Your Ultimate Guide to Sublimation Tote Bags

Share

Sublimation tote bags are a fantastic way to create vibrant, full-colour designs that literally become part of the fabric. The end result is a print that will never crack, peel, or fade away. Unlike other methods that just sit a layer of ink on top of the material, sublimation dyes the fibres themselves for a premium, professional finish that’s as durable as it is beautiful.

What Are Sublimation Tote Bags?

At its heart, sublimation is a clever bit of science used for some seriously creative customisation. Imagine turning a solid directly into a gas, completely skipping the liquid stage. That's exactly what's happening here. We start by printing a design onto special transfer paper using sublimation inks. When we apply heat and pressure with a heat press, these solid inks vaporise and are absorbed deep into the fabric's fibres.

As the tote bag cools down, the ink turns back into a solid—but now it’s permanently locked inside the material. Think of it less like a sticker and more like a tattoo for your tote bag; it becomes one with the fabric. This process is why sublimation tote bags are famous for their stunning, photorealistic quality and incredible durability. The design feels completely smooth to the touch because there’s no layer of ink sitting on the surface at all.

The Magic of Polyester

This whole chemical bonding process has one crucial rule: it only works on polyester or fabrics with a high polyester content. The synthetic fibres are designed to open up under heat, which allows the gaseous ink to get right in. Natural fibres like cotton just don’t have the right structure to accept the sublimated dye, making material choice absolutely critical for getting those bright, lasting results.

This unique dance between the ink and polymer-based materials is what makes sublimation stand out from the crowd. If you want to see how this works on other types of clothing, our guide on dye sublimation for T-shirts offers a bit more context.

Why They Are So Popular

The demand for customised gear just keeps growing, and sublimation tote bags are a perfect fit. They offer a brilliant canvas for everything from complex artistic designs to bold company logos. Their popularity really boils down to a few key advantages:

- Unmatched Durability: Because the design is infused, it’s as tough as the fabric itself. You can pop it in the washing machine without worrying about losing its brilliance.

- Vibrant, Full-Colour Prints: Sublimation can reproduce millions of colours, which means you can get beautiful gradients and fine details that other methods often struggle with.

- Professional, High-End Feel: With no texture or raised edges, the final product looks and feels like it came straight from a high-end retail shop.

To get a better picture of how sublimation fits into the wider world of custom products, it’s helpful to understand what print on demand (POD) entails. This business model often relies on sublimation because it’s so good at creating high-quality, one-off items efficiently.

The Step-by-Step Sublimation Printing Process

Turning a blank tote into a vibrant piece of art might sound like magic, but it’s actually a pretty straightforward process once you get the hang of it. Think of it as a blend of careful prep work, the right gear, and a bit of science involving heat and pressure.

Let's walk through the journey, from a simple digital file to a finished, beautifully printed tote bag. Each step is crucial, building on the last to get that flawless, professional finish.

Preparing Your Design and Equipment

First things first: your artwork. For sublimation to really pop, you need a high-resolution file—aim for 300 dots per inch (DPI). This ensures your final print is crisp and sharp, not a blurry, pixelated mess.

Now for the most common rookie mistake: you absolutely have to mirror your image before printing. Your design gets transferred face-down onto the tote, so flipping it horizontally ensures any text or logos look correct on the final product. Trust me, it’s an easy one to forget!

Once the design is sorted, you'll print it onto special sublimation paper using sublimation inks. Your standard printer ink just won't cut it here; you need the specific dye that’s designed to turn from a solid into a gas under heat. These are the non-negotiables that make the whole process work.

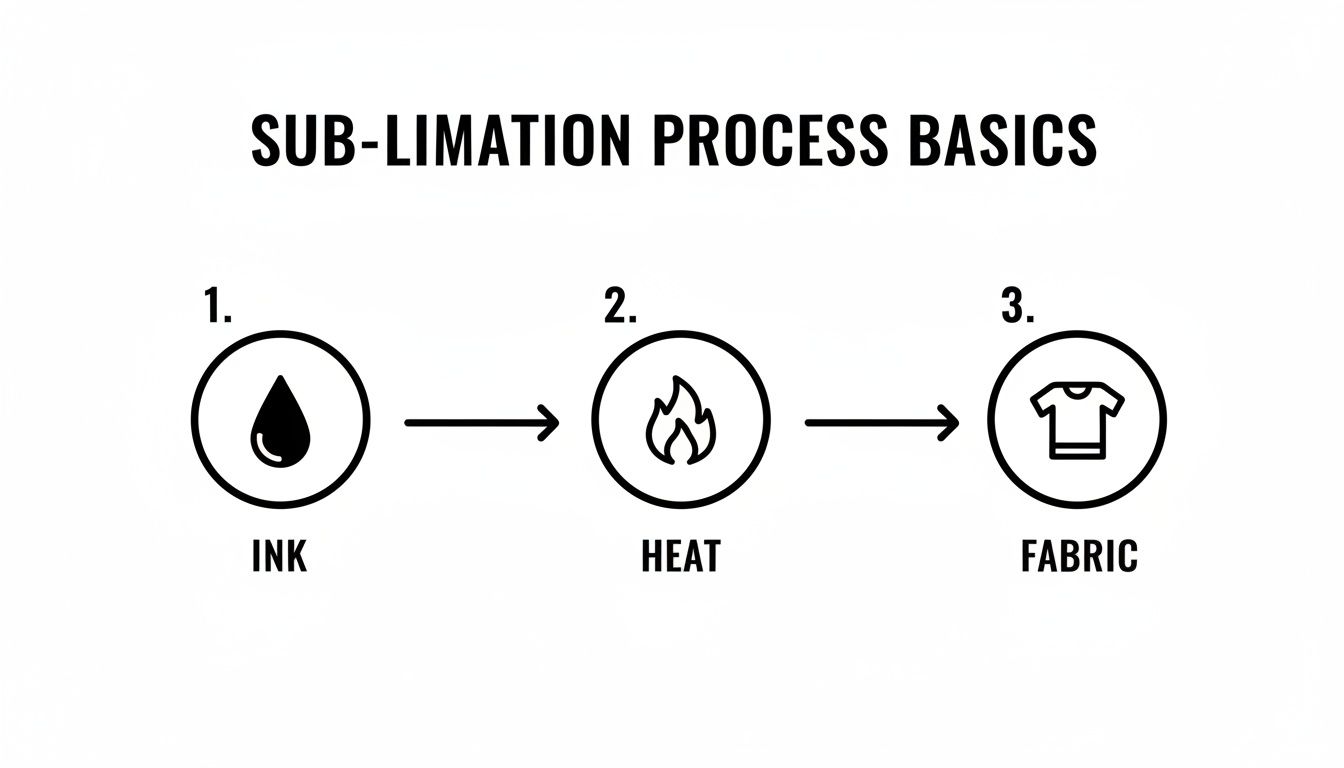

This simple visual shows how solid ink becomes a permanent part of the fabric, all thanks to the heat press.

The Heat Press Transfer

With your design printed and ready, it's time for the main event. Your heat press is the star of the show, delivering the exact temperature and even pressure needed for the magic to happen. Before you even think about placing your design, give the tote bag a quick pre-press for a few seconds. This little step irons out any wrinkles and removes hidden moisture, giving you a perfect canvas.

Next, carefully position the printed paper face-down on the tote. A bit of heat-resistant tape is your best friend here—use it to secure the paper so it doesn't shift during pressing. Any movement can cause "ghosting," which leaves you with a blurry, shadowed image.

Pro Tip: Always slide a sheet of protective paper (parchment or butcher paper works great) inside the tote bag and place another one on top of your design. This is a simple trick to stop ink from bleeding through to the other side of the bag or staining your heat press.

Now you're ready to press. The perfect settings depend on your specific equipment and the tote's material, but here’s a solid starting point:

- Temperature: Usually somewhere between 180°C to 200°C (360°F to 400°F).

- Time: Around 45 to 60 seconds is typical.

- Pressure: Go for a medium to firm pressure.

Once the timer goes off, open the press. While it's still hot, peel away the transfer paper in one smooth, confident motion. You'll see your design has completely lifted from the paper and infused itself right into the fibres of your sublimation tote bags. If you want to dive deeper into nailing the settings, checking out an in-depth guide on heat press sublimation can help you master the finer points.

Final Touches and Troubleshooting

After you've removed the paper, let the bag cool down completely before you start handling it. The design is now permanent, with a smooth-to-the-touch finish and brilliant colours that will never crack, peel, or fade away.

Of course, things don’t always go perfectly on the first try. If your print looks faded or patchy, you might have an issue with uneven pressure or the temperature being too low. On the flip side, if the colours look a bit burnt or brownish, you’ve probably got the heat cranked up too high. It’s a great idea to keep a little notebook with your settings for different materials—it'll save you a lot of guesswork down the line.

Choosing the Right Materials for Flawless Results

The secret to a jaw-dropping, photo-quality sublimation print isn’t just about the printer or the heat press. The real magic is locked away in the fabric itself. For sublimation to work, the material has to be able to bond with the special ink, and in this arena, one fibre is king: polyester.

Here’s how it works: when you heat up a polyester tote bag, the synthetic fibres temporarily open up their pores. This creates a small window of opportunity for the vaporised sublimation ink to get deep inside the material. As the tote cools down, those pores close, permanently trapping the ink within the very fibres of the bag.

This molecular fusion is exactly why sublimation tote bags feel so smooth to the touch, and why the designs will never crack, peel, or fade away. It’s not a layer of print sitting on the surface; it’s a permanent part of the fabric.

The Polyester Rule: Why It Matters

Getting the material right is non-negotiable. Natural fibres like cotton just don’t have the polymer structure needed to accept sublimation dye. If you try it, the ink will just sit on the surface and wash out almost immediately. It’s a costly mistake to make.

To guarantee vibrant, long-lasting prints, you need to stick to these guidelines:

- 100% Polyester: This is the gold standard. It gives you the brightest colours, the sharpest details, and the best durability for your designs.

- High-Polyester Blends: You can get a really cool, vintage-style look by using a blend, like 65% polyester and 35% cotton. The ink will only bond with the polyester fibres, which results in a more faded, retro vibe.

The same rules apply to other garments, too. If you're curious about different fabrics, you can learn more in our detailed guide on choosing t-shirts for sublimation printing.

A Crucial Limitation: Colour Matters

Sublimation ink is transparent. This means it dyes the fibres rather than covering them. Because of this, it only works properly on white or very light-coloured fabrics. Trying to sublimate on a black tote bag is like using watercolour paint on black paper—the design simply won’t show up.

Exploring Different Tote Bag Styles

Not all polyester is created equal. The actual texture and finish of the tote bag will influence the final look and feel of your product, giving you a surprising amount of creative control.

Just think about the different polyester options you can get:

- Sleek and Smooth: A classic, slightly shiny polyester offers a modern finish and makes colours pop with incredible vibrancy.

- Textured Canvas-Style: Many suppliers now offer polyester totes that mimic the feel of canvas. These are perfect if you’re aiming for a more rustic or natural aesthetic without giving up the benefits of sublimation.

- Eco-Friendly Options: Sustainable materials are a growing trend, and the rise of eco-friendly sublimation totes in the UK is tied to stricter environmental policies and changing shopping habits. With single-use plastic bag usage dropping by a massive 98% since the 2015 levy, the demand for durable, reusable bags has shot up. These polyester-canvas hybrids are not only long-lasting but also perfect for the UK's wet weather, as the designs are completely wash-resistant. You can discover further insights into the tote bag market from SkyQuestt.

Once you understand how your choice of fabric impacts the final design, you can source the perfect blanks for any project. You’ll avoid expensive mistakes and make sure every tote bag you create is a success.

How Sublimation Compares to Other Printing Methods

When you're looking to create custom tote bags, sublimation is an incredible tool to have in your arsenal, but it's not the only one. To really get the best result for your project, you need to understand how it stacks up against other popular methods like Direct-to-Film (DTF), screen printing, and Heat Transfer Vinyl (HTV).

Each technique has its own strengths and is suited for different jobs. The best choice often boils down to the complexity of your design, the fabric you’re working with, and how many bags you need to print. Let's break down the key differences to help you make the right call.

Sublimation vs Screen Printing

Screen printing is the classic, tried-and-true method that involves pushing ink through a stencilled mesh screen onto the fabric. It's the go-to for many large-scale commercial operations, and for good reason.

If you’re printing a large batch of totes with a simple design—say, one or two solid colours—screen printing is almost always more cost-effective. The initial setup of creating the screens takes time, but once that’s done, you can churn out hundreds of totes incredibly quickly. That same setup cost, however, makes it impractical for small runs or one-off orders.

The biggest difference comes down to the feel and the level of detail. Screen printing lays a layer of ink on top of the fabric, which you can physically feel. In contrast, sublimation tote bags have absolutely no texture because the ink becomes one with the material. Sublimation is also the champion of photorealistic images and complex colour gradients, things that are notoriously difficult and pricey to achieve with screen printing's colour-separated screens. While a promo company might find that over 91% of their jobs are single-colour, having the option for full-colour prints is a game-changer.

Sublimation vs Heat Transfer Vinyl (HTV)

Heat Transfer Vinyl, or HTV, is exactly what it sounds like: designs are cut from sheets of coloured vinyl and then heat-pressed onto the tote. It's a fantastic option for simple text, bold logos, or layered graphics, and it’s very popular with hobbyists and small businesses just starting out.

HTV gives you a crisp, opaque finish and works beautifully on all sorts of fabrics, including dark colours and cotton—materials that are off-limits for sublimation. But, like screen printing, the design sits on top of the fabric and has a distinct plastic-like feel. Over time and with repeated washing, HTV can be prone to cracking or peeling.

Sublimation, on the other hand, offers far superior durability and a completely seamless finish. For intricate, full-colour artwork, there's no contest; sublimation is the clear winner. Creating a similar multi-coloured design with HTV would mean painstakingly cutting and layering individual pieces of vinyl.

Sublimation vs Direct-to-Film (DTF)

Direct-to-Film (DTF) is a newer technology on the block and is often seen as sublimation's biggest rival, specifically because it solves many of sublimation's limitations. The process involves printing a design onto a special film, coating it with a powdered adhesive, and then heat-pressing the whole thing onto the garment.

The real superpower of DTF is its versatility. It works brilliantly on pretty much any fabric you can think of—cotton, polyester, blends—and it doesn't matter if the material is light or dark. This flexibility makes it an incredibly powerful alternative for any project where sublimation just isn't an option.

Much like HTV and screen printing, a DTF transfer sits on the surface, so it will have a slight texture. However, modern DTF transfers are impressively thin, soft, and flexible. When it comes to colour vibrancy and detail, both DTF and sublimation produce stunning, high-resolution results. If you're weighing up your options, taking a look at a detailed guide on choosing the right printer for clothes can give you some great insights into the specific hardware needed for each method.

Comparison of Tote Bag Printing Methods

To make things even clearer, here’s a simple side-by-side comparison of these methods, focusing on the factors that matter most when you're making custom tote bags.

| Feature | Sublimation | DTF (Direct-to-Film) | Screen Printing | HTV (Heat Transfer Vinyl) |

|---|---|---|---|---|

| Colour Vibrancy | Excellent (Photorealistic) | Excellent (Vibrant & Opaque) | Good (Limited Colours) | Good (Solid Colours) |

| Durability | Permanent (Won't crack or peel) | Very High (Flexible & durable) | High (Can crack over time) | Medium (Can peel over time) |

| Fabric Feel | Zero texture (Part of the fabric) | Soft, slight layer on top | Noticeable layer of ink | Noticeable plastic-like layer |

| Best For | Full-colour photos, complex art | Any fabric, light or dark | Large batches, simple designs | Names, numbers, simple logos |

| Fabric Type | Polyester & high-poly blends | Cotton, polyester, blends, etc. | Most fabrics | Most fabrics |

| Cost (Small Run) | Low | Low-Medium | High (Due to setup) | Low |

| Cost (Large Run) | Medium | Medium | Low | Medium-High |

Ultimately, sublimation truly shines when you need permanent, photorealistic designs on light-coloured polyester fabrics. For just about everything else, powerful alternatives like DTF and screen printing are ready to step in and get the job done.

Finding Your Niche in the Custom Tote Market

The amazing thing about sublimation tote bags is just how versatile they are. Once you get the hang of the technical side, the real challenge—and where the money is—is figuring out who you’re selling to. You need to find a niche where your designs can truly connect with people.

These totes are tough. Their professional, vibrant finish makes them incredible promotional tools. Forget those cheap, flimsy bags that fall apart after a few uses; a quality sublimated tote becomes a walking billboard for a brand, lasting months or even years. That’s a fantastic return on investment.

This makes them a brilliant pick for corporate giveaways, merchandise at events, or even as part of a proper retail collection. With edge-to-edge, full-colour printing, your creativity is really the only thing holding you back.

Tapping into the Personalised Goods Market

One of the liveliest spaces for custom totes is the world of personalised gifts. Just look at online marketplaces like Etsy—they’re teeming with people hunting for one-of-a-kind items that scream them. This is where sublimation shines, as it perfectly reproduces detailed artwork and photos.

Think about these profitable ideas:

- Custom Artwork Totes: Team up with local artists or sell your own illustrations, effectively turning tote bags into wearable art.

- Pet Portrait Bags: A guaranteed winner. People adore their pets, and offering custom totes with their furry friends’ faces is an easy sell.

- Photo Collage Totes: These make for brilliant keepsakes for family reunions, holidays, or special gifts for grandparents.

- Unique Wedding Favours: Design bespoke tote bags for wedding guests. It’s a practical and personal memento they’ll actually use.

The demand for stylish, reusable bags is huge and isn't going away. In the UK alone, the tote bag market was valued at a whopping USD 986.70 million back in 2019. With forecasts predicting the wider UK handbags market will grow by another USD 854.8 million between 2025 and 2029, it’s clear that people want fashionable and functional bags.

By focusing on a specific audience—whether it's book lovers, gym enthusiasts, or eco-conscious shoppers—you can create designs that resonate deeply and command a premium price.

Building Your Brand and Reaching Customers

Once you’ve found your niche, you need to get your products in front of the right eyes. The visual pop of sublimation tote bags makes them perfect for platforms like Instagram and Pinterest, where a great product photo can stop someone mid-scroll.

To really connect with your target audience, you’ll want to explore different fashion marketing strategies on social media that play up what makes your totes special. Getting involved in your community, running targeted ads, and working with influencers are all solid ways to build buzz. For a more detailed guide on growing your brand online, check out our own article on social media marketing for fashion.

Whether you’re a small business owner, an event planner, or an artist, sublimation tote bags offer a fantastic and profitable canvas. By pairing top-notch production with a clever niche strategy, you can turn your creative spark into a successful business.

Keeping Your Sublimated Totes Looking Brand New

One of the biggest selling points for sublimation tote bags is just how tough they are. Because the dye is fused right into the polyester fibres, you don't have to worry about the design cracking or peeling off like you would with other printing methods.

Still, to keep those colours looking as sharp and vibrant as they did on day one, a little bit of care goes a very long way.

Giving your customers clear, simple care instructions is a brilliant touch. It shows you care about the product long after the sale and helps them get the most out of their new tote. When customers know how to look after their purchase, they're happier and far less likely to run into problems down the line. It’s a small detail that builds a big reputation for quality.

Simple Washing Guidelines

The golden rule for washing is simple: be gentle and stay away from high heat. Extreme temperatures can actually reactivate the sublimation dye, which can cause the colours to bleed or fade over time. Not what you want!

For the best results, stick to these steps:

- Turn the bag inside out: This is a simple trick to protect the printed surface from rubbing against other clothes or the inside of the machine.

- Go for a cold wash cycle: Always use a cold setting on your machine with a mild detergent. This is the single most important step for locking in that colour vibrancy.

- Wash with similar colours: Just like you would with any other laundry, this stops any accidental colour transfer in its tracks.

Follow these tips, and the design will stay looking crisp and brilliant for years to come.

Following proper care instructions is not just about maintenance; it's about preserving the integrity of the art. Gentle washing ensures that the vibrant, permanent bond between the ink and fabric remains undisturbed, keeping your tote looking brand new.

Drying and Ironing Best Practices

Just like with washing, high heat is the enemy when it comes to drying and ironing your tote bags. Getting this part wrong can cause damage that you just can't undo.

When it comes to drying, air drying is always your best bet. Hang the tote up or lay it flat and let nature do the work. Steer clear of the tumble dryer—that intense heat is the fastest way to ruin a beautiful sublimated print. If you’re in a real pinch and have to use a machine, make sure you only use a no-heat or air-fluff setting.

If the bag gets a bit wrinkled, you can iron it, but you need to be careful. Use a low heat setting and—this is crucial—never put the iron directly on the printed area. Always place a protective layer, like a clean tea towel or a sheet of parchment paper, over the design before you start pressing.

Common Questions About Sublimation Tote Bags

As you start exploring the world of custom printing, it’s only natural for a few practical questions to pop up. When it comes to sublimation tote bags, getting the small details right is what separates a professional, long-lasting product from a disappointing flop. Let’s clear up some of the most common queries.

We've pulled together the top concerns we hear from creators and small business owners to give you some straight-up answers. These tips should help you troubleshoot common issues and really nail the core principles of sublimation, setting you up for a perfect press every time.

Can I Use a Regular Iron Instead of a Heat Press?

This is easily one of the most frequent questions, and the short answer is a firm no. While it’s tempting to try and make do with a home iron, it simply won't give you the results you’re after. A successful sublimation transfer boils down to three critical things working in harmony: precise temperature, consistent timing, and even pressure.

A household iron has an uneven heating surface riddled with hot and cold spots, and it’s impossible to apply uniform pressure across a whole design by hand. This lack of consistency is a recipe for patchy, faded, and blurry transfers.

A heat press isn’t just a nice-to-have; it’s a non-negotiable piece of kit for sublimation. It guarantees that every square inch of your design gets the exact heat and pressure needed for the ink to turn into a gas and properly bond with the polyester fibres.

Why Does My Design Look Faded After Washing?

If you notice a design losing its punch after the first wash, it almost always points back to one of two things: the material or your settings. Sublimation ink can only form a permanent bond with polyester. If you’ve accidentally used a tote bag with a low polyester count (or even worse, 100% cotton), the ink is just sitting on the surface and will wash straight out.

The other likely culprit is your heat press settings. If the temperature was too low or the pressing time was too short, the ink didn’t get a chance to fully sublimate and infuse into the fabric. Always double-check that you’re using the recommended settings for your specific tote bag blank to get that permanent, wash-resistant finish.

Why Does Sublimation Only Work on Light Colours?

Getting your head around this limitation is crucial. Sublimation ink is transparent, which means it dyes the fabric fibres rather than laying an opaque layer of colour on top. Think of it like using watercolour paints—you can’t paint yellow on black paper and expect it to show up brightly. The exact same principle applies here.

The sublimation process adds colour to the existing base colour of the tote. On a white or light-coloured bag, your design's colours will look true and vibrant. But on a dark bag, the fabric’s own colour would completely overpower the transparent dye, making your design invisible. This is why white and pastel polyester tote bags are the industry standard for this printing method; they ensure your designs always pop.

At Psyque, we specialise in DTF printing, a fantastic alternative for achieving vibrant, durable designs on any fabric colour, including dark cotton. Explore our custom printing solutions at https://psyque.co.uk to see how we can bring your creative visions to life.