Choosing T Shirt Print Machines for Your Business

Share

Dipping your toes into the world of custom apparel can feel a bit overwhelming, but picking the right t-shirt print machines doesn't have to be. Think of this guide as your friendly navigator, here to make sense of modern printing so you can invest with confidence.

Your Guide to T-Shirt Printing Technologies

Getting to grips with the fundamental differences between printing methods is probably the most important decision you'll make for your business. It's no exaggeration. Your choice directly shapes your startup costs, how quickly you can fulfil orders, and the kinds of designs you can offer. It’s the foundation you'll build your entire apparel brand on.

This guide will give you a clear, straightforward look at how each machine works and what kind of business it’s best suited for. Whether you're launching an Etsy shop from your spare room or gearing up for a full-scale production line, the right technology is out there. Our goal is to swap that feeling of uncertainty for a clear path forward, so you can make a smart investment that truly fits your vision.

The Four Pillars of Apparel Printing

The custom apparel industry really boils down to four key technologies. Each has its own job to do, a bit like a chef having different knives for different tasks. Getting to know them is the first step towards building a successful operation.

- Direct-to-Garment (DTG): This is basically a high-tech inkjet printer for fabric. It applies ink straight onto the t-shirt, making it fantastic for detailed, full-colour photos that feel soft to the touch.

- Direct-to-Film (DTF): With this method, you print your design onto a special film first, then heat-press it onto the garment. Its biggest strength is its incredible versatility – it works on almost any type of fabric.

- Screen Printing: The classic workhorse of the industry. This technique uses stencils (screens) to push ink onto the fabric. For big orders, it’s still the king for durability and cost-effectiveness.

- Heat Press Vinyl (HTV): Think of this as the go-to for personalisation. You cut designs from coloured vinyl sheets and then heat-apply them. It's perfect for names, numbers on sports kits, and bold, simple graphics.

Once you understand the core mechanics of these t shirt print machines, you stop being just a buyer and start thinking like a strategic business owner. The machine you pick defines what you can produce, what it will cost, and ultimately, what makes your brand special.

Making a well-researched choice is crucial. If you want to dive a bit deeper, our detailed overview of printing on t-shirts in the UK offers more insight into how these technologies are used right here at home. This foundational knowledge empowers you to choose equipment that not only fits your budget but also fuels your long-term growth.

Decoding The Four Core Printing Methods

Choosing the right t-shirt printing machine is a lot less daunting once you get to grips with how they actually work. Think of it like picking a tool for a specific job; you wouldn't use a sledgehammer to hang a picture frame.

Each of the four main printing methods has its own process, its own unique strengths, and a scenario where it truly shines. Let's break down these core technologies to help you see where your business fits in. Once you can visualise what they do, you'll have a much clearer, more strategic path to making a smart investment.

Direct To Garment (DTG): The Digital Artist

Imagine a high-end inkjet printer, but instead of feeding it paper, you're printing straight onto fabric. That's Direct-to-Garment (DTG) in a nutshell. A DTG machine meticulously sprays water-based inks directly onto a t-shirt, allowing for an incredible level of detail and a practically unlimited palette of colours.

This method is the undisputed champion for photorealistic images, complex illustrations, and designs with subtle gradients and shading. Because the ink soaks right into the cotton fibres, the finished print feels exceptionally soft and breathable, with almost no texture at all.

It's absolutely perfect for one-off custom orders and small batches, as there are no hefty setup costs for each new design. If your business model is built on selling intricate, multi-coloured graphics on demand, DTG is your go-to digital artist.

Direct To Film (DTF): The Versatile Translator

Now, let's look at another digital approach that works a bit differently. Direct-to-Film (DTF) printing acts as a kind of universal translator between your digital design and the garment.

Instead of printing onto the fabric, a DTF machine first prints the design onto a special transfer film. An adhesive powder is then applied to the wet ink, which is melted and cured. This film—now a high-quality, ready-to-go transfer—can be heat-pressed onto almost any material you can think of.

Cotton, polyester, blends, nylon... even hard surfaces are fair game. This incredible flexibility is DTF's superpower. It smashes through the fabric limitations of DTG, making it ideal for sportswear, workwear, and a massive range of promotional items. The final print is vibrant, durable, and has a smooth, slightly raised feel. If your brand needs to print on a wide variety of product types, DTF is the most adaptable tool in the box.

Screen Printing: The Industrial Workhorse

Screen printing is the time-tested giant of the apparel world. The best way to picture it is as a highly refined stencilling process. For every single colour in a design, a separate screen (a fine mesh stretched over a frame) is prepared with a stencil of that part of the artwork. Ink is then pushed through the mesh onto the t-shirt, one colour at a time.

This hands-on setup makes it impractical for single items, but incredibly efficient for large volumes. Once those screens are made, you can churn out hundreds or even thousands of shirts quickly and at a very low cost per item. The ink sits on top of the fabric, creating a thick, bold, and extremely durable print that can withstand countless washes.

For simple logos, bold text, and graphics with a limited number of colours, screen printing is still the undisputed king, especially for bulk orders. This cost-effectiveness at scale is why it continues to dominate the market.

In fact, the UK custom t-shirt printing market is booming, with revenue projected to climb from £200.1 million in 2023 to £419.6 million by 2030. Screen printing accounted for over 57% of that revenue, proving its value for businesses big and small. You can dig into more data on the UK's custom apparel market growth from Grand View Research.

Heat Press Vinyl: The Custom Craftsman

Finally, we have Heat Press Vinyl (HTV), the artisan's choice for personalisation. Think of this method as digital cutting and pasting. A machine called a vinyl cutter precisely cuts your design out of a sheet of coloured vinyl. You then "weed" away the unwanted bits, leaving your design on a sticky backing sheet.

This is then positioned on the t-shirt and applied using a heat press, which uses a combination of heat and pressure to bond the vinyl permanently to the fabric. HTV is perfect for simple, solid-colour graphics like names on jerseys, team numbers, and sharp company logos.

It has a low startup cost and is ideal for custom, one-of-a-kind jobs. You can even get creative by layering different colours of vinyl to build more dynamic looks. To see how these ideas come to life, check out our guide on getting my design on a t-shirt.

At-a-Glance Comparison Of T-Shirt Printing Methods

Feeling a bit overwhelmed by the options? It’s completely normal. Each technology has its place. To make things a little clearer, here’s a quick-reference table that summarises the key strengths of each method.

| Technology | Best For | Colour Complexity | Feel on Shirt | Ideal Volume |

|---|---|---|---|---|

| DTG | Photorealistic, detailed designs on cotton | Unlimited colours, gradients | Soft, breathable, no feel | 1 to 50 |

| DTF | Vibrant graphics on any fabric (poly, blends) | Unlimited colours | Smooth, slightly raised | 1 to 100+ |

| Screen Printing | Simple, bold graphics with few colours | Limited (1-6 colours is typical) | Thick, durable, raised | 100 to 10,000+ |

| Heat Press Vinyl | Names, numbers, simple logos | Very limited (solid colours) | Smooth, flexible plastic feel | 1 to 25 |

Think of this table as your cheat sheet. Use it to quickly narrow down which printing machine aligns best with the kind of products you want to create and the customers you want to serve.

A Deep Dive into Digital Printing with DTG and DTF

Digital printing has completely shaken up the custom apparel game. It's shifted the focus from mass production to on-demand artistry, and the two technologies leading the charge are Direct-to-Garment (DTG) and Direct-to-Film (DTF). Both use advanced t shirt print machines to bring digital designs to life with stunning detail.

While they both start with a digital file, how they get that design onto a shirt couldn't be more different. Their processes, strengths, and the jobs they’re best suited for are worlds apart. Nailing these differences is the key to choosing the right machine for your business goals, the fabrics you want to use, and how you plan to work.

Let’s get into what makes each of these digital powerhouses tick.

The DTG Process: A Direct Approach

Think of Direct-to-Garment (DTG) printing as a specialised inkjet printer, but for clothes. The machine sprays water-based inks straight onto the fabric, where they soak into the fibres. The result is a print that’s incredibly soft to the touch and breathable—you can barely feel it's there. This makes it a fantastic choice for premium, fashion-forward garments.

To get those colours to really pop, especially on dark t-shirts, the garment needs a bit of prep work. It’s coated with a special solution that acts like a primer on a wall. This pre-treatment creates the perfect canvas for the ink, stopping it from soaking in too far and looking dull. It's a non-negotiable step if you want rich, vibrant colours.

The real magic of DTG is its ability to reproduce photographic detail and unlimited colours without any setup cost per design. This makes it the champion for one-off prints and small-batch orders where every shirt can be completely different.

For a bit more context on this popular method, we've covered the ins and outs in our guide on direct printing to garment.

DTF Printing: The Versatility Champion

Direct-to-Film (DTF) takes a completely different path. Instead of printing on the garment, the machine prints the design onto a special transfer film. A fine adhesive powder is then sprinkled over the wet ink and cured with heat, creating a durable, ready-to-press transfer. From there, it’s just a matter of applying it to the t-shirt with a standard heat press.

This two-step process is where DTF gets its superpower: fabric versatility. Because the design sits on top of the fabric rather than soaking in, DTF works brilliantly on materials that give DTG a hard time.

- Polyester: Perfect for sportswear and athletic gear.

- Nylon: Great for jackets, raincoats, and bags.

- Blends: Handles common cotton/poly blends with ease.

- Leather and more: You can even press these transfers onto a much wider range of items.

This flexibility makes DTF an incredibly powerful tool for any business looking to offer a diverse product catalogue without needing a whole workshop full of different t shirt print machines.

Key Differences in Workflow and Costs

While both are digital, the day-to-day reality and financial side of things are quite different. DTG printers are notoriously high-maintenance. Daily cleaning routines are essential to stop the print heads from clogging, which can quickly lead to eye-watering repair bills.

DTF, on the other hand, is a bit more forgiving. A huge plus is that it doesn't need any pre-treatment, which cuts a whole step out of the production process. You do, however, have the extra step of pressing the transfer at the end.

This move to digital has had a massive impact right here in the UK. The UK's custom t-shirt printing market was valued at £366.63 million, with some analysts predicting it could soar past £1 billion by 2033. This explosion is largely fuelled by small businesses and designers using these accessible digital tools to launch on-demand printing services.

If you really want to get into the weeds, this guide on DTF vs DTG Printing: A Guide to Choosing the Right Method is a fantastic resource that compares quality, cost, and durability. Ultimately, your choice between DTG and DTF will boil down to the fabrics you want to print on and the kind of volume you're planning for.

Mastering Traditional Methods: Screen Printing and Heat Press

While the latest digital printers get all the attention, the old-school powerhouses of the apparel world—screen printing and heat press vinyl—are still going strong. These non-digital t shirt print machines are the backbone of countless successful businesses, and for good reason. They offer unbeatable cost-effectiveness for big jobs and a straightforward way to get into personalisation.

Getting to grips with these hands-on methods is essential for any aspiring t-shirt entrepreneur. They represent a different way of thinking about production, one that values volume and simplicity over digital bells and whistles. Let's dig into when these reliable workhorses are the smartest move for your business.

Screen Printing: The Industrial Powerhouse

When it comes to high-volume production, screen printing is the undisputed champion. Think of it as a highly refined stencilling process. For every colour in your design, a separate mesh screen is created. Ink is then pushed through the screen's stencil onto the t-shirt, one colour at a time.

This layered approach creates a thick, vibrant, and incredibly durable print that sits right on top of the fabric. The manual setup means it’s not really suited for one-off custom jobs. But once those screens are made, you can churn out hundreds or even thousands of identical shirts at an incredible pace, bringing the cost per unit right down. The result is that classic, tactile finish you see on band merch, company uniforms, and event apparel.

The real magic of screen printing is its economies of scale. The more you print, the cheaper each individual shirt gets. This makes it the most profitable method by far for bulk orders with simple, solid-colour graphics.

Even with digital printing on the rise, screen printing machines still dominate large-scale production because they're just so efficient. In the UK, while print-on-demand has given digital a huge boost, a growing focus on sustainability has led to new eco-friendly, water-based inks for screen printing, keeping it a major contender. For a deeper dive into how these technologies are shaping the industry, check out the custom t-shirt printing market analysis from Future Market Insights.

Heat Press Vinyl: The Gateway to Personalisation

If screen printing is the industrial giant, then heat press vinyl (HTV) is the nimble artisan. This method is the perfect entry point for anyone wanting to offer custom designs without a massive upfront investment. It’s a beautifully simple and satisfying process to master.

It all starts with a sheet of coloured vinyl. A cutting machine precisely slices out your design, and then you get to the hands-on part: weeding. This is where you peel away all the unwanted vinyl, leaving just your design behind on a sticky carrier sheet. You then place it on the t-shirt and use a heat press to bond it permanently to the fabric.

This technique is perfect for things like:

- Personalised Names: Adding individual names to the back of team jerseys or work uniforms.

- Bold Logos: Creating crisp, single-colour logos for small business branding.

- Simple Graphics: Applying straightforward text and shapes for custom gifts and novelty tees.

The process is ideal for small batches and one-of-a-kind jobs where the time and cost of setting up screens just wouldn't make sense. A heat press machine for t-shirts is a low-cost, low-maintenance way to get your apparel business off the ground, making it a firm favourite for startups and hobbyists.

Ultimately, choosing between these traditional methods comes down to your business model. Are you planning to fulfil large, identical orders for events or companies? Screen printing is your best bet. Or do you want to offer personalised, one-off items for individual customers? In that case, a heat press vinyl setup is the perfect, accessible starting point.

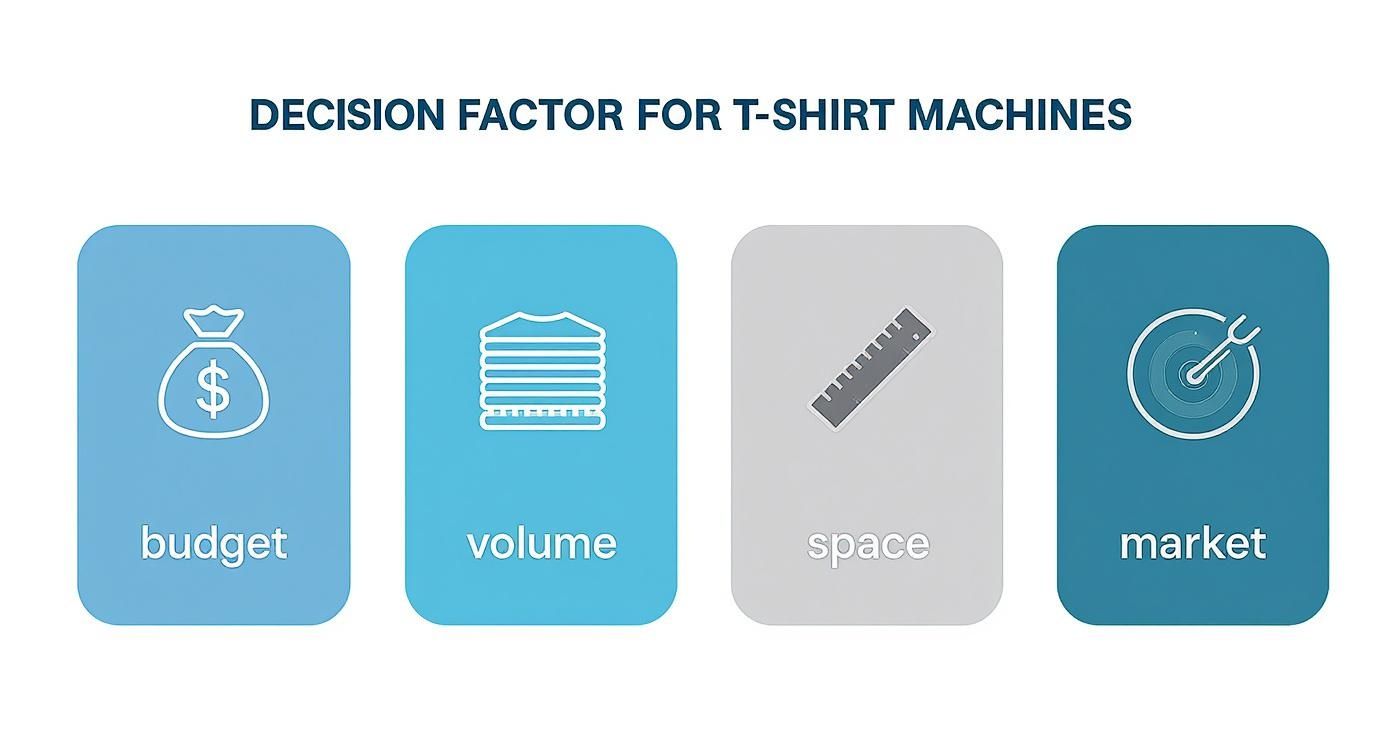

Critical Factors to Consider Before Buying a Machine

Choosing the right t-shirt printing machine is less about the shiny new tech and more about making a smart business decision. Before you get lost in a sea of technical specs, you need to ground your choice in the practical realities of what you're trying to build.

Think of this as your pre-flight checklist. Running through these points now will save you from the classic mistake of buying a machine that’s a terrible fit for your goals, preventing a lot of headaches and wasted cash down the line. It's all about matching the tool to the job you actually need to do.

Your Budget and the True Costs

That initial price tag on a machine? It's just the tip of the iceberg. A proper budget looks at the total cost of ownership, not just the upfront purchase. A machine that seems like a bargain can quickly become a money pit if its running costs are sky-high.

You need to break down your financial plan into three core areas:

- Initial Investment: This is the big one—the cost of the machine itself.

- Setup Supplies: Don't forget everything you'll need on day one. We're talking starter ink sets, cleaning fluids, software, and a stack of blank tees for those crucial first test prints.

- Operational Costs: These are the long-term expenses that keep you running. Think ink, vinyl, transfer films, powders, electricity, and any routine maintenance parts.

Getting a clear picture of the whole financial commitment is vital. For example, a heat press setup is cheap to get started with, but a dedicated t-shirt transfer printer for DTF could end up giving you a much lower cost per print once your order volume starts to climb. A solid budget helps you choose a machine you can afford not just to buy, but to run profitably.

Production Volume and Scalability

Your business plan should be the number one thing guiding your equipment choice. Are you a hobbyist making a few custom orders for friends on the weekend? Or are you gearing up to churn out hundreds of shirts for big events every day? Be brutally honest about where you are now and where you want to go.

A simple heat press and vinyl cutter is a dream for low-volume, highly personalised jobs. But just imagine trying to fulfil an order for 200 identical shirts that way—it would be a logistical nightmare. On the flip side, setting up a massive multi-screen printing press for a single, one-off t-shirt would be a wild waste of time and money.

The right machine feels effortless at your target production volume. A mismatch between your machine's capacity and your order flow creates friction, costing you either time on small jobs or profitability on large ones.

Space and Infrastructure Needs

T-shirt printing machines have a real physical footprint, and some are pretty diva-ish about their environment. Before you even think about clicking "buy," grab a tape measure and have a serious look at your workspace. A big automatic screen printing press, for instance, doesn't just need a corner; it needs a significant chunk of dedicated floor space.

And it goes beyond just square footage. You need to consider the infrastructure, too:

- Ventilation: Curing DTF prints and flashing screen prints can create fumes. Proper ventilation isn't just a nice-to-have; it's a critical health and safety requirement.

- Power: Do you have the right kind of electrical outlets? Can your circuit handle a commercial-grade heat press or a big curing unit without constantly tripping the breaker?

- Humidity Control: DTG printers are especially sensitive to their surroundings. Keeping humidity levels stable is often the secret to getting consistent, high-quality prints day in and day out.

Aligning with Your Target Market

Finally, let's talk about the most important factor of all: your customer. The technology you pick absolutely must be able to produce the kind of designs your target audience wants to buy.

If your brand is all about complex, full-colour photorealistic art, a screen printing setup limited to a handful of colours is going to hold you back, big time. If you're selling to the sportswear crowd, you need a machine—like DTF or vinyl—that works flawlessly on polyester. And if you're aiming for a premium, fashion-conscious market, the super-soft and breathable feel of a DTG print is a huge selling point.

Always connect your machine's capabilities directly to what your customers expect. That’s how you make products they’ll genuinely love and come back for.

Cost and Feature Breakdown by Machine Type

To help you visualise how these factors play out, we've put together a quick comparison of the four main printing technologies. This table breaks down the typical upfront costs, printing expenses, and practical requirements for each.

| Machine Type | Upfront Cost Range (£) | Avg. Cost Per Print (50+ Units) | Space Required | Maintenance Level |

|---|---|---|---|---|

| Heat Press Vinyl | £300 - £1,500 | £1.50 - £3.50 | Small (Desktop) | Low |

| DTG (Direct-to-Garment) | £8,000 - £20,000+ | £1.00 - £4.00 | Medium | High |

| DTF (Direct-to-Film) | £3,000 - £15,000 | £0.75 - £2.50 | Medium | Medium |

| Screen Printing | £500 - £25,000+ | £0.25 - £1.50 | Large | Medium |

This table isn't about finding a single "best" option—it's about finding the best fit for you. A low initial investment like heat press vinyl is perfect for starting out, but the higher cost per print becomes a problem at scale. Conversely, screen printing's incredibly low per-print cost is only achievable after a significant upfront investment in space and equipment. Use this as a guide to balance your budget against your business ambitions.

Which T Shirt Print Machine Is Right for You?

Choosing the right printing technology can feel like a massive hurdle, but it really just boils down to matching the machine’s strengths with your business goals. Let's break this down into some real-world scenarios to make the decision clearer.

Getting the right equipment from day one is what sets you up for steady growth instead of headaches down the line.

You’re a Startup on a Shoestring Budget

When you're just starting out and watching every single penny, the choice usually comes down to a classic heat press setup or an entry-level DTF system. A heat press with vinyl is by far the most affordable way to get in the game, perfect for simple jobs like adding names or basic logos to tees. It gets you started.

But if you can stretch the budget a little, an entry-level DTF machine is a massive leap forward. It unlocks the ability to print vibrant, full-colour designs on pretty much any fabric you can think of. While it costs more upfront, the lower cost-per-print and the sheer variety of products you can offer often mean you'll turn a profit much faster.

You’re a High-Volume Merchandise Brand

If your whole business revolves around shifting large quantities of merch—for a band, a big event, or your own clothing line—then screen printing is still the undisputed champion. There’s more involved in the setup, absolutely, but once you're running, its speed and efficiency for big jobs is unbeatable.

The per-shirt cost plummets on large runs, making it the most profitable choice for bulk orders. For high-volume brands, the durability and vibrant, solid colours of screen printing deliver the professional quality that customers expect, ensuring your brand's reputation for quality.

This decision tree infographic gives a great visual on how different business needs point to different machines.

You can see how high-volume demand naturally leads to screen printing, whereas tight budgets favour starting with a heat press or DTF.

You Run an Online Print-on-Demand Store

For an online shop that thrives on selling unique, one-off designs, a DTG machine is practically made for you. Its power lies in printing incredibly detailed, photorealistic graphics with zero setup cost per design, which is the heart and soul of the print-on-demand model.

This flexibility lets you fulfil individual orders profitably and offer your customers virtually endless customisation options.

Of course, when you're weighing up which machine to go for, figuring out your funding options is a big piece of the puzzle. A good guide to equipment financing loans can give you some valuable pointers on that front.

Your Top Questions Answered

Diving into the world of custom apparel always brings up a few big questions. It's only natural. Getting your head around the realities of profit, day-to-day upkeep, and the skills you'll need for different t shirt print machines is the key to investing with confidence and setting your business up for a flying start.

So, let's tackle some of the most common queries we hear from people just like you.

What Is the Most Profitable T Shirt Print Machine?

This is the million-dollar question, but the answer isn't a specific machine—it's about matching the right machine to your business goals.

If your plan is to sell unique, multi-colour designs in small batches or even one at a time, then a DTF or DTG printer is almost certainly your most profitable bet. Why? Because they have next to no setup cost per design, which means you can make good money even on single-shirt orders.

On the other hand, if you're aiming to print bulk orders for events, businesses, or sports teams, screen printing is where the real money is. The cost-per-shirt drops dramatically at high volumes, making it far more profitable when you're printing hundreds of the same design. And for those just starting out, a simple heat press vinyl setup has the lowest entry cost, letting you turn a profit very quickly on simple jobs like adding names and numbers to jerseys.

How Much Maintenance Do These Machines Require?

The amount of looking after these machines need couldn't be more different from one type to the next.

DTG printers are the most high-maintenance of the bunch. Think of them like a high-performance car; they need daily attention. You'll be doing routine nozzle checks and head cleanings every single day. Skipping this is simply not an option, as it leads to clogged ink heads—a problem that can mean costly repairs and your business being out of action.

DTF machines also need regular love, like shaking the adhesive powder and keeping the film path clean, but they're generally seen as a bit more forgiving than their DTG cousins. Screen printing gear is much simpler mechanically; it's mostly a case of giving your screens and tools a good manual clean-down after you finish a print run. By far the easiest to care for are heat presses, which just need you to keep the heat platen wiped clean and free of any gunk.

Do I Need Graphic Design Skills to Get Started?

While being a pro designer is a huge plus, it's definitely not a deal-breaker when you're starting out. At the end of the day, every printing method begins with a digital art file.

For DTG and DTF, you can absolutely get going by using pre-made designs you've bought online or by creating simple graphics with just text. The same goes for heat press vinyl, where basic software is all you need to create names, numbers, and simple shapes.

However, if you want to create truly standout products that build a brand people love, you'll eventually want to get comfortable with programs like Adobe Illustrator or Affinity Designer. The good news is that many machine suppliers know this and often throw in basic design software and some training to help you get up and running right away.

Ready to bring your creative vision to life with prints that are as vibrant as they are durable? Psyque specialises in top-quality DTF printing that's perfect for any fabric. Check out our collections or get in touch for all your custom apparel needs at https://psyque.co.uk.