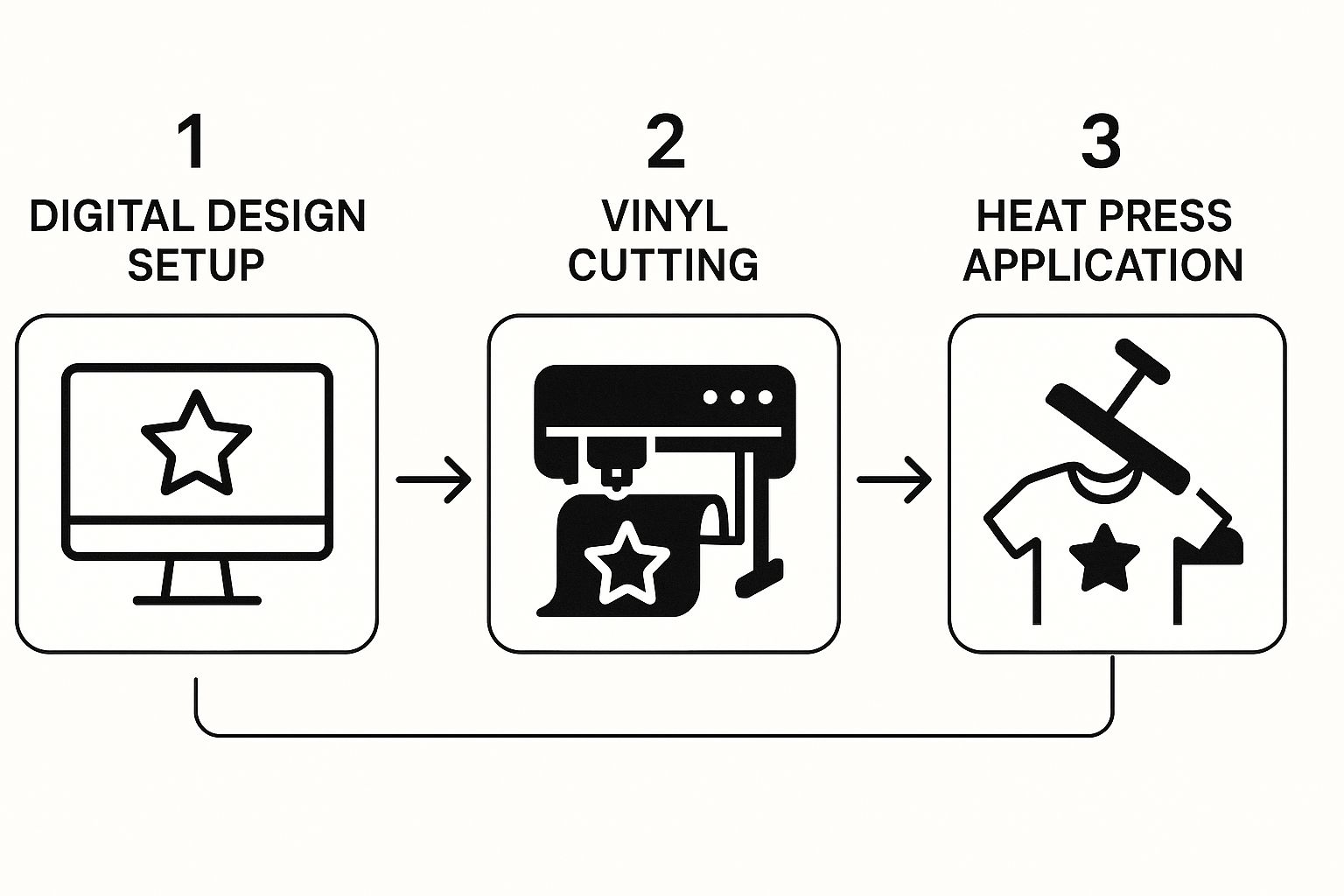

This visual shows you exactly how the digital design, the cutting, and the heat press all come together to make the final product.

As you can see, it's a step-by-step method where each part builds on the last to get that flawless finish.

Bringing the Heat for a Permanent Bond

With the design fully weeded and ready to go, it's time for the final act. The graphic, still on its carrier sheet, is positioned perfectly on the shirt. Then, the whole thing goes into a heat press – a beast of a machine that clamps down with serious heat and pressure.

This combo of heat and pressure is what creates the magic. The heat melts the adhesive on the back of the vinyl, while the pressure forces it deep into the fabric's fibres. It’s not just sitting on top; it's fused into the material.

Getting the settings just right is absolutely critical. Different vinyls and fabrics need different temperatures and press times. If you're curious about the science behind it, our complete heat press temperature guide breaks down how the pros dial in the perfect settings for a bond that lasts.

After pressing, the clear carrier sheet is peeled away, leaving behind a sharp, vibrant graphic that's now a permanent part of the shirt.

Exploring the Different Types of Heat Transfer Vinyl

Think vinyl printed shirts are just about solid, flat colours? Think again. That’s just scratching the surface. The world of Heat Transfer Vinyl (HTV) is a creative playground packed with different textures, finishes, and wild effects that can turn a basic tee into a proper statement piece.

Going beyond the standard matte or glossy vinyl opens up a whole universe of design possibilities. Each type of vinyl has its own unique vibe, letting you match the material to the mood of your artwork. A slick metallic finish, for example, screams premium quality, while a soft, textured vinyl adds a touch of understated class.

Uncovering Speciality Vinyl Finishes

To really get creative, you need to know what tools are in your arsenal. Some of the most popular speciality vinyls offer completely different aesthetics, turning a flat design into something with real depth and personality.

-

Glitter HTV: This one’s a crowd-pleaser for a reason. It’s infused with fine glitter particles that create a dazzling, sparkling effect that catches the light like nothing else. Perfect for hen parties, dance costumes, or any design that needs to scream for attention.

-

Metallic HTV: With its smooth, reflective surface, metallic vinyl gives you the look of polished metal without the weight. Think gold, silver, and rose gold finishes that can make a brand logo on a uniform look seriously high-end and professional.

-

Flock HTV: Totally different from the others, flock has a soft, slightly fuzzy texture a bit like suede or velvet. It adds a raised, tactile dimension to designs, making it an incredible choice for vintage-style logos or adding a premium feel to polo shirts.

And that's just the start. The materials game is always evolving, so new and exciting finishes are popping up all the time. You can dive deeper into the nuts and bolts of how printed vinyl heat transfer works and see how these different materials act when the heat is on.

Creative Applications for Unique Vinyl Types

Knowing what these materials are is one thing. Knowing how to actually use them is where the fun begins. The real magic happens when you pair the right vinyl with the right idea to create something unforgettable.

The type of vinyl you choose directly shapes the final garment's personality. A holographic vinyl can turn a simple shape into a futuristic statement, while a puff vinyl can give text a fun, three-dimensional pop.

Imagine designing a kid’s pyjama top with glow-in-the-dark vinyl stars that light up the room at night. Or using an iridescent, colour-shifting holographic vinyl for a streetwear brand to create a design that looks different from every angle.

These speciality materials aren't just for decoration; they're part of the garment's story. They give designers the power to make unique vinyl printed shirts that cut through the noise, turning a creative vision into wearable reality.

So, you're trying to figure out if vinyl is the right choice for your T-shirts. Picking a printing method can feel like a minefield, but it all comes down to what you're making. Each technique has its own superpower, and vinyl’s is all about precision and flexibility.

Think of it like this: if you were painting a wall, you'd grab a big roller for the main colour but switch to a fine-tipped brush for the sharp, detailed edges. Vinyl is that fine-tipped brush—perfect for crisp graphics, especially on smaller jobs.

Vinyl Versus Screen Printing

Screen printing is the undisputed king of bulk orders. It's the classic method of pushing ink through a stencilled screen onto fabric. For massive runs—think merchandise for a band tour or company-wide event shirts—it's incredibly efficient, and the cost per shirt plummets as the quantity goes up.

But here’s the catch: its biggest strength is also its greatest weakness. Every single colour in your design needs its own dedicated screen. That means setup costs are high and the prep work is a massive time sink, making it a terrible choice for small orders or designs with a rainbow of colours.

This is where vinyl printing swoops in to save the day. Because every design is cut digitally from a sheet of vinyl, there are no setup costs tied to screens or colours. This makes it the go-to choice for:

- Small Batches: Perfect when you just need a handful of tees for your team, a family reunion, or a weekend event.

- One-Off Prototypes: Want to test a new design without committing to a hundred units? Vinyl lets you make just one.

- Personalisation: Adding individual names or numbers to team jerseys is a breeze with vinyl. Trying to do that with screen printing would cost a fortune.

In the UK, screen printing still dominates the custom printing market, pulling in over 54% of the revenue, mainly because of its stronghold on large-scale production. But methods like vinyl are catching up fast, offering the kind of on-demand flexibility that modern creators and small businesses crave. If you're interested in the data, GrandView Research has a great breakdown of the UK's custom printing landscape.

Vinyl Versus Direct to Garment (DTG)

Direct-to-Garment (DTG) printing is basically an inkjet printer for clothes. It sprays ink directly onto the fabric, which is amazing for reproducing super complex, photorealistic images with millions of colours and smooth gradients. That's something vinyl just can't do.

Because the ink soaks into the fibres, the final print has a really soft feel, especially on lighter-coloured shirts. The trade-off, however, is with vibrancy and fabric choice. DTG ink is translucent, so on dark garments, it can look a bit faded unless a white underbase is printed first, which adds a layer and changes the feel.

Vinyl, on the other hand, is a solid, opaque material that sits right on top of the fabric. This guarantees that its colours stay 100% vibrant and bold, no matter what colour the shirt is. You get a crisp, clean graphic with a slightly raised texture that really pops.

If you want to go deeper down the rabbit hole of T-shirt printing, our guide on DTF vs screen printing for graphic tees offers some extra perspective on how these different methods stack up. But when it comes down to it, for bold, block-colour designs that need to make a statement, vinyl printed shirts almost always have the visual edge.

Why Choose Vinyl for Your Custom Shirts?

When you’re making custom gear, the reasons for picking vinyl printed shirts are as bold and clear as the designs themselves. This isn’t just another printing option; it's a total powerhouse for jobs where you need durability, eye-popping colour, and a price that makes sense for small runs.

Basically, if you need a design that refuses to fade into the background, vinyl is your answer.

The biggest win is its incredible resilience. A high-quality vinyl print, done right and looked after, can easily outlast the t-shirt it's printed on. The material is built to handle countless washes without cracking, peeling, or losing its colour. That makes it the perfect choice for gear that gets a lot of action, like workwear or your team’s uniforms.

Unmatched Vibrancy and Small-Batch Economy

Another thing that makes vinyl stand out is its insane colour vibrancy. Because the vinyl is a solid, opaque layer pressed onto the fabric, the colour stays true and brilliant, no matter what shade the garment is. A bright yellow design will look just as intense on a black hoodie as it does on a white tee — a trick that ink-based methods often struggle with without a lot of extra faff.

This makes vinyl printed shirts the go-to for creating high-impact logos and graphics that need to pop.

For small businesses, event organisers, or anyone needing a handful of custom garments, vinyl is the most sensible choice, financially. It completely sidesteps the hefty setup fees you get with methods like screen printing, making it affordable to produce even a single, unique shirt.

This cost advantage has made vinyl a favourite for grassroots sports clubs and community groups. In the UK, government initiatives to get more people into sports have massively boosted the demand for custom team kits. Take the Rugby Football Union's 'Impact 25' programme, for example. It's backed by over £12 million in government funding and aims to get 100,000 women playing by 2027, which means a huge need for personalised team gear. You can read more about the custom apparel market drivers from Research and Markets.

Real-World Applications

The benefits of vinyl translate directly into everyday, practical uses. Think about these scenarios where vinyl absolutely kills it:

- Local Sports Teams: Need to create personalised jerseys with individual names and numbers? Vinyl makes it simple and affordable.

- Small Business Uniforms: A small café can produce professional-looking staff shirts with a crisp, durable logo without a huge upfront cost.

- Personalised Gifts: Designing a one-of-a-kind t-shirt for a birthday or special occasion is quick, easy, and looks amazing.

- Event Merchandise: Selling standout shirts at a local festival or charity run becomes totally feasible, even for small-scale events.

In every case, vinyl delivers a high-quality, professional finish that’s both accessible and built to last.

Caring for Your Vinyl Printed Garments

A quality vinyl print is tougher than it looks, but a bit of smart care will keep your custom shirts looking sharp for years. If you want to stop that awesome design from cracking, peeling, or fading, all it takes is a few simple rules when laundry day rolls around.

The golden rule? Protect the design from high heat and harsh friction. It’s a simple one, but it makes all the difference. Always, always turn your vinyl printed shirts inside out before they hit the machine. This small step puts a layer of fabric between the design and the metal drum, acting like a shield against abrasion.

Washing and Drying Best Practices

When it comes to the wash cycle, cooler is always better. Heat is the natural enemy of the adhesive that bonds the vinyl to the fabric.

- Wash Temperature: Stick to a cold or cool cycle. We're talking 30°C maximum.

- Detergent: Go for a mild detergent. Steer clear of bleach or aggressive fabric softeners, as they can weaken the adhesive.

- Drying: Never tumble dry. Seriously. The intense heat from a dryer is the fastest way to wreck a vinyl print. Just hang the garment up and let it air dry.

The most crucial takeaway is this: high heat will destroy the vinyl's adhesive. If you avoid hot washes and tumble dryers, you’re preserving the life of the print, keeping it as bold and crisp as the day you got it.

And if you absolutely must iron the shirt, never let a hot iron touch the vinyl directly. Keep the shirt turned inside out and use a low heat setting, carefully pressing around the design area. Following these steps is a must for anyone wanting to get the most out of the different methods of printing on t-shirts in the UK.

Common Questions About Vinyl Shirts

Even after you get the hang of how it's done, a few questions about vinyl printed shirts always seem to crop up. Getting the right answers sorted means you can feel confident, whether you're just ordering a one-off custom tee or planning a bigger drop. Let's tackle the usual suspects.

One of the biggest is always about how long the print will last. If you follow the care rules we've covered—cool wash, inside out, steer clear of the tumble dryer—a solid vinyl print can easily survive 50 washes or more. Honestly, a lot of the time the high-quality HTV we use will probably outlive the shirt itself, staying bold and sharp without cracking or peeling away.

Technical and Safety Queries

People also get curious about the limits of Heat Transfer Vinyl and whether it's safe. The material is a beast when it comes to versatility, but you need to know where it shines.

Can you print complex, photographic images with vinyl?

Short answer: not really. Vinyl absolutely slays when it comes to solid colours, bold text, and clean shapes. But since every colour is a separate piece of vinyl cut and pressed on, it’s not built for photorealistic images with all their gradients and subtle tones. If you want a photo on a shirt, you need to be looking at Direct to Film (DTF) or DTG printing. No contest.

Is HTV safe to wear against the skin?

Absolutely. Good quality, modern HTV is usually made from polyurethane—an inert plastic that’s perfectly safe for skin contact. It’s used on everything from kids' clothes to sportswear. Any reputable vinyl will be CPSIA certified, which means it’s passed strict safety tests for children's products.

The best fabrics for vinyl are the ones that can take the heat. Cotton, polyester, and poly-cotton blends are your best bets. They give the vinyl a stable surface to grab onto, creating a bond that’s built to last.

Knowing these details helps you pick the right weapon for your creative battle. Vinyl is still a top-tier choice for punchy, bold graphics that need to be seriously durable and vibrant, especially if you're not printing hundreds at a time.

At Psyque, we specialise in high-detail, full-colour designs using advanced DTF printing technology to bring your ideas to life with stunning clarity. Explore our collections or start your custom project today at https://psyque.co.uk.